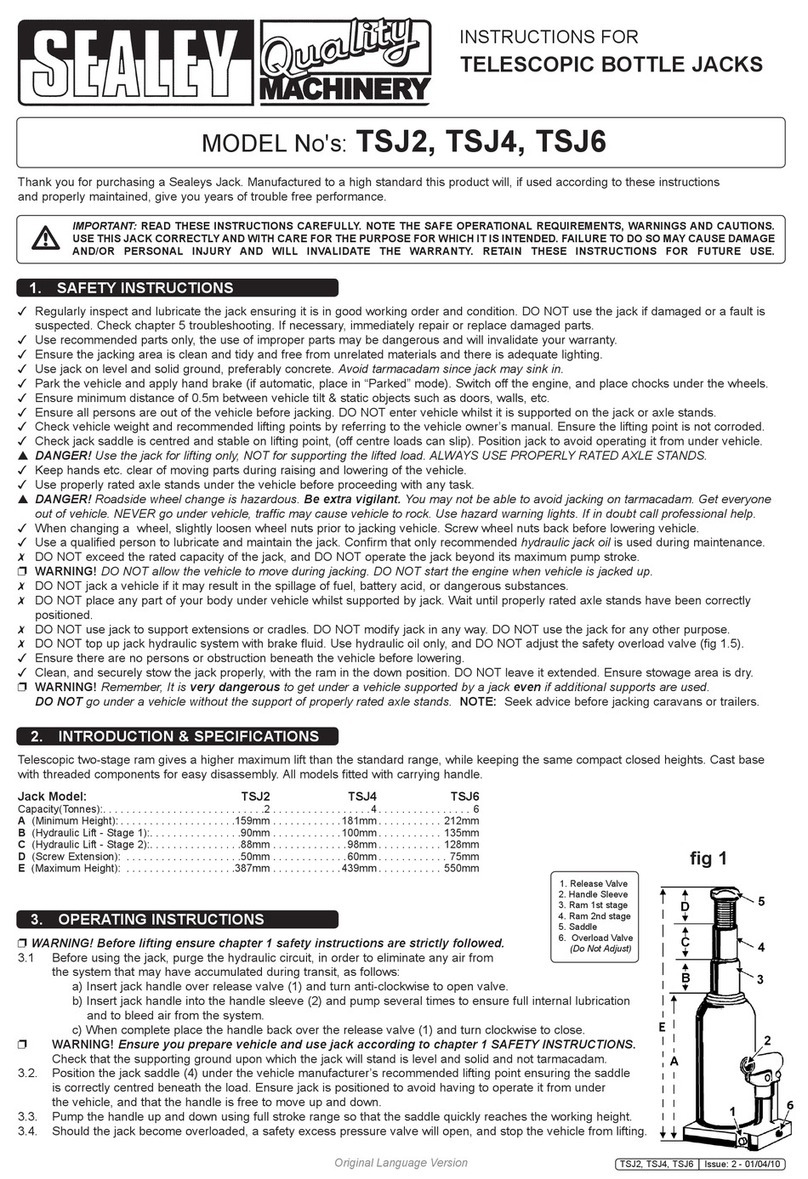

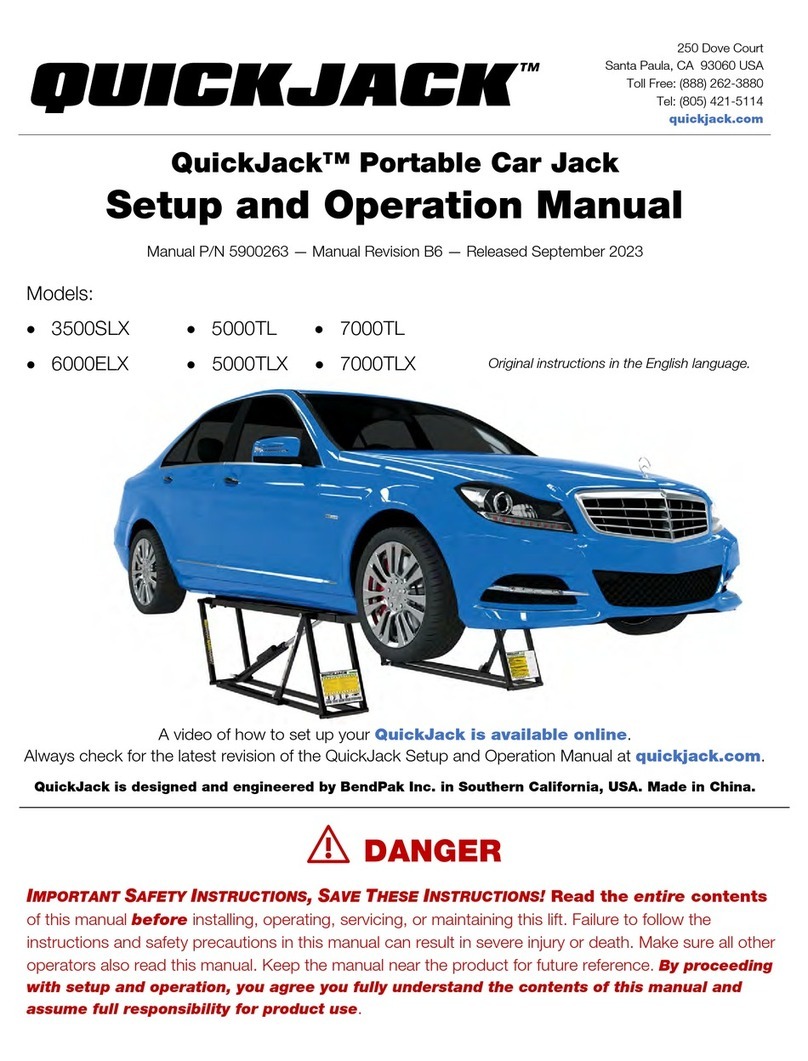

Titan Pro 14361 User manual

INSTRUCTION MANUAL

#14361

4 TON HEAVY DUTY

FLAT TOP JACK STANDS

!WARNING!

Save This Manual Keep this manual for the safety warnings and precautions, assembly, operating,

inspection, maintenance and cleaning procedures. Write the product’s serial number in the back of the man-

ual near the assembly diagram (or month and year of purchase if product has no number).

Keep this manual and the receipt in a safe and dry place for future reference.

Read this material before using this product. Failure to do so can result in serious injury.

SAVE THIS MANUAL.

14361 INSTRUCTION MANUAL

!WARNING!

To avoid serious personal injury, always wear proper protective gear, such as hard hats,

safety glasses, gloves, and steel toe shoes when using hydraulic equipment. Failure to

chock the wheels and crib the vehicle can result in Serious injury or death. Always deate

tires before removing a wheel, a rim, or part of a rim clamp or nut. If you do not deate the

tire, the tire could explode, causing serious injury or death.

Safety Information

Visuallyinspectallpartsforshippingdamage.Ifyoundshippingdamage,notifythecarrierat

once. Shipping damage is not covered by your warranty. The carrier is responsible for all costs of replace-

ment or repair caused by shipping damage.

Warrantyofthisunitwillbevoidonanypartiftheunitissubjectedtomisuseduetooverloading,

abuse,lackofmaintenanceandunauthorizedmodications.Nowarranty(verbal,writtenorimplied)other

thantheofcial,publishedAMEnewmachineryandequipmentwarrantywillbevalidwiththisunit.Inaddi-

tion,itisyourresponsibilitytobeawareofexistingFederal,StateandLocalcodesandregulationsgovern-

ing the safe use and maintenance of this unit.

Toavoidpersonalinjuryorpropertydamagewhileusingthisproduct,readandfollowallDANGERS,

WARNINGS, CAUTIONS, and INSTRUCTIONSthatareattachedto,orincludedwith,thisproduct.

1. Study,understand,andfollowallinstructionsbeforeoperatingthisdevice.

2. Donotexceedratedcapacity.

3. Useonlyonhard,levelsurfaces.

4. Center load on saddle.

5. Use as matched pair to support one end of a vehicle only.

The14361JackStandshavea4toncapacityeachpair(2toncapacityperstand).Thejackstands

haveaminimumheightof13-13/16″.Andamaximumheightof21-13/16″.

2

Important Receiving Information

Product Description

3

14361 INSTRUCTION MANUAL

6. WearANSI-approvedsafetygogglesandheavy-dutyworkglovesduringuse.

7. Do not use for aircraft purposes.

8. Support vehicle only at manufacturer-recommended locations.

9. Inspect before every use; do not use if parts loose or damaged.

10.ExamineJackStandsforcracksordamagebeforeeachuse.Donotuseifevenaminorcrack,

bendorotherdamage/deformationappears.DiscardJackStandifdamagedordeformed.

11.Keepworkareaclean.Clutteredareasinviteinjuries.

12.Observeworkareaconditions.Keepworkareawelllighted.

13.Keepchildrenaway.Childrenmustneverbeallowedintheworkarea.

14.Storeidleequipment.Whennotinuse,toolsmustbestoredinadrylocationtoinhibitrust.Always

lockuptoolsandkeepoutofreachofchildren.

15.There are certain applications for which this tool was designed. Do not modify this tool and do not

use this tool for a purpose for which it was not intended.

16.Dress properly. Do not wear loose clothing or jewelry as they can be caught in moving parts. Pro-

tective,electricallynon-conductiveclothesandnon-skidfootweararerecommendedwhenworking.

Wear restrictive hair covering to contain long hair.

17.Maintaintoolswithcare.Keeptoolscleanforbetterandsaferperformance.Followinstructionsfor

lubricating and changing accessories.

18.Stayalert.Watchwhatyouaredoing,usecommonsense.Donotoperateanytoolwhenyouare

tired.

19.Donotoperatetoolifundertheinuenceofalcoholordrugs.Readwarninglabelsonprescriptions

todetermineifyourjudgmentorreexesareimpairedwhiletakingdrugs.Ifthereisanydoubt,do

not operate the tool.

20.Onlyuseonpropersurface.OnlyusetheJackStandsonadry,level,atsurface,whichisfreeof

grease or debris. The surface to be used must be capable of supporting the combined weight of the

vehicleandtheJackStands.

21.Thewarnings,precautions,andinstructionsdiscussedinthismanualcannotcoverallpossiblecon-

ditions and situations that may occur. The operator must understand that common sense and cau-

tionarefactors,whichcannotbebuiltintothisproduct,butmustbesuppliedbytheoperator.

22.AMEInternationalcannotbeheldresponsiblefordamageorinjuryresultingfromunsafeuseofthis

product;lackofmaintenance;orincorrectproductandsystemapplication.

23.ContactAMEInternationalwhenindoubtaboutsafetyprecautionsorapplications.

1. MakesurethevehicledoesnotexceedthecapacityoftheJackStands.Note:Checkthattheweightis

evenlydistributedbetweentheJackStands.YoumustevenlydistributetheweightortheJackStands

mayfail,causingsevereinjuryordeath.Onlyapplytheloadvertically.

WARNING! TO PREVENT SERIOUS INJURY:IfavehicledropsontheJackStands(evenifitisunder

theweightcapacitylimit),theprincipleof“dynamicloading”takesaffect.Theforceoftheweightfalling

maycausetheJackStandstofail.AvehicleweighingmuchlessthantheJackcapacitymaycausethe

JackStandstofailifdroppedonthem.

2. ExamineJackStandsforcracksordamagebeforeeachuse.Donotuseifevenaminorcrack,bend,or

otherdamage/deformationappears.DiscardJackStandifdamagedordeformed.

3. Ifyourareraisingonlyoneendofthevehicle,blockthetiresthatremainontheground.

4. LowertheJackStandstothelowestheight.SecurethepositionbyinsertingtheLockingPinthrough

the Post.

5. Followingtheinstructionsinyouroorjackmanual,raiseyourvehicletojustabovetheminimumheight

ofyourJackStands.

6. SlideyourJackStandstotheproperpositionpointsreferredtointhevehicleowner’smanual.Make

suretheJackStandsareonthesamepointoneachsideofthevehicle.RaisePostuntilCirclePadis

justbelowthejackcontactpointonthevehicle.CentertheloadontheCirclePadofthePost.

7. SecurePostpositionbyinsertingLockingPinthroughPost.

8. SecureLockingPinbyinsertingSafetyPinthroughtheopeningattheendoftheLockingPin.

9. Gentlylowerthevehiclewiththeoorjack.Itmaydropdownaverysmallamountuntiltheratchet

catchesonthePawl.Repeatonotherside.

WARNING! TO PREVENT SERIOUS INJURY:SetboththeJackStandstothesameheight.

10.Determineifthevehicleisstable.Ifnot,raisethevehicleandrepositiontheJackStands.

SeeFigureC.

Operating Instructions

!WARNING!

To avoid serious personal injury, always wear proper protective gear, such as hard

hats, safety glasses, gloves, and steel toe shoes when using hydraulic equipment.

Supporting a Vehicle

14361 INSTRUCTION MANUAL

Figure C: Locking Pin and Safety Pin

5

DANGER

Do not use Jack Stands as a permanent stand for the vehicle. Use them only while

making repairs, then immediately lower vehicle to the ground.

1. RaisethevehiclewithaoorjacktotaketheloadoffoftheJackStands.

2. RemoveSafetyPinfromtheLockingPin.RemovetheLockingPinfromthePost.

3. LowerthePostandremoveJackStandfromunderneathvehicle.

4. Usetheoorjacktosafelylowerthevehicletotheground.

WARNING: Procedures not specically explained in this manual must be performed only by a

qualied technician.

DANGER

TO PREVENT SERIOUS INJURY FROM TOOL FAILURE:

Do not use damaged equipment.

If abnormal noise or vibration occurs, have the problem corrected before further use.

1. PeriodicallycleanthebottomoftheBasesandtopofPostsofanydirt,grease,ordebris.

2. Beforeeachuse,inspectthegeneralconditionoftheJack.Checkforbroken,cracked,orbentparts,

looseormissingparts,andanyconditionthatmayaffecttheproperoperationoftheproduct.Donot

usedamagedequipment.DiscardJackStandifdamagedordeformed.

Removing the Jack Stands

AME INTERNATIONAL

2347 Circuit Way, Brooksville, Florida USA 34604

Phone: (+1) 352.799.1111 • Toll Free (+1) 877.755.4AME (4263)

Fax: (+1) 352.799.1111 • E-mail: [email protected]

14361 INSTRUCTION MANUAL

Parts Breakdown

14361 INSTRUCTION MANUAL

Item: Part Number: Description: Quantity:

1 14361-001 Rubber Cushion 1

2 14361-002 Post 1

3 14361-003 Safety Pin 1

4 14361-004 Chain 1

5 14361-005 Locking Pin 1

6 14361-006 Base 1

Table of contents

Popular Jack manuals by other brands

Pro-Lift

Pro-Lift B-033D Operating instructions & parts manual

Clarke

Clarke STRONG-ARM VPJ300 Installation and maintenance instructions

Compac

Compac A10T-C User's guide & instructions

Sealey

Sealey AJS10000 instructions

Sealey

Sealey 3000HL instructions

Clarke

Clarke Strong-Arm CTJ1500QULP Operation & maintenance instructions