Titan Dynamics Comet User manual

Titan Dynamics

Titan Dynamics Webpage

Visit our Facebook page

Join our Discord server

Page 2of 25

Contents

Section 1: Model Information ................................................................................................................. 3

Section 2: Model Specifications & Performance............................................................................... 4

Section 3: Required Build Materials ...................................................................................................... 5

Section 4: 3D printing ................................................................................................................................ 7

4.1: Things to know before you start printing. .............................................................................. 7

4.2: Part Orientation............................................................................................................................... 8

4.3: Tuning “hole horizontal expansion”........................................................................................... 9

4.4: Bed Adhesion and warping........................................................................................................... 9

Section 5: Assembly of 3D Printed Parts ...........................................................................................12

Section 6: Final Setup & Tuning Tips ...................................................................................................17

Section 7: Additional Images .................................................................................................................18

Titan Dynamics

Titan Dynamics Webpage

Visit our Facebook page

Join our Discord server

Page 3of 25

Section 1: Model Information

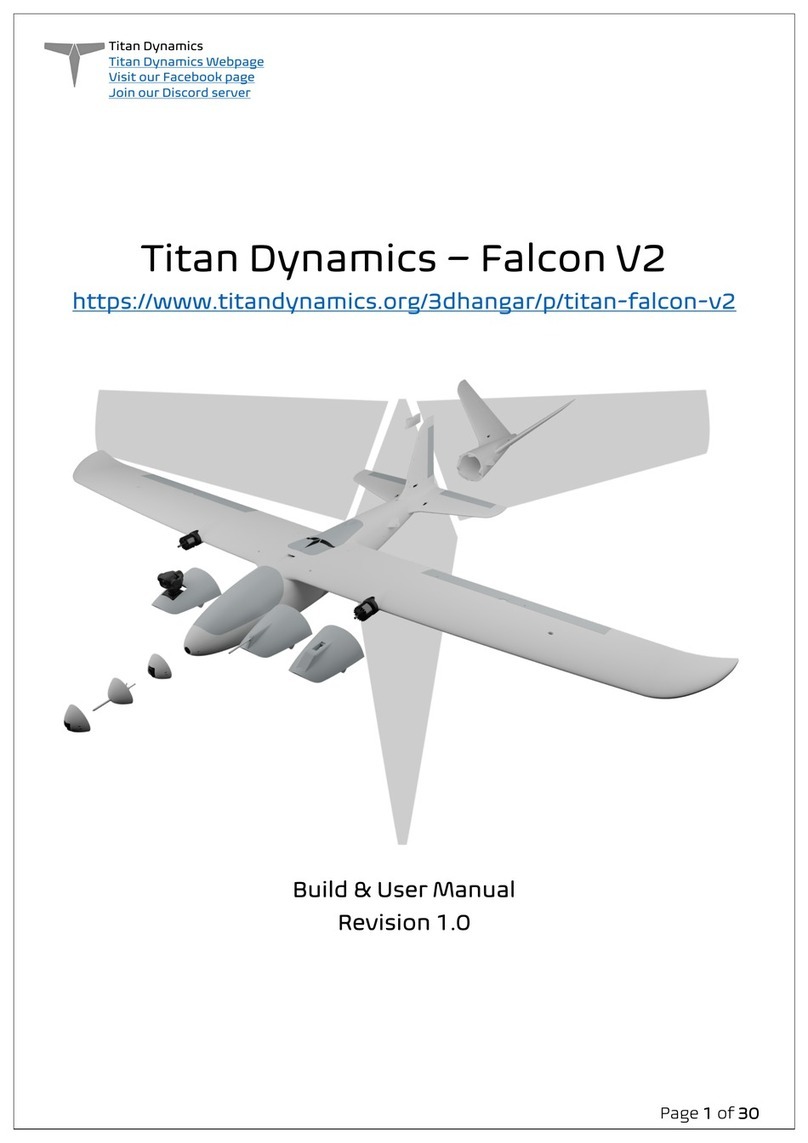

Introducing the Titan Comet, a 1.46m wingspan twin tractor UAV built for the ultimate

FPV and mapping experience. The Comet is ultra-efficient and can fly for up to 4.5 hours

and 330km on one charge.

Incredible attention to detail has gone into making Comet lightweight yet structurally

rigid. The motors for Comet are commonly sized (2212/2216 up to 28xx) and flush

mounted to the nacelles. The Comet comes equipped with a double decker FPV deck

suitable for action cameras, gimbals, or pan/tilt setups. It’s got enough room in the

fuselage to fit your entire arm through the rear hatch or front canopy. Additionally,

there’s optional fuselage sections that allow for mounting a mapping camera in the belly

and external antennas. The elevator and rudder servos are concealed and serviceable via

the removable stabs. The wings are also removable for transport. Just like the Falcon,

the wings feature large bays underneath for mounting VTX/RX or other high temp

equipment with ample antenna separation. All control surfaces feature nearly 0 gap with

rounded leading edges that are sunk into the wings/stabs.

Titan Dynamics

Titan Dynamics Webpage

Visit our Facebook page

Join our Discord server

Page 4of 25

Section 2: Model Specifications & Performance

General Stats:

•Wingspan: 1450mm

•Wing area: 3316cm2

•Maximum take-off Weight: 4.5kg

•Efficiency: 1.3Wh/km

•Cruise speed: 45-65kph

•Maximum prop diameter: 10 inches

Aerodynamic Properties:

•Root airfoil: NACA 5412

•Tip airfoil: NACA 2410

•Root chord: 240mm

•Tip chord: 205mm

•Average Chord: 219mm

•Root incidence: 3°

•Tip incidence: 1°

•Aspect ratio: 6.29

•Max L/D: 13.1

•Dihedral: 2°

•Sweep: 0°

Titan Dynamics

Titan Dynamics Webpage

Visit our Facebook page

Join our Discord server

Page 5of 25

Section 3: Required Build Materials

Spars needed:

(2) 8x500mm (main wing spars)

(2) 8x500mm (wingtip support)

(2) 4x400mm (aileron hinge)

(1) 3x200mm (hstab support)

(1) 3x60mm (vstab support)

(1) 3x200mm (rudder hinge)

(1) 3x500mm (elevator hinge)

Recommended motor & prop:

Recommended motor 2212 or 2216 –maximum size 28xx

Counterrotating 8-10” propellers

Recommended electronics:

TBS crossfire / ELRS / Dragonlink.

5.8ghz / 1.2ghz video (19x19 camera).

Matek F405-WTE flight controller or similar.

Matek M8Q-5883 GPS/Compass or similar.

(2) 35a BLHeli ESCs (place in the fuselage).

(4) Emax ES08MAII servos. 2 for ailerons, 1 for elevator, 1 for rudder (and one more if you

want a servo for a pan camera on the FPV deck).

Example battery for beginners:

Example battery for medium endurance:

Example battery for max endurance:

Misc:

2 750g rolls of Polymaker Polylite prefoamed LWPLA.

Polycarbonate, PETG or other high-temp filament for the motor mount.

Medium CA glue.

220x220x250 minimum size print bed (Ender 3).

Control horns (this one).

M3 threaded inserts (max 6mm height).

M3 bolts of various sizes.

(4) 6x3mm magnets

Titan Dynamics

Titan Dynamics Webpage

Visit our Facebook page

Join our Discord server

Page 7of 25

Section 4: 3D printing

4.1: Things to know before you start printing.

1. Titan Dynamics strongly recommends using Polymaker Polylite prefoamed LWPLA

for the best results. This filament is much easier to tune your printer for and has

less stringing than active foaming filaments.

2. You likely will not get good results unless your printer is well maintained and

calibrated, we would suggest learning how to check and adjust your printer to

perform at its absolute best before starting. This website has useful guides:

https://teachingtechyt.github.io/calibration.html#intro.

3. All the below guidance should be taken as a starting point only. Print a test piece

and check things like retraction settings and fitment of the carbon rods in the

wings for yourself as every printer is different. If the carbon rods are too tight,

increase the “Hole Horizontal Expansion” setting in Cura (or the equivalent setting

in other slicers).

4. All our models are designed to be printed predominantly in LW-PLA filament. All

fuselage, tail, and wing parts should be printed in LW-PLA.

There are 3 levels of infill / wall settings that we recommend for the LWPLA parts:

1. Maximum efficiency: 3% cubic subdivision, single wall

2. Balanced efficiency and strength: 5% cubic subdivision, single wall

3. Maximum strength: 8% cubic subdivision, single wall

Notes:

•For the best flight characteristics and maximum range, LWPLA parts should be

printed with single wall and 3% cubic subdivision infill.

•Cubic subdivision infill can be increased to 5 or 8% to increase durability, but this

will have an impact on maximum payload capacity (battery), and range by

extension. We recommend and use 3% cubic subdivision infill as it has been tested

to survive 6.4G in flight, but some may desire greater general durability when

handling/carrying the model around etc. It will still break if you crash it!

•Because the fuselage takes the most abuse during landings, some may choose to

just print the fuselage sections in higher infill. Using a higher infill just for the

fuselage (4%-8%) can greatly increase the longevity of the plane without as much

of a weight penalty as printing the entire plane in high infill.

Polycarbonate, PETG or other high-temp filament should be used for the motor nacelle

caps and wing bay covers.

•High temp Polycarbonate or PETG parts should be double wall and high infill (25%).

Titan Dynamics

Titan Dynamics Webpage

Visit our Facebook page

Join our Discord server

Page 8of 25

We recommend using the newest version of Ultimaker Cura. This link can be used to

download our own slicer profile.

4.2: Part Orientation

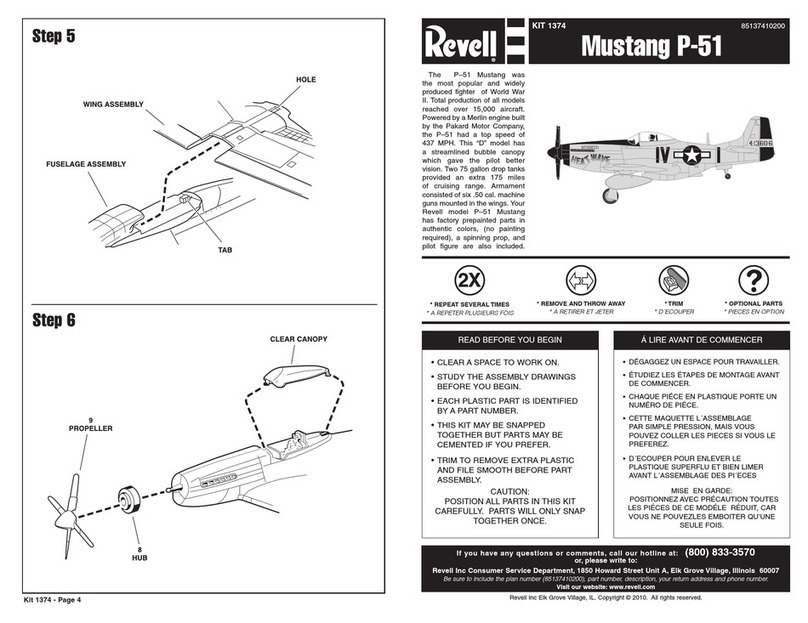

It is necessary to orient each part correctly on the build plate to avoid disconnected

overhangs. Take care when doing this as the entire model is designed to be printed with

no supports. If you orient some parts wrong, the print will fail. It may also be necessary

to rotate and carefully position some parts to fit within the build area on smaller

printers.

Examples for part orientation:

Fuse 1

Fuse 3

Titan Dynamics

Titan Dynamics Webpage

Visit our Facebook page

Join our Discord server

Page 9of 25

Wing 2

Wing 1

4.3: Tuning “hole horizontal expansion”

It is very important to check the fitment of the carbon rods in their holes on the first

parts you print. Because everyone may be using different printers, materials and slicer

settings, it is not possible to provide the models with a slicing profile and hole size that

will work for everyone.

Print your first part with carbon spar hole and check fitment, if it is too tight increase the

hole horizontal expansion setting in the “walls” section in Cura (or your slicer’s similar

setting). A good starting point is 0.25mm. If it is too loose, just decrease the setting until

you can reliably push the rods in and still get a snug fit.

4.4: Bed Adhesion and warping

When printing tall parts like this model requires, having good print adhesion to the bed is

a necessity. Ideally you will print each part without any extra aids, however this may not

be possible for many, especially those printing without an enclosure for their printer. A

full brim can be used but this will typically have mixed results. If it works for you, use a

Titan Dynamics

Titan Dynamics Webpage

Visit our Facebook page

Join our Discord server

Page 10 of 25

glue stick on the print surface to improve adhesion. Cura also has a plugin that can be

used to help with bed adhesion and to avoid warping.

Cura Marketplace: TabAntiWarping Plugin.

When installed, use the new icon at the bottom of the left menu to choose tab diameter

and thickness, then click on the model to add a tab at each point you think is at risk of

warping or poor adhesion (typically parts with low surface area in contact with the print

surface in relation to their height). These new tabs can now be moved around to fine

tune their position using the normal move controls on Cura.

Titan Dynamics

Titan Dynamics Webpage

Visit our Facebook page

Join our Discord server

Page 11 of 25

Once completed, be careful when removing these tabs from the print as they are quite

strong and can damage the bottom of your part if not removed carefully. Re-open any

holes the tab may have filled on the bottom of the print.

If you find these hard to remove from the print bed, select the “Define as Capsule”option.

This makes the edge of the tabs raised, so you can get a scraper underneath them.

Titan Dynamics

Titan Dynamics Webpage

Visit our Facebook page

Join our Discord server

Page 14 of 25

The spar layout for Comet is as depicted below. None of the spars need to be glued in,

they will all be retained by the printed parts. The two wing spars that intersect the

fuselage are the joiners for the wings and the fuselage and can be removed completely

from the fuselage and wing during transport.

Titan Dynamics

Titan Dynamics Webpage

Visit our Facebook page

Join our Discord server

Page 15 of 25

•Medium CA glue should be used to assemble all fuselage parts

•When first putting the glued parts together be sure to wipe any excess glue off

before it sets. A kicker may then be used to speed up the setting time; technically

this results in a weaker joint, however it will still be stronger than the base material

LW-PLA.

•Use care when aligning parts for gluing. With medium CA, you should have a few

seconds to get alignment right. Small mistakes in alignment can stack up and

eventually lead to a part not fitting perfectly. We have taken care when designing

Titan Dynamics

Titan Dynamics Webpage

Visit our Facebook page

Join our Discord server

Page 16 of 25

the aircraft to make sure there is tolerance for some minor mistakes, but try to be

as perfect as possible when gluing.

•When gluing the wings together, use the carbon rods to ensure alignment however

be careful not to glue them in, they should not be glued in on the final product.

•IMPORTANT! - Do not glue the wing tips on until you have the carbon rod and

aileron/flap installed as it’s the wing tip that secures these in place. If you glue the

wing tip on before inserting the control surfaces + carbon rod you will not be able

to insert them afterwards.

•Threaded inserts can be properly installed by using a soldering iron at low heat

setting, a good guide for doing this can be found at this link.

Titan Dynamics

Titan Dynamics Webpage

Visit our Facebook page

Join our Discord server

Page 17 of 25

Section 6: Final Setup & Tuning Tips

•Titan Dynamics strongly recommends the use of Arduplane for all our models.

•Give all control surfaces +- 35 degrees or more throw. The Comet has extremely

effective flaperons, and should be configured as such in Ardupilot.

•Setup motor rotation such that props rotate inwards towards the fuselage for

added torque roll during differential yaw.

•Take-off does not require flaps, but landing can be done easier with half flaps.

•CG is marked under the wing, however, is very forgiving +/- 10mm.

•Add duct tape or other abrasion resistant material to bottom of the fuselage to

increase durability if landing on rough surfaces.

Table of contents

Other Titan Dynamics Toy manuals

Titan Dynamics

Titan Dynamics Falcon V2 User manual

Titan Dynamics

Titan Dynamics Raven User manual

Titan Dynamics

Titan Dynamics Eagle User manual

Titan Dynamics

Titan Dynamics Hawk User manual

Titan Dynamics

Titan Dynamics Hornet VTOL User manual

Titan Dynamics

Titan Dynamics Quail User manual

Titan Dynamics

Titan Dynamics Viper User manual