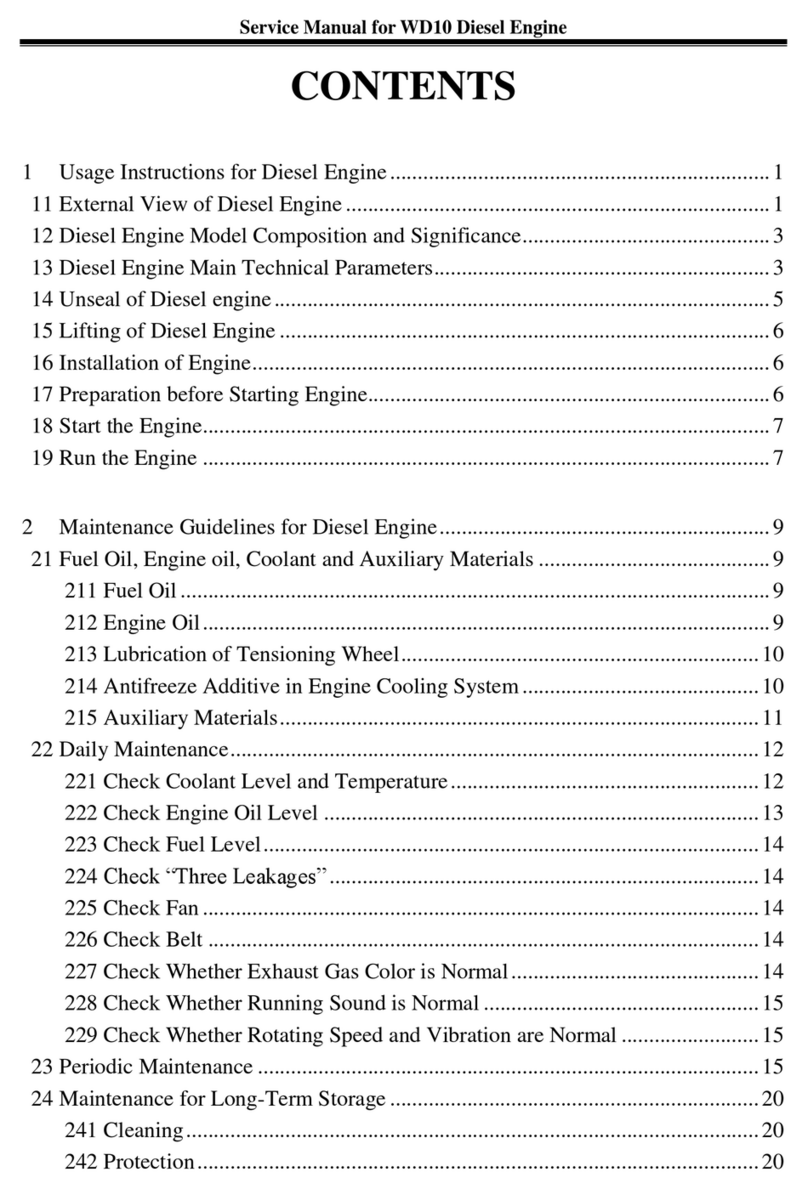

T225RS User Manual

Assembly Guidelines

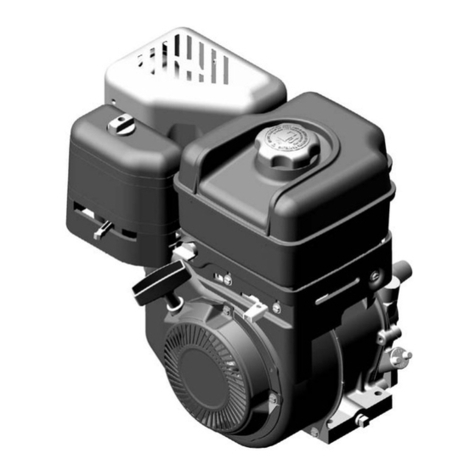

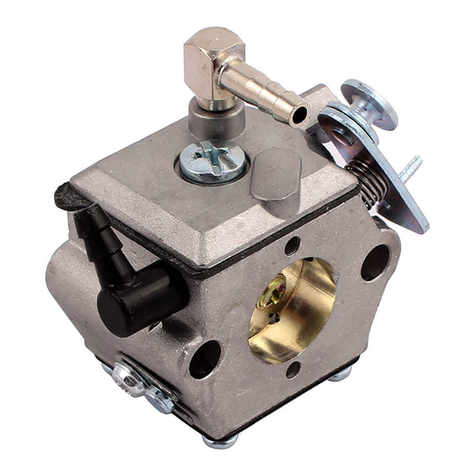

• Assemble the auxiliary engine components – Intake Manifold,

FM22-1A Carburettor, Air Filter, Exhaust, Clutch, Clutch guard

• It is recommended that the exhaust heat wrap is mounted to

the exhaust manifold to protect from heat build-up

• Ensure the Fuel Pump connections are correct as per photo:

• Mount the 45cm Fuel Pipe supplied from the fuel pump outlet to

the carburettor inlet connector

• Fill the engine with

T4 Engine Oil 500ml (17oz)*

Note: Black Fuel Line represents the Pulse Connection

from the fuel pump to the intake manifold connector.

Note: For a Video Link showing all of the above steps mentioned please visit the Tillotson Racing Youtube Page:

https://youtube.com/channel/UCZgldHZl8EBj93WnvcKFRHA

Installation to Chassis

When mounting to a Tillotson T4 chassis, using the supplied engine mount and no chassis modifications are needed.

However, with other chassis brands there may be a need for an alternative sliding engine mount, which will allow for the

engine to be offset giving more space for the chain & chain guard.

Starting the Engine

When starting the engine from new or when empty of fuel

1. It is necessary to blow the fuel to fill the carb bowl from the overflow pipe on the tank. Make sure to blow for

no less than 15seconds as the bowl requires a large volume of fuel before the engine will start.

2. Lift the Choke to the raised position which means the choke is now ‘ON’ and ensure the engine ignition

switch is in the ‘ON’ position also.

3. Using some small throttle opening (10-30%) pull the starter chord until the engine fires and reset the Choke

so it is in the ‘Off’ position.

4. Once the engine is running it may be necessary to adjust the idle speed screw on the side of the carburetor.

Recommended engine idle is 1,800 - 2,000rpm.

Engine Break-in Procedure

Note: DO NOT REV THE ENGINE HARD WITH NO LOAD FROM NEW.

1. Insert 500ml of T4 Oil (17oz).

2. For the first 10 minutes, drive moderately at varying speeds up to 5,000rpm (half throttle). It is important to

vary the RPM for proper camshaft, piston rings and moving component bed in.

3. Stop and allow the engine to cool, check that there are no fuel or oil leaks.

4. For the second 10 minutes, build up to max 6,500rpm by the end of the session.

5. Once you have completed the running-in procedure it is recommended to change the oil. This is to remove any

metal particles which could arrive from the new components in the engine. Drain the oil when hot so it can

easily transport any particles.

6. After the engine is empty, replace the drain plug (make sure the aluminium washer is still there)

and re-fill the engine with 500ml of fresh oil. The engine is now ready for competition.

*VERY IMPORTANT: If the engine is run on less oil than recommended it will overheat the engine components

and performance / reliability will be reduced for the remainder of the engine life.

3