Tinker & Rasor M1/AC Instruction sheet

Web: www.tinker-rasor.com E-mail: Info@tinker-rasor.com

–1 –

CORROSION MITIGATION INSTRUMENTATION

P. O. BOX 1667 SAN BERNARDINO,CA 92402 TEL:(909) 890-0700 FAX:(909) 890-0736

PRODUCT INSTRUCTIONS

MODEL M/1

WET SPONGE HOLIDAY DETECTOR

DESCRIPTION

The Model M/1 Holiday Detector is a highly sensitive device designed to locate holidays (pin

holes, voids, etc.) in thin film protective coating of relatively high electrical resistance when such

films are applied to the surface of material of low electrical resistance. In these applications, such

as painted metal surfaces, the Model M/1 Holiday Detector will locate these points very

accurately with an audible signal. This method of inspection of thin film is a non-destructive test

and will not injure the protective coating.

EQUIPMENT

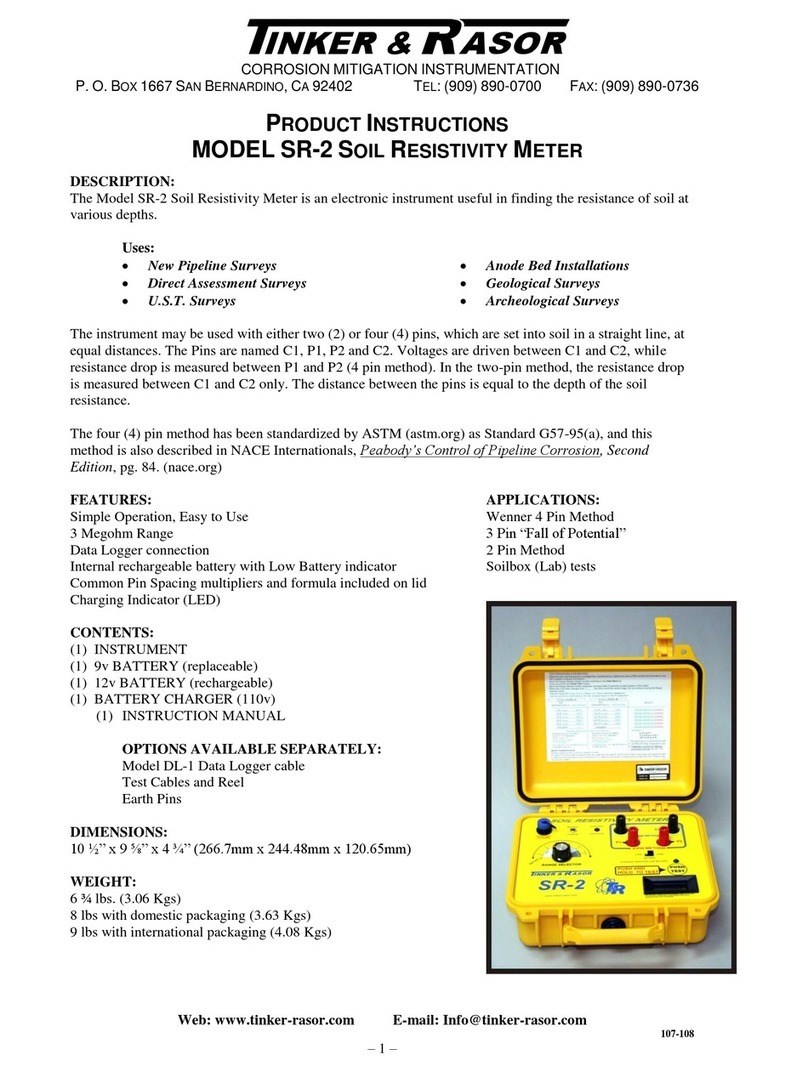

The Model M/1 Holiday Detector consists of a portable battery powered electronic instrument, a

non-conductive handle w/sponge clamps, open cell sponge (cellulose) and ground wire. The

instrument is housed in a sturdy plastic case with provision for attachment to the operators belt.

The detector is a “non-destructive wet sponge” type holiday detector. The basic electronic design

of the Model M/1 Holiday Detector is that of a very sensitive circuit which is energized by six “AA”

batteries. When current of 500 or 700 (+/- 10/%) micro-amperes flows in the circuit, an audible

signal is actuated.

The test lead wire used in the wand handle and ground wire is capable of handling a minimum of

100 milliamps at 100 volts. If replacement or additional wire is needed, make sure it meets these

requirements. Length of ground wire does not adversely effect the detectors operation.

The exploring electrode is open-cell sponge material and is conductive when saturated with a

wetting solution. The sponge electrode is attached to the non-conductive wand handle by

securing it between the metal clamps.

The wetting solution should consist of potable tap water and a wetting agent. The ratio of one (1)

ounce agent to one (1) gallon tap water is recommended. Tinker & Rasor WATER-WETTER©is

a non-sudsing wetting agent, available in 8 oz. bottles, factory direct or through stocking

distributors.

RECOMMENDED TESTING PROCEDURES

PRE-ELECTRICAL TEST PROCEDURES

The protective coatings should be dry and free of all contamination prior to electrical holiday

testing. Proper curing and drying time of the protective coating must be established prior to

conducting electrical holiday testing.

Note: Solvents retained in the protective coating film can cause erroneous indications (false

holidays) during electrical testing.

Web: www.tinker-rasor.com E-mail: Info@tinker-rasor.com

–1 –

CORROSION MITIGATION INSTRUMENTATION

P. O. BOX 1667 SAN BERNARDINO,CA 92402 TEL:(909) 890-0700 FAX:(909) 890-0736

PRODUCT INSTRUCTIONS

The dry film thickness should not exceed 20 mils when electrical holiday testing is done with the

low voltage Model M/1 Holiday Detector. Film thickness should be determined with a non-

destructive dry film thickness gauge to make sure limits are not exceeded.

Special Note: Ordinary tap water will generally suffice to dampen the sponge electrode,

provided the protective coating thickness does not exceed 10 mils. The factory

recommended practice is to use a wetting agent at all times, regardless of coating

thickness to 20 mils.

Check battery voltage. This can be done by shorting the terminals of the holiday detector. If a

steady, level audible signal is heard, the battery voltage is OK. If the audible signal starts to

attenuate while testing, REPLACE battery. Note: A battery output voltage drop of over 10% also

indicates weak battery.

HOLIDAY DETECTOR ASSEMBLY

Assemble the Holiday Detector by connecting the wire leading from the handle to one terminal of

the detector and the plain end of the ground wire to the other detector terminal. Connect the

saturated (see below) electrode by means of the metal clamp on the end of wand handle.

ELECTRICAL TESTING PROCEDURES

The sponge electrode should contain sufficient amount of wetting solution to assure moisture

penetration from the sponge electrode into any defect that may be present in the protective

coating. Excess wetting solution should be squeezed out of the sponge electrode.

Attach ground wire directly to the bare structure (substrate) under test. On coated steel

structures the ground wire must be directly connected to the bare metal.

On coated concrete structures the ground wire should be connected directly to the reinforcing

steel embedded in the concrete. If rebar is not present, a ground connection to the concrete can

be made by placing the bare end of the ground wire against the bare concrete surface and

anchor it down with a burlap bag filled with damp sand.

The ground wire can be checked quickly for proper connection by contacting the wetted sponge

electrode to the bare structure and observing an audible signal, indicating correct electrical

continuity of the holiday detector circuit.

The rate of inspection speed of the sponge electrode over the protective coated surface should

not exceed sixty (60) linear feet per minute. Using a double stroke of the sponge electrode over

each area assures better inspection coverage with less likelihood of any missed areas.

CALIBRATION

Factory calibration on Model M/1 Holiday Detectors are set at 700 micro-amperes (+/- 10) of

current flow to complete the circuit for the audible signal to indicate a coating holiday on metal

substrates. For coatings on concrete substrates, the Model M/1 must be adjusted for current flow

of 500 micro-amperes (+/- 10%).

Web: www.tinker-rasor.com E-mail: Info@tinker-rasor.com

–1 –

CORROSION MITIGATION INSTRUMENTATION

P. O. BOX 1667 SAN BERNARDINO,CA 92402 TEL:(909) 890-0700 FAX:(909) 890-0736

PRODUCT INSTRUCTIONS

ADJUSTMENT OF SIGNAL SYSTEM

Model M/1 Holiday Detectors with mechanical relays, the sensitivity may be changed by

adjustment of the armature contacts. The signal sensitivity is determined by the setting of the

electronic relay. Turning the adjusting screw of the potentiometer clockwise REDUCES the

sensitivity and turning counterclockwise INCREASES the sensitivity. Factory setting of the

sensitivity is made by having the relay just close when 80,000 ohms is across the external

terminals which is the proper setting for use on coated metal substrates. For concrete substrates

the sensitivity would be adjusted with a 90,000 ohm resistor.

Model M/1 Holiday Detectors, Serial Number 10181 and higher FACTORY calibration can be

verified by simply depressing push buttons on the front of the instrument.

Depress BLACK button (80K); Detector should signal and LED will light if detector is in

calibration.

Depress RED button (90K): Detector should NOT signal and LED will NOT light if detector is in

calibration.

If the detector signals when RED button (90K) is depressed, the unit is not in calibration and

should be FACTORY calibrated prior to use.

To check for proper calibration of the detector for use on concrete substrates simply verify unit is

properly FACTORY calibrated at 80,000 ohms and then remove the small jumper wire inside the

red cover side of the detector.

904-248

Web: www.tinker-rasor.com E-mail: Info@tinker-rasor.com

–1 –

CORROSION MITIGATION INSTRUMENTATION

P. O. BOX 1667 SAN BERNARDINO,CA 92402 TEL:(909) 890-0700 FAX:(909) 890-0736

PRODUCT INSTRUCTIONS

MODEL M/1 INFORMATION BULLETIN

The electrical holiday detector commonly used for inspection for brushed, sprayed or

dip-applied protective coatings is considered a non-destructive device with a source of

less than 75 volts applied to the coatings using an electrode consisting of a cellulose

sponge dampened with an electrically conductive liquid such as tap water. The

electrode pushes a film of liquid over the surface and when a holiday is encountered,

current will flow through the liquid to the metal. An audible indicator is used to signal

coating defects.

Recommended points to be included in a specification for the electrical inspection of thin

film coating with the so-called “non-destructive” type holiday detector, Tinker & Rasor

Model M/1 are:

1. The voltage between the electrode (sponge) and the metal surface upon which the

coatings lies should not exceed 75 volts measured between the electrode sponge

and the coated metal when the detector is in it’s normal operating position.

2. An electrical connection must be made from the detector to some bare spot on the

metal structure to be coated.

3. The holiday detector should be equipped with an audible signal which is

responsive to high current flows between electrode and the metal surface.

4. The coated surface should be dry prior to making the inspection and if the surface

is in an environment where electrolytes might form on the surface such as salt

spray, the coated surface should be washed with fresh water and allowed to dry.

The consensus of the industry is that ordinary tap water will suffice to wet the sponge

electrode when this type of electrical holiday inspection is conducted on protective

coatings up to 10 mils in thickness. On film thickness between 10 and 20 mils a non-

sudsing type wetting agent added to the water is recommended. This allows for faster

penetration of the liquid into pinhole defects. A wetting agent such as TINKER &

RASOR’S “WATER-WETTER” is an excellent product for this purpose. Available in 8

ounce size bottle.

It is further agreed that this type holiday detector is not satisfactory for inspection of

protective coatings over 20 mils in thickness and completely ineffective on prefabricated

coatings such as PVC, etc.

An electrical holiday detector should be used at the time the coating is applied. The

holiday detector should never be used to evaluate the quality or usefulness of a coating

and should be used only as an aid in the application of the coating. When the detector is

used at the time of application, holidays can be readily located and repaired. The

detector not only locates holidays, but it enables the applicator to develop techniques of

better application.

Other manuals for M1/AC

1

This manual suits for next models

1

Table of contents

Other Tinker & Rasor Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Precision Digital Corporation

Precision Digital Corporation Survivor PD662 instruction manual

Keysight

Keysight E4980AL user guide

Sony

Sony MAV-555A installation manual

Hach

Hach POCKET COLORIMETER II user manual

Siemens

Siemens SITRANS FC310 Compact operating instructions

ABB

ABB Navigator 600 Series user guide