TIP TIG ALLINONE User manual

.

TIP TIG - ALLINONE

Operating Manual

Version 1.5 Revision 0

TIP TIG – ALL IN ONE

OPERATING MANUAL

TIP TIG - ALLINONE, OPERATING MANUAL

Page 2 of 57

INTRODUCTION

Thank you for the trust you have placed in our company and congratulations on buying this high-

quality TIP TIG product. These instructions will help you familiarize yourself with the product. Reading

the instructions carefully will enable you to learn about the many different features it has to offer. This

will allow you to make full use of its advantages.

Please also note the safety rules to ensure greater safety when using the product. Careful handling

of the product will repay you with years of safe and reliable operation. These are essential

prerequisites for excellent results.

TIP TIG - ALLINONE, OPERATING MANUAL

Page 3 of 57

CONTENTS

1. GENERAL INSTRUCTIONS 5

2. INTENDED USE 6

2.1 Declaration of conformity 6

2.2 Welding in environments with increased electrical hazards 6

2.3 Calibration/Validation 6

3. SAFETY RULES 7

3.1 Explanation of safety symbols 7

3.2 General safety instructions 7

4. GENERAL 10

4.1 Device concept 10

4.2 Power sources 10

4.3 Crane transport 11

5. CONTROLS, CONNECTIONS AND MECHANICAL COMPONENTS 12

5.1 System overview 12

5.2 Front connection 15

5.3 Rear connection 16

5.4 Main power switch with fuses 17

5.5 Hotwire amperage adjustment 17

5.6 Control panel – D24B2M1.6 18

5.7 Control panel – Version 2.0 20

6. INSTALLATION AND COMMISSIONING 24

6.1 Before installation and commissioning 24

6.2 Connecting the interconnection hose package, welding torches and workpiece

lead 25

6.3 Inserting/replacing feed rollers 29

6.4 Inserting the wires pool 29

6.5 Inching the wire electrode 30

6.6 Spool brake setting 32

7. START-UP 33

8. TROUBLESHOOTING, MAINTENANCE AND DISPOSAL 34

8.1 Troubleshooting 34

8.2 Care, maintenance and disposal 42

9. TECHNICAL DATA 43

10. APPENDIX 45

10.1 Spare part list 45

TIP TIG - ALLINONE, OPERATING MANUAL

Page 4 of 57

10.2 Wire Feed Speed 51

10.3 Wiring diagram 55

TIP TIG - ALLINONE, OPERATING MANUAL

Page 5 of 57

1. GENERAL INSTRUCTIONS

In the event of queries on installation, commissioning, operation or special conditions at the

installation site, or on usage, please contact your sales partner or our customer service

A list of authorized sales partners can be found at www.tiptig.com.

Liability relating to the operation of this equipment is restricted solely to the function of the equipment.

No other form of liability, regardless of type, shall be accepted. This exclusion of liability shall be

deemed accepted by the user on commissioning the equipment.

The manufacturer is unable to monitor whether or not these instructions or the conditions and

methods are observed during installation, operation, usage and maintenance of the equipment.

An incorrectly performed installation can result in material damage and injure persons as a result.

For this reason, we do not accept any responsibility or liability for losses, damages or costs arising

from incorrect installation, improper operation or incorrect usage and maintenance or any actions

connected to this in any way.

© TIP TIG Automation GmbH, Baumayrweg 5, 4631 Krenglbach, Austria

The copyright to this document remains the property of the manufacturer. Reprinting, including

extracts, only permitted with written approval.

The content of this document has been prepared and reviewed with all reasonable care. The

information provided is subject to change, errors excepted.

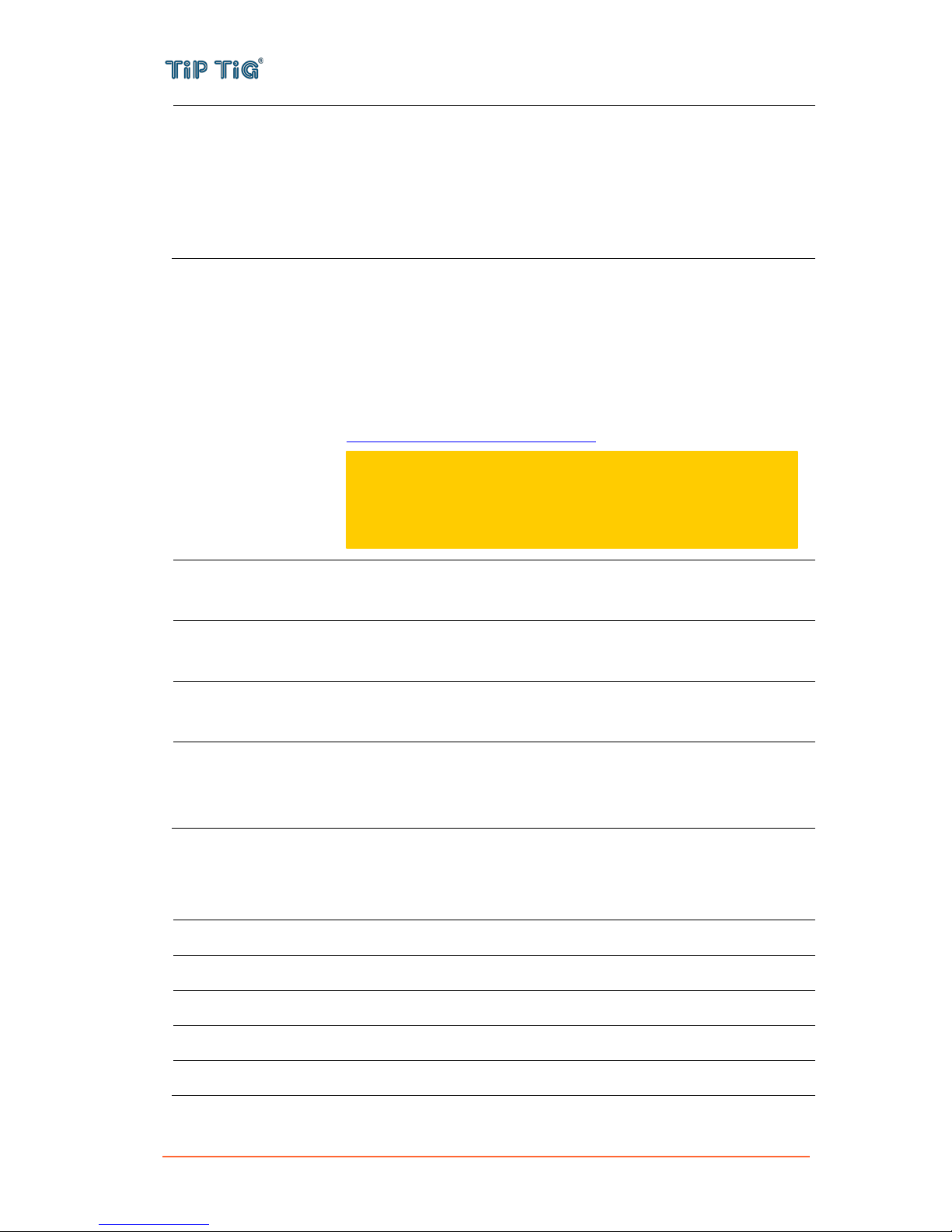

CAUTION

Read the operating instructions!

The operating instructions provide an introduction to the safe use of the products.

• Read the operating instructions for all system components!

• Observe accident prevention regulations!

• Observe all local regulations!

• Confirm with a signature where appropriate.

TIP TIG - ALLINONE, OPERATING MANUAL

Page 6 of 57

2. INTENDED USE

2.1 Declaration of conformity

The labelled machine complies with the following EC directives and standards in

terms of its design and construction:

• 2014/35/EU Low Voltage Directive (LVD)

• 2014/30/EU Electromagnetic Compatibility Directive (EMC)

• 2011/65/EU Restriction of Hazardous Substance (RoHS)

Standards

• IEC 60974-1: 2012 Arc welding equipment - Part 1: Welding power sources

• IEC 60974-3: 2013 Arc welding equipment - Part 3: Arc striking stabilizing

devices

• IEC 60974-10: 2014 Arc welding equipment – Part 10: Electromagnetic

compatibiliy requirements

August 1, 2018

______________________________ ______________________________

Jürgen Plasch, CEO Date of Declaration

In case of unauthorised changes, improper repairs, and/or prohibited modifications which have not

been explicitly authorised by TIP TIG Automation GmbH, this declaration shall be voided.

2.2 Welding in environments with increased electrical hazards

In compliance with IEC / DIN EN 60974, VDE 0544 the machines can be used in

environments with an increased electrical hazard.

2.3 Calibration/Validation

We hereby confirm that this machine has been tested using calibrated measuring equipment, as

stipulated in IEC/EN 60974, ISO/EN 17662, EN 50504, and complies with the admissible tolerances.

Recommended calibration interval: 12 months

2

Konformitätserklärung

TIP TIG Automation GmbH

Erklärt, dass die Schweißautomatisation:

TIP TIG - Automation

den folgenden Richtlinien entspricht:

2014/35/EU, 2014/30/EU

und in Übereinstimmung mit den folgenden

Normen hergestellt wurde:

EN 60974-1:2012, EN 60974-3:2014,

EN 60974-10:2014

14.02.2018

Jürgen Plasch

TIP TIG Automation GmbH., Baumayrweg 5, 4631 Krenglbach, Austria

WARNING!

Hazards due to improper usage!

The machine has been constructed to the state of the art and any regulations and

standards applicable for use in industry and trade. It may only be used for the welding

procedures indicated at the rating plate. Hazards may arise for persons, animals and

material objects if the equipment is not used correctly. No liability is accepted for any

damages arising from improper usage!

• The equipment must only be used in line with its designated purpose and by trained or

expert personnel!

• Do not improperly modify or convert the equipment!

Intended use

Applications

8 099-000180-EW501

27.06.2017

3 Intended use

WARNING

Hazards due to improper usage!

The machine has been constructed to the state of the art and any regulations and

standards applicable for use in industry and trade. It may only be used for the welding

procedures indicated at the rating plate. Hazards may arise for persons, animals and

material objects if the equipment is not used correctly. No liability is accepted for any

damages arising from improper usage!

•The equipment must only be used in line with its designated purpose and by trained or

expert personnel!

•Do not improperly modify or convert the equipment!

3.1 Applications

Wire feeder to feed welding consumables for MMA welding.

3.1.1 Use and operation solely with the following machines

A suitable power source (system component) is required in order to operate the wire feed unit!

This machine can be combined with any TIG welding machine.

3.2 Documents which also apply

3.2.1 Warranty

For more information refer to the "Warranty registration" brochure supplied and our information

regarding warranty, maintenance and testing at www.ewm-group.com!

3.2.2 Declaration of Conformity

The labelled machine complies with the following EC directives in terms of its design and

construction:

•Low Voltage Directive (LVD)

•Electromagnetic Compatibility Directive (EMC)

•Restriction of Hazardous Substance (RoHS)

In case of unauthorised changes, improper repairs, non-compliance with specified deadlines for "Arc

Welding Equipment –Inspection and Testing during Operation", and/or prohibited modifications which

have not been explicitly authorised by EWM, this declaration shall be voided. An original document of the

specific declaration of conformity is included with every product.

3.2.3 Welding in environments with increased electrical hazards

In compliance with IEC / DIN EN 60974, VDE 0544 the machines can be used in

environments with an increased electrical hazard.

3.2.4 Service documents (spare parts and circuit diagrams)

WARNING

Do not carry out any unauthorised repairs or modifications!

To avoid injury and equipment damage, the unit must only be repaired or modified by

specialist, skilled persons!

The warranty becomes null and void in the event of unauthorised interference.

•Appoint only skilled persons for repair work (trained service personnel)!

Original copies of the circuit diagrams are enclosed with the unit.

Spare parts can be obtained from the relevant authorised dealer.

3.2.5 Calibration/Validation

We hereby confirm that this machine has been tested using calibrated measuring equipment, as

stipulated in IEC/EN 60974, ISO/EN 17662, EN 50504, and complies with the admissible tolerances.

Recommended calibration interval: 12 months

Intended use

Applications

8 099-000180-EW501

27.06.2017

3 Intended use

WARNING

Hazards due to improper usage!

The machine has been constructed to the state of the art and any regulations and

standards applicable for use in industry and trade. It may only be used for the welding

procedures indicated at the rating plate. Hazards may arise for persons, animals and

material objects if the equipment is not used correctly. No liability is accepted for any

damages arising from improper usage!

•The equipment must only be used in line with its designated purpose and by trained or

expert personnel!

•Do not improperly modify or convert the equipment!

3.1 Applications

Wire feeder to feed welding consumables for MMA welding.

3.1.1 Use and operation solely with the following machines

A suitable power source (system component) is required in order to operate the wire feed unit!

This machine can be combined with any TIG welding machine.

3.2 Documents which also apply

3.2.1 Warranty

For more information refer to the "Warranty registration" brochure supplied and our information

regarding warranty, maintenance and testing at www.ewm-group.com!

3.2.2 Declaration of Conformity

The labelled machine complies with the following EC directives in terms of its design and

construction:

•Low Voltage Directive (LVD)

•Electromagnetic Compatibility Directive (EMC)

•Restriction of Hazardous Substance (RoHS)

In case of unauthorised changes, improper repairs, non-compliance with specified deadlines for "Arc

Welding Equipment –Inspection and Testing during Operation", and/or prohibited modifications which

have not been explicitly authorised by EWM, this declaration shall be voided. An original document of the

specific declaration of conformity is included with every product.

3.2.3 Welding in environments with increased electrical hazards

In compliance with IEC / DIN EN 60974, VDE 0544 the machines can be used in

environments with an increased electrical hazard.

3.2.4 Service documents (spare parts and circuit diagrams)

WARNING

Do not carry out any unauthorised repairs or modifications!

To avoid injury and equipment damage, the unit must only be repaired or modified by

specialist, skilled persons!

The warranty becomes null and void in the event of unauthorised interference.

•Appoint only skilled persons for repair work (trained service personnel)!

Original copies of the circuit diagrams are enclosed with the unit.

Spare parts can be obtained from the relevant authorised dealer.

3.2.5 Calibration/Validation

We hereby confirm that this machine has been tested using calibrated measuring equipment, as

stipulated in IEC/EN 60974, ISO/EN 17662, EN 50504, and complies with the admissible tolerances.

Recommended calibration interval: 12 months

TIP TIG - ALLINONE, OPERATING MANUAL

Page 7 of 57

3. SAFETY RULES

3.1 Explanation of safety symbols

NOTE! Indicates a risk of flowed and possible damage to the equipment.

IMPORTANT! Indicates tips for correct operation and other particularly useful information. It does

not indicate a potential damaging or dangerous situation.

If you see any of the symbols depicted in the “Safety rules” chapter, special care is required.

3.2 General safety instructions

WARNING: This symbol indicates that instructions must be followed to avoid

serious personal injury, loss of life, or damage to this equipment. Protect yourself

and others from possible serious injury or death.

READ AND UNDERSTAND INSTRUCTIONS: Read and understand this manual

before operating this equipment. Arc welding can be hazardous. Failure to follow

the instructions in this manual could cause serious personal injury, loss of life, or

damage to this equipment.

ELECTRIC SHOCK CAN KILL: Welding equipment generates high voltages. Do

not touch the electrode, work clamp, or connected work pieces when this equipment

is on. Insulate yourself from the electrode, work clamp, and connected work pieces.

ELECTRICALLY POWERED EQUIPMENT: Turn off input power using the

disconnect switch at the fuse box before working on this equipment. Ground this

equipment in accordance with local electrical regulations.

DANGER! Indicates immediate and real danger. If is not avoided, death or serious

injury will result.

WARNING! Indicates a potentially situation. Death or serious injury may result if

appropriate precautions are not taken.

CAUTION! Indicates a situation where damage or injury could occur. If it is not avoided,

minor injury and/or damage to property may result.

CAUTION

This equipment must be used by qualified personnel. Be sure that all installation, operation,

maintenance and repair procedures are performed only by qualified person. Read and

understand this manual before operating this equipment. Failure to follow the instructions in this

manual could cause serious personal injury, loss of life, or damage to this equipment. Read and

understand the following explanations of the warning symbols. TIP TIG is not responsible for

damages caused by improper installation, improper care or abnormal operation.

TIP TIG - ALLINONE, OPERATING MANUAL

Page 8 of 57

ELECTRICALLY POWERED EQUIPMENT: Regularly inspect the input, electrode,

and work clamp cables. If any insulation damage exists replace the cable

immediately. Do not place the electrode holder directly on the welding table or any

other surface in contact with the work clamp to avoid the risk of accidental arc

ignition.

ELECTRIC AND MAGNETIC FIELDS MAY BE DANGEROUS: Electric current

flowing through any conductor creates electric and magnetic fields (EMF). EMF

fields may interfere with some pacemakers, and welders having a pacemaker shall

consult their physician before operating this equipment.

CE COMPLIANCE: This equipment complies with the European Community

Directives.

ARTIFICIAL OPTICAL RADIATION: According with the requirements in

2006/25/EC Directive and EN 12198 Standard, the equipment is a category 2. It

makes mandatory the adoption of Personal Protective Equipment (PPE) having filter

with a protection degree up to a maximum of 15, as required by EN169 Standard.

FUMES AND GASES CAN BE DANGEROUS: Welding may produce fumes and

gases hazardous to health. Avoid breathing these fumes and gases. To avoid these

dangers the operator must use enough ventilation or exhaust to keep fumes and

gases away from the breathing zone.

ARC RAYS CAN BURN: Use a shield with the proper filter and cover plates to

protect your eyes from sparks and the rays of the arc when welding or observing.

Use suitable clothing made from durable flame-resistant material to protect you skin

and that of your helpers. Protect other nearby personnel with suitable, non-

flammable screening and warn them not to watch the arc nor expose themselves to

the arc.

WELDING SPARKS CAN CAUSE FIRE OR EXPLOSION: Remove fire hazards

from the welding area and have a fire extinguisher readily available. Welding sparks

and hot materials from the welding process can easily go through small cracks and

openings to adjacent areas. Do not weld on any tanks, drums, containers, or

material until the proper steps have been taken to insure that no flammable or toxic

vapors will be present. Never operate this equipment when flammable gases,

vapors or liquid combustibles are present.

WELDED MATERIALS CAN BURN: Welding generates a large amount of heat.

Hot surfaces and materials in work area can cause serious burns. Use gloves and

pliers when touching or moving materials in the work area.

SAFETY MARK: This equipment is suitable for supplying power for welding

operations carried out in an environment with increased hazard of electric shock.

EQUIPMENT WEIGHT OVER 30kg: Move this equipment with care and with the

help of another person. Lifting may be dangerous for your physical health.

TIP TIG - ALLINONE, OPERATING MANUAL

Page 9 of 57

CYLINDER MAY EXPLODE IF DAMAGED: Use only compressed gas cylinders

containing the correct shielding gas for the process used and properly operating

regulators designed for the gas and pressure used. Always keep cylinders in an

upright position securely chained to a fixed support. Do not move or transport gas

cylinders with the protection cap removed. Do not allow the electrode, electrode

holder, work clamp or any other electrically live part to touch a gas cylinder. Gas

cylinders must be located away from areas where they may be subjected to

physical damage or the welding process including sparks and heat sources.

CAUTION: The high frequency used for contact-free ignition with TIG (GTAW)

welding, can interfere with the operation of insufficiently shielded computer

equipment, EDP centers and industrial robots, even causing complete system

breakdown. TIG (GTAW) welding may interfere with electronic telephone networks

and with radio and TV reception.

NOISE APPEARES DURING WELDING CAN BE HARMFUL: Welding arc can

cause noise with high level of 85dB for 8-hour week day. Welders operating welding

machines are obligated to wear the proper ear protectors /appendix No. 2 for the

Decree of the Secretary of Labor and Social Policy from 17.06 1998 – Dz.U. No. 79

pos. 513/. According to the Decree the Secretary of Health and Social Welfare from

09.07.1996 /Dz.U. No. 68 pos. 194/, employers are obligated to carry examinations

and measurements of health harmful factors.

The manufacturer reserves the right to make changes and/or improvements in design without

upgrade at the same time the operator’s manual.

TIP TIG - ALLINONE, OPERATING MANUAL

Page 10 of 57

4. GENERAL

4.1 Device concept

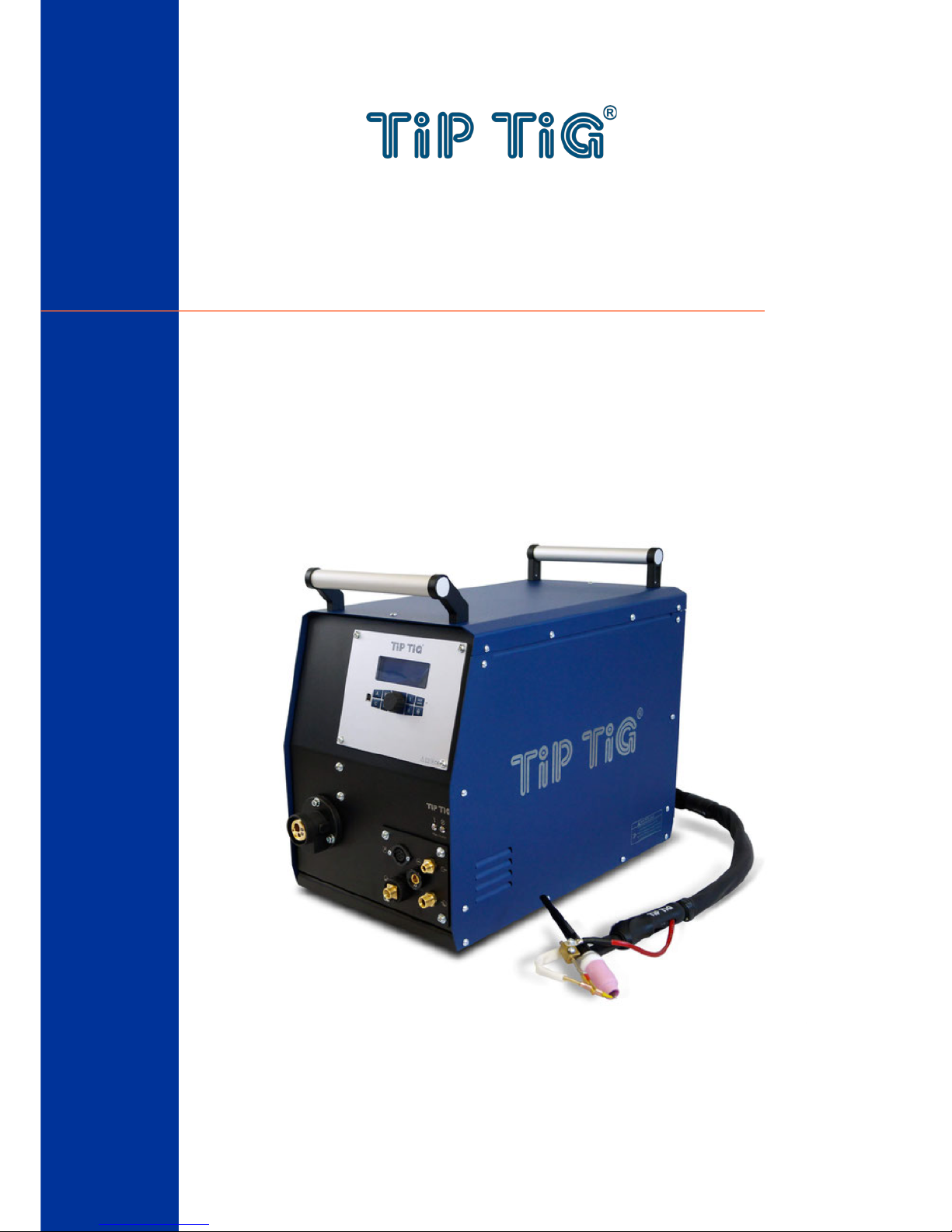

The TIP TIG – AllinOne wire feeder is

contained in a metal housing and is suitable

for wire spools with max. diameter of 300 mm

(11.81 in.).

The 4-roller drive has good wire-feeding

properties. The wire feeder is also suitable for

long hose packages.

4.2 Power sources

The TIP TIG – AllinOne wire feeder can be used with many power sources available on the market

– See Table 3-1: Power supply compatibility. Preferably TIP TIG – AllinOne is used in combination

with the specially designed power source TIP TIG – TIG 350, 350 AC, 500, 500 AC.

Table 3-1: Power supply compatibility

Company

Model

Miller Electric

Maxstar 280DX, 350, 400, 700, 800

Dynasty 280DX, 350, 400, 700, 800

Dimensions MP 452, 650, 652

XMT MP 304, 350, 450

MP PipeWorks / PipeWorks Field Pro

Lincoln Electric

Aspect 375

Precision TIG 225, 275, 375

Invertec V311, V350Pro

Flextec 350X MP

Powerwave S350, S500 MP

Fronius

Magic Wave 3000, 4000, 5000

TransTIG 3000, 4000

ESAB

ET 301

HeliArc 281

Warrior 400, 500

TIP TIG - ALLINONE, OPERATING MANUAL

Page 11 of 57

4.3 Crane transport

The TIP TIG – AllinOne wire feeder can be transported by crane using its handles.

The maximum load-bearing capacity of the handles is 35 kg (77.16 lb.)

Before transporting by crane:

- feed out the wire electrode, remove the wire spool

- disconnect the torch hose package and interconnecting hose package from the wire feeder

- if present, unplug the coolant connections

WARNING

Falling equipment can cause death or serious injury.

• Only use a suitable lifting tackle when transporting devices by crane (e.g. belt with round

slings)

• The lifting tackle must be undamaged and in perfect condition

• Do not transport any other loads by the handle apart from the wirefeeder itself

• Do not hang from the wirefeeder as it is being transported

TIP TIG - ALLINONE, OPERATING MANUAL

Page 12 of 57

5. CONTROLS, CONNECTIONS AND MECHANICAL COMPONENTS

5.1 System overview

Front of TIP TIG – AllinOne wire feeder

No.

Description

(1)

Carrying handle

(2)

Control panel – See 5.7 Control panel

(3)

Hotwire indicator lamps

Temperature fault indicator (left)

is lit in the case of overheating. It extinguishes after a few minutes when the unit has

cooled down.

Hotwire-on indicator (right)

(1) is lit when there is live operating voltage and the hot wire unit is ready for service,

(2) blinks in case of a fault.

(4)

Wire electrode connection – for connecting the welding torch wire feed

(5)

Front connection – See 5.2 Front connection

(6)

Cooling air inlet

(5)

(4)

(3)

(2)

(1)

(1)

(6)

TIP TIG - ALLINONE, OPERATING MANUAL

Page 13 of 57

Rear of TIP TIG – AllinOne wire feeder

No.

Description

(1)

Main power switch with fuses – See 5.4 Main power switch with fuses

(2)

Cooling air outlet

(3)

Rear connection – See 5.3 Rear connection

(4)

Protective cap

Cover for the wire feed mechanism and other operating elements.

(5)

Lock for the protective cap

(1)

(3)

(4)

(5)

(5)

(2)

TIP TIG - ALLINONE, OPERATING MANUAL

Page 14 of 57

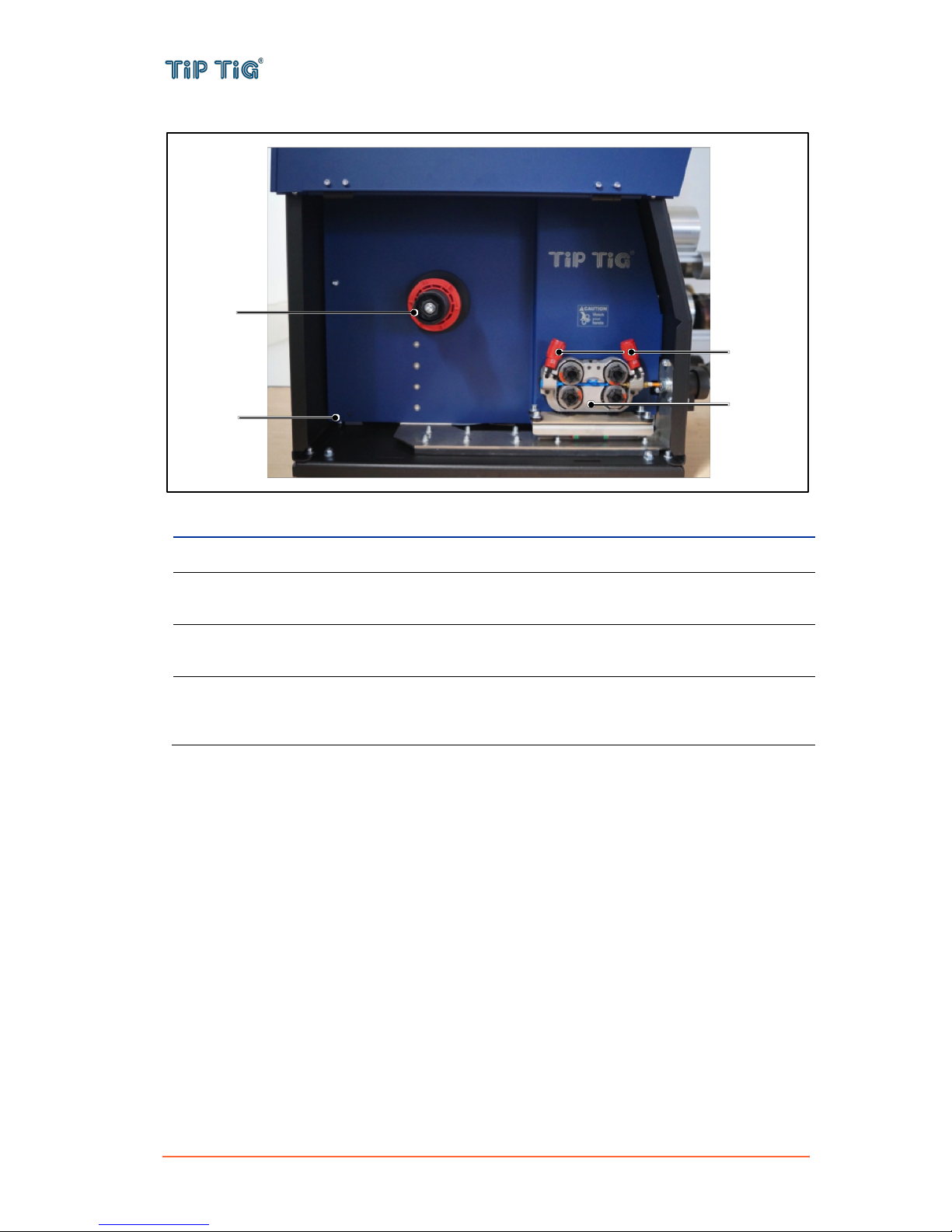

TIP TIG – AllinOne wire feeder: operating elements in the machine

No.

Description

(1)

Four roll wire drive

(2)

Clamping levers

for setting the contact pressure of the feed rollers

(3)

Hotwire amperage adjustment – See 5.5 Hotwire amperage adjustment

for adjusting the ampere setting of the hotwire unit

(4)

Wires pool holder with brake

for holding standard wire spools with max. diameter of 300 mm (11.81 in.) and max.

weight of 15 kg (33.1 lb.)

(1)

(4)

(3)

(2)

TIP TIG - ALLINONE, OPERATING MANUAL

Page 15 of 57

5.2 Front connection

No.

Description

(1)

Connection socket control lead (7-pole)

for connecting control lead from the welding torch hose package

(2)

Connecting nipple current / coolant supply (blue)

for connecting current / coolant supply (G3/8" RH) from the welding torch hose package

(3)

Connecting nipple shielding gas

for connecting shielding gas (G1/4" RH) from the welding torch hose package

(4)

Connecting nipple coolant return (red)

for connecting coolant return (G3/8" LH) from the welding torch hose package

(5)

Connection socket hot wire

for connecting hot wire power from the welding torch hose package, minus potential

(1)

(3)

(4)

(5)

(2)

TIP TIG - ALLINONE, OPERATING MANUAL

Page 16 of 57

5.3 Rear connection

No.

Description

(1)

Connector plug (7-pole) – option

for connecting TIP TIG Automation 0-10V (AUTOMATION ONLY)

(2)

Connection socket (7-pole)

Communication Connection for the welding machine

(3)

Connector plug (4-pole) – Mains connection

120/230 VAC main power connection

(4)

Connecting nipple shielding gas

for connecting shielding gas (G1/4" RH) from the interconnection hose package

(5)

Connecting nipple coolant supply (blue)

for connecting coolant supply (G3/8" RH) from the interconnection hose package

(6)

Connecting nipple coolant return (red)

for connecting coolant return (G3/8" LH) from the interconnection hose package

(7)

Connector plug hot wire and workpiece

for connecting hot wire power from the interconnection hose package, plus potential,

workpiece connection

(8)

Connector plug welding current

for connecting welding current, minus potential from the interconnection hose package

(3)

(6)

(1)

(2)

(5)

(4)

(7)

(8)

TIP TIG - ALLINONE, OPERATING MANUAL

Page 17 of 57

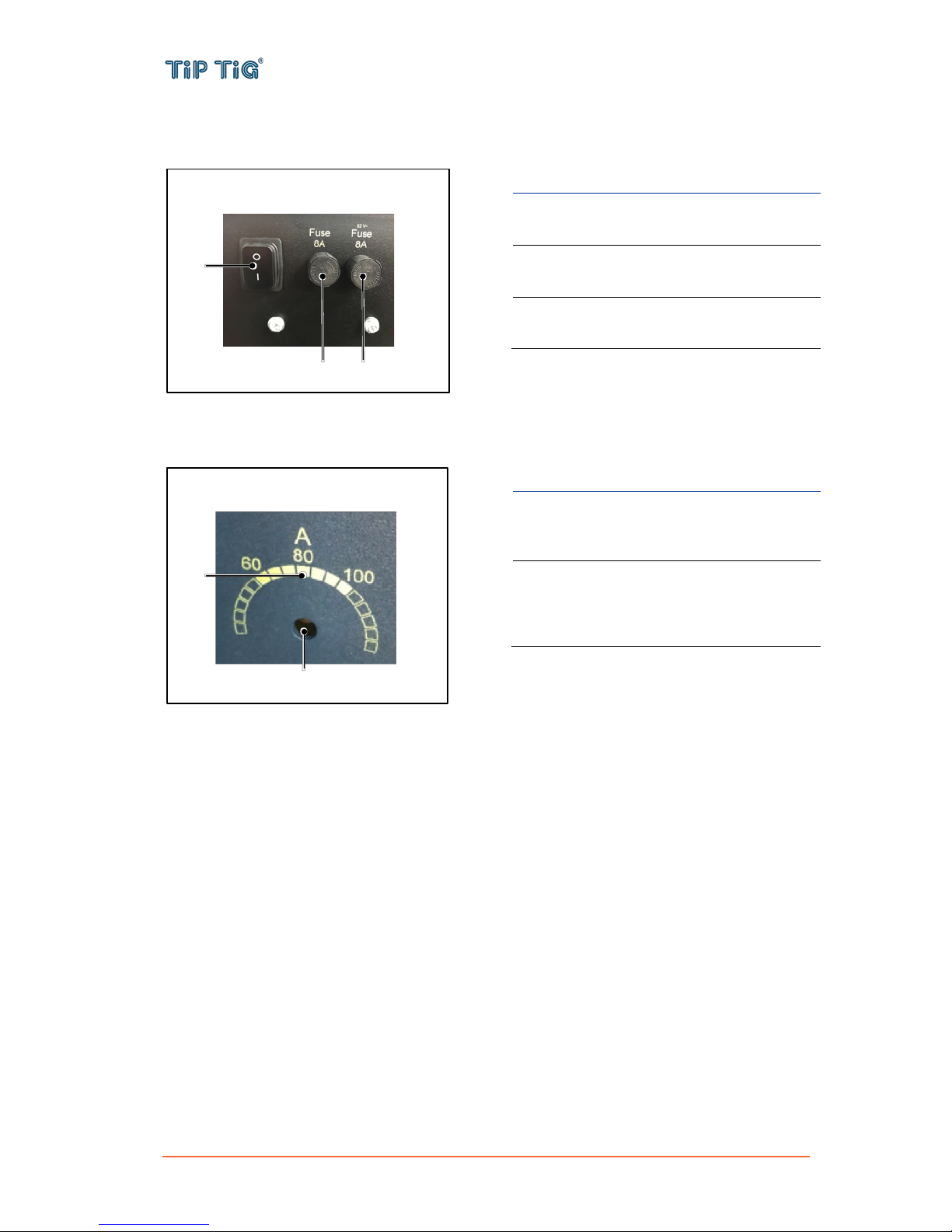

5.4 Main power switch with fuses

No.

Description

(1)

Main power switch

machine on/off

(2)

Mains fuse

T8 A, 120/230 VAC

(3)

Feeder fuse

T8 A, 32 VAC

5.5 Hotwire amperage adjustment

No.

Description

(1)

Adjustment screw

adjust the setting with a flat screw

driver

(2)

Adjustment range

60 – 100 A

Presetting 80 A (optimum setting

point)

(1)

(3)

(2)

(2)

(1)

TIP TIG - ALLINONE, OPERATING MANUAL

Page 18 of 57

5.6 Control panel – D24B2M1.6

No.

Function

(1)

Display

shows the current figure of the selected parameter

(2)

Parameter selection button

for selecting the parameters listed below (5)

(3)

Adjusting button -

for negative adjustment of the selected parameter (5)

(4)

Adjusting button +

for positive adjustment of the selected parameter (5)

(5)

Parameter indicator

shows which parameter is selected:

- Wire Feeding Speed

- Frequency Control

- Start Delay

- Wire Retract

- Spot Time

(6)

Mode button

for selecting the desired mode (7)

(1)

(2)

(3)

(4)

(5)

(7)

(6)

TIP TIG - ALLINONE, OPERATING MANUAL

Page 19 of 57

(7)

Mode indicator

shows which mode is selected:

- 4-Stroke

- 2-Stroke

- Lead Voltage 0-10 V

- Spot Function

- Program Load

- Program Save

Display values

Wire Feeding Speed

Display value multiplied by 0,0635 is the wire feed speed in m/min

or display value multiplied by 2,5 is the wire feed speed in IPM

(WIRE FEED SPEED = 0,0635*Display value)

Example: Factor 100 = 6,35 m/min or 250 IPM

For more information please go to Appendix 9.2.1 or visit

https://www.tiptig.com/english/support/

Frequency Control

The value is as shown as factor

For all applications use 230 = 17 Hz

Start Delay

The value is as shown as factor (optional)

Useful for track weld

Wire Retract

The value is as shown as factor (optional)

Is an option – normally not used

Spot Time

The value is as shown as factor (optional)

Only for spot weld

To use spot time it's needed to adjust the mode spot function

Modes

4-Stroke

Generally select 4-Stroke mode for hand welding

2-Stroke

2-Stroke mode mostly used for tack welding

Lead Voltage 0-10 V

optional

Spot Function

optional

Program Load

optional

Program Save

optional

CAUTION

The wire feed speed may have a variation of ± 10%. It depends on

the settings of the feed roll tensioner (see 5.5 (2)) and the quality

of the wire.

TIP TIG - ALLINONE, OPERATING MANUAL

Page 20 of 57

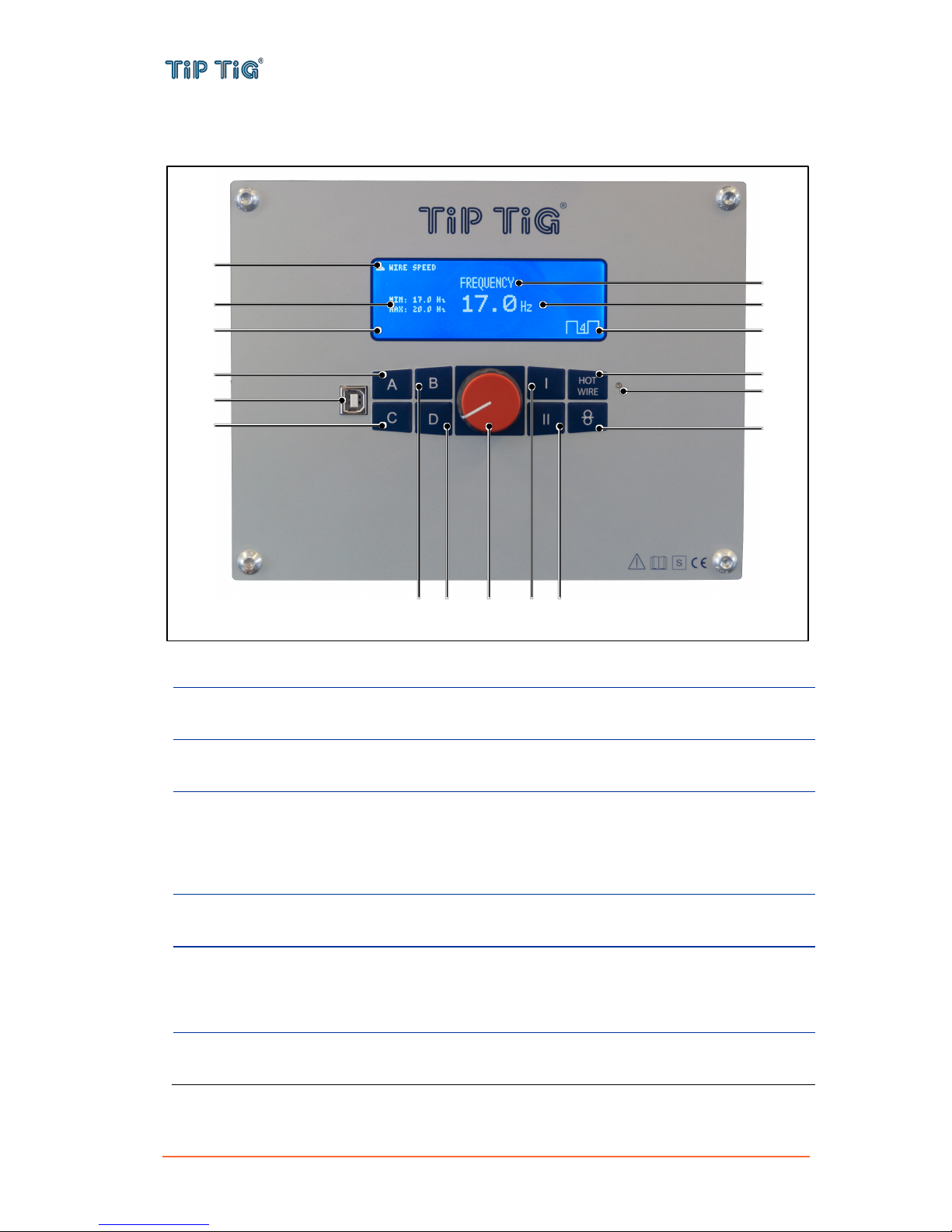

5.7 Control panel – Version 2.0

Display – Parameters and Modes

No.

Function

(1)

Menu (parameter) forecast up/down

shows which parameter will be selected when switching menu up/down

(2)

Parameter range indicator

shows min. and max. value of the selected parameter

(3)

Menu (parameter) indicator

shows which parameter is selected:

- Wire speed

- Frequency

- Weld amps

(4)

Parameter

shows the current value and unit of the selected parameter

(5)

Mode indicator

shows which mode is selected:

- 2-Step

- 4-Step

(6)

A – Menu (parameter) up button

switching menu up

(1)

(7)

(3)

(4)

(2)

(9)

(5)

(14)

(16)

(6)

(8)

(10)

(12)

(13)

(11)

(1)

(15)

Table of contents

Other TIP TIG Welding System manuals

Popular Welding System manuals by other brands

widos

widos 7000 WM quick start guide

Adtech

Adtech ADT-HC4500 user manual

Castolin

Castolin dyomix Oxy-Hydrogen Mobile 2.4 user manual

Lincoln Electric

Lincoln Electric Harris 62-E operating instructions

EWM

EWM Picotig 200 puls TG operating instructions

Asahi/America

Asahi/America McELROY SmartFab 125 Operator's manual

Lincoln Electric

Lincoln Electric RANGER 8 Operator's manual

Lincoln Electric

Lincoln Electric Square Wave TIG 200 Quick reference guide

Miller

Miller DYNASTY DX Technical manual

Nelson

Nelson NS-40 Instruction and maintenance manual

Pro-Weld

Pro-Weld CD-312 user manual

Alfain

Alfain PEGAS 160 MIG MAN operating manual