Titan Attachments 12PRESS1 User manual

12 TON SHOP PRESS

12PRESS1-12PRESS2

840020

Operator’s Manual

Read the Operator’s Manual entirely. When you see this

symbol, the subsequent instructions and warnings are

serious follow without exception. Your life and the lives

of others depend on it!

Cover photo may show optional equipment not supplied

with standard unit. For an Operator’s Manual and Decal

Kit in French or Spanish Language, please see your dealer.

2

PARTS DIAGRAM / EXPLODED VIEW

3

GENERAL COMMENTS

Congratulations on the purchase of your new TITAN product! This product was carefully designed

and manufactured to give you many years of dependable service. Only minor maintenance (such

as cleaning and lubricating) is required to keep it in top working condition. Be sure to observe all

maintenance procedures and safety precautions in this manual and on any safety decals located

on the product and on any equipment that you use in conjunction with this product.

This manual is designed to help you do a better, safer job. Read this manual carefully and become

familiar with its contents. SAVE THIS MANUAL FOR FUTURE REFERENCE!

UNPACKING INSTRUCTIONS

INSTRUCTION WHEN UNPACKING THE TOOL:

•Carefully remove the tool and accessories from the box.

•Make sure that all items listed in the packing list are included.

•Inspect the tool carefully to make sure no breakage or damage occurred during shipping.

•Do not discard the packing material until you have carefully inspected and successfully

operated the tool.

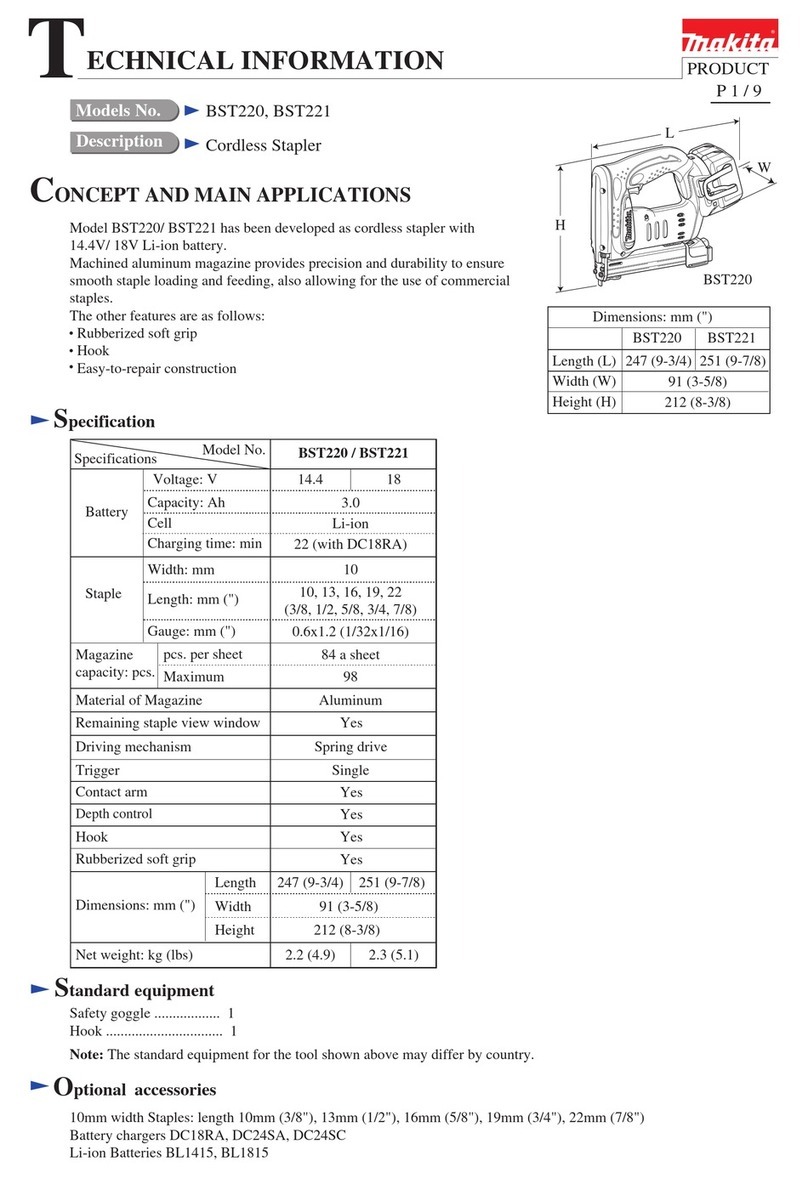

KEY DESCRIPTION QTY KEY DESCRIPTION QTY

(1) BOLT M12X110 4 (13) M10 NUT 12

(2) 12 WASHER 4 (14) BOLT M10X25 4

(3) 12 SPRING WASHER 4 (15) UPPER BEAM 1

(4) M12 NUT 4 (16) POST 2

(5) SPRING 2 (17) PUMP BASE 1

(6) PUMP 1 (18) BLOCK 2

(7) BOLT M8X20 2 (19) FRAME 1

(8) M8 BOLT 2 (20) BASE SUPPORT 4

(9) M8 NUT 2 (21) BASE SECTION 2

(10) LONG PIN 2 (22) PLANK 1

(11)

BOLT M10X20

8 (23) HANDLE 1

(12)

10 WAHSER

12

4

WARNING

WARNINGS:

Safety, performance, and dependability have been given top priority in the design of this TITAN

product making it easy to maintain and operate.

WARNING:

Do not attempt to use this product until you thoroughly read and completely understand the

operator’s manual. Pay close attention to the safety rules, including Dangers, Warnings, and

Cautions. If you use your product properly and only as intended, you will enjoy years of safe,

reliable service.

WARNING:

The operation of any tool can result in foreign objects being thrown into your eyes, which can

result in severe eye damage. Before beginning operation, always wear ANSI-approved safety

goggles and heavyduty work gloves. WARNING: When using the tool basic safety precautions

should always be followed to reduce the risk of personal injury and damage to equipment!

WARNING:

The warnings, cautions, and instructions discussed in this instruction manual cannot cover all

possible conditions and situations that may occur. It must be understood by the operator that

common sense and caution are factors which cannot be built into this product but must be

supplied by the operator.

WARNING:

NEVER operate this machine if the arbor plates are uneven – this can cause them to break. Any

obstruction under the arbor plates can cause this to happen.

WARNING:

ALWAYS align your items vertically prior to pressing them together, otherwise one or both items

may eject itself sideways from your press at a high velocity and force.

WARNING:

ALWAYS check your bottle jack to make sure it is working properly prior to actual use. If it does not

appear to be working properly, troubleshoot prior to actual use. Bleeding the bottle jack is

recommended when it does not appear to be working properly.

WARNING:

Change your hydraulic fluid – we recommend a minimum of once every three years.

WARNING:

DO NOT EXEED the stated limit or operate the jack beyond its rated capacity

5

WARNING:

NEVER USE THIS PRESS IF ANY PART

OF IT SEEMS TO BE DAMAGED OR

MALFUNCTINING! THIS CAN BE

HIGHTLY DANGEROUS

6

GENERAL SAFETY RULES

•Work area conditions. Cluttered

areas invite injuries.

•Additional work area conditions. Do

not use machines or power tools in

damp or wet locations. Do not expose

to rain. Keep work area well lit.

•Keep children away. Children must

never be allowed in the work area. Do

not let them handle machines, tools or

extension cords.

•Store idle equipment. When not in

use tools must be stored in a dry

location to inhibit rust. Always lock up

tools and keep them out of the reach

of children.

•Use the right tool for the job. Do not

attempt to force a small tool or

attachment to do the work of a larger

industrial tool. There are certain

applications for which this tool was

designed. It will do the job better and

safer at the rate for which it was

intended. Do not modify this tool and

do not use this tool for a purpose for

which it was not intended.

•Dress properly. Do not wear loose

clothing or jewelry as they can get

caught in moving parts. Protective,

electrically non-conductive clothing

and non-skid footwear are

recommended when working. Wear

restrictive hair covering to contain

long hair.

•Use eye protection. Always wear

ANSI-approved impact safety glasses

underneath a full-face shield during

use. Also wear heavy duty work

gloves.

•Do not over reach. Always keep

proper footing and balance. Do not

reach over or across running

machines.

•Maintain tools with care. Keep tools

sharp and clean for better and safer

performance. Follow instructions for

lubricating and changing accessories.

The handles must be kept clean, dry,

and free from oil and grease always.

•Remove adjusting keys and

wrenches. Check that the keys and

adjusting wrenches are removed from

the tool or machine work surface

before starting work.

•Stay alert. Watch what you are doing.

Use common sense. Do not operate

any tool when you are tired.

•Check for damaged parts. Before

using any tool, any parts that appear

damaged should be carefully checked

to determine that it will operate

properly and perform its intended

function. Any part that is damaged

should be replaced.

•Replacement parts and accessories.

When servicing use only identical

replacement parts. Use of any other

parts will void the warranty. Only use

accessories intended for use with this

tool. Approved accessories are

available from our company.

•Do not operate tools if under the

influence of alcohol or drugs. Read

warning labels on prescriptions to

determine if your judgment or

reflexes are impaired while taking

drugs.

7

ASSEMBLY INSTRUCTIONS

USE THE PARTS DIAGRAM AND TABLE AS YOUR GUIDE FOR THIS ASSEMBLY. ASSEMBLY WITH

TWO OR MORE PEOPLE IS MUCH SAFER AND EASIER THAN ASSEMBLING THIS PRESS ALONE!

1. Lay out all the pieces in front of you in an organized fashion so that you can easily access them

throughout assembly.

2. Start at the bottom by assembling the base sections to the frame supports, followed by the

bottom frame support and the base section supports. Use the bolts, washers, and nuts as

numbered in the parts diagram.

3. At this stage, place the base of your press in the location where it will be used, and bolt it to the

floor using appropriate hardware (not included) using the pre-drilled holes in the base

sections. Appropriate hardware will be dependent on what type of floor you are Ensure that

your base is stable prior to proceeding with the assembly.

4. Next, install the upper beam using the bolts, washers, spring washers, and nuts as shown in

the parts diagram. BEFORE TIGHTENING FULLY: check to make sure the assembly is square.

5. Put your support pins into the holes on the frame posts. Note: put them somewhere below the

top holes in the initial set up so that you have room to install your jack plate.

6. Set the press apron on top of your support pins – you will have to angle the press apron to

make it fit inside your frame posts, leveling it out as you lower it onto the support pins.

7. Secure the eye bolts to the jack plate PRIOR to installation of the jack plate. Then, put the jack

plate (with eye bolts installed) onto the press apron – you will again have to angle it initially to

make it fit between your frame posts, leveling it out as you lower it onto the press apron.

8. Hang your springs onto the spring hangers on the upper beam.

9. Be sure to check fluid levels, bleed, and fully test your bottle jack prior to installation.

10. Place the bottle jack on the center of the jack plate, aligning it with the two mounting holes.

Secure it with the two bolts as shown in the parts diagram.

11. Now, slide your jack plate into place and secure the springs to the eye bolts. Note: the bottle

jack will fit in the bracket on the bottom of the upper beam.

8

ACKNOWLEDGEMENT OF RISK AND RELEASE OF LIABILITY

The use of any equipment, including this one, involves the potential risk of injury. Apart from any

warranty claim that might be presented for a claimed defect in material or workmanship of the product,

you accept and assume full responsibility for any and all injuries, damages (both economic and non-

economic), and losses of any type, which may occur, and you fully and forever release and discharge

Titan, its insurers, employees, officers, directors, associates, and agents from any and all claims,

demands, damages, rights of action, or causes of action, present or future, whether the same be known

or unknown, anticipated, or unanticipated, resulting from or arising out of the use of said equipment.

This equipment must be used with care by capable and competent individuals under supervision, if

necessary.

WARNING

Do not overfill! Mower should be level

when checking oil in gear box.

some activities might be able to cause

electric shock

Sharp objects may be involved.

Use protective cover during maintenance.

TITAN LIMITED WARRANTY: TERMS, EXCLUSIONS AND LIMITATIONS OF REMEDIES

This product comes with a one (1) year limited warranty that can be found at

www.palletforks.com/warranty.html. Please review the same for all details regarding the Titan Limited

Warranty.

THE TITAN LIMITED WARRANTY FOUND AT WWW.PALLETFORKS.COM/WARRANTY.HTML IS

EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR PURPOSE, EACH

OF WHICH IS HEREBY DISCLAIMED.

9

NEED HELP? CONTACT US FIRST.

1-800-605-7595

info@palletworks.com

www.palletforks.com

© 2021 Titan Brands

This manual suits for next models

2

Other Titan Attachments Power Tools manuals

Popular Power Tools manuals by other brands

EINHELL

EINHELL TE-CD 12 Li Original operating instructions

VARO

VARO Powerplus POWEB2530 instructions

Hilti

Hilti TE 300-A36 Original operating instructions

Triton

Triton mof001 Operating/safety instructions

Higo

Higo HHG-2000 Translation of the original instruction manual

Makita

Makita BST220 technical information

pellenc

pellenc C35 operating instructions

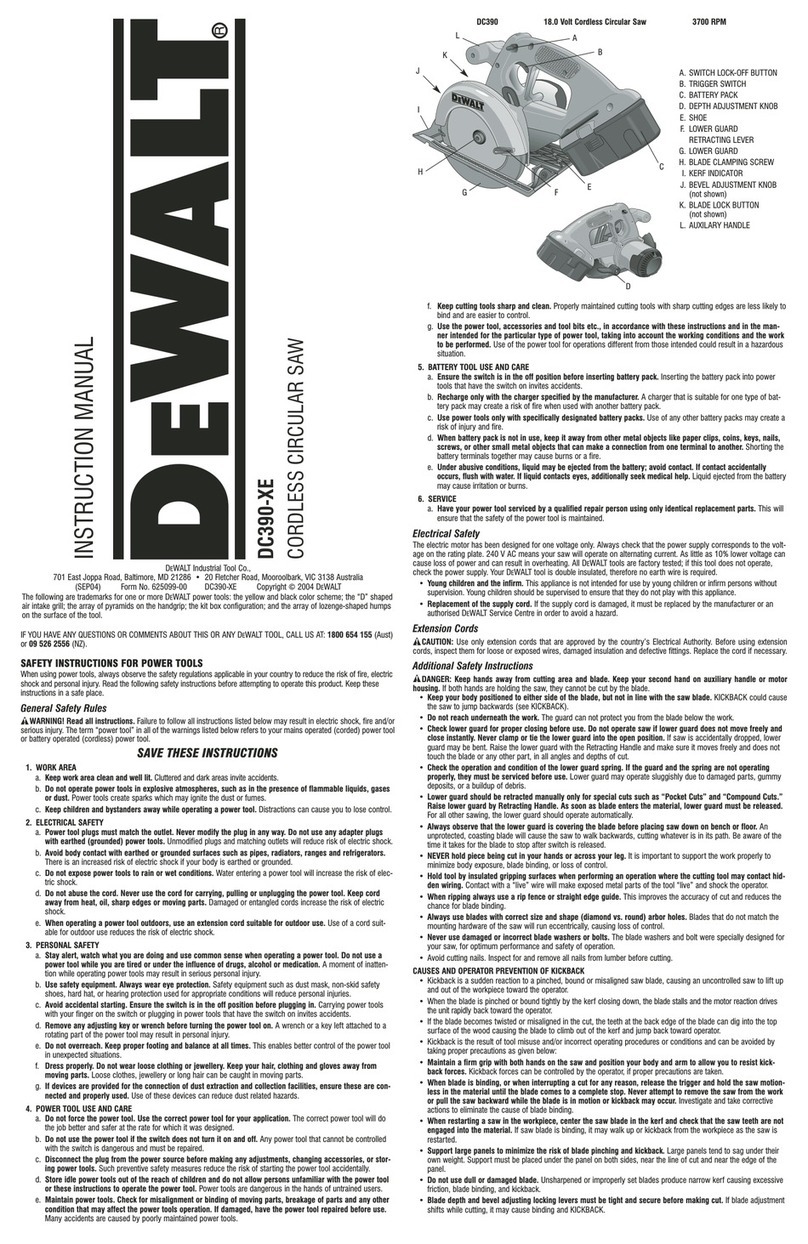

DeWalt

DeWalt DC390-XE instruction manual

Draper

Draper PT1200 instructions

Central Pneumatic Professional

Central Pneumatic Professional 42248 Set up and operating instructions

Josef Kihlberg

Josef Kihlberg JK20 Repair instructions

WAGNER

WAGNER FURNO 300 2363333 owner's manual