Machine Terminology

Electrical

Panels

Electrical Panels contain the brains and power for the machine. The Main Electrical Panel contains the

main PLC and sevo drivers to control the sevo motors. The High Frequency Panels contain the VFD’s to

drive the routers, width adjust, and feed motors.

Door Clamp The Door Clamp secures the door for stable routing and drilling.

Probes Probes are an option. Encoder based assemblies that measure door width ,lenth, or depth of a cut. Data is

fed back to the PLC to create exact measurements of the door.

Door Stop The Door Stop sets a reference for the door to be in the correct position for processing.

Cuter Head The Cuter Head contains the cuting motor. The Head picks up a Tool Holder and cuts the face of the

door.

Edge Router (Option) The Edge Router is an available option to rout the edge of the door.

Tool Holder

Rack

Tool Holder Rack stores the Tool Holders. The rack is located at the end of the machine. The Cuting Head

is programmed to automatically pickup and replace the desired tool at the rack.

Sensors Sensors provide input to the PLC as pat of the automation of the door cuting process, including feed

through, door clamping, and door location. It is impotant to keep the sensors cleaned and aligned to keep

the door process running smoothly. There are wo classiications of sensors, Photo Electronic and Induc-

tive Proximiy Sensor.

Tool Holder The Tool Holder Assembly contains the Flange, Collet, Collet Nut and the Cuting Tool. A Tool Holder is

automatically picked up by the Cuting Head to peform the cuting process. The Tool Holders are stored

at the Tool Holder Rack.

Chisels (Option) Chisels are located in the Cuter Head. The chisels square corners on the Lite Cut-Out.

Tools

Operator’s

Station

The Operator’s Station is the inteface of operator to machine. It contains power controls and touch

screen inteface to control the cuting parameters of the door.

KvalCAM The KvalCAM soware includes a single User Inteface to control the entire machine line. Each machine

can also be controlled separately or as a collective. Door Jobs and Features from a libray can be download-

ed remotely and created at the station. The KvalCAM inteface uses tabbed navigation to jump to desired

screens.

Door Job In the Door Job creation screen, door cuts can be created, the door parameters stored and machining of

the door can be processed using this information.

Feature Group In the Features Group creation screen, door cuts can be created and veriied by way of the Job Preview

screen. Templates are stored to be called into the Door Job.

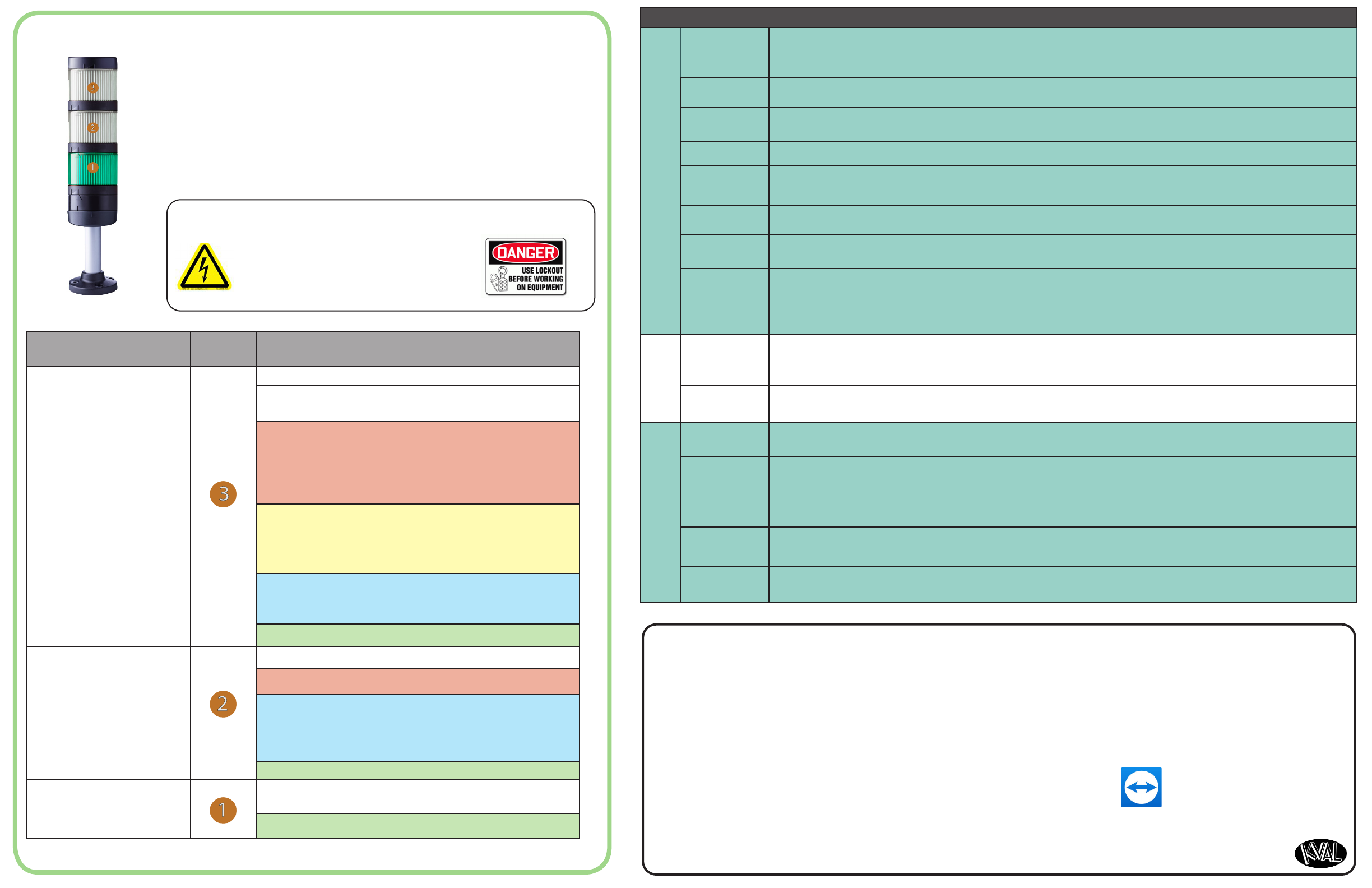

Categoy Desig. Descriptions

Machine Status

OFF (Clear): Machine not in operation.

White: Initializing

1 Flash: Waiting for all systems to initialize

Red: Machine Error

Solid: General Error

• 1 Flash: EtheCat Device not Ready to Run

• 2 Flashes: VFD, Sevo, or Motor Error

• 3 Flashes: 24 VDC Power Error

Yellow: External Error

Solid: General Error

• 1 Flash: 3 Phase Voltage Error

• 2 Flashes: Low Air Error

Blue: Operator Status

Solid: Waiting for Operator

• 1 Flash: Reposition Door

Green: Machine is Operational

Safey

OFF (Clear): Safey Project not Running

Red: Safey PLC Error

Blue: Waiting for Safey Re-Set

• Solid: General Error

• Flashing: Not Ready to Re-Stat (E-Sop Switch is Ac-

tive)

Green: Machine is Operational

Control Power

O: No Control Power

ON (Green): 24 VDC Control Power ON

About the Light Tower

Machine

High Voltage may cause injury or death.

Troubleshooting checks must be performed

by a Qualied Electrical Technician.

The Light Tower indicates the working status of the system. The

Light Tower is mounted on top of the Electrical Boxes. Each light dis-

plays dierent colors and lashing codes to show the machine status.

The table below describes the dierent states of the Lght Tower.

Be Smat! Follow all Safey Precautions.

Operation

Remote Troubleshooting

Kval’s Suppot Team is able to work remotely with your maintenance sta or contractor to diagnose and troubleshoot machin-

ey issues. To get stated, please create a suppot ticket online. Call (800)- 553-5825 or stat a suppot ticket Online htps://

www.kvalinc.com/suppot.

Tools Needed for machine hardware troubleshooting:

• Access to a broadband internet connection

• An iPhone or Android smat-phone (We use Apple FaceTime or

Google Duo for video)

• A DMM

• A standard toolset

For machine soware troubleshooting:

• Access to a broadband internet connection

• A computer running Windows

• Our remote suppot client

Allow Kval to Logon to the Machine

• Exit the KvalCAM program. On the

Windows Screen, select the KVAL

Sevice Icon