Gorlitz Jetters Operating & Maintenance Manual 6

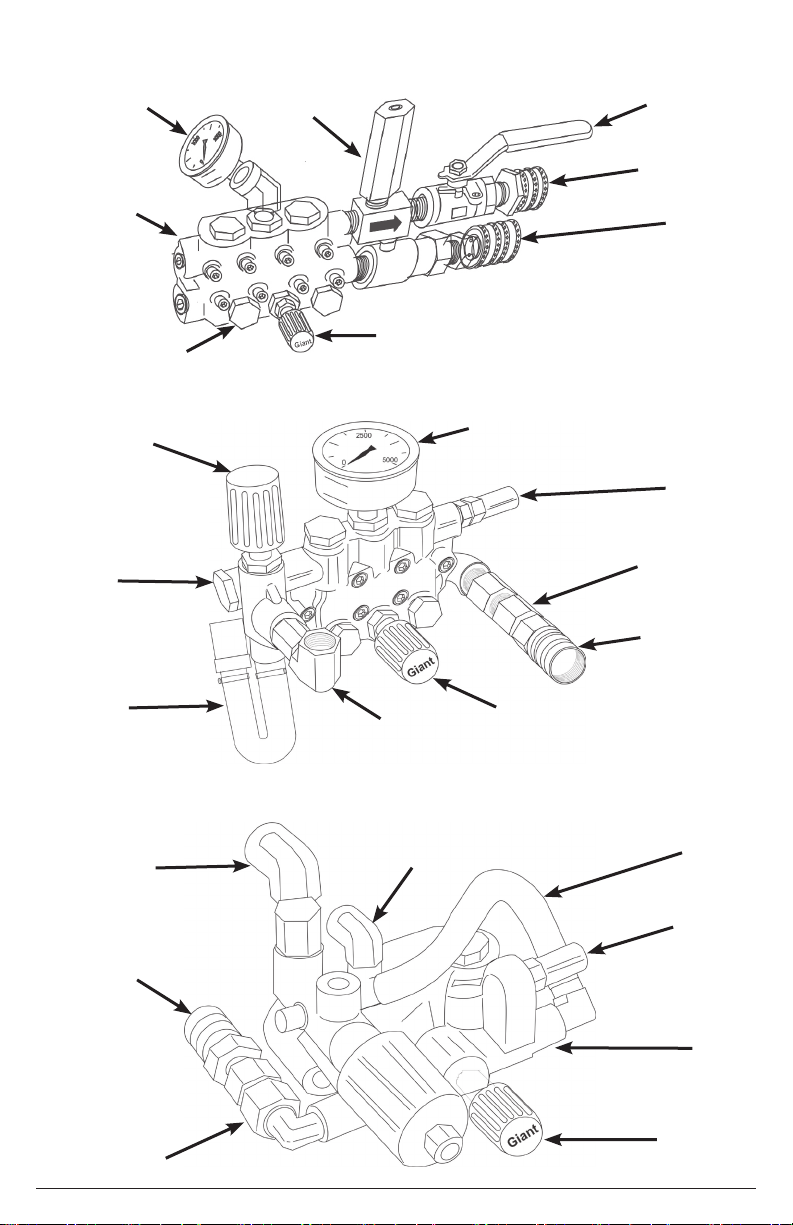

LIQUID INJECTOR

THE CHEMICAL INJECTION WITH A FIXED OR ADJUSTABLE FEED RATE SHOULD BE INSTALLED BETWEEN

THE PRESSURE REGULATOR AND THE REEL. THIS ADDED FEATURE PERMITS THE OPERATOR TO ADD A

CLEANING OR SOAP SOLUTION TO THE WATER FLOW. A HIGH/LO NOZZLE MUST BE USED IN ORDER TO

ACTIVATE THE CHEMICAL INJECTOR.

FOR PERFORMANCE, SPECIFICATIONS, INSTALLATION AND HOW TO SERVICE THE

CHEMICAL INJECTOR REFER TO THE OPERATING INSTRUCTIONS SUPPLIED BY THE PUMP

MANUFACTURER.

PULSATOR

THE PULSATOR PRODUCES A SHORT INTERRUPTION OF WATER FLOW NOTICED AS A VIBRATION FELT

THROUGHOUT THE JETTING HOSE (MORE OBVIOUS WITH SMALL DIAMETER HOSE). THIS PULSATION

PERMITS A BETTER HOSE MOVEMENT THROUGH THE PIPE AND ALSO HELPS TO CUT THROUGH

OBSTRUCTIONS WITH EASE. WHEN STARTING YOUR MOTOR UNDER NORMAL OPERATING CONDITIONS,

THE PULSATOR VALVE SHOULD ALWAYS BE OFF.

NEVER USE POISONOUS OR CORROSIVE SOLUTIONS AS A CLEANING OR CUTTING AGENT.

THE PULSATION DIAL OR KNOB SHOULD ONLY BE TURNED IN UNTIL VIBRATION IS ACTIVATED.

CONTINUED TURNING OF THE DIAL OR KNOB WILL DAMAGE THE PUMP.

ONCE IN THE PULSATION MODE, THE OPERATOR SHOULD ALWAYS AND CONTINUOUSLY

MOVE THE JETTER HOSE TO AVOID EXCESSIVE WEAR AND TEAR OF THE HOSE.

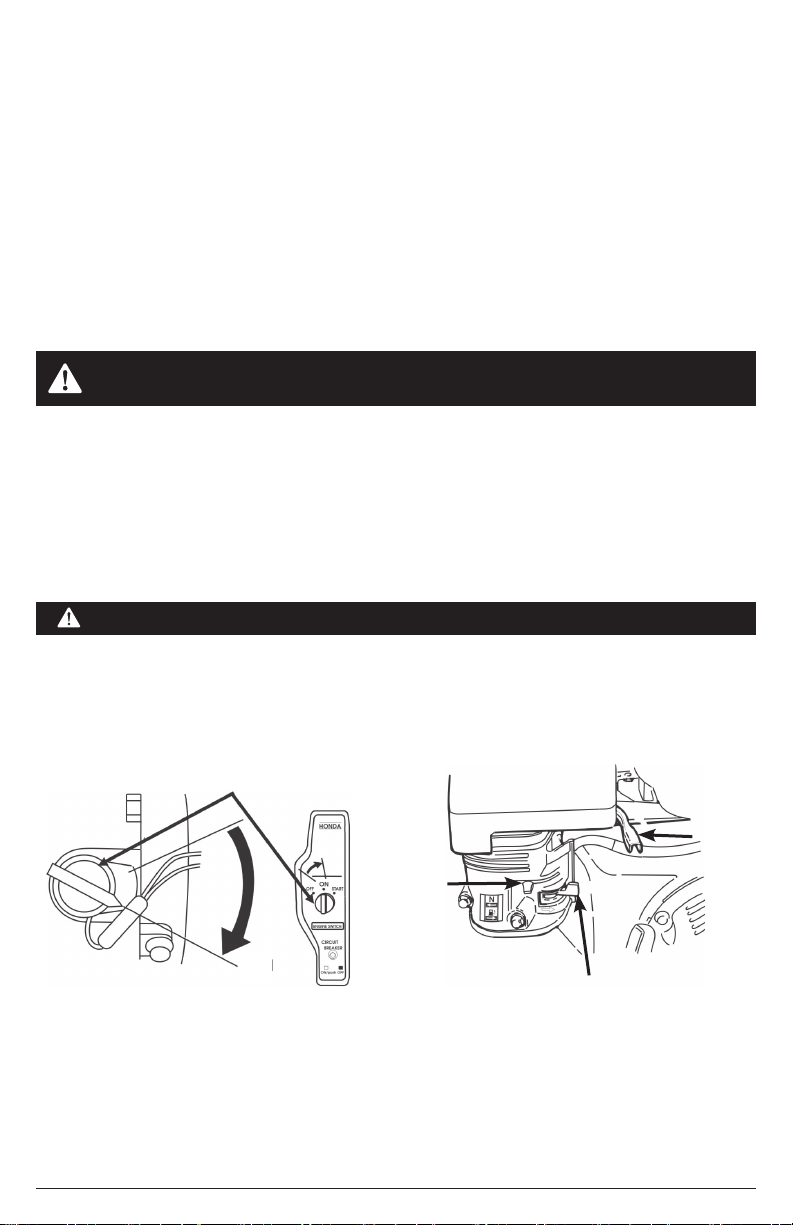

PRESSURE REGULATOR

THE PRESSURE REGULATOR KNOB, LOCATED AT THE PUMP, ALLOWS THE OPERATOR TO ADJUST

THE PRESSURE DURING OPERATION. THE ADJUSTMENT SHOULD BE PERFORMED ONLY AFTER

THE MOTOR/ENGINE HAD BEEN STARTED. IT IS RECOMMENDED TO START ELECTRIC UNITS WITH

AS LITTLE PRESSURE AS POSSIBLE TO AVOID TRIPPING A CIRCUIT BREAKER. THEN GRADUALLY

INCREASE TO NORMAL WORKING PRESSURE. ON GASOLINE POWERED MODELS THE PRESSURE

AND RPM OF THE ENGINE ARE DIRECTLY RELATED. LOW RPM EQUALS LOW PRESSURE, HIGH

RPM EQUALS HIGH PRESSURE ON LARGER DIAMETER HOSE. ON SMALLER DIAMETER HOSE

THE PRESSURE REGULATOR MUST BE MANUALLY ADJUSTED TO REACH LOWER PRESSURE

SETTINGS DUE TO LESS WATER VOLUME PASSING THROUGH HOSE. IF DESIRED THE PRESSURE

REGULATOR CAN BE ADJUSTED FROM ZERO TO DESIRED PRESSURE SETTINGS AFTER STARTING

ENGINE AND ATTAINING PROPER ENGINE RPM IN RELATION TO EXPECTED PRESSURE SETTING.

DUE THE HIGH SENSITIVITY OF THESE REGULATORS THEY ARE NOT COVERED IN THE WARRANTY.

PRESSURE SETTINGS: 1250 PSI (1500 PSI MAXIMUM) FOR 2 HP ELECTRIC MODELS

2750 PSI (3000 PSI MAXIMUM) FOR 389 cc GASOLINE MODELS

3250 PSI (3500 PSI MAXIMUM) FOR 688 cc GASOLINE MODELS

MACHINE SETUP CHECK LIST

GORLITZ JETTERS SHOULD BE GIVEN THE BEST OF CARE. IF KEPT CLEAN AND LUBRICATED, THEY

CAN PROVIDE MANY YEARS OF TROUBLE-FREE SERVICE. THE FOLLOWING INSTRUCTIONS SHOULD BE

CAREFULLY OBSERVED AT ALL TIMES:

• CHECK FUEL SUPPLY ON GASOLINE OPERATED JETTERS.

• TEST GFCI ON ELECTRIC DRIVEN JETTERS.

• CHECK OIL LEVEL AT PUMP.

• CHECK WATER INLET STRAINER.

• CHECK JETTING HOSE FOR KINKS OR EXCESSIVE WEAR.

• CHECK ALL HOSE AND REEL CONNECTORS.

• CHECK JETTING NOZZLE FOR ANY CLOGGED HOLES.

• CHECK FOR ADEQUATE WATER SUPPLY.

WATER FLOW RATE:

3 GPM MINIMUM FOR 2 HP ELECTRIC MODELS

5 GPM MINIMUM FOR 389 cc GASOLINE MODELS

7 GPM MINIMUM FOR 688 cc GASOLINE MODELS

REPAIR OR REPLACE ANY UNSAFE PART WHICH MAY CAUSE THE JETTER TO MALFUNCTION.