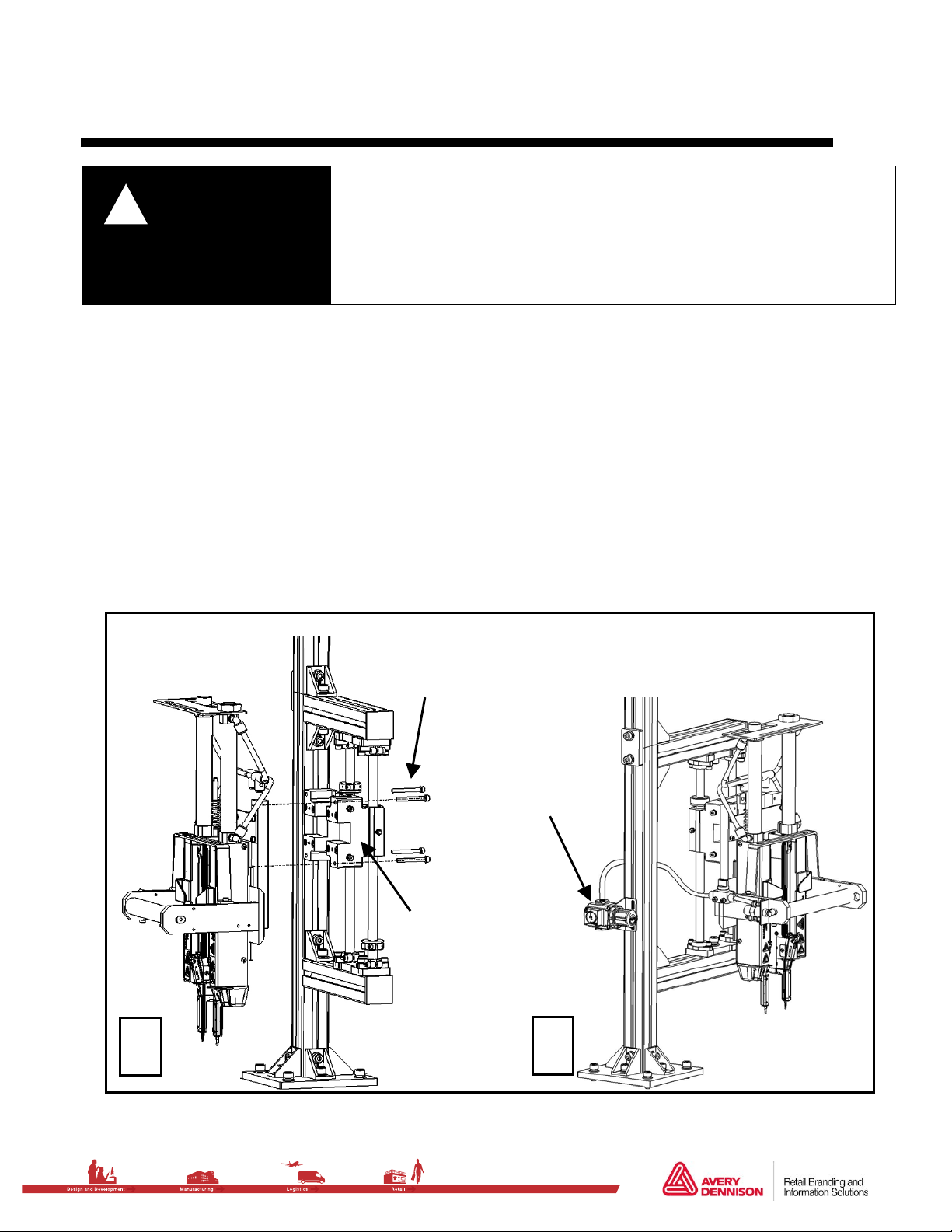

FOR USE BY QUALIFIED PERSONNEL ONLY

This manual is copyrighted with all rights reserved and may not be copied, in part or in whole, without the written

consent of Avery Dennison Corporation. Avery Dennison makes no warranty, express or implied, as to its

accuracy and assumes no liability arising out of its use by others.

The descriptions and specifications contained in this manual were in effect at the time the manual was approved

for printing. Avery Dennison, whose policy is one of continuous improvement, reserves the right to discontinue

models at any time or change specifications or design, without notice and without incurring obligations or liability.

Copyright (c) 2013 Avery Dennison Corporation. All rights reserved. Avery Dennison and all other Avery

Dennison brands, product names and codes are trademarks of Avery Dennison Corporation.

WARRANTY

All statements, technical information and recommendations about AVERY DENNISON products are based upon

tests believed to be reliable but do not constitute a guarantee or warranty. All AVERY DENNISON products are

sold with the understanding that PURCHASER has independently determined the suitability of such products for

its purposes. AVERY DENNISON products are warranted to be free from defects in material or workmanship for

a period of 90 days from the date of shipment. Any product shown to the satisfaction of AVERY DENNISON

within the time provided to be so defective shall be replaced without charge or AVERY DENNISON may issue a

credit in such an amount as it deems reasonable; however, in no way shall AVERY DENNISON be responsible

for claims beyond the replacement value of the defective product or in any way liable or responsible for

consequential or incidental damages.

NO EXPRESS WARRANTIES AND NO IMPLIED WARRANTIES, WHETHER OF MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR USE, OR OTHERWISE, EXCEPT AS SET FORTH ABOVE (WHICH IS

MADE EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES) SHALL APPLY TO THE PRODUCTS

DESCRIBED HEREIN. AVERY DENNISON SPECIFICALLY DISCLAIMS AND EXCLUDES ALL OTHER

SUCH WARRANTIES. NO WAIVER, ALTERATION, ADDITION, OR MODIFICATION OF THE FOREGOING

SHALL BE VALID UNLESS MADE IN WRITING AND SIGNED BY AN AUTHORIZED REPRESENTATIVE OF

AVERY DENNISON.

No salesman, representative, or agent of AVERY DENNISON is authorized to give any guarantee, warranty, or

make any representation contrary to the above.

LIMITATION OF LIABILITY

In no event shall AVERY DENNISON be liable for any incidental or consequential damages, including but not

limited to, loss of profit, loss of use or production or loss of capital. The remedies of PURCHASER set forth

herein are exclusive and the total liability of AVERY DENNISON with respect to any contract, or anything done in

connection therewith such as the performance or breach hereof, or from the manufacture, sale, delivery, resale,

installation or use of any products whether arising out of contract, negligence, strict tort, or under any warranty, or

otherwise, shall not exceed the purchase price of the products upon which liability is based.

Avery Dennison Corporation

224 Industrial Road

Fitchburg, MA 01420