Tinius Olsen L Series User manual

Unit 6 Perrywood Business Park, Honeycrock Lane, Salfords, Surrey, RH1 5DZ, England, UK

Telephone: +44 1737 765001 Facsimile: +44 1737 764768 Website: www.tiniusolsen.com

L-Series Tensile Test Machines

Instructions For Use

Issue 01

© Tinius Olsen Ltd L-Series Manual – Issue 1 Page 2 of 31

Contents

1.

Introduction...................................................................................................................................3

2.

Specifications ...............................................................................................................................4

2.1.

Load Frame................................................................................................................................4

2.2.

Control Panel..............................................................................................................................4

2.3.

Force Measurement ...................................................................................................................4

2.4.

Extension Measurement ............................................................................................................5

2.5.

Speed Control ............................................................................................................................5

2.6.

Hardware Options ......................................................................................................................5

2.7.

Dimensions.................................................................................................................................5

2.8.

Temperature...............................................................................................................................6

2.9.

Humidity .....................................................................................................................................6

2.10.

Power .........................................................................................................................................6

2.11.

Machine Supply Requirements ..................................................................................................6

2.12.

CE Mark .....................................................................................................................................6

2.13.

Manufacture ...............................................................................................................................6

3.

Unpacking the Material Testing Machine...................................................................................7

3.1.

H1KL & H5KL.............................................................................................................................7

3.2.

H10KL, H25KL & H50KL..........................................................................................................10

4.

Contents ......................................................................................................................................13

4.1.

Checking Contents...................................................................................................................13

5.

Machine Installation ...................................................................................................................15

5.1.

Location....................................................................................................................................15

5.2.

Mains Supply............................................................................................................................15

5.3.

Warning Symbols .....................................................................................................................16

5.4.

Connection to Supply ...............................................................................................................16

5.5.

Fitting Load Cell .......................................................................................................................17

5.6.

Connection to PC .....................................................................................................................18

6.

Power ON Checks.......................................................................................................................20

6.1.

Emergency Stop Switch ...........................................................................................................20

6.2.

Power ON/OFF Switch.............................................................................................................20

6.3.

Mechanical Limit Switches .......................................................................................................21

6.4.

Crosshead Control Keys ..........................................................................................................22

6.5.

Alarms ......................................................................................................................................23

6.6.

Auxiliary Equipment..................................................................................................................25

7.

Installation of Tooling ................................................................................................................26

7.1.

Attachment Parts......................................................................................................................26

7.2.

Method .....................................................................................................................................26

7.3.

Tooling Alignment.....................................................................................................................27

8.

Operator Safety...........................................................................................................................29

8.1.

Protective Screens ...................................................................................................................29

8.2.

Operator Training .....................................................................................................................29

9.

Routine Maintenance .................................................................................................................30

9.1.

Electrical...................................................................................................................................30

9.2.

Calibration ................................................................................................................................30

9.3.

Lubrication................................................................................................................................31

9.4.

Machine Storage ......................................................................................................................31

© Tinius Olsen Ltd L-Series Manual – Issue 1 Page 3 of 31

1. Introduction

This manual is to help the operator understand the operation of the L-Series Universal Testing

Machine. The L-Series range of machines are designed to operate with an external personal

computer (PC). Software is supplied to enable the machine to conduct tests in the chosen

materials. The software operates under the Microsoft Windows environment.

The L-Series range of testing machines with their versatile, easy-to-use software package are

ideal for determining the mechanical and physical properties of materials in Tension,

Compression, Flexure and Shear. Many other physical properties may also be investigated.

There are five machine capacities in the L-Series range. These are H1KL (1000N), H5KL

(5000N), H10KL (10KN), H25KL (25KN) and H50KL (50KN). All machines are similar in

functionality and are supplied with the same auxiliary interface. The L-Series range of testing

machines employs two load frame configurations. A single screw arrangement for low capacity

machines (H1KL and H5KL) and a twin screw arrangement for high capacity machines

(H10KL,H25KL and H50KL)

All L-Series machines are supplied with an external Power Transformer. The standard power

transformer is designed to operate from a 230V 50Hz public network supply. The output of the

power transformer is 48V AC and is used to power the testing machine. The power transformer

can be supplied for different public network supply voltage and frequency’s, (110V 60Hz)

however this must be specified when ordering

There may be aspects of material testing not covered in this operation manual in particular the

type of grips used and additional optional equipment, such as Extensometers, Printers, etc. See

the accessory instructions provided for these options.

© Tinius Olsen Ltd L-Series Manual – Issue 1 Page 4 of 31

2. Specifications

2.1. Load Frame

2.1.1. Capacity

H1KL Capacity 1kN (100kg)

H5KL Capacity 5kN (500kg)

H10KL Capacity 10kN (1000kg)

H25KL Capacity 25kN (2500kg)

H50KL Capacity 50kN (5000kg)

2.1.2. Style

Vertical Bench Mounting

2.1.3. Construction

(H1 &5 KL) Cast Aluminium crossheads with sheet steel panelling

(H10,25 & 50KL) Solid steel -crossheads with sheet steel panelling

Precision Ball Screws

Ballscrew cover/protection bellows

Pre-loaded Lead Screw Thrust Races

Precision DC Servo Motor

Programmable crosshead Limit Switches

Emergency Stop Switch

2.1.4. Travel & Stiffness

H1KL Maximum crosshead travel excluding grips is 445mm

Maximum Test Specimen Diameter 150mm

Frame Stiffness 2kN/mm at normal load points

H5KL Maximum crosshead travel excluding grips is 750mm

Maximum Test Specimen Diameter 200mm

Frame Stiffness 7kN/mm at normal load points

H10KL Maximum crosshead travel excluding grips is 1100mm

Distance between Columns 405mm

Frame Stiffness 100kN/mm at normal load points

H25KL Maximum crosshead travel excluding grips is 1100mm

Distance between Columns 405mm

Frame Stiffness 100kN/mm at normal load points

H50KL Maximum crosshead travel excluding grips is 1075mm

Distance between Columns 405mm

Frame Stiffness 100kN/mm at normal load points

2.2. Control Panel

Crosshead Up, Down, Stop and Test Keys

LED Direction and Alarm indicators

1 Auxiliary option slot for external equipment

High Speed RS232 Interface Port

16 Bit Microcontroller

Audible alarms

System Watch Dog Timer

2.3. Force Measurement

Load Cell Z Beam Construction

Conforms to EN10002, ASTM E4, DIN 51221, ISO 75001

Range 2% to 100% with Guaranteed Accuracy of 0.5% of applied force

Extended Range down to 1% with Guaranteed Accuracy of 1%

Rapid Change Load Cells Available:-

50kN, 25kN, 10kN, 5kN, 2.5kN, 1kN,

© Tinius Olsen Ltd L-Series Manual – Issue 1 Page 5 of 31

500N, 250N, 100N, 50N, 25N, 10N, 5N

Digital Encoding for automatic load cell recognition

Automatic Load Cell Protection system, Triggered at 9% above load cell capacity.

Force sampling rate typically 200 Times per Second

Load cell resolution 1 part 64,000 (Tension or Compression)

Digital Load Tear ±20% whilst maintaining full load cell capacity

2.4. Extension Measurement

Extension Measurement by Precision optical encoder

Single measurement range 0 to 1000mm

Resolution 0.0001mm accuracy 0.01mm/300mm

2.5. Speed Control

2 Default Test Speeds (5 mm/min & 100 mm/min)

1 Default Jog Speed (1 mm/min)

Dual Speed Function whilst under test

Speed Velocity Programmable in 0.001 mm/min steps

Speed accuracy ±0.05% of full speed

32 Bit Precision Motor Controller

Drive system:- DC 4 Quadrant Motor Drive

Automatic Over/Under Speed Alarms

Motor Drive Alarms on Under/Over Voltage, Current, and Temperature

2.5.1. Velocity Speed Range

H1KL 0.001 mm/min to 500 mm/min (up to 500N)

0.001.mm/min to 1000 mm/min (up to 1kN)

Return Speed. 0.001 mm/min to 1500 mm/min

Jog Speed. 0.001 mm/min to 1000 mm/min

H5KL 0.001 mm/min to 500 mm/min (up to 2.5kN)

0.001.mm/min to 1000 mm/min (up to 5kN)

Return Speed. 0.001 mm/min to 1500 mm/min

Jog Speed. 0.001 mm/min to 1000 mm/min

H10KL 0.001 mm/min to 500 mm/min (up to 5kN)

0.001.mm/min to 1000 mm/min (up to 10kN)

Return Speed. 0.001 mm/min to 1000 mm/min

Jog Speed. 0.001 mm/min to 1000 mm/min

H25KL 0.001 mm/min to 500 mm/min (up to 10kN)

0.001.mm/min to 1000 mm/min (up to 25kN)

Return Speed. 0.001 mm/min to 1000 mm/min

Jog Speed. 0.001 mm/min to 1000 mm/min

H50KL 0.001 mm/min to 250 mm/min (up to 25kN)

0.001.mm/min to 500 mm/min (up to 50kN)

Return Speed. 0.001 mm/min to 500 mm/min

Jog Speed. 0.001 mm/min to 500 mm/min

2.6. Hardware Options

Tinius Olsen range of Clip on Extensometers

Tinius Olsen range of Displacement Transducers

Tinius Olsen range of Grips and Attachments

Clear protective screen

Dust cover

2.7. Dimensions

H1KL Height 820 mm Width 360 mm Depth 360 mm Weight 25kg

H5KL Height 1140 mm Width 490 mm Depth 360 mm Weight 50kg

H10KL Height 1575 mm Width 650 mm Depth 450 mm Weight 115kg

H25KL Height 1575 mm Width 650 mm Depth 450 mm Weight 117kg

H50KL Height 1620 mm Width 720 mm Depth 500 mm Weight 180kg

© Tinius Olsen Ltd L-Series Manual – Issue 1 Page 6 of 31

2.8. Temperature

Operating 0°C to 38°C

Storage -10°C to 45°C

2.9. Humidity

10% to 90% Non-Condensing Wet Bulb Method

2.10. Power

External Power Transformer

H1KL Type TX****-H1KL

H5KL Type TX****-H5KL

Input Supply Voltage 230V +/- 10% 50/60Hz

Output Voltage 48v 50/60Hz @ 330VA

Internally Fused(5x20mm HRC 3.15A Type (T) for 230V Supply)

H10KL Type TX****-H10KL

H25KL Type TX****-H25KL

H50KL Type TX****-H50KL

Input Supply Voltage 230V +/- 10% 50/60Hz

Output Voltage 48v 50/60Hz @ 530VA

Internally Fused(5x20mm HRC 6.30A Type (T) for 230V Supply)

2.11. Machine Supply Requirements

H1KL 48v +/-10% 50/60Hz @ 330VA

H5KL 48v +/-10% 50/60Hz @ 330VA

H10KL 48v +/-10% 50/60Hz @ 530VA

H25KL 48v +/-10% 50/60Hz @ 530VA

H50KL 48v +/-10% 50/60Hz @ 530VA

2.12. CE Mark

EMC Directive 89/336/EEC, and conforms to the following Generic EMC specification for

Commercial and Light Industrial products.

Emissions EN 50081-1,

Immunity EN 50082-1

Low Voltage Safety Directive 73/23/EEC, and conforms to the following specification.

EN 61010-1 (Safety requirements for Measurement, Control and Laboratory use)

2.13. Manufacture

TINIUS OLSEN LTD,

6 Perrywood Business Park,

Honeycrock Lane,

Salfords, Redhill,

Surrey, RH1 5DZ, England.

Tel. 01737 765001 Fax 01737 764768

© Tinius Olsen Ltd L-Series Manual – Issue 1 Page 7 of 31

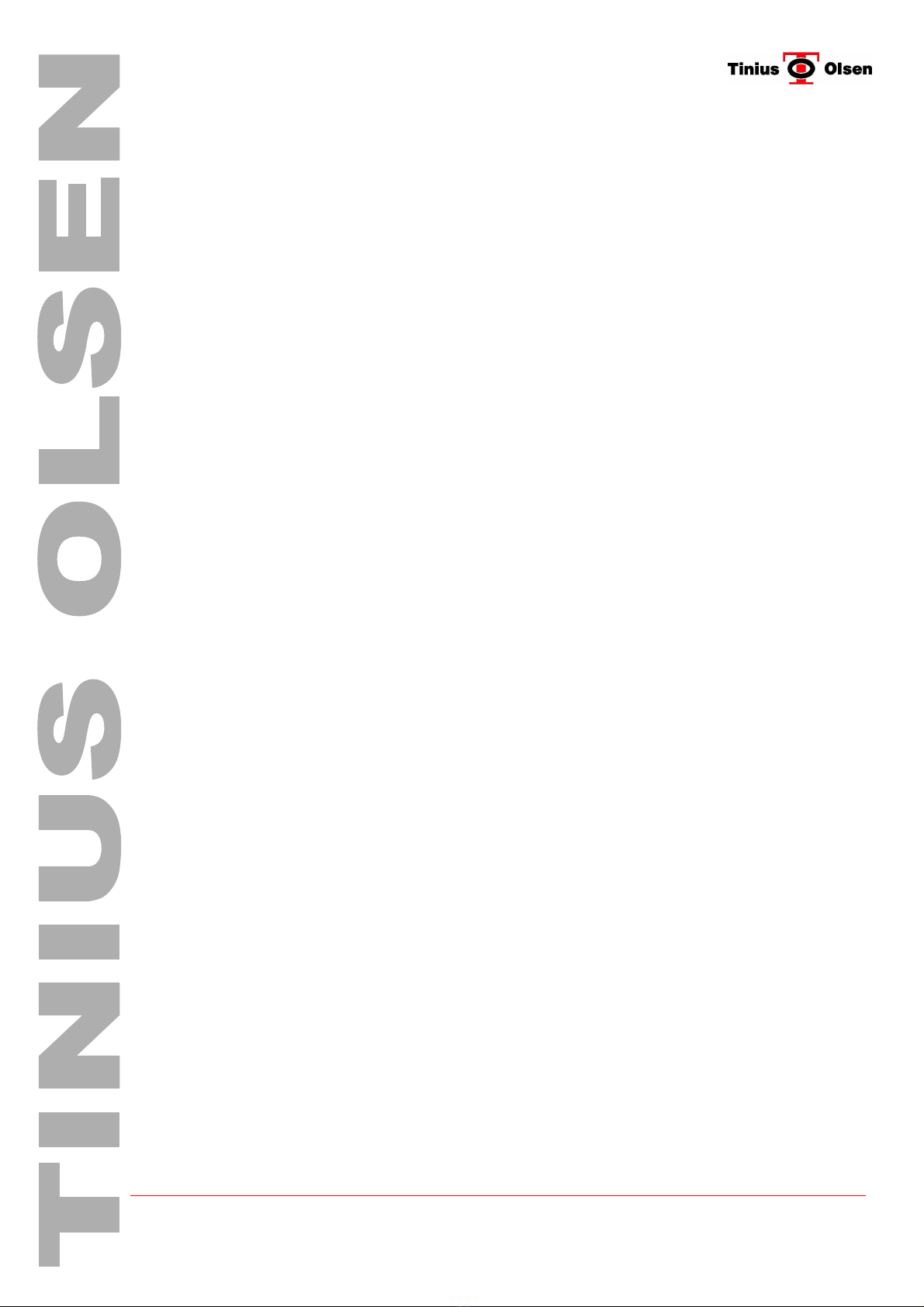

3. Unpacking the Material Testing Machine.

3.1. H1KL & H5KL

Save all packing materials. You may need to re-pack and transport your Materials Testing

Machine at a later date

The machine is delivered packed in a Tri-wall cardboard case. This case has pallet style blocks

at its base enabling the case to be moved with a fork lift truck.

The diagram below shows the machine as delivered.

3.1.1. Cut all straps.

Care must be taken as these straps are under tension.

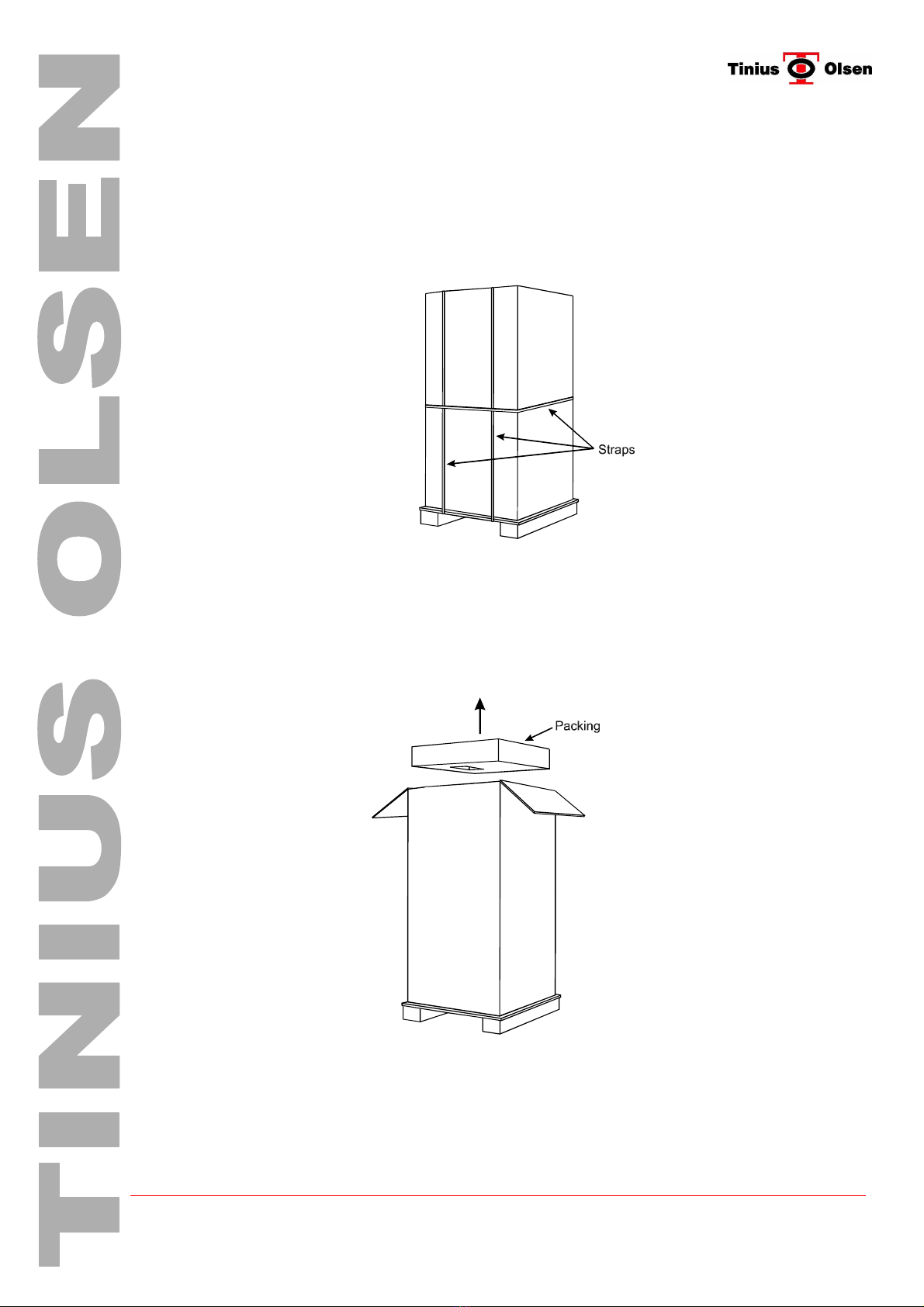

3.1.2. Cut tape at top of case to enable the access and remove internal top packing.

The diagram below indicates packing to be removed.

© Tinius Olsen Ltd L-Series Manual – Issue 1 Page 8 of 31

3.1.3. Remove case by lifting it upwards.

Care must be taken as internal cartons may have become dislodged.

The diagram below indicates the direction of case removal.

3.1.4. Remove internal cartons.

Care must be taken when removing these cartons as they may be heavier than first

expected.

The diagram below indicates the location of internal cartons.

3.1.5. Remove base packing from the machine by lifting the machine vertically.

Whilst carying out this operation it is an ideal opportunity to transfer the machine to the

prepared location.

Caution This material testing machine weighs 50Kg/110 pounds. It is

recommended two or more people carry out this operation.

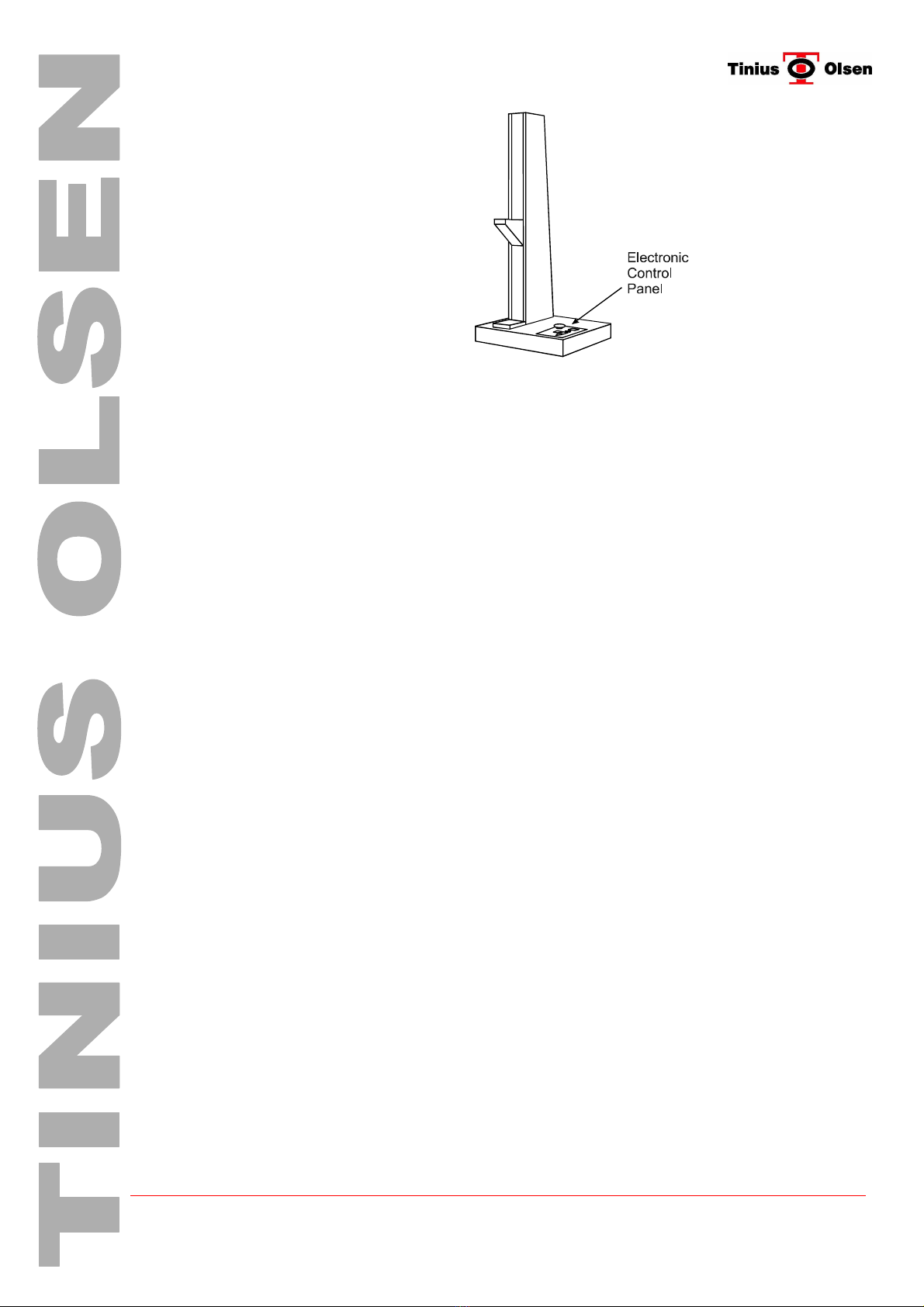

The diagram below shows the machine with its packing removed.

© Tinius Olsen Ltd L-Series Manual – Issue 1 Page 9 of 31

3.1.6. Remove the protective packing around the electronic control panel.

© Tinius Olsen Ltd L-Series Manual – Issue 1 Page 10 of 31

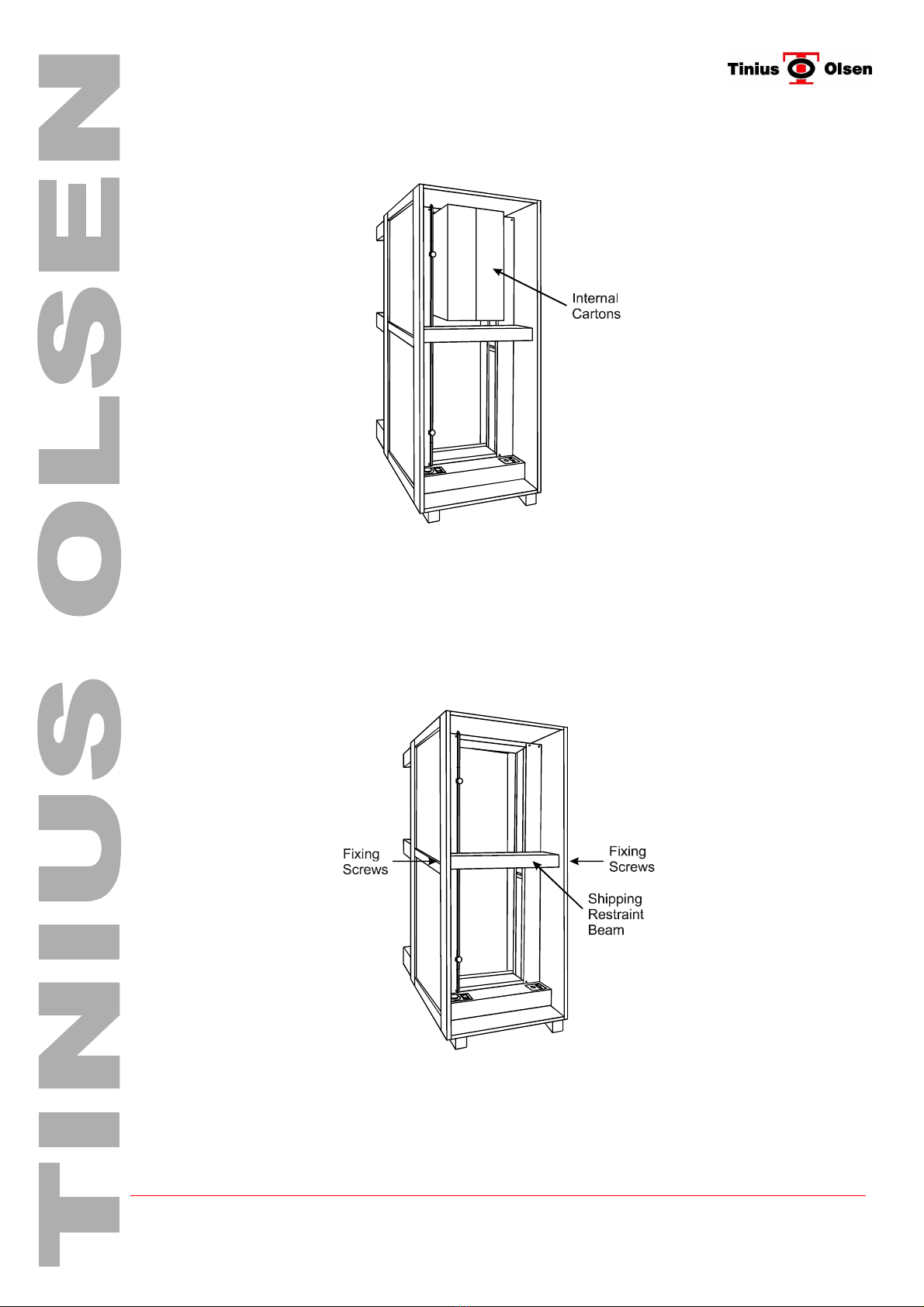

3.2. H10KL, H25KL & H50KL

Save all packing materials. You may need to re-pack and transport your Materials Testing

Machine at a later date

The machine is delivered packed in a wooded case. This case has pallet style blocks on its

back and bottom sides enabling a fork lift truck to be used when manoeuvring the case.

The packing case has been designed so that it can be shipped on its back. This is to enable

easier transportation for air shipment etc.

The diagram below shows the machine as delivered.

3.2.1. Place Upright

Before attempting to unpack the machine, the case must be stood on end, bottom end

indicated by pallet style blocks. Rotating the case to its upright position should not be

attempted by hand and will require a overhead hoist or fork lift truck.

The diagram below the machine in its up-right position.

3.2.2. Open Case

Remove all screws around the edge of the panel and remove side. Care must be taken

when detaching the side as internal cartons may have become dislodged.

© Tinius Olsen Ltd L-Series Manual – Issue 1 Page 11 of 31

Remove all internal cartons. Care must be taken when removing these cartons as they

may be heavier than first expected.

The diagram below indicates the position of additional cartons.

3.2.3. Remove Constraints

The machine is held in position by packing material at top and bottom and by a shipping

restraint beam mounted at the machines crosshead. Remove the shipping restraint

beam. This beam is held in position by screws each side of the case. Finally remove all

packing material.

The diagram below indicates the shipping restraint bead to be removed.

© Tinius Olsen Ltd L-Series Manual – Issue 1 Page 12 of 31

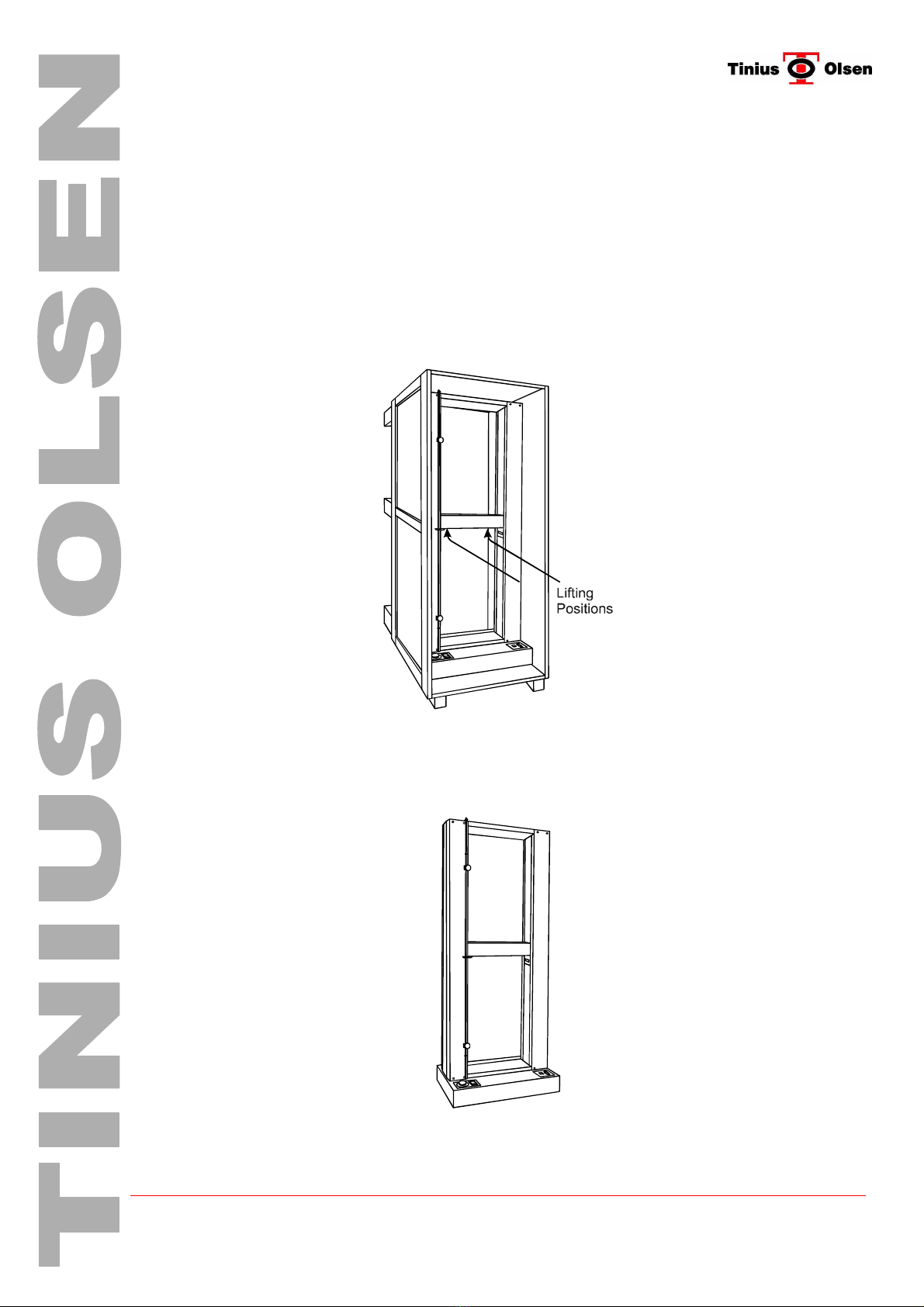

3.2.4. Remove Machine

The machine is now in a position to be removed from the case. Position the fork lift

truck, in front of the case.

Arrange the forks of the truck so that they can fit between the side covers of the

machine and below the crosshead. Slowly move the fork lift truck towards the machine

ensuring the forks do not hit the machine side covers. Raise the forks to lift the machine

so that its base is clear of the case, then remove the machine form the case.

Note To stop damage to the paint work on the machines crosshead place strips of

cardboard on the forks before lifting.

The diagram below indicates machine lifting positions.

If a fork lift truck is not available the machine may removed using a hoist and straps.

The lifting positions are the same however the top of the case will need to be removed.

The diagram below indicates the machine removed from its case.

© Tinius Olsen Ltd L-Series Manual – Issue 1 Page 13 of 31

4. Contents

4.1. Checking Contents

The machines are shipped completely assembled except for the optional accessories. The

basic machines are supplied with the following items, please ensure that these are included for

the installation.

4.1.1. Load Cell

Z-Beam Load Cell at or below the maximum capacity of the load frame.

Single screw machines will have a mounting bolt, hex key and washer for the load

cell(s) (H1KL and H5KL) and twin screw models (H10KL, H25KL and H50KL) will have

mounting stud(s) with different threads depending on the capacity of the load cell(s)

supplied.

4.1.2. Nose Piece

25 kN capacity 5/8" diameter nose piece attachments and 5/16" diameter Grip

Pins.,(machines above 25 kN will also be provided with a set of 50 kN capacity with 3/4"

diameter nose piece attachments and 3/8" diameter Grip Pins )

4.1.3. Breaker Bar

1/4" diameter Breaker Bar (5/16" bar with 10 kN and larger load cells

4.1.4. Power Transformer with twist-on connector

4.1.5. Operating instruction manual and load cell calibration certificate.

4.1.6. D type 9 way socket RS232 Serial Port Lead for external computer control.

4.1.7. Hex Key (H1KL and H5KL only)

4.1.8. Load Cell Bolt Sleeve (H5KL only)

4.1.9. Mounting Studs ( H10KL, H25KL and H50KL only )

© Tinius Olsen Ltd L-Series Manual – Issue 1 Page 14 of 31

The following diagrams are to help to identify each item

Load Cell

Nose Piece Attachment Grip Pins

Load Cell Bolt Sleeve

Breaker Bar Hex Key Bolt & Washer

Hex Key

Mounting Studs Power Transformer

RS232 Lead Operating Manual Calibration Certificate

Additional parts may be supplied, which are not listed above and will depend on the system

configuration.

© Tinius Olsen Ltd L-Series Manual – Issue 1 Page 15 of 31

5. Machine Installation

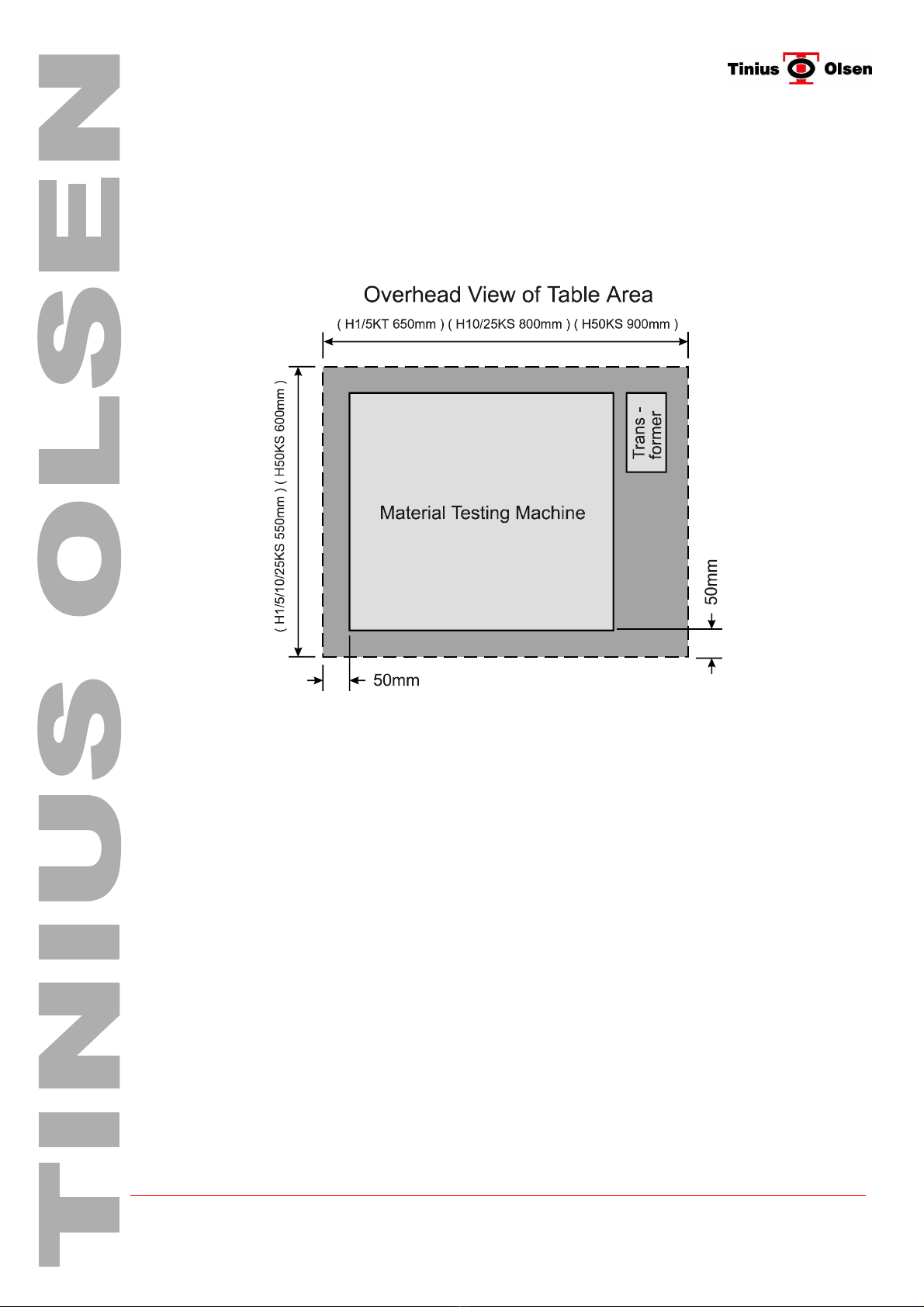

5.1. Location

Place the machine on a sturdy bench ensuring that is capable of taking the following loads

(H1/5KL > 50kg), (H10/25KL > 117kg),(H50KL > 180kg). It is also important to make sure the

bench is level especially when using lower capacity load cells.

The diagram below outlines the required area for each machine.

5.2. Mains Supply

Place the external power transformer within reach of the of the machine. (shown in the above

diagram) The transformer voltage is indicated on the power transformer label and will require a

supply connector to be fitted. The supply cable must be connected as follows :-

Brown=Live , Blue=Neutral , Yellow/Green =Earth

NOTE External Power Transformer MUST BE EARTHED. Under no circumstance must the

machine be operated without an earth connection

Positioning of the machine and external power transformer should be arranged so that the

mains supply plug and socket are easily accessible. Under NO CIRCUMSTANCE must the

main supply plug and socket be OBSTRUCTED by any equipment. This is to allow

disconnection of the external power transformer in the event of an emergency.

© Tinius Olsen Ltd L-Series Manual – Issue 1 Page 16 of 31

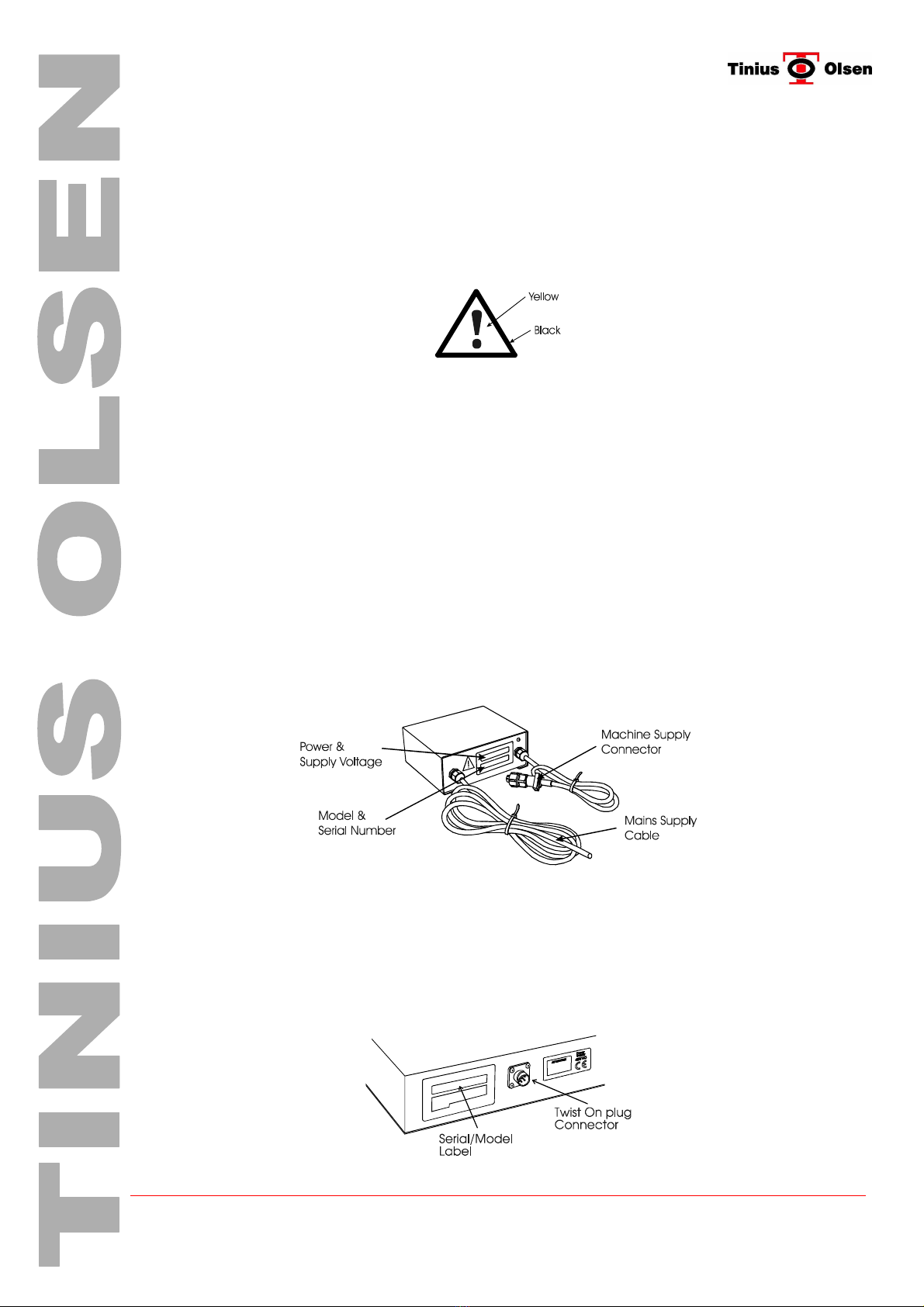

5.3. Warning Symbols

There are two warning symbols displayed on the L-Series machine. The purpose of these

symbols is to indicate a potential hazard and requires reference to the operating instructions.

5.3.1. Refer to Manual

The Refer to Manual Symbol is shown below

The warning symbol is located on the front left hand edge of the protective screen if

fitted. It indicates a hazard due to moving mechanical parts and the operator must refer

to the operating instructions when attempting to operate the machine. Additional

hazards may be present when carrying out sample testing and for this reason the

operator must ensure the protective screen be closed throughout the test

5.3.2. Power Transformer Hazardous Warning Symbol

The power transformer hazardous warning symbol is located on the front of the unit next

to the serial number/voltage/power label. It indicates that the unit is operating at a

HAZARDOUS VOLTAGE and the operator must refer to the operating instructions

regarding ‘Installation Environment’, ‘Operating Voltage’, ‘Connection’ and

‘Maintenance’.

Power and Voltage Ratings The diagram below shows where to locate the Power and

Voltage rating of the equipment. (H1/5KL 230V =+/- 10% 50/60Hz 330VA is) and

(H10/25KL and H50KL 230V =+/- 10% 50/60Hz 530VA) The mains supply cable and

machine supply connector are also indicated.

5.4. Connection to Supply

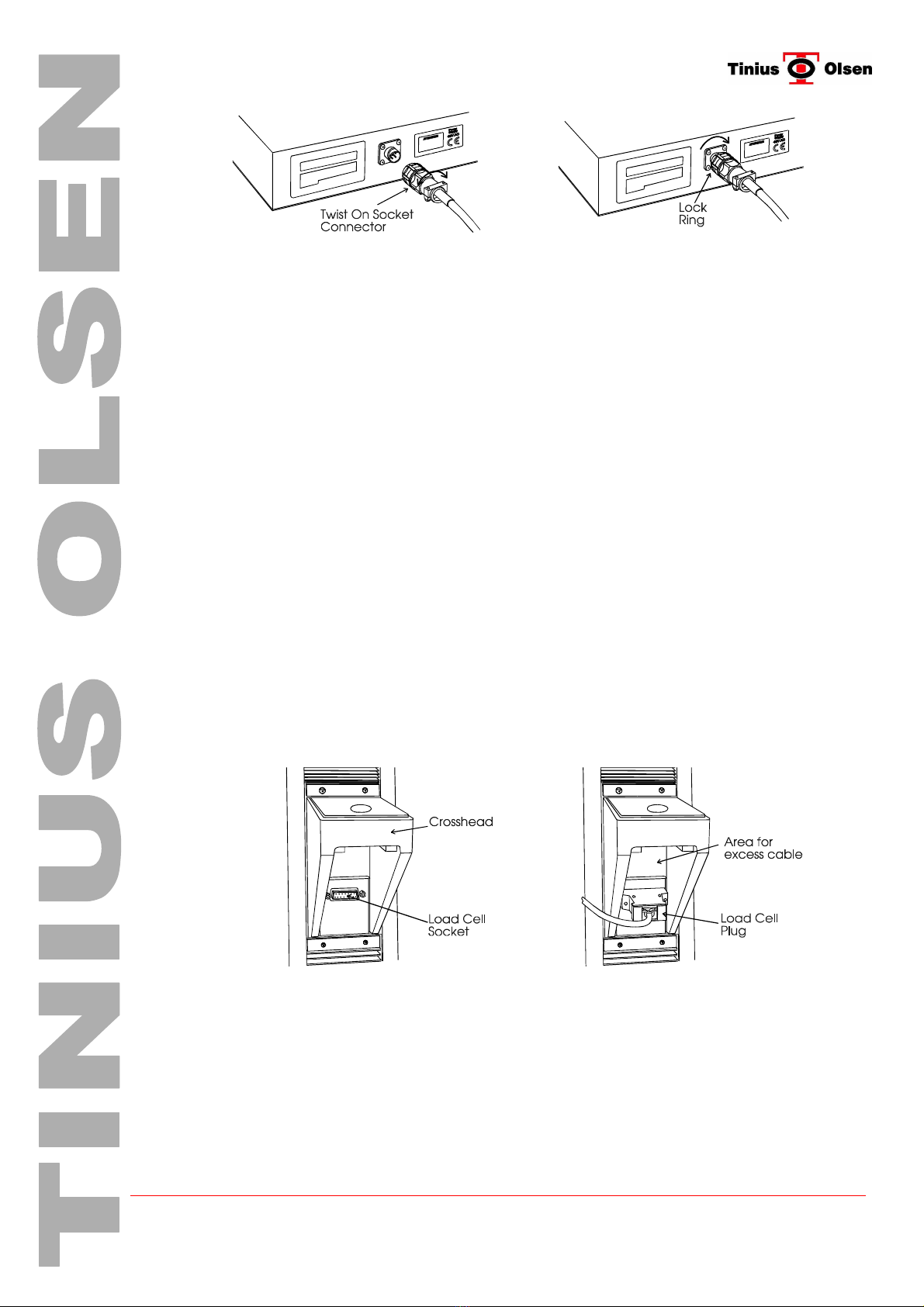

The connection of the power transformer to the machine is via a 4 pin twist on connector. The

following diagrams indicate how to connect the power transformer :-

Although these diagrams relate to the H5KL the method still applies to the 1/10/25/50KL)

© Tinius Olsen Ltd L-Series Manual – Issue 1 Page 17 of 31

Rotate socket to align with plug then push to

engage lock ring Rotate lock ring clockwise to jack socket into

final position.

5.5. Fitting Load Cell

The machine will be provided with a load cell equal to or less than the maximum capacity of the

machine.

These interchangeable Load Cells are available in capacities from 50kN (11,250 lbf, 5100 kgf)

down to 5N (1.1 lbf, 0.5 kgf).

5.5.1. Single Screw Machines

On H1KL single screw machines, the load cell is mounted on the underside of the fixed

crosshead at the top of the loading column.

The H5KL requires the load cell to be mounted on the underside of the moving

crosshead, both machines use a hex bolt and washer for fixing. Lower capacity load

cells require a spacer sleeve to be inserted in the crosshead enabling smaller load cell

mounting bolts to be used (H5KL only). Use the hex key provided to tighten the cell in

place. Before mounting any load cells to the crosshead, always check to insure that the

contact surfaces are clean.

Connect the load cell by plugging the 15 pin connector into the load cell socket just

under the crosshead. Care must be taken when mounting the cell as it is handed. The

correct orientation is with the slot to the top and cable at the rear for single screw

machines

Note Failing to do so will effect the overall performance of the cell.

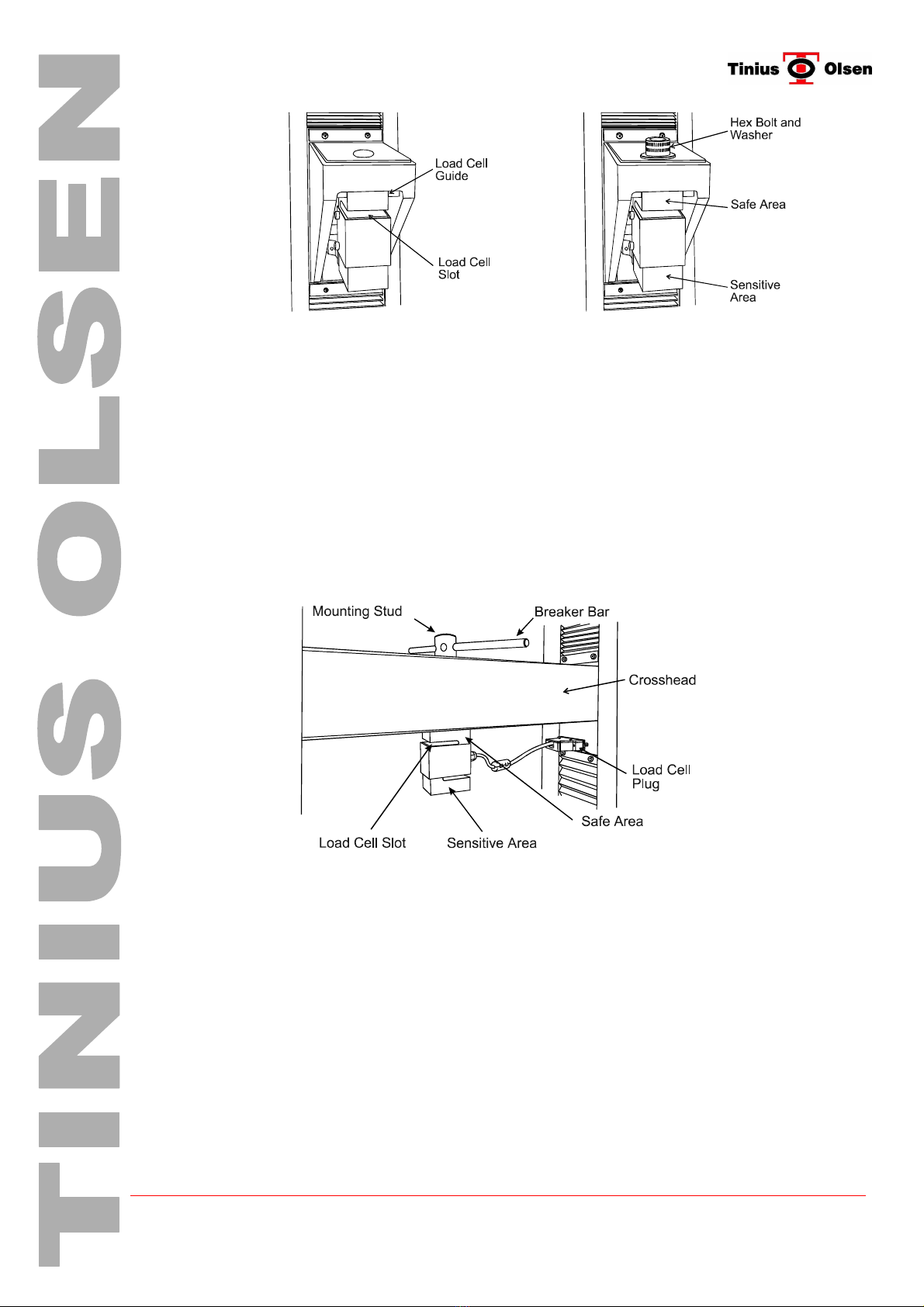

The following diagrams indicate how to mount a 5KN load cell to the H5KL Machine.

Ensure both areas are free of packing

and are clean Align plug with socket and push together

Store excess cable in area shown

Hold load cell in safe area and position it parallel to the crosshead then fully tighten with

Hex Key. When installing low capacity load cells (less than 5kN) it is imperative the load

be held in the safe area when locking the load cell in position (shown in the diagram

below).

Failure to carry out the above procedure may lead to load cell damage beyond repair.

© Tinius Olsen Ltd L-Series Manual – Issue 1 Page 18 of 31

Align load cell to guides and mounting

hole with slot at top and facing out Fit hex bolt and washer , hold load cell in

safe area when tightening with Hex key

Note Load Cells other than 5kN rely on manual alignment with crosshead.

5.5.2. Twin Screw Machines

On the larger capacity twin screw machines, the load cells are mounted under the

moving crosshead with a mounting stud, and a breaker bar provided for tightening the

load cell in place. Again care must be taken when mounting the load cell as it is handed.

The correct orientation for twin screw machines is with the slot to the left and cable to

the right.

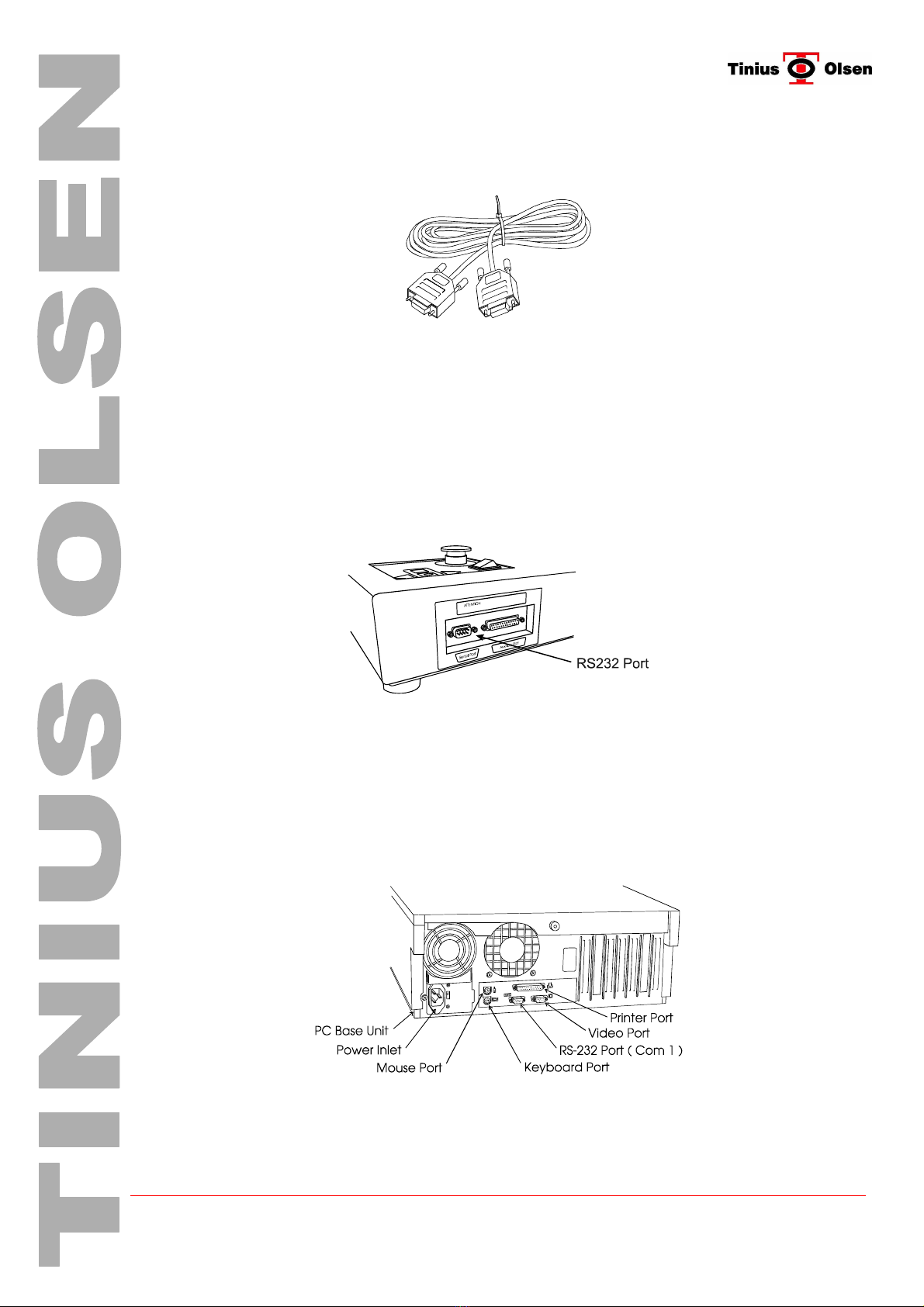

The diagram below indicates how to mount the load cell to a twin screw machine

(H10KL / H25KL / H50KL)

Align the load cell with the with mounting hole beneath the crosshead. Place the

mounting stud through crosshead and screw into load cell. Hold load cell in safe area

and position it parallel to the crosshead then fully tighten with breaker bar. Connect load

cell by plugging the 15 pin load cell plug connector into load cell socket located beneath

and to the right of the moving crosshead.

5.6. Connection to PC

Before attempting to connect the RS-232 Serial cable, ensure both Testing Machine and

PC computer are SWITCHED OFF

This connection allows the computer to communicate with the testing machine’s internal

electronics.

© Tinius Olsen Ltd L-Series Manual – Issue 1 Page 19 of 31

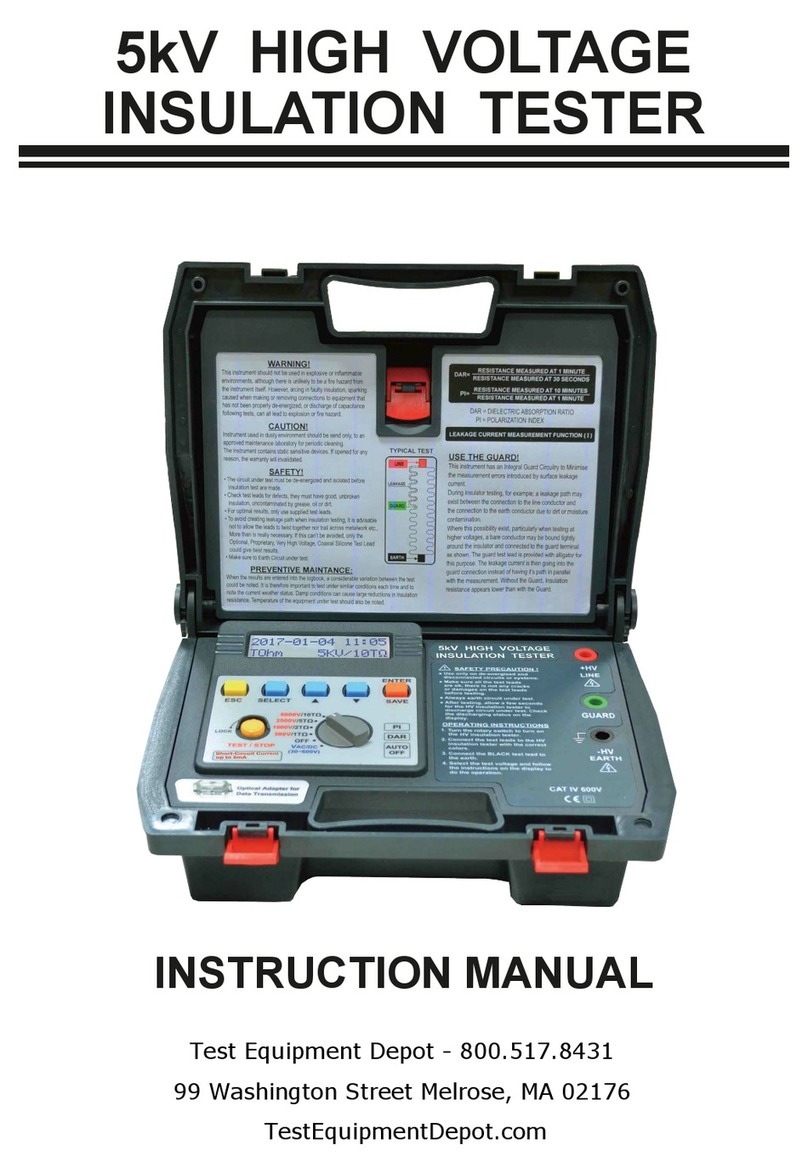

5.6.1. Lead

Connection from your “ PC “ to the Testing Machine is via a D type 9 way RS-232

socket to socket cable, as indicated below.

Note This cable is not a one to one cable, (some of the signals are reversed). For this

reason it should only be used for RS-232 machine to computer connection.

5.6.2. Machine Port

The RS-232 Port is located on the front, right hand side of the machine. Simply align

the 9 way D type cable socket connectors to its mating plug on the machine, taking care

not to bend any pins, whilst held in this position tighten the two socket jack screws until

the connector is fully engaged.

The diagram below indicates position of machine RS-232 Port.

The other end of the RS-232 serial cable connects to the PC Computer RS-232 Port

(Com 1) located at the rear of the PC Base Unit. The method is the same as used on

the machine by aligning the 9 way D-type connectors then tighten the two jack screws.

5.6.3. PC Port

The diagram below shows a rear view of a typical PC Base Unit. Care must be taken to

locate the RS-232 Port (Com 1) as many of the connectors look very similar.

© Tinius Olsen Ltd L-Series Manual – Issue 1 Page 20 of 31

6. Power ON Checks

Before Powering the machine on, check the following

6.1. Emergency Stop Switch

Before the machine can be turned ON it is necessary to check the position of the emergency

stop switch. The function of this switch is to STOP the machine as quickly as possible in the

case of an emergency. e.g.:- where the machine behaves in an unexpected manner, or when

there is a risk of injury to the operator. The emergency Stop switch should NOT be used as the

Machine OFF/ON switch.

6.1.1. Location

The emergency stop switch for the H1KL and H5KL is located on the front, top right

hand side of the machines base. Twin screw machines (H10/25 and 50KL) have the

emergency stop switch located on the top left hand side of the machine’s base.

The diagrams below indicate location of the emergency stop button

H1KL / H5KL Emergency and Power Switch

located on right hand side of machine H10KL / H25KL / H50KL Emergency and

Power Switch located on left hand side of

machine

6.1.2. Operation

To check if the emergency stop switch is in its normal position rotate the top part of the

switch clockwise (direction shown by arrows on top of switch). If the switch had been

previously activated, on rotation the top will spring upwards. If no upwards movement is

felt the switch is already in its normal position.

6.2. Power ON/OFF Switch.

6.2.1. Location

Power ON/OFF

Switch

Power ON/OFF

Switch

H1KL / H5KL Power Switch located on right

hand side of machine

H10KL / H25KL / H50KL Power Switch

located on left hand side of machine

Turn the machine ON with the power switch. The control panel STOP Switch LED will now

illuminate. If the direction/stop LEDS are blinking and the alarm beeping the EMERGENCY

STOP Switch is probably activated. Reset the emergency stop switch as described in the above

section, turn the machine OFF, allowing a few seconds before turning the back ON again.

This manual suits for next models

5

Table of contents

Popular Test Equipment manuals by other brands

Tektronix

Tektronix 507 instruction manual

Circuitlink

Circuitlink BrakeCheck 2 Series user manual

Besantek

Besantek BST-IT706 instruction manual

PCB Piezotronics

PCB Piezotronics 394A11 Installation and operating manual

Futura Apsol

Futura Apsol HAAP96 user manual

inTest

inTest THERMOSTREAM ATS-545 Interface & Applications manual