P 3/ 9

[4]-2. Disassembling Motor, Switch, Terminal

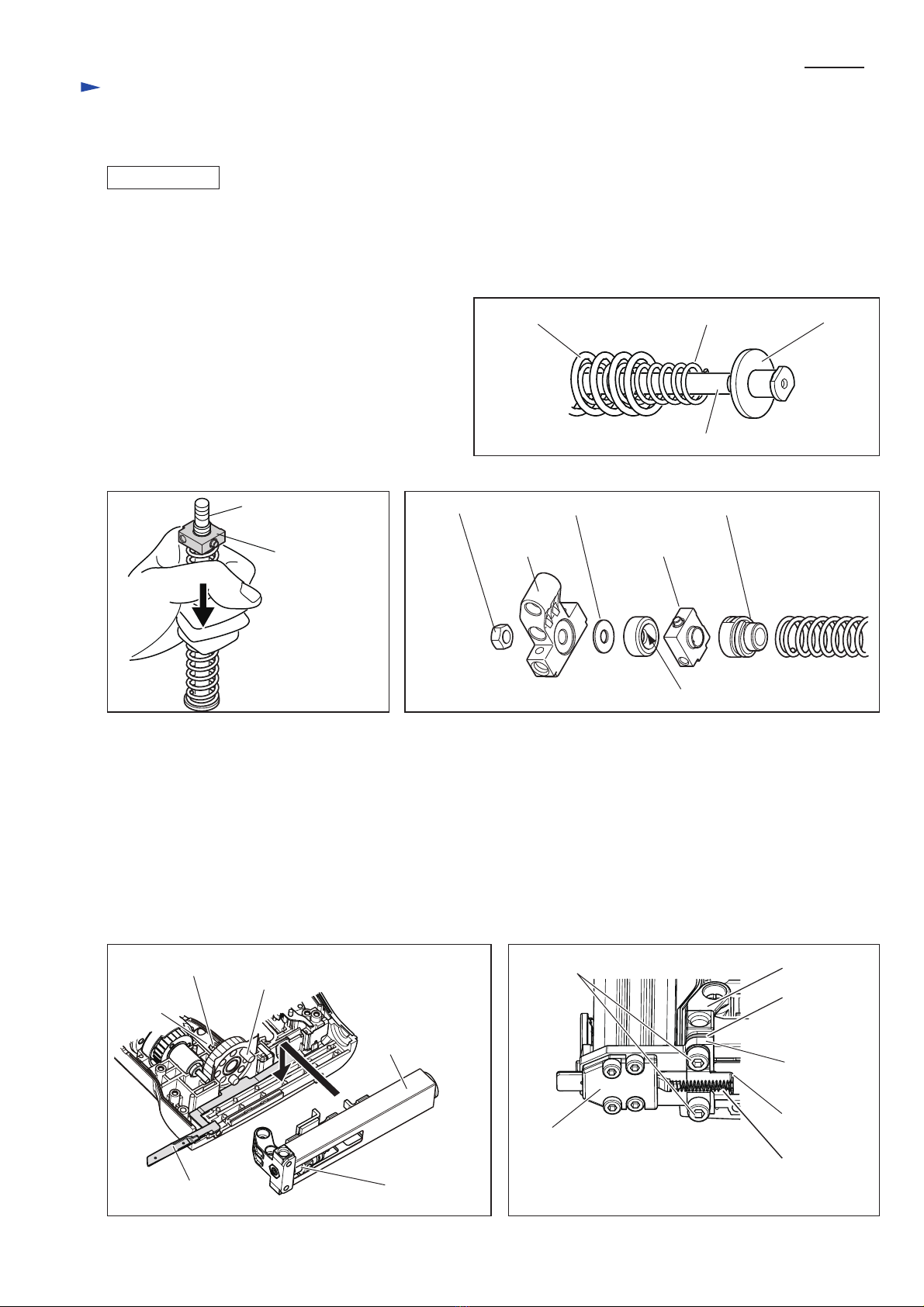

1) Remove 4x18 Tapping screws (4pcs.) and Front cover. (Fig. 2)

2) Slide Upper plate out of the grooves, then pull out Pin 4 for connecting Driver and Hammer. (Fig. 3)

Driver can be replaced.

3) Take the disassembling step in reverse. Face the hole of Driver to the upper side.

The chamfered corner of Driver is allowed to face either right or left side. (Fig. 3)

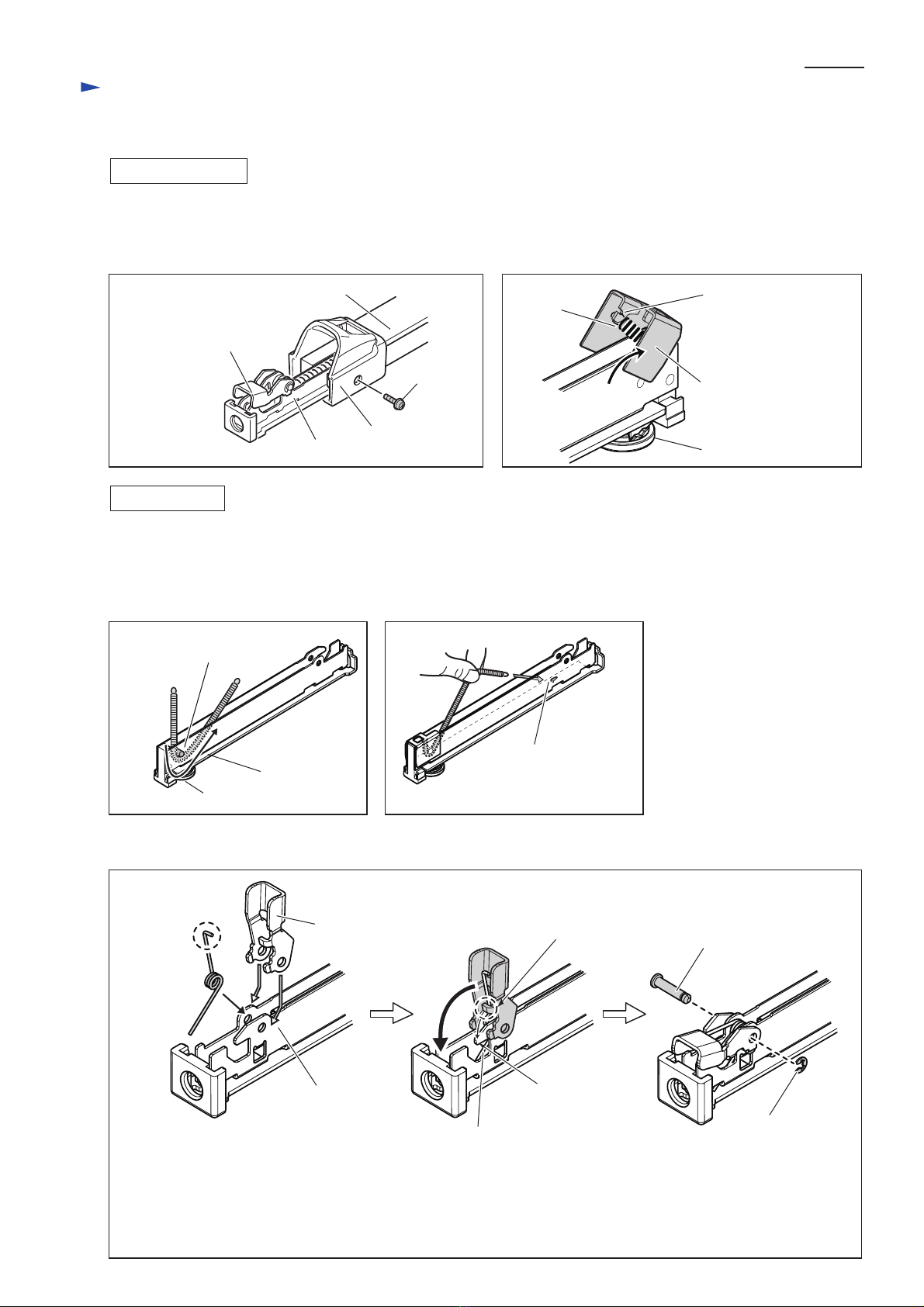

1) Remove Front cover, 4x18 Tapping screws (4pcs.), Upper plate, Pin 4 and Driver.

2) Remove Compression spring 4. (Fig. 8)

3) When Hammer is not located at the lowest position (i.e., the left illustration of Fig. 4);

1. Install Battery.

2. Pull Trigger in a blink and release it repeatedly until Hammer reaches the lowest position. (the right illustration of

Fig.4)

The pressure of Compression springs is now disappeared. Remove Battery.

4) Remove 4x18 Tapping screws (6pcs.), M4x10 Pan head screws (2pcs.), M4x35 Pan head screws (2pcs.) and Housing R

while holding Trigger to prevent popping out. (Fig. 5) Switch and Terminal can be replaced.

5) Remove Spur gear 55 complete, and then lever up Spur gear 7 complete with slotted screwdriver. (Fig. 6)

Internal gear 69, DC motor and their linked parts come with Spur gear 7 complete.

[4] DISASSEMBLY/ ASSEMBLY

[4]-1. Replacing Driver

Repair

Fig. 2

4x18 Tapping

screws (4pcs.)

Front cover

Driver

Upper plate

Fig. 4 Fig. 5

Fig. 3

chamfered

corner

hole

Pin 4

Upper side

Lower side

Upper side

Hammer

M4x35 Pan

head screws

(2pcs.)

4x18

Tapping

screws

(6pcs.)

M4x10 Pan head screws (2pcs.)

Lower side

Note: In the event of failure on Motor and Switch, Compression springs

in Driving section remain compressed.

Consequently, DC motor can not be removed due to the pressure.

Therefore, take the following step while holding the around of Trigger

with cloth to prevent popping out.

(Be careful not to pinch your hand between Hammer and Cushion.)

1. Insert slotted screwdriver between the gear teeth of Spur gear 7

complete.

2. Revolve Spur gear 7 complete by moving a gear tooth to the direction

designated in white arrow with the slotted screwdriver.

Fig. 6

Spur gear 7 complete

Spur gear 7

complete

slotted

screwdriver

Fig. 7

Internal gear 69, DC motor

and their linked parts