Titan Attachments TOWL30 User manual

30 TON LOG SPLITTER

TOWL30

198374

Operator’s Manual

Read the Operator’s Manual entirely. When you see this

symbol, the subsequent instructions and warnings are

serious follow without exception. Your life and the lives

of others depend on it!

Cover photo may show optional equipment not supplied

with standard unit. For an Operator’s Manual and Decal

Kit in French or Spanish Language, please see your dealer

2

GENERAL WARNINGS

READ and UNDERSTAND this manual completely before using 30 Ton Log Splitter.

Operator must read and understand all safety and warning information, operating instructions, maintenance,

and storage instructions before operating this equipment. Failure to properly operate and maintain the log

splitter could result in serious injury to the operator or bystanders.

OPERATION WARNINGS

•Do not at any time carry passengers, sit, or stand on the log splitter.

•Do not allow children to play on, stand upon or climb on the log splitter.

•Always inspect the log splitter before using to assure it is in good working condition.

•Replace or repair damaged or worn parts immediately.

•Always check and tighten hardware and assembled parts before operation.

•Do not exceed equipment maximum load capacity of 30 tons.

•Avoid large holes and ditches when towing the equipment.

•Always operate the log splitter on clear and level ground.

•Do not operate the log splitter at night, only during daylight hours.

•Always tow at reduce speed in rough terrain, along creeks, ditches and on hillsides.

•To avoid personal injury and/or equipment damage DO NOT EXCEED 45 MPH.

•Always refer to the vehicle owner’s manual for proper towing.

•Always secure and lock the log splitter to the vehicle hitch before towing.

CRUSH AND CUT HAZARDS

Always keep hands and feet clear from moving parts while operating the equipment.

Always clear and keep work area clean and free of debris when operating.

Always wear safety gear, eye protection, gloves and work boots when operating the log splitter.

ASSEMBLY IS REQUIRED

This product requires assembly before use. See “Assembly” section for instructions. Because of the weight

and/or size of the log splitter, it is recommended that another adult be present to assist with theassembly.

INSPECT ALL COMPONENTS closely upon receipt to make sure no components are missing or damaged.

WARNING

The warnings, cautions, and instructions outlined in this instruction manual cannot cover all possible

conditions or situations that may occur. It must be understood by the operator that common sense

and caution are factors which cannot be built into this product and must be supplied by the operator.

PROP 65 WARNING

This product can expose you to chemicals including lead and lead compounds which are known to

the State of California to cause cancer and birth defects or other reproductive harm. For more

information, go to www.P65Warnings.ca.gov.

3

HAZARD SIGNAL WORD DEFINITIONS

ABOUT YOUR 30 TON LOG SPLITTER

This hydraulic log splitter has a heavy-duty steel construction and 30 tons of ram force. When there's work to be

done, you need outdoor power equipment you can rely on, this log splitter will get the job done fast. It is

designed to work in both the horizontal and vertical position. It is easy to tow, easy to use and maintain. Never

exceed the rated capacity of 30 tons when operating the log splitter.

Technical specifications on the log splitter are provided in the “Specifications” section of this manual.

This is the safety alert symbol. It is used to

alert you to potential personal injury hazards.

Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury.

WARNING

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

CAUTION

CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

CAUTION CAUTION used without the safety alert symbol

indicates a potentially hazardous situation

which,

if not avoided, may result in property damage.

4

Read this owner’s manual before operating the equipment. Familiarize yourself with the location

andfunction of the controls and features. Save this manual for future reference.

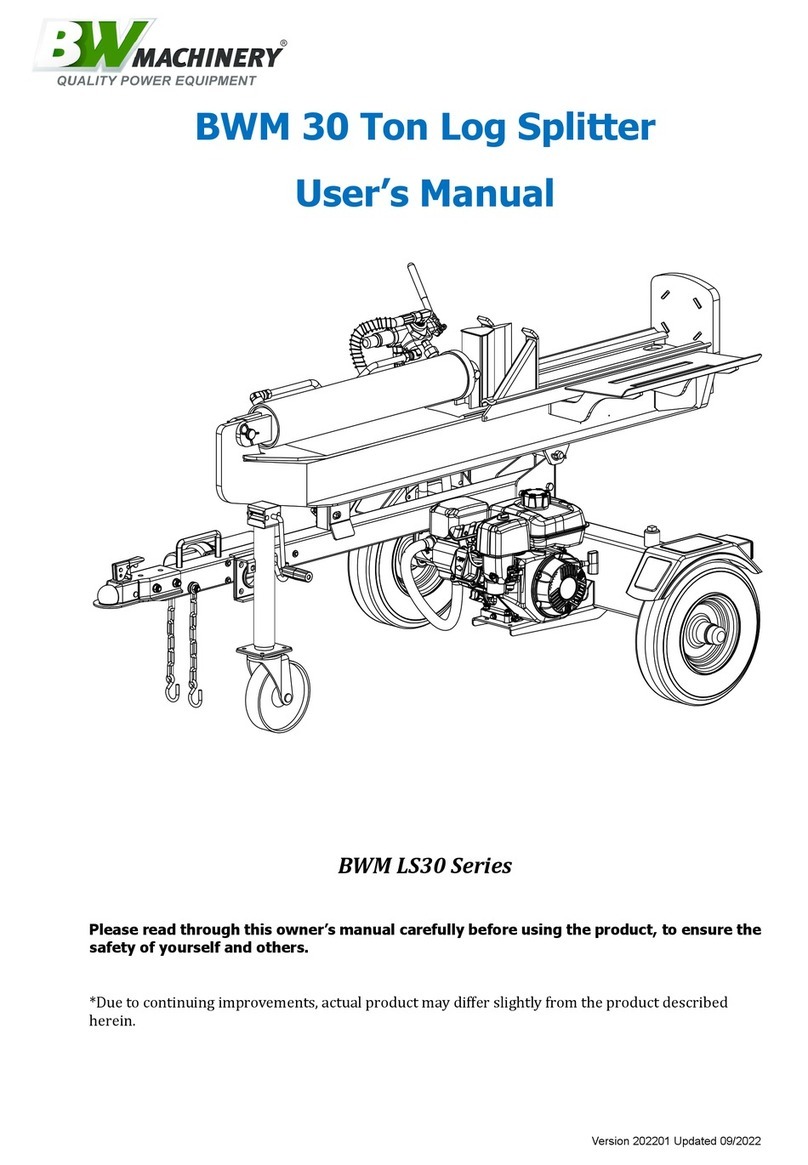

1) 2” Coupler – Attaches the log splitter to the 2” ball.

2) Hydraulic Cylinder – 4.5” bore and 24.5” stroke, rated to 3625 psi.

3) Control Valve – Controls the forward and backward movement of splitting wedge.

4) 8” Wedge - Feature’s wedge wings and tapered ends making splitting easier.

5) External Filter – Filters the hydraulic oil.

6) Beam – 7.9” wide

7) Engine - Air cooled engine powers the hydraulic pump.

8) Tires - Maximum rated towing speed is 45 MPH.

9) Gear Pump - Pumps the hydraulic oil through the system.

10) Support Leg - Supports the log splitter while operating.

11) Safety Chains - Safety feature to prevent loss of log splitter while towing.

CONTROLS AND FEATURES IDENTIFICATION

5

WARNING

Read and follow all instructions for assembly and operation. Failure to properly assemble this

equipment could result in serious injury to the user or bystanders, or cause equipment damage.

Engine Shipped Without Oil.

Before starting engine, fill with SAE 10W

-30 motor oil.

See

engine manual for engine oil capacity.

Hydraulic

Reservoir is Shipped Without Oil.

When

adding oil verify the oil level reads 1 from the top of hydraulic

reservoir

if marking is not shown fill to the neck.

Inspect

all Log Splitter Components.

If

you have damaged components: Contact the freight company

that

delivered the log splitter and file a claim.

30 TON LOG SPLITTER ASSEMBLY

Set the shipping crate on a solid flat surface and carefully remove the lid. Use two people and take all

parts out of the shipping crate and inspect the components to ensure there are no missing pieces

before starting to assemble the log splitter follow steps 1 through 8.

TOOLS REQUIRED

•Rubber or Wooden Hammer

•13mm, 16mm, 17mm, 18mm, 19mm, 24mm, 27mm Wrenches

•Large Adjustable Wrench

•Phillips Screwdriver

•Pliers

STEP 1: WHEEL ASSEMBLY

1. Attach the wheel (#35) to the oil tank axle (#44) using a flat washer Ø20 (#54) and tighten the

wheel with the hex slotted nut M20x1.5 (#37). Lock the hex slotted nut M20x1.5 (#37) in place

using the cotter pin Ø4x36 (#73). Install the axle cap (#41) on the end using rubber hammer.

NOTE: Use a black plastic bushing to fix the axle cap (#41) like below

picture. Please cover the black bushing onto the axle cap and use

rubber/wooden hammer knocking the end of the plastic bushing and

make the axle cap fixed on wheel.

ASSEMBLY INSTRUCTIONS

6

STEP 2: ATTACH TOW BAR TO THE WHEEL ASSEMBLY

1. Attach the tow bar (#62) to the oil tank using hex bolt M12x100 (#24), flat washer Ø12 (#65)

and lock nut M12 (#13).

STEP 3: ATTACH THE BEAM ASSEMBLY

1. Connect the Beam (#17) and Oil Tank using Hitch Pin (#18), then lock the Hitch Pin (#18)

using R Pin (#21).

WARNING: After the slotted nut is

tightened, turn back 1/4 circle to

make sure the wheel can rotate

smoothly and freely. Failure to turn

the slotted nut back will cause the

wheel not to operate correctly

7

Lock in this

STEP 4: ATTACH ENGINE TO MOUNTING PLATE

1. Position the engine (#33) the mounting plate put the hex bolt M8x40 (#46) through the

bottomof the plate, then put flat washer flat washer Ø8 (#36), lock washer Ø8(#32) and

tighten with the nylon lock nut M8 (#31).

2. Attach the clean oil pipe (#53) to the bottom of the gear pump and secure with clamp (#51).

8

STEP 5: ATTACH HYDRAULIC HOSE

1. Put O ring Ø11x2.5 (#19) on the gear pump connector (#23) and attach the hydraulic hose

(Connector-valve) (#16) to the gear pump connector (#23).

2. Put the O ring Ø17x2.5 (#71) on the connector (#50) and attach the hydraulic hose (#7) to the

end of the connector (#50).

STEP 6: ADD ENGINE OIL

1. Make sure the log splitter is on a level surface.

2. Remove oil fill cap/dipstick to add oil.

3. Refer to the separate owner’s engine manual for the amount needed of SAE10W-30 engine oil;

replace oil fill cap/dipstick.

4. Check engine oil level daily and add as needed.

NOTE: During the break-in period check the engine oil level often.

STEP 7: ADD GASOLINE TO THE ENGINE

1. Use only clean, fresh, regular unleaded fuel with a minimum 85 octane rating.

2. DO NOT mix oil with fuel.

3. Remove the fuel cap and slowly add fuel to the tank. DO NOT overfill allow approximately ¼

inch of space for fuel expansion.

4. Screw on the fuel cap and wipe away any spilled fuel.

CAUTION

DO NOT attempt to crank or start the engine before it has been properly filled with the

recommended type and amount of oil. Damage to the log splitter because of failure to follow

these instructions willvoid your warranty.

9

STEP 8: ADD HYDRAULIC OIL

1. The log splitter needs to be on a flat level surface before adding the hydraulic oil.

2. Remove the oil cap from the hydraulic reservoir.

3. Add 4.49 gallons of hydraulic oil AW32, AW46 & universal hydraulic oil are all acceptable typesof

fluid. Automatic transmission fluid should be used when operating in temperatures

below 32 degrees (all units are tested and have excess oil in the ram).

4. Check the hydraulic oil level.

5. Start engine and use the control lever to extend and retract wedge several times to remove air

from the lines.

6. With the wedge retracted, check hydraulic oil level again and fill if necessary.

DANGER

Log splitter engine exhaust contains carbon monoxide, a colorless, odorless, poison gas.

Breathing carbon monoxide will cause nausea, dizziness, fainting or death. If you start to feel dizzy

or weak, get to fresh air immediately.

Operate log splitter outdoors only in a well-ventilated area.

DO NOT operate the log splitter inside any building, enclosure, or compartment.

DO NOT allow exhaust fumes to enter a confined area through windows, doors, vents, or other

openings.

DANGER CARBON MONOXIDE, using a log splitter indoors CAN KILL YOU IN MINUTES.

CAUTION

Fuel and fuel vapors are highly flammable and extremely explosive. Fire or explosion can cause

severe burns or death.

Unintentional startup can result in entanglement, traumatic amputation, or laceration. Only use

regular unleaded gasoline with a minimum 85 octane rating.

DO NOT mix oil and gasoline together.

Fill tank approximately ¼” below the top of the tank to allow for fuel expansion.

DO NOT fill fuel tank indoors or when the engine is running or hot.

DO NOT light cigarettes or smoke when filling the fuel tank.

WARNING

DO NOT remove the hydraulic oil fill cap when the engine is running or hot. Hot oil can escape

causing severe burns. Always allow the log splitter to cool completely before removing the

hydraulic oil cap. High fluid pressure and temperatures are created in the hydraulic log splitters.

Hydraulic fluid will escape through a pin-size hole opening and can puncture skin and cause

severe blood poisoning. Inspect hydraulic system regularly for possible leaks. Never check for

leaks with your hand while the system is pressurized. Seek medical attention immediately

if injured by escaping fluid. Make sure all fittings are tight and secure before applying pressure.

Relieve system pressure before servicing. Make sure the hydraulic hoses do not touch any hot

surfaces or cutting areas. Hoses need to be positioned where they are clear from the engine and

cutting wedge. To avoid serious bodily injury always inspect the hoses before operating the log

splitter.

10

USING YOUR LOG SPLITTER

1. DO NOT at any time carry passengers, sit, or stand on the log splitter.

2. Check the hydraulic oil level and visually inspect all hoses and attachments for problems.

3. Inspect the engine and make sure the engine oil level is correct.

4. Before towing the log splitter, the tires need to be fully inflated.

5. Refer to the vehicle owner’s manual for proper safety and towing instructions.

WARNING

Before operating or using the log splitter, review the instructions below and all safety information.

Failure to follow these instructions may result in property damage or injury to the operator or

bystanders.

WARNING

ALWAYS use the log splitter for its intended use.

ONLY use the log splitter to split wood logs, length wise with the grain.

NEVER modify, alter, or change the log splitter in anyway, modifications will void the

warranty.

NEVER attach a rope, cable, or other device to the control lever on the log splitter.

ONLY operate the log splitter in daylight.

NEVER leave the log splitter unattended while the engine is running.

DO NOT change the splitting position with the engine running. Contact with the muffler

can causeserious burns.

ALWAYS make sure the beam is in the locked position.

DO NOT let the beam drop as it could crush fingers or cause damage to the log splitter.

NEVER operate or let anyone else operate, the log splitter while under the influence of

alcohol, drugs,or medication.

TIRE WARNING

DO NOT over inflate tires. Serious injury can result if tires explode.

DO NOT tow the log splitter if the tires are worn or will not hold air.

DO NOT exceed the maximum 45 MPH towing speed.

TOWING WARNING

Serious injury or death can occur if towing safety rules are not followed.

Always use safety chains, secure, and lock the log splitter to the vehicle hitch before moving. Drive

safely. Be aware of the added length of the log splitter.

Never exceed the maximum travel speed of 45 mph. Never ride or transport cargo on the log

splitter.

Turn off the vehicle before leaving the log splitter unattended. Block the log splitter wheels to

prevent unintended movement.

OPERATION INSTRUCTIONS

11

6. The log splitter must have at least seven feet of clearance from combustible material. It

needsto be on a dry and level surface with good footing. Do not work on mud, ice, brush, or

snow. When using the log splitter, the work zone must be always maintained.

NOTE: Serious accidents can happen when other people are allowed inside the work zone.Keep

everyone else outside the work zone while operating the control lever.

7. Always wear safety gear, eye protection, gloves and work boots when operating the log

splitter.

8. Start the engine and make sure the log splitter is on level ground before operating.

NOTE: The hydraulic oil needs to be above 10°F (-12C°) before starting the engine. Cold hydraulic

oil can damage the hydraulic pump. If outdoor air temperature is below 32°F (0C°)

allow the log splitter to warm up by extending and returning the wedge several times before

splitting wood.

9. Put the support leg in the down position to prevent the log splitter from moving

duringoperation and block both tires.

10. Set the log splitter in either the horizontal or vertical position.

NOTE: HORIZONAL position is used for lighter logs that can easily be loaded onto the beam. The

VERTICAL position is used for either light logs or heavy logs that are difficult to load ontothe beam.

Back injury can result from lifting logs onto the log splitter if proper lifting techniques are not used.

11. Load a log onto the beam against the endplate (Max Log Length-26”).

12

12. Make sure hands are clear from the wedge and crush hazard areas.

13. Push control lever FORWARD by one hand to split the log.

14. Push control lever BACKWARD by one hand to return wedge to its original position.

15. Always keep work zone clean and free of split wood and debris.

CRUSH WARNING

Wedge can cut through skin and break bones. Keep both hands away from wedge and beam slide.

Serious accidents can happen when other people are allowed inside the work zone. Keep

everyone else out of the work zone while operating control lever.

DO NOT wear loose clothing. It can get tangled in moving parts of log splitter. Only use the log

splitter in daylight so you can see what you are doing.

CAUTION

If a log gets stuck, embedded, or will not split completely, push the control lever in the reverse

direction and allow the splitter to strip the log from the wedge.

If the log remains stuck, embedded, or will not split, turn the machine off and use a

sledgehammer and crowbar to remove the log.

ALWAYS keep hands clear of the log and wedge while it is retracting.

13

OPERATION INSTRUCTIONS

14

MAINTENANCE

•Before performing maintenance, the log splitter must be placed in maintenance mode. Turn

off the engine and move the control lever forward and backwards to relieve the hydraulic

pressure.

•After performing any maintenance, make sure all guards, shields and safety features are put

back in place before operating the log splitter.

•Before operating make sure the tires have the RECOMMENDED TIRE PRESSURE.

•Regularly grease axle and wheel bearing area or when needed.

•Periodically check all fasteners and hoses for tightness and leaks.

•Annually clean and lightly lubricate all moving parts or when needed.

•Use a glossy enamel spray paint to touch up scratched or worn painted metal surfaces.

•Never exceed load capacity rating of 30 tons it will damage the log splitter.

What

When

How

Hoses

Each Use

Inspect hoses for exposed wire mesh and leaks.

Replace all worn or damaged hoses before starting

the

engine.

Hydraulic

Fittings

Each Use

Inspect fittings for cracks and leaks. Replace all

damaged

fittings before starting the engine.

Nuts and Bolts

Each Use

Check for loose bolts, tighten before operating.

Beam

Each Use

Apply grease to beam surface.

Moving Parts

Each Use

Clear debris from log splitter.

REFER TO THE ENGINE OWNER’S MANUAL FOR ENGINE MAINTENANCE.

IMPORTANT:

If a part needs replacement, only use parts that meet the manufacturer’s specifications. Replacement

parts that do not meet specifications may result in a safety hazard or poor operations.

STORAGE

•Before storing make sure the log splitter is clean and dry for years of trouble-free service.

•Lightly lubricate all log splitter surfaces and moving parts to prevent rust.

•Store indoors or protected area during severe weather and winter months.

WARNING

Improper maintenance and storage of the log splitter may void your warranty.

MAINTENANCE AND STORAGE

15

PROBLEM

Cylinder

rod will not move SOLUTION: A, D, E, H, J

Slow

cylinder rod speed when extending

or

retracting

SOLUTION: A, B, C, H, I, K, L

Wood

will not split or splits extremely

slowly

SOLUTION: A, B, C, F, I, K

Engine

bogs down during splitting SOLUTION: G, L

Engine stalls under low load condition

SOLUTION: D, E, L, M

Engine starts problem

SOLUTION: N

Cause

Solution

A

-Insufficient oil to pump Check oil level in reservoir

B-Air in oil

Check oil level in reservoir

C

-Excessive pump inlet vacuum Check pump inlet hose for blockage or

kinks

D

-Blocked hydraulic lines Flush and clean the splitter

hydraulic

system

E

-Blocked control valve Flush and clean the splitter

hydraulic

system

F

-Low control valve setting Adjust control valve with a pressure

gauge

G

-High control valve setting Adjust control valve with a pressure

gauge

H

-Damaged control valve Return control valve for authorized repair

I-Internal control valve leak

Return control valve for authorized repair

J-Internal cylinder leak

Return cylinder for authorized repair

K-Internally damaged cylinder

Return cylinder for authorized repair

L

-Engine Control out of adjustment Adjust idle control nuts

M

-Engine is loaded during idle down mode Use shorter log length (26” or less) to

allow

engine to speed up before contact.

N-Engine operation

Refer to the English owner’s manual

TROUBLESHOOTING

16

Ram Force .........................................................................................................30 Ton

Cycle Time ..................................................................................................... 13.5 Sec

Wedge Size.........................................................................................8” Harden Steel

Gear Pump.................................................................................................... 2-Stage

Hydraulic Oil ..................................AW32, AW46, ISO32 or Universal Hydraulic Oil

Amount of Hydraulic Fluid............................................................................….8 Gal

Max. Log Length.................................................................................................... 24”

Hydraulic Cylinder........................................................................... .4-1/4” x 29-3/4”

Max. Pressure......................................................................................... 3625 PSI

Max. Flow ....................................................................................................... 14 GPM

Wheel Size...........................................................................................16” / 4.80-8

Hitch Type ........................................................................................... 2” Ball Coupler

Max. Towing Speed ....................................................................................... 45 MPH

Manual Start Engine .........................................................................................250cc

NOTE: For Engine Details Refer to the Engine Owner’s Manual.

SPECIFICATIONs

17

PARTS DRAWING & PARTS LIST

18

REF#

DRAWING NO.

DESCRIPTION

QTY

1

9101-05010-DX8.8

Hex Bolt M5x10

4

2

9121-06010-FH

Inner Hex Cone Point Set Screw

1

3

LSP30B-03000

Cylinder

1

4 LSP25-00001-DX

Metal Tube

1

5

LSP25-00005-DX

R Pin

2

6

LSP25-00004-DX

Cylinder Pin

1

7 LSP25-00017 Hydraulic Hose (valve-external filter) 1

8

LSP25-06000

Connector

2

9

LSA22-09000

Control Valve

1

10

LSP25-17000

Combination Connector

1

11

LSP25-00002-DX

130°Joint

1

12

LSP25-00006-DX

Safety Pin

1

13

9206-12000-DX

Nylon Lock Nut M12

7

14

LSP30B-02000

Wedge

1

15

9101-14085-DX8.8

Hex Bolt M14x85

1

16

LSP25-00016

Hydraulic Hose(valve-Pump)

1

17 LSP30B-01000 Beam 1

18

LSP25-05000

Hitch Pin

1

19

9901-11x2.5

O Ring Ø11x2.5

2

20 LSP25-00010-DX Oil Plug 1

21

LSP25-00012-DX

R Pin Ø12

1

22

9901-15x2.5

O Ring Ø15x2.5

2

23 LSP25-00014-DX Gear Pump Connector 1

24

9101-12100-DX8.8

Hex Bolt M12x100

2

25

LSP30-10001

Gear Pump

1

26 LSP25-13000

New

Oil Bolt 1

27

LSP25-10003

Gear Pump Connector

1

28

LSP25-10002

Engine Connector

1

29 LSP25-10004-DX Engine Axle Sleeve 1

30

LSP25-10005

Gear Pump Stand

1

31

9206-08000-DX

Nylon Lock Nut M8

8

32

9306-08000-DX

Lock Washer Ø8

12

33

LSP25-10001

Engine

1

34

LSP25-10006

Connector Cover

1

35

LSP25-14000

Wheel

2

36

9301-08000-DX

Flat Washer Ø8

8

37

LSP25-00020-FH

Hex Slotted Thin Nut M20

2

38

LSP25-00019-DX

Angle Connector

1

39

LSP25-00007

Oil Fitter

1

40

9404-03030-DX

Cotter Pin Ø3x30

3

PARTS DRAWING & PARTS LIST

19

REF#

DRAWING NO.

DESCRIPTION

QTY

41 LSP25-00009-DX Axle Cap 2

42

LSP30-00006

Rubber Washer

1

43

LSP25-10008-FH

Steel Wire Snap Ring for Shaft

1

44

LSP30-03000

Oil Tank

1

45

9301-06000-DX

Flat Washer Ø6

6

46

9101-08065-DX8.8

Hex Bolt M8x65

4

47

9101-06020-DX8.8

Hex Bolt M6x20

6

48

LSP30-15000-DX

Filter Fixed Plate

1

49

LSP25-09000

Oil Return Filter

1

50

LSP25-00007-DX

Connector

1

51

LSP25-00011-DG

Clamp

2

52

N29W-00001

Plate

1

53

LSP25-00018

Oil Pipe

1

54

9301-20000-DX

Flat Washer Ø20

2

56

LSP25-00003-DX

Spring

3

57

9101-08025-DX8.8

Hex Bolt M8x25

4

59

LSP30-07000

Support Leg

1

60

9304-62000-FH

Steel Wire Snap Ring for Shaft Ø62

1

61

LSP25-00008-DX

Safety Pin

2

62

LSP30-04000

Tow Bar

1

63

LSP25-11000-DX

Chain

2

64

9110-08010-DX

Screw M8x10

4

65

9301-12000-DX

Flat Washer Ø12

11

66

Z103

Coupler

1

67

9101-12080-DX8.8

Hex Bolt M12x80

2

68

LSP25-00015-DX

Thick Washer Ø12

2

69

9101-12090-DX8.8

Hex Bolt M12x90

1

70

9306-06000-DX

Lock Washer Ø6

6

71 9901-17X2.5 O Ring Ø17x2.5 2

72 9101-08030-DX8.8 Hex Bolt M8x30 4

73

9404-04036-DX

Cotter Pin Ø4x36

2

74 9206-14000-DX

Nylon Lock Nut M14

1

75

/

Gear Pump Flat Key

1

76

/

Engine Flat Key

1

20

ATTACH THE LOG CRADLE TO THE BEAM WITH THE Ø12 FLAT WASHERAND

M12 LOCK NUT.

LOG CRADLE

Ø12 FLAT WASHER

M12 LOCK NUT

This manual suits for next models

1

Table of contents

Other Titan Attachments Log Splitter manuals

Popular Log Splitter manuals by other brands

Clarke

Clarke LOGBUSTER 10 Operation & maintenance instructions

AL-KO

AL-KO KHS 3704 Translation of the original instructions for use

MTD

MTD 522 owner's guide

SpeeCo

SpeeCo SplitMaster 401622BL owner's manual

GÜDE

GÜDE GHS 1000/9TE Translation of the original instructions

Meec tools

Meec tools 721-485 operating instructions

Far Tools

Far Tools FBV 10C Original manual translation

Hudson

Hudson HDH-1 Operator's manual

woodmizer

woodmizer MP100 E5S Safety, Setup, Operation & Maintenance Manual

Far Tools

Far Tools FB 5T Original manual translation

B.W. Machinery

B.W. Machinery LS30 Series user manual

Bluesky

Bluesky LSF-001 owner's manual