Caution! Residual Hydraulic Energy!

Residual energy must be released from the pressurized hydraulic fluid before any maintenance or repair

work is done on the firewood conveyor. Hydraulic fluid can remain highly pressurized even while the

conveyor’s motor is off. Escaping pressurized hydraulic fluid can penetrate skin and cause serious injury.

To release residual hydraulic energy:

1. Shut off engine

2. Move control valve back and forth, from one limit of travel to the other, at least four times

3. Hold valve for three seconds at each limit of travel

TIMBERWOLF FIREWOOD PROCESSING EQUIPMENT

TW-C12, TW-C20, TW-C24, TW-C26, TW-C30HD CONVEYORS OPERATOR’S MANUAL

Table Of Contents

Attention Rental Companies

It is extremely important that any person who operates this equipment has access

to and has read the operator’s manual. Timberwolf Firewood Processing Equipment

strongly urges you to keep the manual with the conveyor at all times, and to instruct

all persons who will operate this machine to read the manual.

Safety

Hydraulic Safety ........................................................................... 1-2

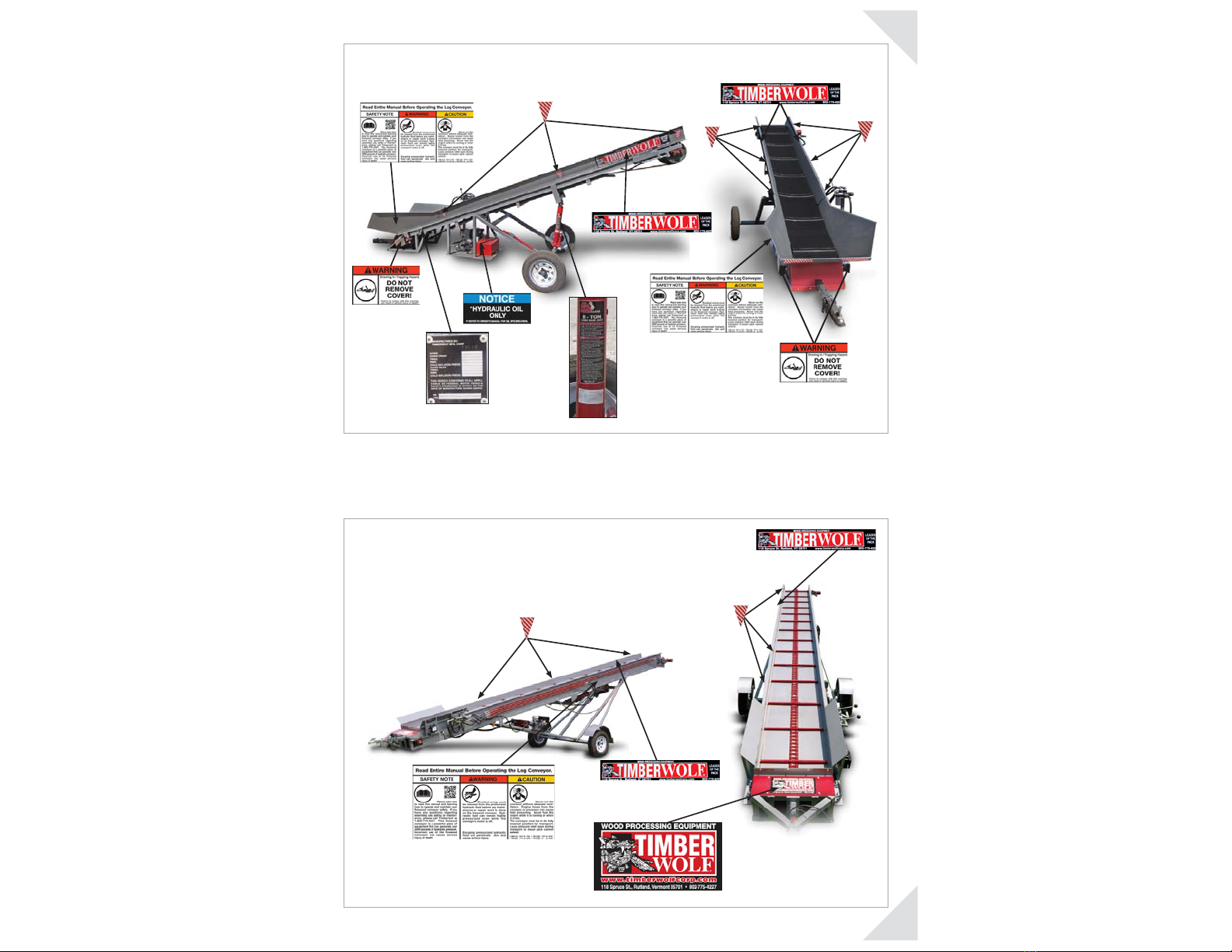

C12, C20, C24, C26 Decal Locations ............................................. 3

C30HD Decal Locations .................................................................. 4

General Information

General ........................................................................................... 5

Set Up and Take Down

Overview ......................................................................................... 6

Set Up Procedures ................................................................... 6

Take Down Procedures ............................................................ 6

Set Up Procedures .......................................................................... 7

Work Area Layout .................................................................... 7

New Location Set Up .............................................................7-8

C12, C20, C24, C26 Height Adjustment ................................... 8

C30HD Height Adjustment Overview ........................................ 9

C30HD Hyrdrauic Height Adjustment .................................... 10

Processor Hydraulic Power ............................................... 10-11

Take Down Procedures ..................................................................11

C12, C20, C24, C26 Lowering the Conveyor .................... 11-12

C30HD Lowering the Conveyor .............................................. 12

C12, C20, C24, C26 Tow Vehicle Hookup .............................. 13

C30HD Tow Vehicle Hookup .................................................. 14

Operating Instructions

Start Up Procedure ....................................................................... 15

Hydraulic Start Up ......................................................................... 16

Operation ...................................................................................... 16

Maintenance

General ............................................................................................... 17

Periodic Maintenance .......................................................................... 17

Conveyor Belt Adjustment (C12, C20, C24, C26) ............................... 18

Conveyor Chain Adjustment (C30HD) ................................................ 19

Specifi cations .................................................................................... 20

Limited Warranty ..........................................................................21-22

Maintenance Log ..........................................................................23-24