TITAN MODEL KITS 747-8i User manual

1:72 747-8i /8f

Assembly Guide

Thank you for purchasing a Titan Model Kit. These kits are intended for experienced intermediate to

advanced adult scale modelers. Kits will require you to measure, mark, cut, scratch-build, and modify

various pieces. Builders are cautioned to review the assembly instructions in their entirety prior to

beginning any work. These instructions are provided only as a guide. You may choose to alter the

sequence of steps, change techniques, or omit steps at your discretion. You will find the following

tools useful in your build: hobby knife, dial calipers, ruler or measuring tape, drill with various bit sizes,

rotary tool (Dremel or equivalent), sand paper of various grit, sanding block, styrene model cement

(solvent based), and cyanoacrylate glue (Superglue or equivalent).

Assembly instructions may contain images that do not correspond precisely to the physical kit parts.

Physical parts are in a state of continuous improvement and you may have earlier or later versions of

an individual part or kit than what is shown in the assembly instructions. The images are intended to

provide you with general orientation only. Additionally some images are used to illustrate concepts

which are common to multiple kits.

Screenshots of CAD models are used for concept illustration only and the images may contain

elements that may or may not be present in the physical parts. For instance, cabin window and door

outlines are shown in these images to help in visual orientation and are not present in the physical

parts. Screenshots may omit adjacent parts for clarity.

© Titan Model Kits 2 Revision 1.2 26 Aug 2022

Table of Contents

I. Parts Preparation

A. Vacform Parts

1. Remove parts from sheet

2. Remove stock thickness

3. Thin trailing edges

4. Drill out engine and flap track attachments

5. Cut out wing & tail passthroughs

6. Install 90° angle styrene reinforcement strips

7. OPTION: Landing Gear Cutouts

B. Resin Parts

1. Remove support columns

II. Assembly

A. General

B. Instructions

1. OPTION: Install wheel wells

2. Install APU

3. Assemble horizontal tail

4. Assemble wing top and bottom

5. OPTION: Install clear cockpit windows

6. Assemble fuselage halves

7. Join the wings

8. Install flap track fairings

9. Install engines

10. Install wingtips

11. OPTION: Assemble and install landing gear

12. Install antennas and red beacons

III. References

© Titan Model Kits 3 Revision 1.2 26 Aug 2022

I. PARTS PREPARATION

I.A VACFORM PARTS

I.A.1. Remove parts from sheet:

Carefully remove the parts by cutting along the silhouette of the part with a sharp utility knife.

You may find it helpful to mark the cut lines with pencil prior to cutting. Always cut from the

top of the parts, never from the bottom. Multiple shallow passes will always yield a better

result than trying to cut through on a single pass.

.

© Titan Model Kits 4 Revision 1.2 26 Aug 2022

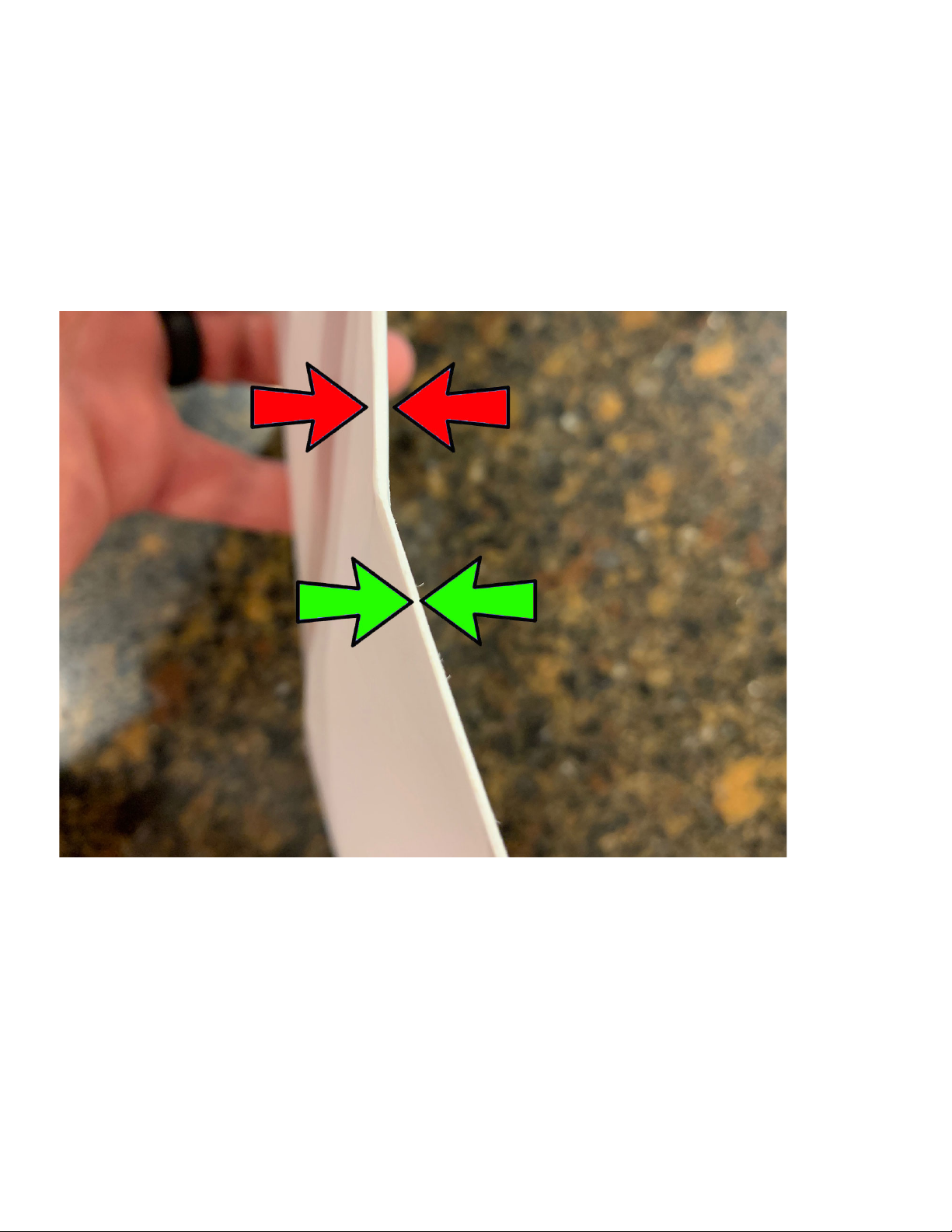

I.A.2. Remove stock thickness:

Once parts are cut away from their sheet they will still need to have the sheet thickness

removed from them. As can be seen from the below photo, the .090” sheet thickness

between the red lines should be removed. Coarse sandpaper in a sanding block is

recommended to remove this material. Work slowly, checking progress often.

© Titan Model Kits 5 Revision 1.2 26 Aug 2022

I.A.3. Thin trailing edges:

As delivered, the trailing edges of the wings and tail parts are the thickness of the plastic

sheet used to produce them. If left alone, assembling raw parts will result in a trailing edge

that is too thick for scale. Using 220 grit sandpaper, thin all trailing edges from the .090”

material thickness to approximately .010”. Work slowly, checking thickness and consistency

as you go. This will result in trailing edges that are more “to-scale”

© Titan Model Kits 6 Revision 1.2 26 Aug 2022

I.A.4. Drill out engine and flap track attachments:

Engine and flap track fairing attachment points should be drilled out with a ⅛” (3mm)

brad-point drill bit. Hole diameter may then need to be enlarged to accommodate certain

engines.

© Titan Model Kits 7 Revision 1.2 26 Aug 2022

I.A.5. Cut out wing & tail passthroughs

Remove plastic to allow for the wing and tail assemblies to pass through the fuselage halves

as shown. The attached templates can be scaled and used to help you know exactly where

to cut.

© Titan Model Kits 8 Revision 1.2 26 Aug 2022

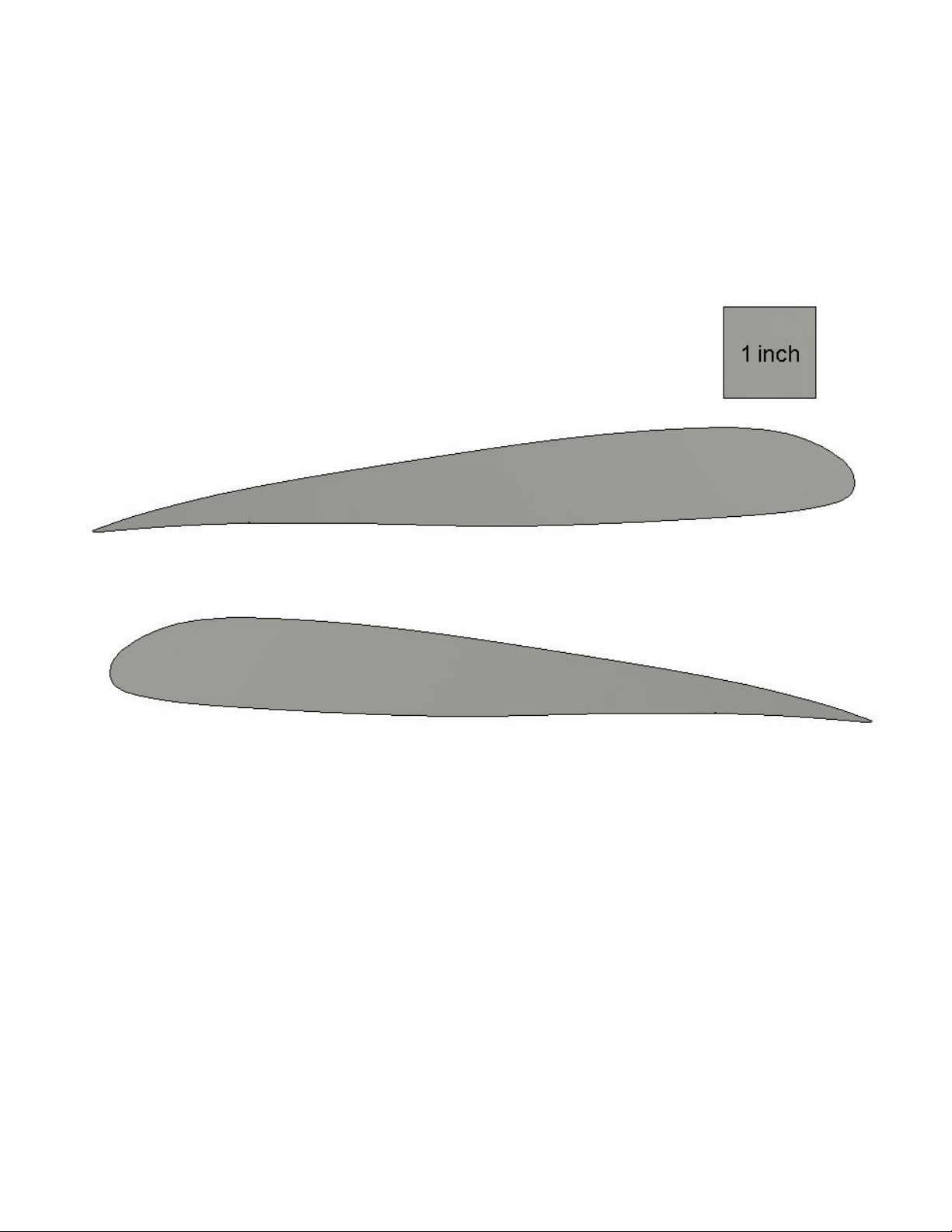

Wing Passthrough Template

If you desire more guidance on the plastic to be removed to accommodate the wing

and tail passthroughs, the below templates can be scaled with a copy machine to ensure that

the block below is exactly 1 inch wide. Use as template to remove material for wing

passthrough.

© Titan Model Kits 9 Revision 1.2 26 Aug 2022

Tailplane Passthrough Template

Scale this page with a copy machine to ensure that the block below is exactly 1 inch

wide. Use as a template to remove material for tailplane passthrough.

© Titan Model Kits 10 Revision 1.2 26 Aug 2022

I.A.6. Install 90° angle styrene reinforcement strips

¼” styrene angle strips are provided to add rigidity to the fuselage and to increase the

area of the fuselage joint for glue-up. Install as shown below. Install on BOTH fuselage

halves. You may wish to add additional bracing or joint reinforcement using scrap styrene at

your discretion.

*concept is illustrated with a photo from the A330 kit but the procedure is the same here

© Titan Model Kits 11 Revision 1.2 26 Aug 2022

747-8i

© Titan Model Kits 12 Revision 1.2 26 Aug 2022

747-8f

© Titan Model Kits 13 Revision 1.2 26 Aug 2022

I.A.7. OPTION: Landing Gear Cutouts:

Typically, only the aft nose gear doors are open during normal operations. Use the

panel lines on the model or use the measurement guide below to remove the desired

material.

Measurements for Nose Gear Door Cutout

© Titan Model Kits 14 Revision 1.2 26 Aug 2022

Measurements for Main Gear Door Cutouts

© Titan Model Kits 15 Revision 1.2 26 Aug 2022

Additional material will need to be removed from the lower wing halves to accommodate

installation of the main landing gear bays.

© Titan Model Kits 16 Revision 1.2 26 Aug 2022

I.B RESIN PARTS PREPARATION

I.B.1. Remove support columns:

Some 3D-printed parts (wheels especially) may come with printer supports still attached.

Carefully remove supports with a utility knife or sprue cutter and gently sand attachment point

dimples away.

© Titan Model Kits 17 Revision 1.2 26 Aug 2022

II. ASSEMBLY

II.A. GENERAL

Vacform parts are made from high impact polystyrene (HIPS) plastic. Vacform parts should

be glued to one another using solvent based ‘glue’. 3D printed parts should be glued to one

another and to vacformed parts using cyanoacrylate (Superglue or equivalent) or 2-part

epoxy.

II.B.1. OPTION: Install wheel wells:

Wheel wells should be installed prior to assembling fuselage halves and wings.

© Titan Model Kits 18 Revision 1.2 26 Aug 2022

© Titan Model Kits 19 Revision 1.2 26 Aug 2022

Main gear wells must be installed in the fuselage halves first. Wings will have to be fitted after

the fuselage halves are glued together. Take your time dry-fitting everything in order to

ensure that glued assembly goes smoothly.

© Titan Model Kits 20 Revision 1.2 26 Aug 2022

This manual suits for next models

1

Table of contents

Other TITAN MODEL KITS Toy manuals

Popular Toy manuals by other brands

Pro Boat

Pro Boat AERO TROOPER instruction manual

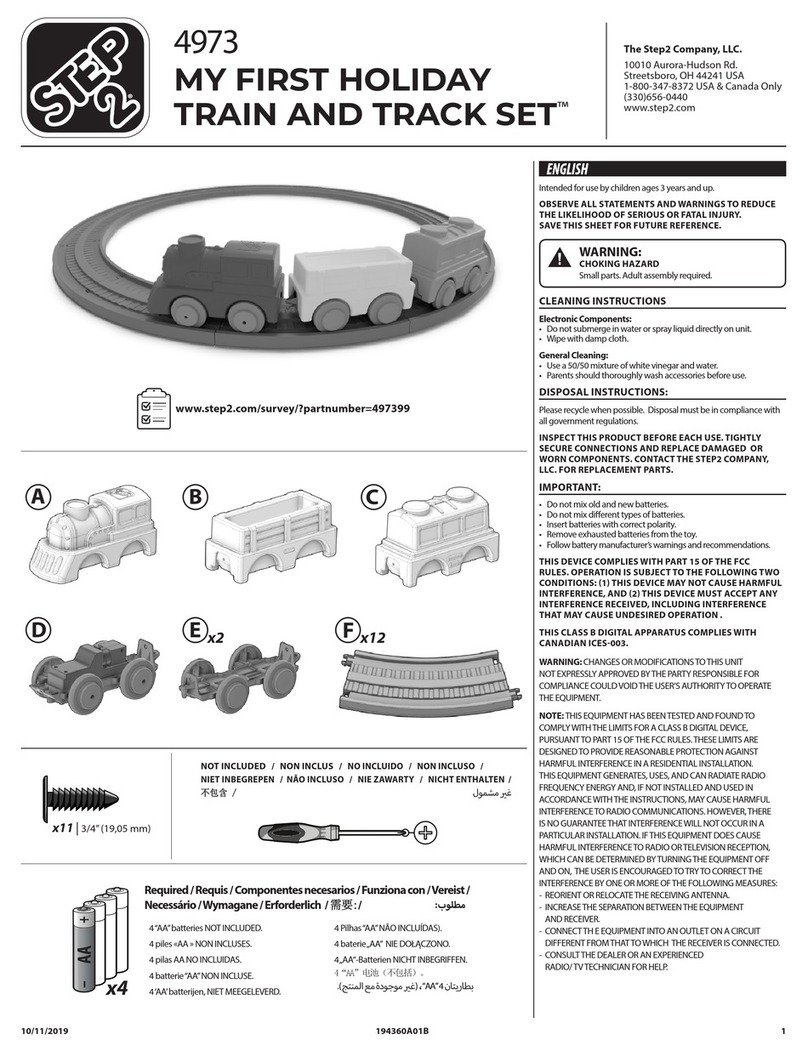

Step 2

Step 2 MY FIRST HOLIDAY TRAIN AND TRACK SET 4973 quick start guide

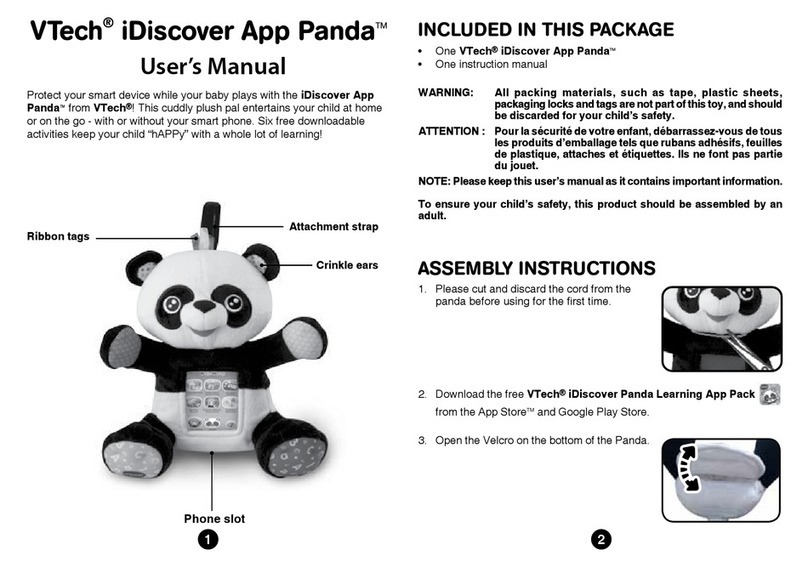

V-tech

V-tech iDiscover App Panda user manual

WATT AGE

WATT AGE 128301 operating instructions

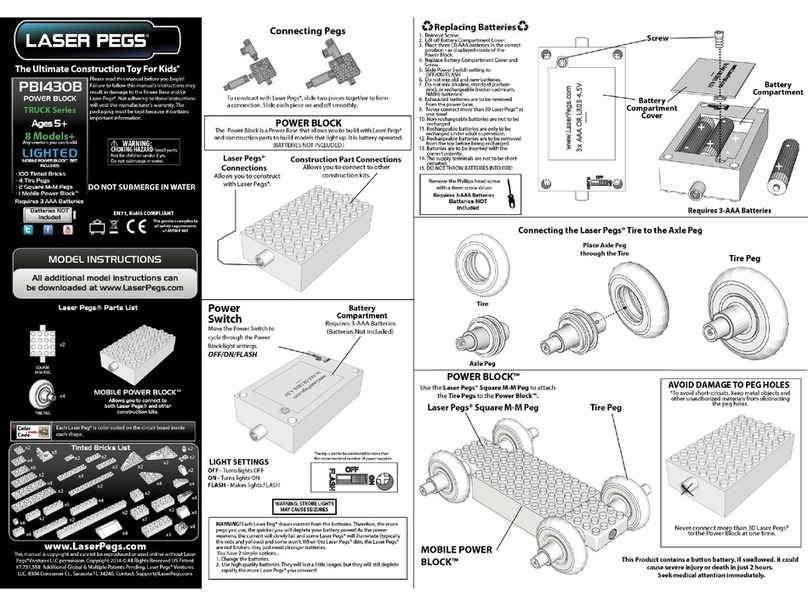

LaserPegs

LaserPegs PBI43OB Power Block Truck Series Model instructions

Fly Fly Hobby

Fly Fly Hobby F-4 Phantom-II manual