TimberPro DS-22 User manual

Operation, Maintenance, and Parts

1

TimberPro DS-22 Disc Saw

Operation, Maintenance, and Parts

Disc Saw

Operation, Maintenance, and Parts 2

Dear Valued Customer,

This catalog contains operating instructions, maintenance instructions and parts information for the

TimberPro 22" Disc Saw attachment, including normally available options. Although great care was

employed during the preparation of this manual to insure the accuracy of illustrations and listings,

TimberPro Inc, cannot be held responsible for errors or substitutions, nor changes made after the

date of issue. This catalog is compiled from information available and current at the time of docu-

mentation, TimberPro Inc, reserves the right to improve it’s products without giving prior notice or

incurring obligation.

TimberPro strongly advises that you take this training manual home and study it so that you

have an understanding and working knowledge of your new equipment

Thank You,

Pat Crawford

President

TimberPro, LLC

Introduction ...

Operation, Maintenance, and Parts

3

Group 1 - Operator and Maintence Information

General Safety Information ...................................... 5

Service And Maintenance Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cutting Attachment Safety ...................................... 8

Disc Saw Maintenance Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Group 2 - Operating Instructions

General Disc Saw Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Group 3 - Disc Saw Hydraulics

Adjusting the Disc Saw Motor Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Adjusting the Disc Saw Disc Motor Begin of Stroke . . . . . . . . . . . . . . . . . . . 11

Disc Saw Hydraulics Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Group 4 - Disc Saw Parts

Structural Parts ............................................... DS-1

Hydraulic Components ......................................... DS-2

Table Of Contents ...

Operation, Maintenance, and Parts 4

Operation, Maintenance, and Parts

5

General Safety Information

TimberPro’s policy is to produce products that are

safe and reliable. However, even when using well

engineered equipment, there will always be an

element of risk in heavy equipment operation.

Most accidents involving heavy equipment

operation, maintenance or service result from

failure to follow basic safety rules and precautions.

Study all the safety messages carefully, remember

them and apply them when operating, maintaining

or servicing equipment.

“Safety Alert” Symbol

The “Safety Alert” symbol is used throughout

the manual text and on the machine to

indicate important personal safety measures and

equipment cautions. Carefully read, understand

and follow these instructions to prevent hazardous

situations, possible injuries to personnel or damage

to equipment.

Understanding Signal Words

In this manual and on the safety decals installed

on the machine, the “Safety Alert” symbol is always

accompanied by a signal word to identify the haz-

ard level. Understand the signal words DANGER,

WARNING, and CAUTION.

Identifies the most serious safety hazards.

Failure to follow a DANGER safety message

would result in high probability of death or

serious personal injury.

Identifies that a safety hazard exists. Failure

to follow a WARNING safety message

can result in death or serious personal

injury if proper precautions are not taken.

Identifies that a safety hazard exists. Failure

to follow a CAUTION safety message can

result in personal injury or equipment damage

if the proper precautions are not taken.

The signal words DANGER, WARNING and

CAUTION are used to identify personal safety

hazards and some equipment cautions. The

signal word NOTICE is used to identify

hazards that may damage equipment or its

components.

Follow procedures as outlined to avoid damage

to equipment or its components as a result of

misuse or improper procedures.

The Careful Operator

A careful operator studies, remembers and applies

the basic safety rules and all safety messages found

in the manuals and on the equipment being oper-

ated, maintained or serviced. This person also has

the required training, skills and tools to operate the

equipment and/or perform the required maintenance

and service procedures.

TimberPro cannot anticipate every possible

circumstance where a potential hazard may exist.

Therefore, the safety messages and equipment

cautions found in the manuals and on the

machine are not all inclusive. If an operating

technique, maintenance or service procedure, tool,

etc... not specifically recommended by TimberPro is

used, it is your responsibility to insure it is safe for

yourself and others. You should also be sure the

machine will not be damaged or made unsafe by

the operation, maintenance procedures or service

procedures you choose.

WHEN IT COMES TO SAFETY, NOTHING WILL

EVER REPLACE A CAREFUL OPERATOR.

Figure 1 - Safety Alert Symbol

Operation, Maintenance, and Parts 6

Service And Maintenance

Precautions

General

Unless otherwise specified, all maintenance or

repair procedures should begin as follows:

1) Position machine on level ground.

2) Lower boom and all attachments to the

ground.

3) Shut down engine. Remove ignition key

and place in safekeeping.

4) Switch off master electrical disconnect or

disconnect the positive (+) battery cable.

Comply with the instructions in this manual and

your company’s regulations for the operation of

this machine.

YOU MUST BE FULLY TRAINED to operate this

machine and its attachments.

00007

Use recommended protective clothing and safety

devices such as gloves, safety boots, safety hat,

reflective vests and eye, ear and respiratory

protection as required by job conditions.

00008

Maintain a charged fire extinguisher on the

machine AND KNOW HOW TO USE IT.

00027

Keep a comprehensive and complete first aid kit

in an easily accessible place on the machine at

all times.

00010

Support components when working beneath

them. Do not depend on hydraulic cylinders for

support. A component may fall if a control is

moved or a hose breaks.

00018

Operation, Maintenance, and Parts

7

Run the engine only when it is required for

test or adjustment purposes.Always use the

proper tools for the job. Repair or replace

any broken or damaged tools, including

lifting equipment, immediately.

When servicing or replacing hardened steel pins,

use a brass drift or other suitable material between

the hammer and pin if it must be driven into the

pivot. Use safety glasses or other suitable eye

protection.

DO NOT make adjustments while the machine is

moving or the engine is running unless otherwise

specified to do so.

DO NOT change the pressure setting on any

hydraulic valve without authorized instruction.

Use all cleaning solutions with care. Avoid

breathing vapors and contact with eyes and skin

Keep all fuels and maintenance items in properly

marked containers.

Place all fuel or oil soaked rags, waste material,

debris and other flammable items in a properly

marked protective container stored in a safe place.

Inspect the machine for missing, unreadable or

damaged safety decals. Keep safety decals clean.

The maximum allowed air pressure used for

cleaning purposes should not exceed 30 psi

(205 kPa).

At operating temperature, the engine, exhaust

system components, cooling system

components and hydraulic system components

are HOT. Any contact can cause severe burns.

00017

Before performing maintenance or repairs on the

machine, consult this manual and follow the

recommended procedures.

00019

Pressurized air can cause personal injury.

When using pressurized air for cleaning, wear

protective clothing, face shield and shoes.

00021

Check hoses carefully. Do not use your

Disce hands to check for leaks. See “Fluid

Penetration”. Tighten all connections to recom-

mended torque. Replace if any of the following

are found:

- End fittings damaged or leaking.

- Outer covering chafed or cut and wire

reinforcing exposed.

- Outer covering ballooning locally.

- Hose shows evidence of kinking or crushing.

00032

Chaffing or Cuts,

Wire Exposed

Evidence of Kinking

or Crushing

Localized

Ballooning

Damaged or

Leaking Fitting

Operation, Maintenance, and Parts 8

Pressure can be maintained in system circuits

long after the engine and pumps have been shut

down. Release trapped pressure in hydraulic,

fuel, and cooling system lines before performing

any maintenance or repair procedures.

00012

Hydraulic System

Do not bend or install bent or damaged hydraulic

hoses and tubelines.

Do not strike hydraulic hoses or tubelines.

Be sure all hose clamps, guards and protective

wrapping is installed correctly to prevent vibration

and rubbing which could lead to hose failure.

Disc Saw Safety Information

It is essential that all operators of the disc-felling

head become familiar with all aspects of its cor-

rect operation.

1. Remember at all times that the disc saw blade,

at operational speed carries a tremendousa-

mount of stored energy. Tooth tip speeds can be

up to 17000 ft/min. Flying chips or other debris

can cause serious injury. Do not approach the

felling head unless the disc saw blade has come

to a complete stop, and the engine has been

shut down.

2. During operation of the disc felling head, all

personnel not in the machine should remain at

least 300’ away and never cross in front of the

saw opening.

3. All observers should stand on the opposite side

of the disc rotation. In other words the opposite

side of the chip path from the primary opening.

4. As debris is always being released from the

saw-housing opening, the operator must remain

in the cab until blade has stopped rotating com-

pletely.

5. Saw operation speed should be respected. Do

not exceed maximum allowable r.p.m. Wait until

disc saw achieves full speed (see saw motor

RPM settings) before proceeding to cut.

6. Inspect saw blade at start of every shift and,

periodically during the shift. See daily inspection

information.

7. Shut saw off immediately if an imbalance occurs.

Imbalances can result from a bent disc, loose or

lost parts and can be indicative of a serious

problem. Inspect all parts of saw blade prior

to restarting. Do not operate saw blade in any

unbalanced condition.

8. Do not work on blade or head while machine

is running, except when performing required

hydraulic checks.

Hydraulic oil under pressure can penetrate body

tissue causing serious injury and possible death.

When troubleshooting a hydraulic system for

leaks, always use cardboard or other material as

a deflector. DO NOT USE YOUR HANDS.

If you are injected with hydraulic oil or any other

fluids, seek treatment by a doctor familiar with

this type of injury immediately.

00009

Operation, Maintenance, and Parts

9

General Maintenance

Before performing any maintenance or

service work, lower the attachment to the

ground and shut off the engine. Turn off any

master shut-offs and do not allow personnel

in the cab

Re-torquing the boom Adapter Mounting

Bolts

The bolts of which hold the boom adapter

mounting bracket and bearing to the Disc saw

weldment should be re-torqued to 420 ft. lDS.

after a few hours of use and then again every

200 hours. There will be one ring of thirty (30)

3/4" allen bolts (item #10 below) that connect

the mount to the head and get torqued to Torque

to 377 ft.lDS (512 Nm) and one ring of standard

bolts (item #9 below) that secure the bearing to

the mount and get torqued to Torque to Torque

to 420 ft.lDS (570 Nm).

Lubrication and Grease

Before start-up, make sure the saw head has

been greased. Every pin joint will have a grease

zerk. Each cylinder end will also have a grease

zerk.

Grease the saw drive daily at the beginning of

each shift (two separate cavities). Ensure grease

relief tting are functional. If relief ttings are not

functioning properly, damage to shaft seals may

occur. Fill bearing cavities until grease begins to

expel from relief ttings.

Figure 2: Saw Drive Grease Fittings

Note that there is a plug at the center of the saw

disc mounting ange. This is an access hole for

a grease zerk that allows grease to reach the

splined adapter between the motor and shaft.

This should be greased every 500 hours.

Disc Saw Daily Inspections

1. Check lower portion of shaft for grease leaks.

Repair damaged seals if required.

2. Check end shaft for end play. (.006” - .008”

allowance)

3. Check saw retaining bolts on lower ange

once at a 100 hour inspection, and every

2000 hours after that for correct torque. (320

lb./ ft)

4. Inspect and Clean debris between saw

blade, housing and guard.

5. Check disc housing guarding for damage

and blade contact. Make necessary repairs

when needed.

6. Check saw head regularly for cracks. Repair

any damage.

7. Inspect hydraulic hoses, ttings and cylin-

ders for damage or wear. Replace or repair

if necessary.

8. Inspect cutting teeth for damage. Make sure

the teeth are in good shape and that all

mounting hardware is secure. Never mix dif-

Figure 1: Boom Adapter Mounting Bolts

Operation, Maintenance, and Parts 10

ferent styles of cutting teeth. When teeth are

worn and damaged they should be replaced

as a matched set.

Operating Instructions

NOTE: When rst becoming familiar with the

disc saw felling head, tilt the head forward to the

vertical position when the saw is being started

or stopped.

1. Start the saw rotation, open accumulator

arms, open top grab just before you are

ready to cut a tree.

2. Tilt the head to the upright position and move

toward the rst tree.

3. As the cut is being made, the upper clamp

arms should begin to close, but should not

be completely closed until the cut is com-

pleted.

NOTE: It is important not to fully clamp the tree

until after the cut is complete. Clamping the tree

before the cut is complete, may cause damage

to the stem and unnecessary binding or stalling

down of the saw blade.

4. Once the tree is completely severed, the

head should be immediately raised off the

stump. This is important to avoid stalling

down of the saw blade.

NOTE: It is obvious that a smooth and continu-

ous feed speed of the saw will prevent binding

or stalling of the saw blade. Speed of cut must

be related to tree size and species.

5. When cutting smaller trees, at this time the

operator would then close the lower "accu-

mulation" arms. This would ready the the

disc saw for the next cut.

NOTE: The lower "accumutlation" arms are

used to hold the smaller trees when opening the

upper arms to make the next cut.

6. Once done making a cut or multiple cuts, the

trees will be need to be dumped from the disc

saw head. This is done by tilting the head

using the "tool tilt" function into the direction

you would like to place the trees. Then open-

ing all clamp arms to relase the trees.

7. When your nished using the disc saw turn

off the disc saw pump. Then either position

the disc saw in a place that is safe and free

of people or animals and monitor the disc

until it comes to a complete stop. You may

also use a near by stump to stop the disc.

Make sure and slowly pust the disc into the

stump until the disc stops.

NOTE: When using a stump to stop the disc

make sure and push the disc into the stump us-

ing the same procedure as when your cutting a

tree. Never push downward on the stump with

the bottom of the disc. This can cause damage

to the disc and disc drive system. See gure 3

Figure 3: Correct Stopping Procedure

00481

Never leave a disc saw still spinning and un-

attended. Even after a disc saw has been

shut off the disc will continue to spin with

enough force to cause injury or harm. Never

try to manually stop a disc that is spinning.

Operation, Maintenance, and Parts

11

Saw Motor RPM Adjustment

Ensure that the 100 mm (3.94 inch) long saw

speed adjustment screw (see gure 4) is turned

in until 19 mm (.75 inch) of the stud protrudes

beyond the jam nut. (This prevents over speed-

ing the saw at initial start-up)

Figure 4: Saw Drive Motor RPM

With saw free to rotate turn saw circuit ON and

bring engine to full throttle. Turn saw speed

adjustment screw out until saw speed is 1139

r.p.m. Lock jam nut on saw speed adjusting

screw.

Saw Motor Begin of Stroke

Adjustment

Figure 5: Disc Saw Motor Port “M1”

00481

Install 5000 p.s.i. pressure gauges at saw valve

test port and at “G” port (# 4 ORB style) and

“M” port (# 6 ORB style see gure 5) of saw mo-

tor. Block saw blade rotation with pin in base

assembly saw housing.

With engine at full throttle adjust saw circuit re-

lief valve to read 3800 psi at “G” port on saw

motor pressure inlet block.

Figure 6: Disc Motor Begin Of Stoke Adjustment

00482

Locate begin of stroke adjustment screw (gure

6) through the hole at the rear of the head col-

umn or motor housing.

Turn the “begin of stroke” adjustment screw out

until the gauge in the “M” port reads 0 psi.

Then slowly turn the “begin of stroke” adjust-

ment screw in until the pressure gauge in the

“M” port reads 1800-2000 psi. Lock jam nut on

adjusting screw.

Reset the pump pressure to recommended car-

rier specs. (4000 PSI)

Operation, Maintenance, and Parts 12

Disc Saw Hydraulics

Hydraulic pressure,

Saw motor.... 4000 Psi (276 Bar)

Hydraulic flow,

Saw motor.... 28 to 32 GPM (172 to 256 l/min)

Hydraulic pressure,

Clamps, Accumulator, and Tilt Cylinders

4000 Psi (276 Bar)

Disc Saw Schematic

Disc Saw - Parts Breakdown

Section DS-1

22” Disc Saw -

Parts Breakdown

Disc Saw - Parts Breakdown

DS-1-1

Last Updated - 10/09

TimberPro Parts Module DS-R0

Disc Saw - Parts Breakdown

DS-1-2

Last Updated - 10/09

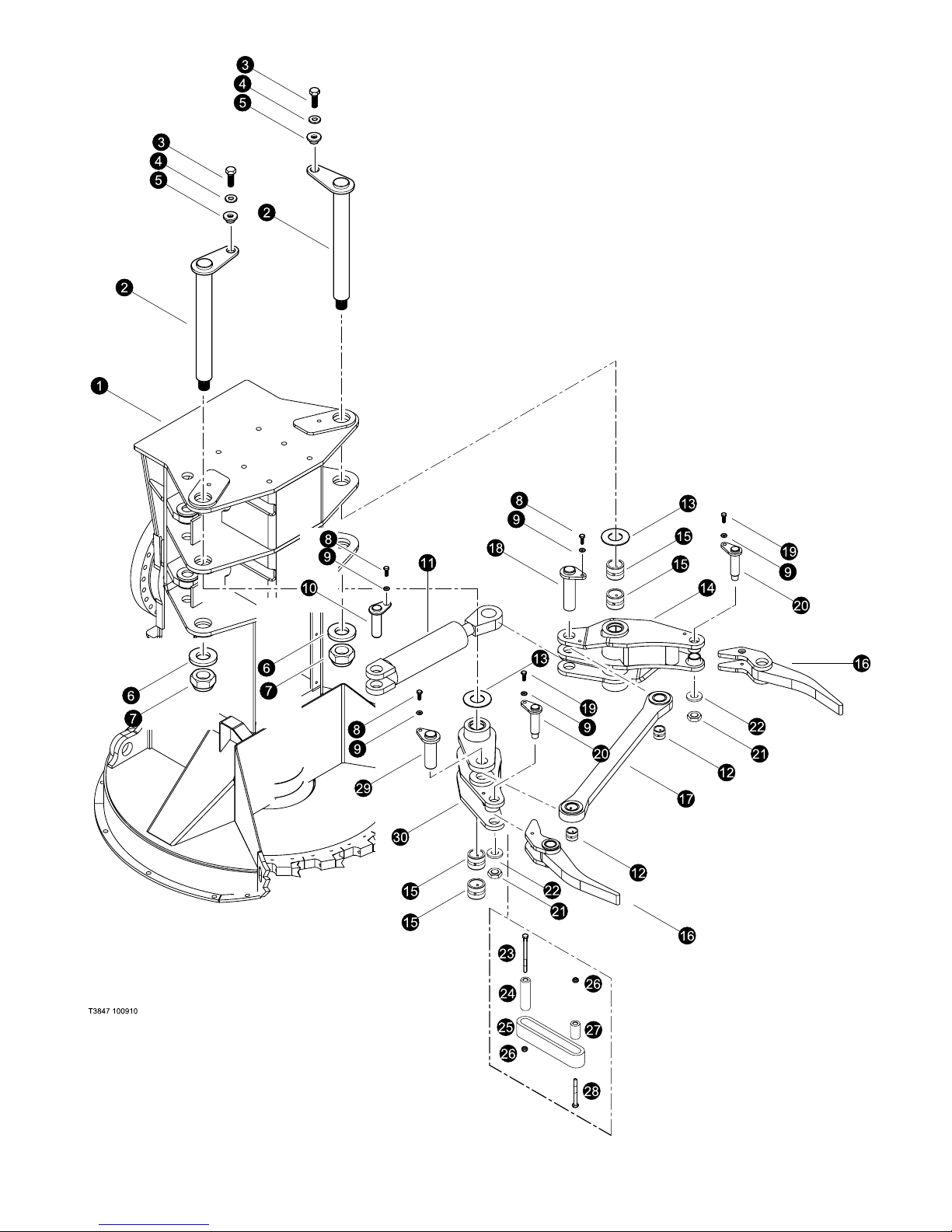

REF PART # QTY DESCRIPTION SEE PAGE

MAIN PAGE HEADING

(Page Sub-Heading)

(Used on machines PDN# 000FWD and above)

TimberPro Parts Module DS-R0

REF PART # QTY DESCRIPTION SEE SECTION

1 52789-DS 1 FRAME, Disc Saw

2 54112-DS 2 ASSEMBLY, TOP - Disc Saw

3 10775-DS 6 BOLT - .75” X 2.5”

4 15550-DS 12 WASHER, SAE FLAT - .75”

5 10817-DS 6 NUT, LOCK - .75”

6 53940-DS 1 BASE, SAW 40 DEG TILT DUAL CYL-53883 BRG

7 53883-DS 1 BEARING, LATERAL TILT DISC/Disc Saw

8 15550-DS 60 WASHER, SAE FLAT - .75”

9 10843-DS 30 BOLT - .75” X 4.5” (Torque to 420 ft.lDS (570 Nm))

10 53996-DS 30 BOLT, ALLEN HEAD - .75” X 4” (Torque to 377 ft.lDS (512 Nm)) (See Note: 1)

11 10776-DS 30 NUT, HEX - .75” (See Note: 1)

12 52795-DS 4 BUSHING - 2” X 2”

13 10783-DS 4 BOLT - .5” X 1”

14 15534-DS 4 WASHER, SAE FLAT - .5”

15 53775-DS 4 PIN ASSEMBLY,

16 52814-DS 2 CYLINDER, DISC SAW HEAD TILT - JARP . . . . . . . . . . . . . . . . . DS-2

17 54039-DS 1 BELTING, HOSE GUIDE - OUTSIDE

18 54038-DS 1 BELTING, HOSE GUIDE - INSIDE

See referenced page for component or assembly breakdown.

Note: 1

Use Loctite 272 (blue) during installation.

Disc Saw

(Top Post and Boom Mount)

Disc Saw - Parts Breakdown

DS-1-3

Last Updated - 10/09

TimberPro Parts Module DS-R0

Disc Saw - Parts Breakdown

DS-1-4

Last Updated - 10/09

REF PART # QTY DESCRIPTION SEE PAGE

MAIN PAGE HEADING

(Page Sub-Heading)

(Used on machines PDN# 000FWD and above)

TimberPro Parts Module DS-R0

REF PART # QTY DESCRIPTION SEE SECTION

1 REF. 1 Disc Saw FRAME ..................................... DS-1

2 54119-DS 2 PIN ASSEMBLY, Disc Saw Top Arms

3 15549-DS 2 BOLT - .75” X 2.0

4 15550-DS 2 WASHER, SAE FLAT - .75”

5 18570-DS 2 WASHER, PIN RETAINING (BRAATZ)

6 12021-DS 2 WASHER, BURNED 2 X

7 10728-DS 2 NUT, nylock - 2”

8 10739-DS 3 BOLT - .5” X 1.5”

9 15534-DS 3 WASHER, SAE FLAT - .5”

10 54120-DS 2 PIN ASSEMBLY, 2.0 DIA X 4.13

11 REF 1 CYLINDER, UPPER CLAMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DS-2

12 52795-DS 2 BUSHING,

13 16266-DS 3 SHIM - 2.51” ID X 3.88” OD X .075” THK

- 16267-DS SHIM - 2.51” ID X 3.88” OD X .135” THK

- 16268-DS SHIM - 2.51” ID X 3.88” OD X .179” THK

14 54055-DS 1 ARM, TOP CLAMP - DOGBONE

15 11704-DS 4 BUSHING - 2.5” X 4.25”

16 54054-DS 1 ARM, TOP CLAMP - CYLINDER

17 54020-DS 1 ASSEMBLY, DOG BONE-DISC SAW ARMS

18 54121-DS 1 PIN ASSEMBLY, DISC SAW DOGBONE/CLAMP

19 54120-DS 1 PIN ASSEMBLY, DISC SAW ARM/CYLINDER

See referenced page for component or assembly breakdown.

Disc Saw

(Clamp Arms)

Disc Saw - Parts Breakdown

DS-1-5

Last Updated - 10/09

TimberPro Parts Module DS-R0

Disc Saw - Parts Breakdown

DS-1-6

Last Updated - 10/09

REF PART # QTY DESCRIPTION SEE PAGE

MAIN PAGE HEADING

(Page Sub-Heading)

(Used on machines PDN# 000FWD and above)

TimberPro Parts Module DS-R0

REF PART # QTY DESCRIPTION SEE SECTION

1 REF. 1 Disc Saw FRAME ..................................... DS-1

2 54119-DS 2 PIN ASSEMBLY, Disc Saw Top Arms

3 15549-DS 2 BOLT - .75” X 2.0

4 15550-DS 2 WASHER, SAE FLAT - .75”

5 18570-DS 2 WASHER, PIN RETAINING (BRAATZ)

6 12021-DS 2 WASHER, BURNED 2 X

7 10728-DS 2 NUT, nylock - 2”

8 10739-DS 3 BOLT - .5” X 1.5”

9 15534-DS 3 WASHER, SAE FLAT - .5”

10 54120-DS 2 PIN ASSEMBLY, 2.0 DIA X 4.13

11 REF 1 CYLINDER, UPPER CLAMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DS-2

12 52795-DS 2 BUSHING,

13 16266-DS 3 SHIM - 2.51” ID X 3.88” OD X .075” THK

- 16267-DS SHIM - 2.51” ID X 3.88” OD X .135” THK

- 16268-DS SHIM - 2.51” ID X 3.88” OD X .179” THK

14 54052-DS 1 ARM, ACCUMULATOR BASE - CYLINDER

15 11704-DS 4 BUSHING - 2.5” X 4.25”

16 54056-DS 2 ARM, ACCUMULATOR - END

17 54020-DS 1 ASSEMBLY, DOG BONE-DISC SAW ARMS

18 54120-DS 1 PIN ASSEMBLY, DISC SAW ARM/CYLINDER

19 50100-DS 2 BOLT - .5” X 1.25”

20 54123-DS 2 PIN ASSEMBLY, DISC SAW ACCUM ARM

21 20811-BS 2 NUT, NYLOCK - 1.5” NF (JAM)

22 19613-BS 1 WASHER, SAE FLAT - 1.5” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23 -DS 2 BOLT - .5” X 6.5”

24 54089-DS 2 SPACER, 1.06 X .68 X 3.93

25 53997-DS 2 RUBER BAND, ACCUMULATOR ARM

26 10815-DS 4 NUT, LOCK - .5”

27 54180-DS 2 SPACER, 1.06 X .68 X 2.0 LG

28 10893-DS 2 BOLT - .5” X 3”

29 54122-DS 1 PIN ASSEMBLY, DISC SAW DOGBONE/ACCUM

30 54053-DS 1 ARM, ACCUMULATOR BASE - DOGBONE

See referenced page for component or assembly breakdown.

Disc Saw

(Accumulator Arms)

Disc Saw - Parts Breakdown

DS-1-7

Last Updated - 10/09

TimberPro Parts Module DS-R0

Table of contents