Tindo Solar Karra Series User manual

INSTALLATION MANUAL

TINDO SOLAR PV Modules

Safety Notes

Installation of modules requires professional skills and knowledge and

is to be carried out by qualified personnel. Please read this manual

carefully before installing and using this module. Installation personnel

shall get familiar with mechanical and electrical requirements of this

system. Please keep this manual properly as reference for future

maintenance or upkeep or for sales and treatment of modules.

#1

APPLICABLE PRODUCTS

This document is applicable to the series of solar module as listed

below:

Karra – XXX (System Voltage 1000V Module)

Karra - XXXH (System Voltage 1500V Module)

Regular modules Mechanical drawing

#2

INTRODUCTION

Thank you for choosing a Tindo solar Module. Background to our

name “TINDO” – Tindo is a word from the Kaurna warra Aboriginal

language which is the language of the peoples indigenous to the

Adelaide plains on which our solar panel manufacturing plant sits.

Tindo

s

. sun; or watch; clock; day

Karra

s

. sky ; or height; heaven

INSTALLATION MANUAL

For our purposes we have taken Tindo as meaning the “SUN” and

Karra as “Sky”, thus you have purchased a panel made by the Sun and

a panel that comes from the Sky.

Tindo solar modules transform the sun’s light energy into electricity.

Please read the following instructions carefully. Failure to observe

them may result in bodily injury and property damage. This manual

only applies for installations in Australia.

And the installation altitude is up to 2000m.

This manual provides information on safety precautions to be used

during the handling and installation of the Tindo Karra panel along

with technical instructions to be followed during installation,

mounting, wiring and commissioning.

#3

GENERAL WARNING & CAUTION

Keep children and unauthorized people away from the

modules and work site.

Appropriate safety practices, suitable protective clothes and

safety equipment must be used.

Appropriate safety practices and equipment for working at

heights must be used.

Do not work alone. Always work with a team of at least two

people.

The modules are not suitable for mobile usage or for indoor

installations.

Transport the modules in its original packaging

Do not expose PV modules to concentrated sunlight with mirrors

or lenses.

The Tindo Karra solar panel should only be installed and

maintained by a qualified and licensed electrician with Clean

Energy Council Solar PV accreditation.

Make sure flammable gases are not generated near the

installation site. Do not install the modules near open flame and

flammable materials. Solar modules are not explosion-proof

operating equipment.

Artificially concentrated sunlight shall not be directed on the

module or panel

Front protective glass is utilized on module. Broken solar

module glass is an electrical safety hazard (may cause electric

shock and fire). These modules cannot be repaired and should

be replaced immediately.

INSTALLATION MANUAL

#4

BEFORE INSTALLATION

Contact local authorities to determine local laws, permits and

codes to make sure your installation is fully compliant.

Make sure to strictly follow the local and national regulations

for work safety and accident prevention.

Observe local regulations concerning fire protection

classification for rooftop installations.

Only install undamaged modules. Ensure that the junction

box, cable and connectors are undamaged prior to

installation.

Store the modules in cool dry rooms before installation.

#5

DURING INSTALLATION

There is a serious risk of various types of injury occurring

during the installation.

Do not work under rain, snow, hot or windy conditions.

The solar panels, tools and other materials must be dry during

installation.

Completely cover the PV module surface with an opaque

material during the entire installation and wiring of the PV

module. Only then the module is reliably de-energised.

DANGER! Danger due to electric shock! A solar module

generates electricity and voltage even at a low intensity of

illumination. Arcing can occur when contacts in a live electrical

circuit are physically disconnected. This can result in grave or

mortal injury. The severity increases when several modules are

connected.

During installation at heights, there is a danger that tools,

panels or other materials could fall and injure people so take

necessary precautions by blocking off danger areas before

beginning work.

Panels must not be installed flat and need a minimum tilt of 5

degrees.

Materials : Fine-wire, tinned-copper conductor.

Only use PV-KST4 EVO 2, PV-KBT4 EVO 2 / Staubli(MC4).

Be very careful with the back of the module as the delicate

thin solar cells may break.

The PV panels are primarily made of glass and should be

handled with caution.

Ensure that adequate ventilation exists below the module to

help avoid elevated module temperatures.

Never touch the end of the connectors. Do not insert

electrically conductive parts into the plugs and junction box.

Do not touch the contacts or exposed terminals.

Do not twist the frame of the module or subject the module to

mechanical stress as the glass or solar cells may break.

Do not touch the PV module with bare hands as the frame has

sharp edges and may cause injury.

Do scratch or hit the back sheet or damage it

Do not stand or step on the module. Do not drop or place

objects on the modules.

Do not rest the module on its unprotected edges.

Do not drop tools or hard objects on PV modules.

Do not lift the modules by the cables or by the junction box.

Do not open the junction box under any circumstances.

Do not over bend the output cable as the insulation may

break down.

Do not drill holes in the aluminum frame.

Do not scratch the aluminum frame as it will cause corrosion

of the frame.

INSTALLATION MANUAL

Do not expose the modules to chemicals.

Do not place the modules in standing water. The junction box

is splash-proof only.

Bind cables to ensure cables are not drooping behind the

panels

Make sure cables are not exposed to direct sunlight as they

could be UV damaged.

Observe the local requirements for functional grounding or

earthing.

Observe the local requirements and regulations for lightening

protection.

#6

AFTER INSTALLATION

Make sure the PV connectors are tightly sealed and connected

properly. Do not disconnect or unplug the PV connectors

when the solar system is under load. Ensure that the modules

are first disconnected from the inverter prior to opening any

contacts in the solar installation. Be absolutely certain to

observe the time intervals specified by the manufacturer after

switching off the inverter and prior to starting subsequent

work such that the energized components can be discharged

In the case of the glass surface of the PV modules is broken,

make sure to be using the appropriate safety for the safe

removal of the panels. The panel could live so ensure it is

safely disconnected and isolated before touching the panel.

Wear rubber gloves for electrical insulation during service.

#7

ELECTRICAL INSTALLATION

Use proper electrically rated insulated tools and do not

use wet tools

TIndo Karra modules must not be connected in series and

parallel with other modules.

For series connections, make sure the maximum open

circuit Voltage is less than the specified maximum system

Voltage and use a safety factor of 1.25

For parallel connections, make sure cables are connected

according the Australian electrical wiring standards and

take proper measures to prevent reverse current flows.

Use a safety factory of 1.25

Ensure a safety factor of 1.25 when determining permitted

voltages for components, cable sizes, fuse sizes and

inverter sizes.

Class of protection against electrical shock : Class II

Solar panels must be installed in accordance with AS-5033

Installation of PV arrays. Other relevant standards are AS-

3000 Electrical Wiring Rules, AS-1768 Lightening

Protection, AS-1170.2 Wind Loads, AS-4777 Grid

Connections of Energy Systems via Inverters.

Do not pull the cables on the junction box as the cable

may disconnect and could cause electric shock.

Specifications for cables are Type Designation : H1Z2Z2-K

1x4㎟, Rated Voltage : DC 1.5kV / AC 1kV, Ambient

Temperature : -40℃ ~ +90℃, Conductor.

INSTALLATION MANUAL

#8

SITE SELECTION

Make sure panels are installed in an un-shaded location

throughout the year. Take into account both summer and

winter sun paths and shading. This will ensure maximum yield

from your solar panel. Avoid shading from chimneys, trees, air

conditioners and other objects.

If you are planning to install the PV modules in a salty

environment such as near the beach, please consult with

Tindo local agent first to determine whether or not the

installation is appropriate for the PV module.

Make sure to tilt the solar panel so that the energy yield

throughout the year is maximized. As a rule of thumb, the tilt

angle should be approximately equal to the latitude of the

installation location.

The modules are certified according to the norm IEC 61215,

IEC 61730-1 and IEC 61730-2 for safe operation in moderate

climates.

The permitted module temperatures lie between -40 °C and

+85 °C.

#9

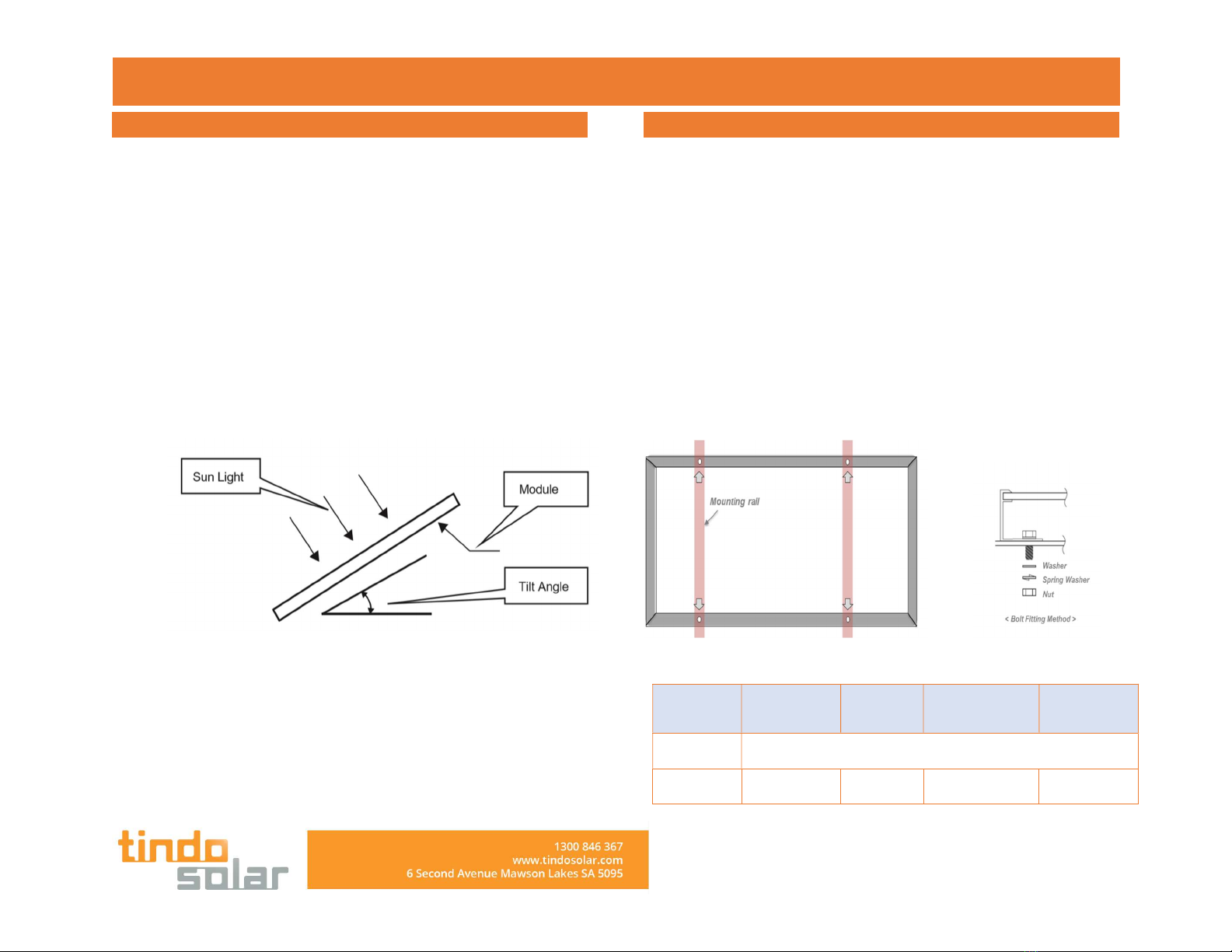

INSTALLATION METHODS

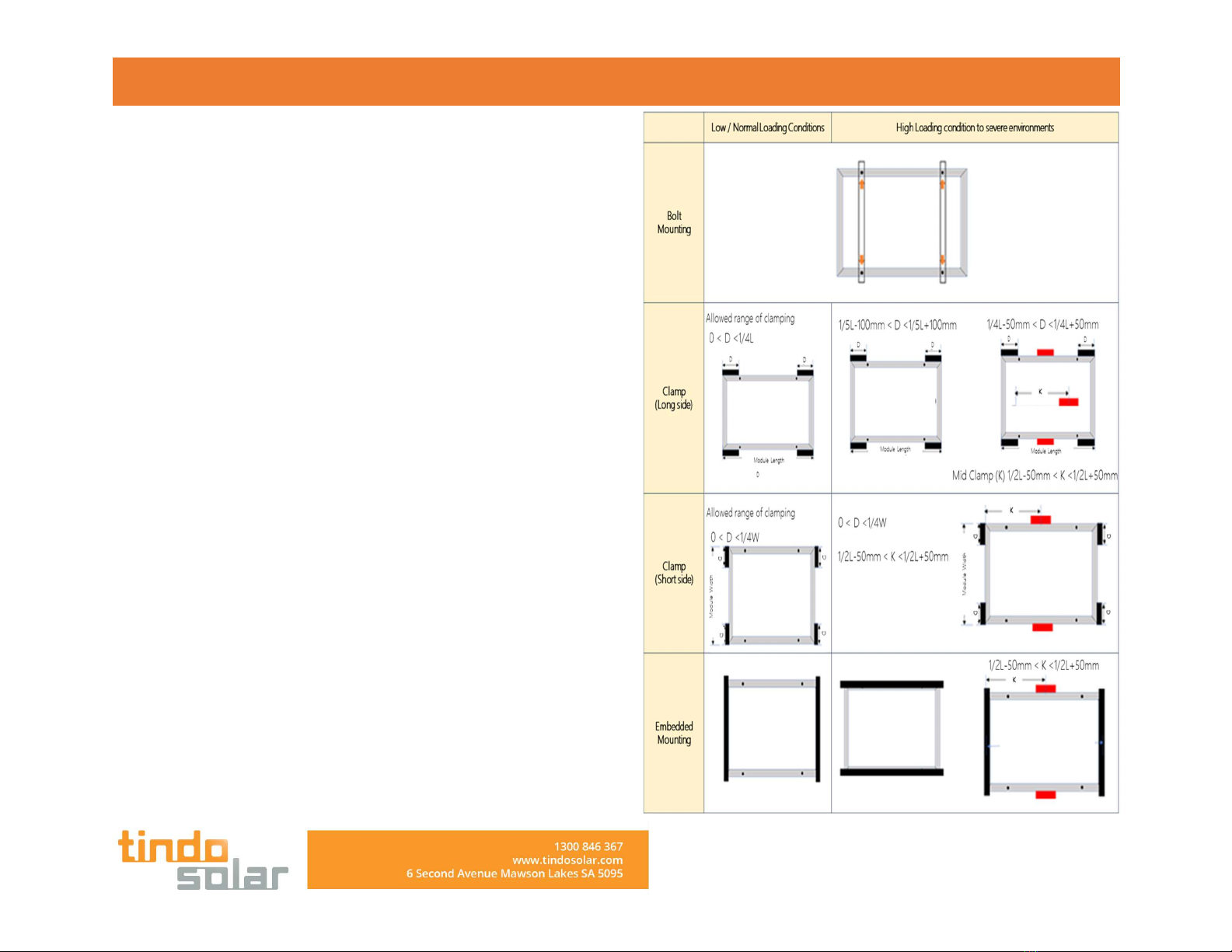

Solar Panel and mounting system ca be fix by mounting holes or

clamps. The installations shall be carried out as the illustrations and

suggestions.

Only use genuine Tindo Mounting hardware for mounting the solar

panel. Support structures that the PV modules are mounted to must

be absolutely rigid.

[Install modules through mounting holes]

Make use of bolts to fix modules on the mounting system through

frame mounting holes on the back of the module frame. This applies

to both portrait and landscape installation orientations. Use four

mounting holes.

Accessories recommended as follows:

Bolt Washer Spring Washer Nut

Material Stainless steel

Dimension

M8 x 16mm M8 M8 M8

INSTALLATION MANUAL

Torque for fastening bolts: 16Nm~ 20Nm

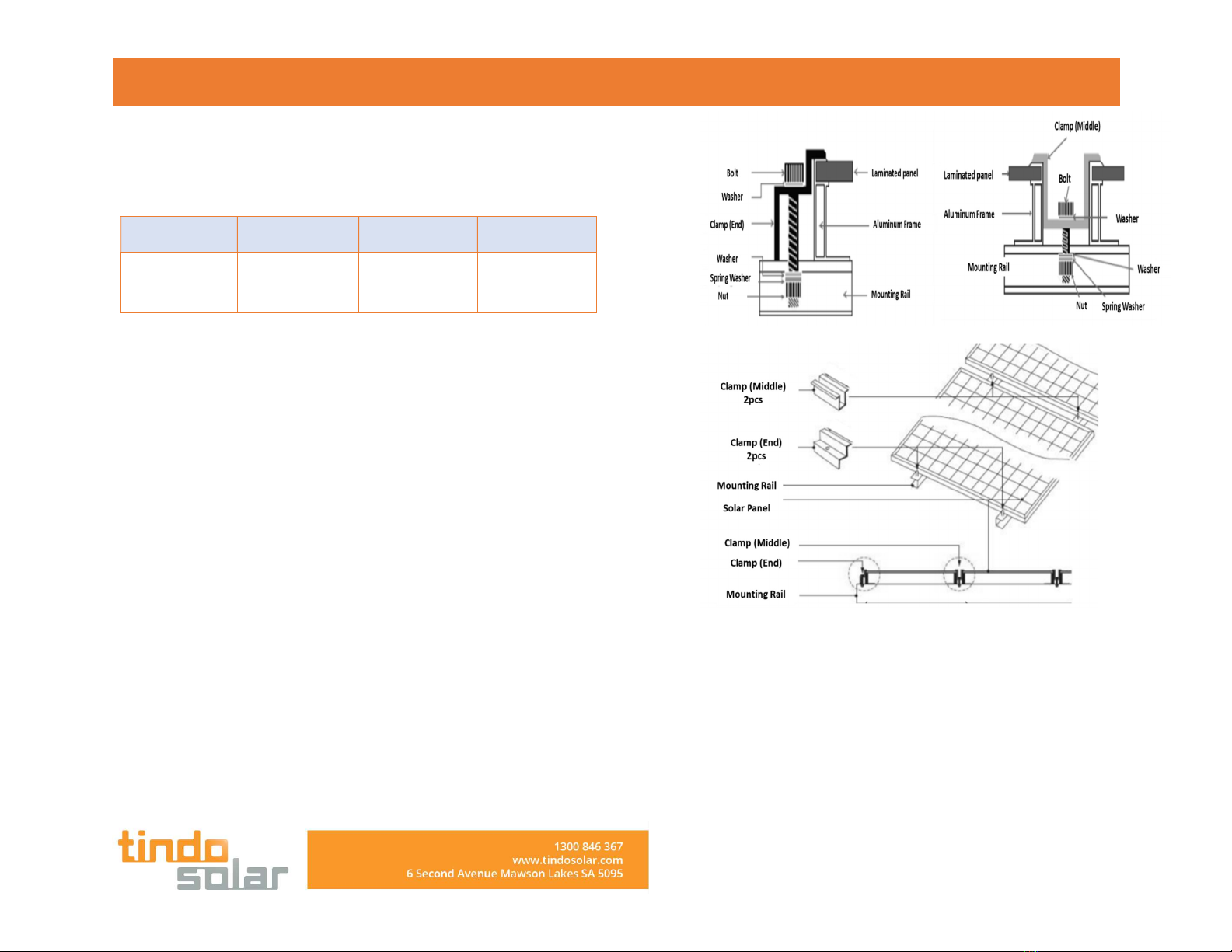

[Install modules with clamps]

Install modules on the mounting system with clamps. (Bolt M8)

Width Thickness Material

Spec No less than

40mm

No less than

3mm

Aluminum

6063-T5

Torque for fastening bolts: 18Nm~ 24Nm

The clamps shall not contact glass or module frame deformed in any

case. The contacting surface of the clamp contacting the front side the

frame shall be even and smooth. Otherwise, the frame and module

may be damaged. Make sure the clamp will not produce any shading

effect.

Approved clamping areas are shown in the following drawing. The

dimensions refer to the distance from the edge of the module to the

center of the clamp. This applies to both portrait and landscape

installation orientations.

[ Mounting details]

Low/ normal loading conditions apply to most environments: the

maximum static pressure on the back side of the module is 2400Pa

and the maximum static pressure on the front side is 5400Pa.

[ Position of Fixing Points ]

Low/normal loading conditions apply to most environments:

the maximum static pressure on the backside of the module

is 2400pa (equal to wind load) and the maximum static

INSTALLATION MANUAL

pressure on the front side is 2400pa (equal to wind load and

snow load).

High loading conditions apply to severe environments (such

as wind storm, heavy snow): the maximum static pressure on

the backside of the module is 2400pa (equal to wind load)

and the maximum static pressure on the front side is 5400pa

(equal to wind load and snow load), which is the highest

requirement on pressure in the IEC standards.

INSTALLATION MANUAL

The modules can be installed in landscape or portrait. Make

sure the junction box is positioned in the upper area of the

modules with the wires hanging down.

Ensure the drain holes in the solar panel frame are

unobstructed to allow drainage of water.

Install panels with a minimum tilt of 5 degrees.

Install panels with a minimum distance of 10mm between

modules.

Ensure the panel and array conforms to local environmental

codes especially for wind loading.

Do not allow dissimilar metals to be in contact with each other

giving rise to galvanic corrosion.

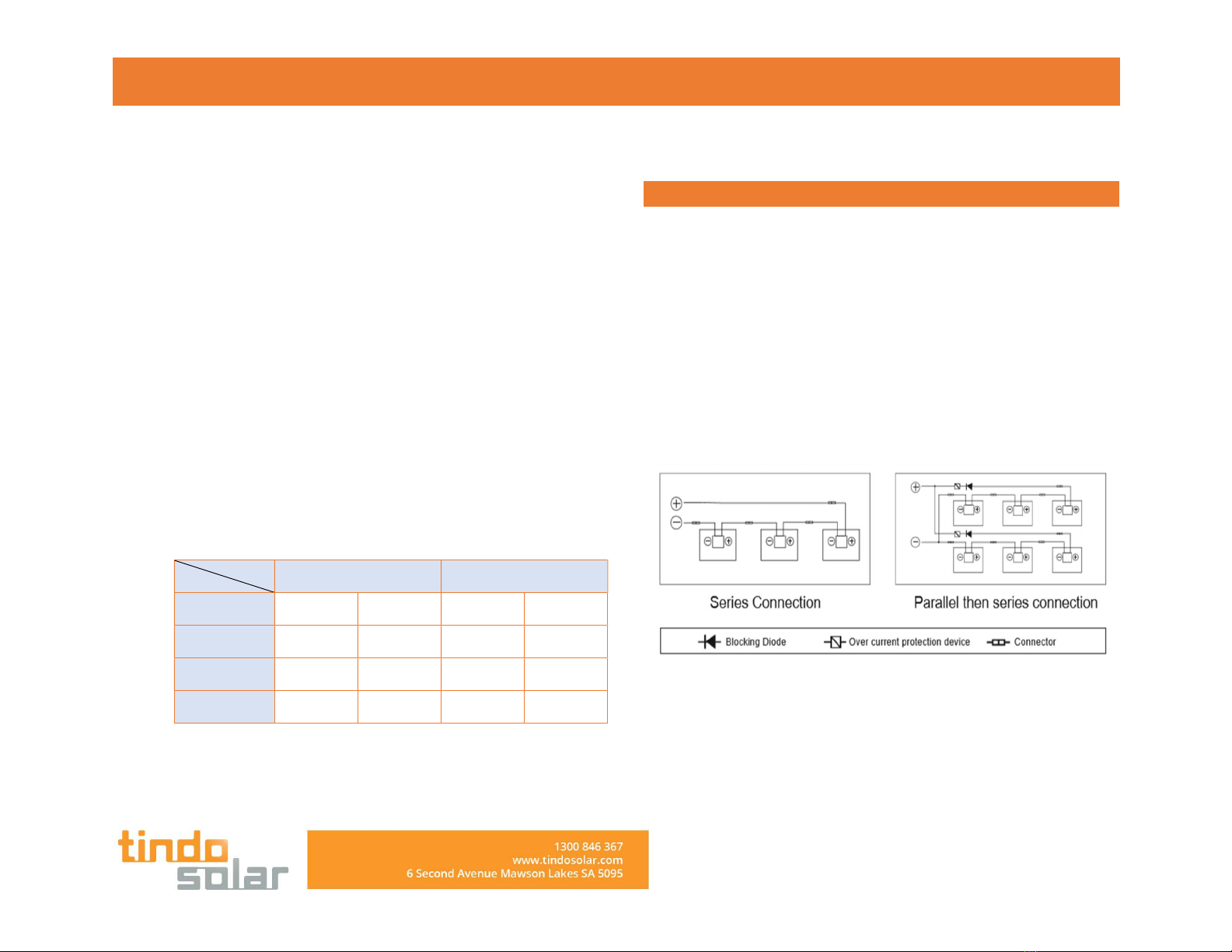

Mechanical Load Test Condition

Clamping Installation Bolting Installation

Test Side Front Back Front Back

Design Load 3600 Pa 1600 Pa 3600 Pa 1600 Pa

Safety Factor 1.5 1.5 1.5 1.5

Test Load 5400 Pa 2400 Pa 5400 Pa 2400 Pa

#10

ELECTRIC INSTALLATION

[ Electric Performance ]

Module electric performance parameters such as Isc, Voc and Pmax

nominal values have ±3% error with those under standard testing

conditions of: irradiance of 1000 W/m2, cell temperature of 25℃ and

air mass of AM1.5. When modules are in series connection, the final

voltage is sum of that of the single module. When modules are in

parallel connection, the final current is sum of the single module as

below shows. Modules with different electric performance models

cannot be connected in series.

Series connection and parallel connection circuit diagram

The number of modules in series connection in each strand shall be

calculated according to relative regulations. The open circuit voltage

value under the expected lowest temperature shall not exceed the

maximum system voltage value stipulated for modules and other

INSTALLATION MANUAL

values required by DC electric parts. (modules maximum system

voltage is DC1000V/DC1500V---actually system voltage is designed

based on the used modules model and inverter.)

The VOC factor can be calculated with the following formula. Voc=1-

βVoc×(25-T) T: The expected lowest temperature of the installation

site. β:VOC temperature coefficient (% /℃) (Refer to modules manual

for further detail)

[ Cables and Connecting Lines ]

In module design, adopt enclosed junction boxes with the protective

level of IP67 for on-site connection to provide environmental influence

protection for wires and connections and contacting protection for

non-insulating electric parts. The junction box has well connected

cables and connectors with the protective level of IP67. These designs

facilitate parallel connection of modules. Each module has two

independent wires connecting the junction box, one is negative pole

and the other is positive pole. Two modules can be in series

connection by inserting the positive pole at one end of wire of one

module into the negative pole of the adjoining module.

According to local fire protection, building and electrical regulation,

apply proper cable and connector; ensure the electrical and

mechanical property of the cables (the cables should be coated in a

catheter with anti-UV aging properties, and if is exposed to air, the

cable itself should have anti-UV aging properties).

[ Connector ]

Please keep connectors clean and dry. Make sure connector nuts are

fastened before connection. Do not connect connectors that are damp

or dirty or under any other improper conditions. Avoid connectors

from direct sun light and water immersion or falling onto ground or

roof. Wrong connection may lead to electric arc and electric shock.

Please make sure that all electric connection is reliable. Make sure all

connectors with lock are fully locked.

[ Bypass diode ]

Solar module junction box contains bypass diode which is in parallel

connection with the cell strands. If heat spot occurs locally with the

module, the diode will come into operation to stop the main current

from flowing through the heat spot cells in order to restrain module

heating and performance loss. Notice, bypass diode is not the

overcurrent protection device. If the diode is found or doubted to be

out of order, the installer or system maintenance supplier shall contact

us. Please do not try to open the module junction box on your own.

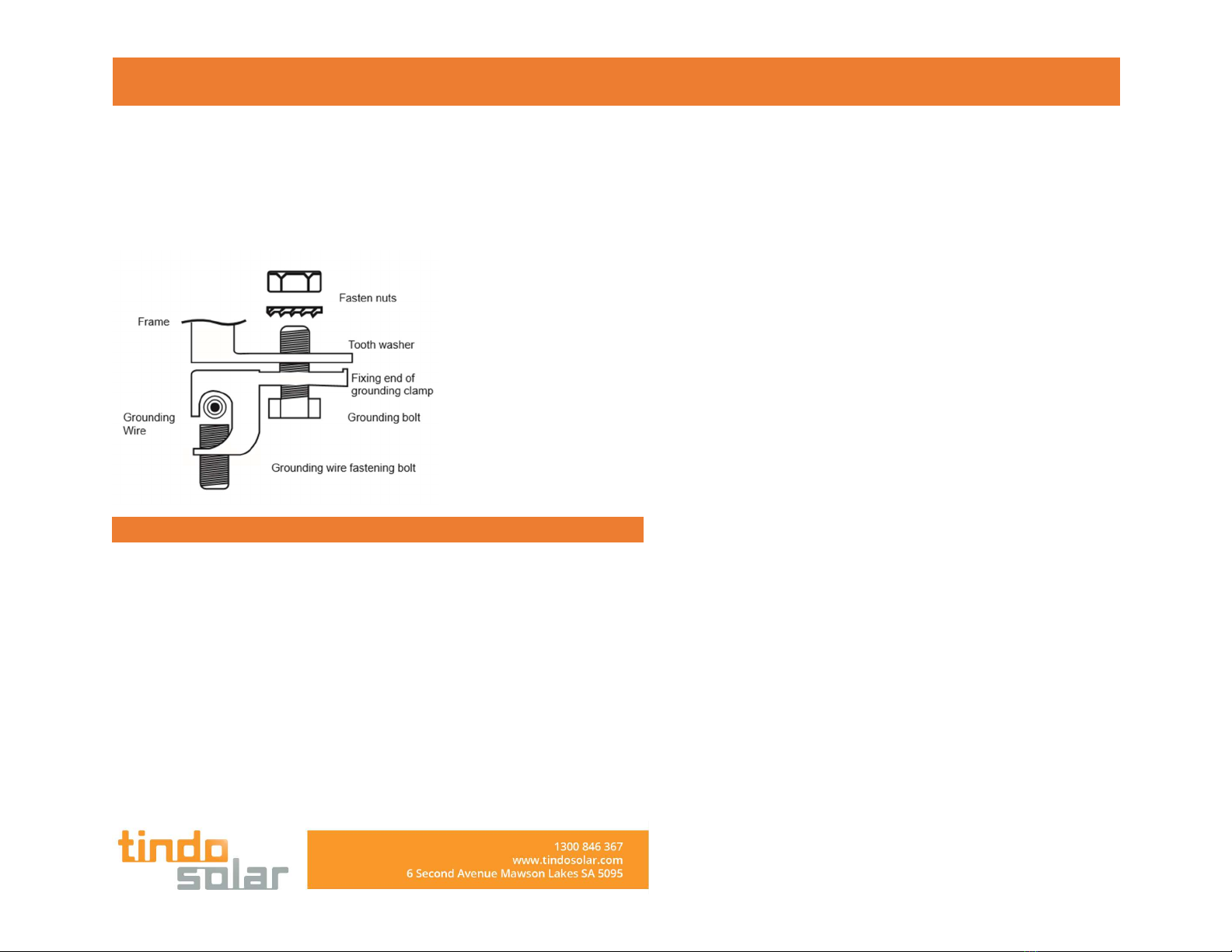

[ Grounding ]

In design of modules, the anodized corrosion resistant aluminum alloy

frame is used for rigidity support. For safety utilization and to protect

modules from lightning and static-electricity damage, the module

frame shall be grounded. The grounding device shall be in full contact

with inner side of the aluminum alloy and penetrate the frame surface

oxide film. Do not drill additional grounding holes on module frame.

The grounding conductor or strap may be copper, copper alloy, or any

other material acceptable for use as an electrical conductor per

respective National Electrical Codes. The grounding conductor must

INSTALLATION MANUAL

then make a connection to earth using a suitable earth ground

electrode. Holes marked with a grounding mark on the frame can only

be used for grounding and not for component mounting. Frameless

double glass modules have no exposed conductor, and therefore

according to regulations it did not need to be grounded.

[ Grounding methods below are permissible ]

Grounding by grounding clamp

There is a grounding hole with the diameter of Ø4.2 mm at the edge

of the module back frame. The central line of the grounding sign also

located on the edge of the module back frame overlaps with that of

the grounding hole. Grounding between modules shall be confirmed

by qualified electricians and grounding devices shall be manufactured

by qualified electric manufacturer. The torque is recommended to be

2.3N•m. 12 AWG copper core wire is used for the grounding clamp.

And copper wires cannot be pressed damaged during installation.

Grounding by unoccupied mounting holes

Mounting holes on modules that are not occupied can be used for

installing grounding devices.

Align grounding clamp to the frame mounting hole. Use

grounding bolt to go through the grounding clamp and

frame.

Put the tooth side of the washer on the other side and fasten

the nuts.

Put grounding wires through the grounding clamp and

grounding wire material and dimension shall meet

requirements in local national and regional law and

regulations.

Fasten bolts of grounding lines and installation ends.

Grounding Clamp Installation Note: TYCO. 1954381-1 (recommended) is used in figures above

INSTALLATION MANUAL

[ Install Method ]

#11

CLEANING & MAINTENANCE

TIndo panels are designed and built for long life and require minimal

maintenance.

Most dirt is washed off the panel by rain. If dirt builds up becomes

excessive:

• wash or rinse of the panel to remove dust, dirt or other deposits with

water.

• clean the glass surface only with soft cloth using warm water or

ethanol.

• no aggressive cleaner such as alkali chemicals including ammonia-

based products on panel.

The solar system should be inspected annually by a specialist installer

for:

• secure fastening and corrosion-free system components.

• secure connection, cleanliness and integrity of all electrical

components.

• the contact resistances of the grounding.

[ Module Appearance Inspection ]

Check module appearance defects visually, especially:

Module glass cracks.

Corrosion at welding parts of the cell main grid: it is caused by

moisture into the module due to damage of surface

packaging materials during installation or transportation.

Check whether there are traces of burning on the module

back plate.

Check PV modules for signs of aging including rodent

damage, weather damage, connection tightness, corrosion

and grounding condition.

Check for any shape objects in contact with PV modules’

surface

Check for any obstacles shielding the PV modules

Check for any loose or damage screws between the modules

and bracket. If so, adjust and fix on time.

Check connector sealing and cable connection.

INSTALLATION MANUAL

Look for gap on the sealant of the terminal box and confirm

whether it is cracking.

#12

MODULING HANDLING

[ Safety ]

• Solar panel weight up to and over 20kg, and at over 1.5m long can

be cumbersome to handle. Care should be taken to avoid injury.

• It is hazardous to install solar panels in high wind conditions.

• It is hazardous to install solar panels in wet weather.

[ General ]

• Take care when transporting and handling solar panels. Many issues

caused by rough handling will arise years after the installation. Taking

additional care can save considerable time and money from avoided

service calls and replacements.

• Never walk on a solar module

• Never drop a heavy object on a solar module

• Do not work on the modules with sharp objects

• Record module serial numbers for system documentation

[ Transport ]

• Transport vehicles and equipment should be fit for purpose ad well

maintained.

• Treat boxes and pallets with care, do not drop or allow the boxes to

receive impacts.

• Any panels transported outside of their boxes should be properly

secured and not allowed to move independently

[ Module Appearance Inspection ]

Check module appearance defects visually, especially:

• Module glass cracks.

• Corrosion at welding parts of the cell main grid: it is caused by

moisture into the module due to damage of surface packaging

materials during installation or transportation.

• Check whether there are traces of burning on the module back plate.

• Check PV modules for signs of aging including rodent damage,

weather damage, connection tightness, corrosion and grounding

condition.

• Check for any shape objects in contact with PV modules’ surface

• Check for any obstacles shielding the PV modules

INSTALLATION MANUAL

• Check for any loose or damage screws between the modules and

bracket. If so, adjust and fix on time.

• Check connector sealing and cable connection.

• Look for gap on the sealant of the terminal box and confirm whether

it is cracking.

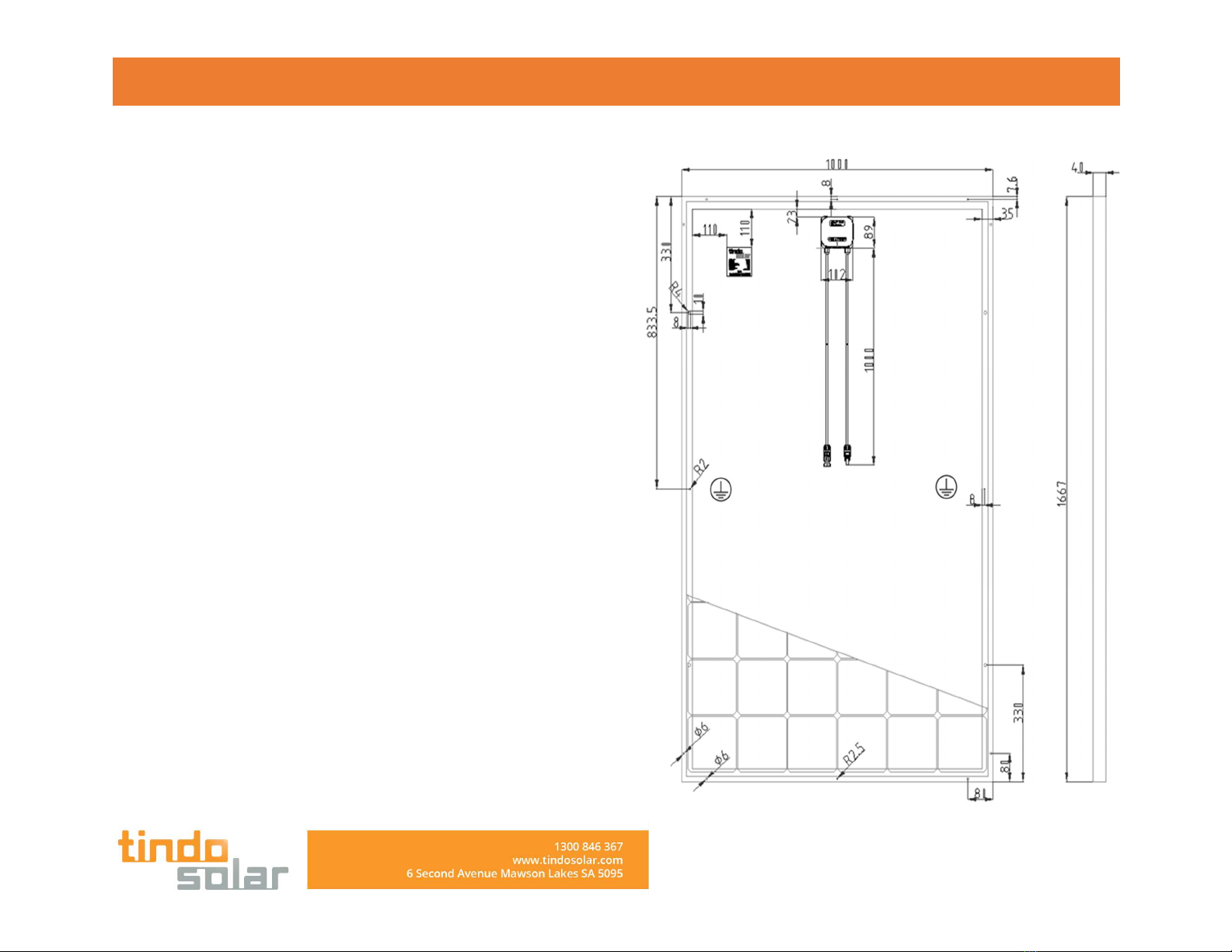

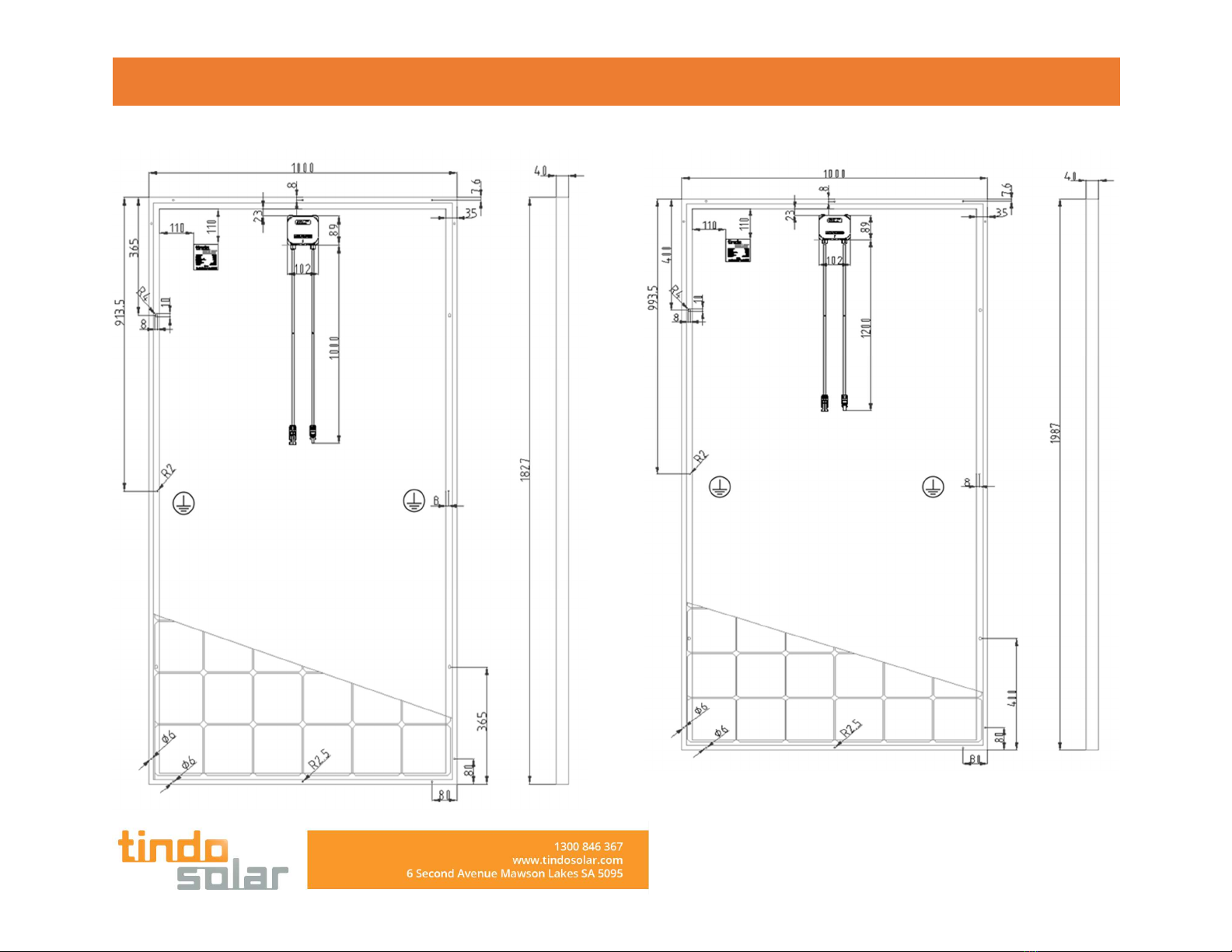

[ MODULE DRAWING: Karra 60cells series ]

INSTALLATION MANUAL

[ MODULE DRAWING: Karra 66cells series ]

[ MODULE DRAWING: Karra 72cells series ]

INSTALLATION MANUAL

Tindo Operations Co Pty Ltd

5 / 6- 8 Second Avenue Mawson Lakes South Australia 5095

Contact : info@tindosola.com, Ph. Office : +61 1300 846 367

This document is subject to change without notice.

This manual suits for next models

2

Table of contents