3. SPECIFICATION

Model No:...............................................................AJS10000

Maximum Capacity:................................................... 10tonne

Minimum Height: ........................................................ 447mm

Maximum Height: ..................................................... 1300mm

Extension: .................................................................. 561mm

Piston Stroke:............................................................. 292mm

Working Pressure:....................................................... 200psi

Length including Handle:.......................................... 1480mm

Weight:...........................................................................80Kg

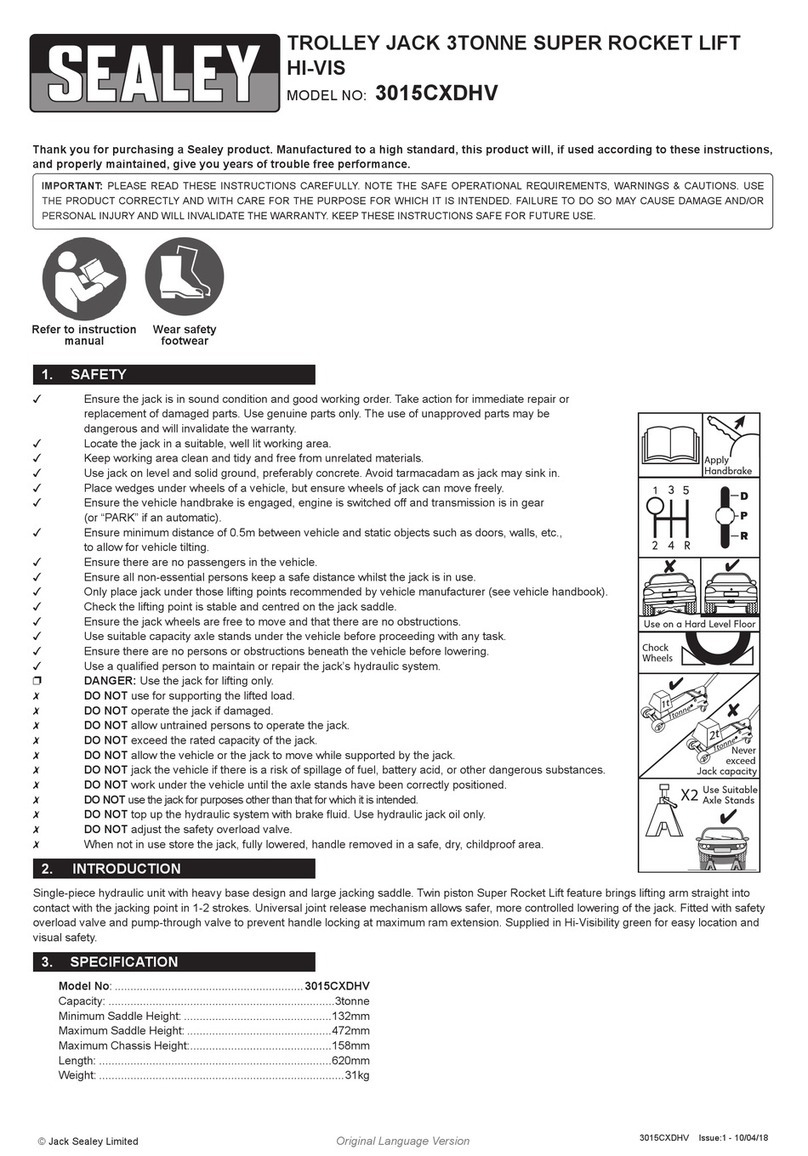

4. OPERATION

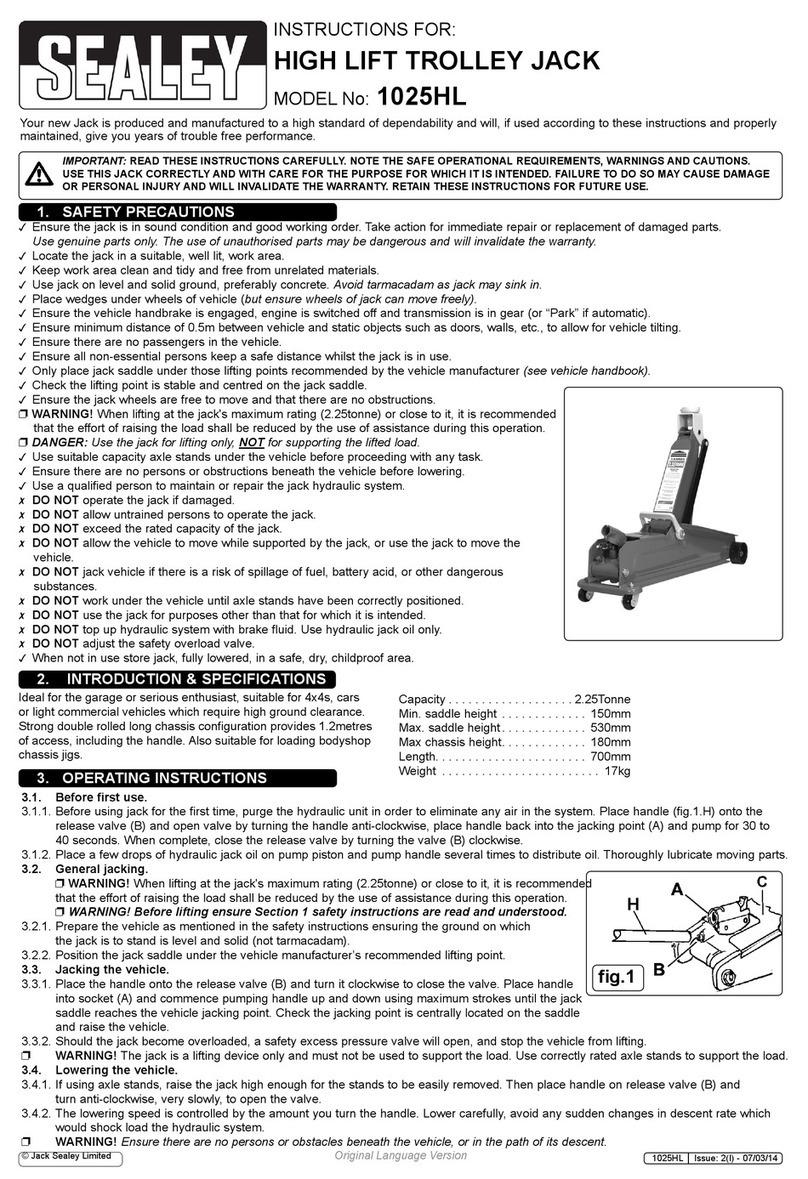

4.1. Assemble handle

4.1.1. Attached handle to the handle bracket (2 part) on cylinder set with bolts and nuts provided. g.1

4.2. Prepare air system

WARNING! Air source must not exceed 200 psi.

4.2.1. Connect a union tting (sold separately) to the air supply inlet. g.2

4.2.2. Attach 1/4” NPT coupler (sold separately) to union tting if desired.

4.2.3. Frequent, but not excessive lubrication is required for best performance.

Too much oil will collect inside jack and be expelled during exhaust

cycle. An automatic inline oiler is recommended, but oil may be added

manually before operation or after approximately 1 hour of continuous use.

Pour 1 teaspoon of good quality air tool lubricant into air supply inlet of

control valve.

Dirt and water may accumulate inside jack during use. An inline lter/dryer

is recommended.

4.2.4. Air Jack/Support Stand is now ready for use.

WARNING! Never use more than one extension with this unit.

Using more than one extension causes the load to be lifted beyond the

maximum designed safety lifting height, which could cause loss of load.

4.3. Check the jack

4.3.1. Examine the jack for broken or damaged parts. Roll the jack to ensure that

it rolls freely and smoothly.

4.3.2. Raise and lower the unloaded saddle throughout the lift range to ensure

proper operation before placing any load on the product.

4.3.3. Replace worn or damaged components with Sealey replacement parts only.

4.3.4. Lubricate as instructed in Maintenance Section.

4.4. Lifting

4.4.1. Follow the vehicle manufacturer’s recommended guidelines for lifting.

4.4.2. Position vehicle on hard level surface with parking brake selected. Chock

wheels at opposite end. When lifting trailers, lower landing gear.

4.4.3. Position the unit under the lift point of the vehicle such that load will be

centered on lifting saddle.

4.4.4. Extend post to desired height and insert locking pin through appropriate

hole. If necessary, use post extension for additional height. Post extension

slides inside post and is held in place with safety pin (ref. parts drawing).

4.4.5. Connect air compressor hose to control valve, then attach to air supply of

200 psi maximum. The unit is now ready to lift.

4.4.6. Press the air control valve lever marked “UP” to raise post until it contacts

vehicle lift point. Ensure lift point is secure and centered on lift post saddle.

4.4.7. Press and hold air control valve until desired height has been achieved,

insert the other lock pin through the hole in the ram post such that the lock

pin will fully engage both sides of the head plate when lowered.

4.4.8. Slowly release the air pressure and make sure the lock pin engages fully

into both sides of the low post slot.

4.4.9. Ensure the vehicle is level and stable, then fully discharge air pressure.

4.4.10. Before working around the lifted vehicle, ensure the vehicle is level and stable between the jacks.

WARNING! After lifting, never work on, under or around a load until the post is properly pinned and the air is exhausted. If the air is

not exhausted and the jack is not properly pinned, the jack may rise or drop suddenly when a heavy object is removed from or placed

on the vehicle.

4.5. Lowering

WARNING! Check that all tools and personnel are clear before lowering load. Maintain control of speed at which load descends at

all times.

4.5.1. Press the “UP” air control valve lever to release post locking pin.

4.5.2. Ensure the vehicle is still stable, then remove lift post locking pin.

4.5.3. Press the “DOWN” air control lever to exhaust air pressure. Vehicle will gradually lower.

4.5.4. Discharge the air pressure from the jack fully once the vehicle is on the ground.

4.5.5. Ensure saddle is fully lowered, remove jack from under the vehicle and store properly.

AJS10000 | Issue 1 19/07/16

Original Language Version

© Jack Sealey Limited

g.1

g.2