TitanTec TT-BV3405 User manual

TT-BV3405

For technical support in the UK please contact Sherpa Tools on 01522 283020.

SAFETY FIRST

Instructions contained in warnings within this

manual marked with a symbol concern

critical points which must be taken into

consideration to prevent possible serious bodily

injury, and for this reason you are requested to

read all such instructions carefully and follow

them without fail.

■WARNINGS IN THE MANUAL

WARNING

This mark indicates instructions which must be

followed in order to prevent accidents which

could lead to serious bodily injury or death.

IMPORTANT

This mark indicates instructions which must be

followed, or it leads to mechanical failure,

breakdown, or damage.

NOTE

This mark indicates hints or directions useful in

the use of the product.

CONTENTS

1. Introduction …………………………………………………………………………………………………………...……………………… 2

2. Identification of Symbols ................................................................................................................……3

3. General Safety Precautions ………………………………………………………………………………………………………….…

4. Identification ……………………………………………………………………………………………..……...........................…. 5

5. Assembly ................……………………………………………………................……………………………………………………6

6. …………………………………………………………………….........…………………………………………………………8

7. Maintenance …………………………………………………………………….……………………………………………………………10

8. Storage ………………………………………………………………..………………………………………………………………………12

9. Troubleshooting Table ………………………………………………………........……………………………………………………13

10. Technical Data ……………………………………………………………………..………………………………………………………13

Operation

3

-- 3 --

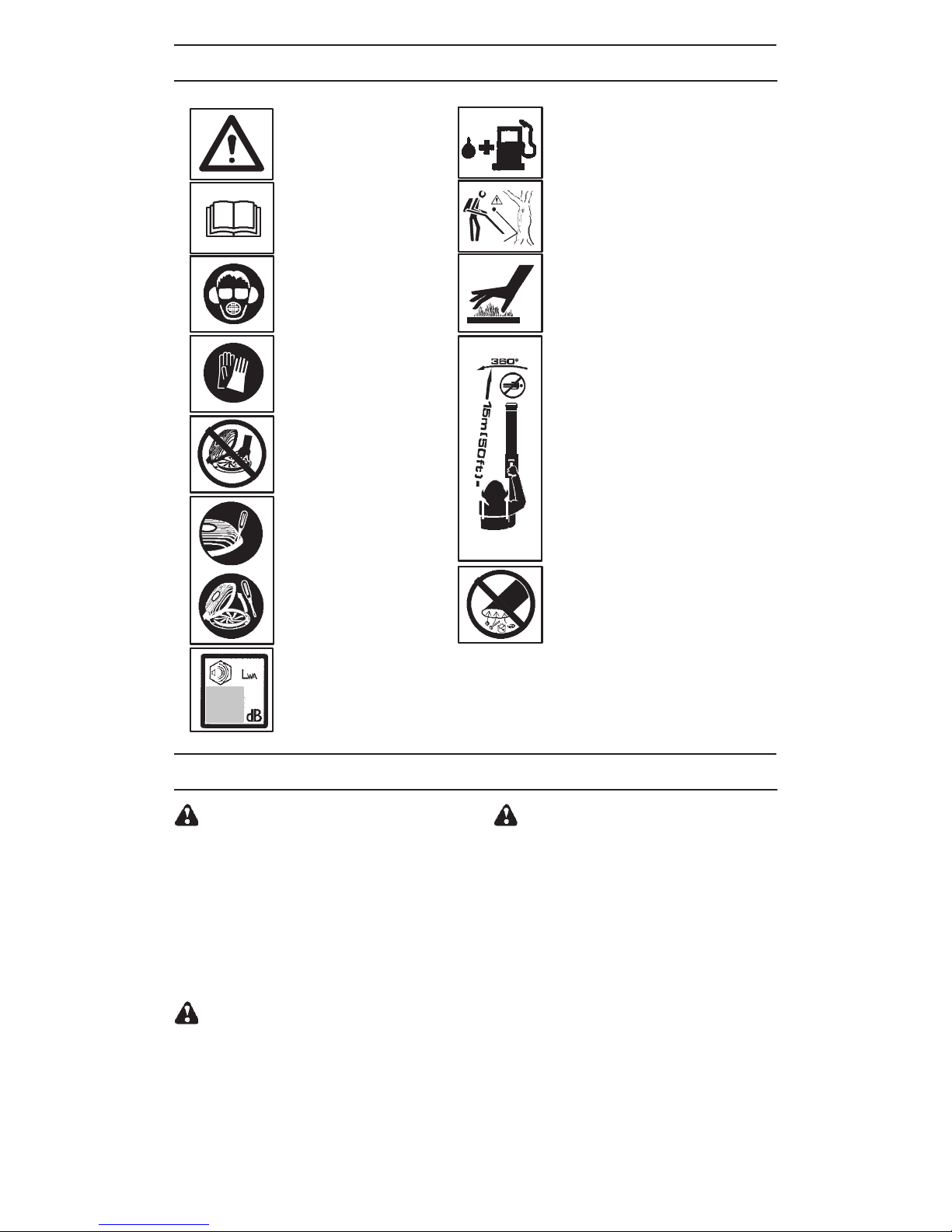

IDENTIFICATION OF SYMBOLS

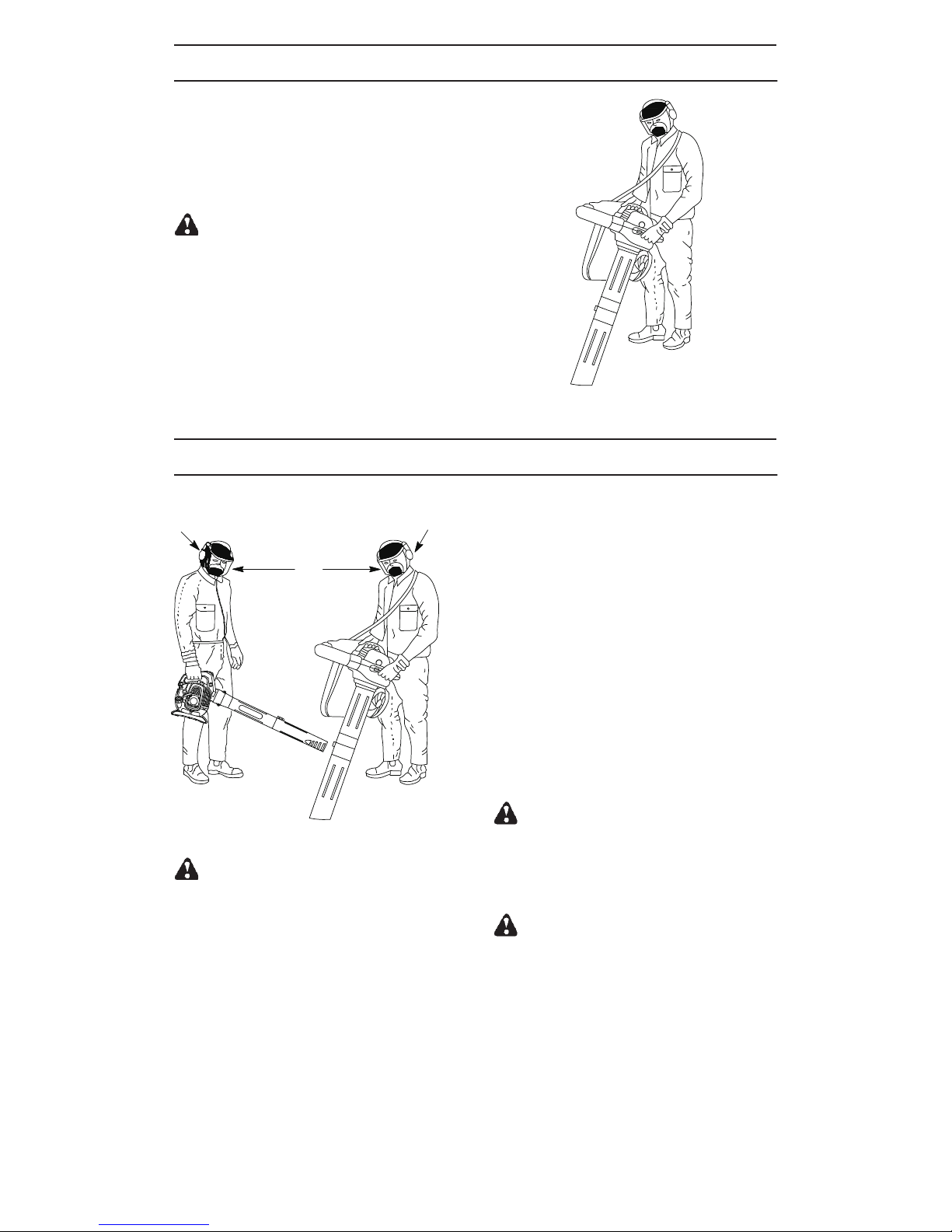

Approved protective goggles

or visor, ear protection, and

face mask in dusty environments

must be worn.

The blower operator must make sure

that no bystanders or animals come

nearer than 15 metres.

Whenever several operators are

working in the same work area, they

should maintain a safe distance of at

least 15 meters from one another.

WARNING: The muffler is very

hot during and after use. Do not

touch the muffler, muffler guard, or

surrounding surfaces, or allow

combustible material such as dry

grass or fuel to do so.

Always wear approved,

protective gloves.

Instructions on how to open

vacuum inlet cover. Gently tilt

the handle of the screwdriver

toward the front of the unit to

release the latch while pulling

up on the vacuum inlet cover

with your other hand.

WARNING: This blower

can be dangerous! Careless

or improper use can

cause serious or even fatal

injury.

Read and understand the

instruction manual before

using the blower.

WARNING: Be sure the

bottom cover is secured or

the vacuum tube is properly

installed. Avoid the impeller

blade with your hand or any

foreign object.

Sound power

level

stroke oil.

WARNING: The blower may throw

objects at high velocity that can

ricochet and hit the operator. This

may cause serious eye damage.

When using the vacuum attachment, the

unit is designed to pick up dry material

such as leaves, grass, small twigs, and

bits of paper. Do not vacuum stones,

gravel, metal, broken glass, etc., to

avoid severe damage to the impeller.

GENERAL SAFETY PRECAUTIONS

WARNING: Failure to follow all

Safety Rules and Precautions can result in

serious injury.

KNOW YOUR UNIT

SRead your instruction manual carefully until

you completely understand and can follow all

warnings and safety rules before operating

the unit.

DRestrict unit to users who understand and will

follow all warnings and safety rules in this

manual.

WARNING: Inspect area before start-

ing unit. Remove all debris and hard objects

such as rocks, glass, wire, etc. that can rico-

chet, be thrown, or otherwise cause injury or

damage during operation.

WARNING: While vacuuming or

blowing debris, hold the unit with the muffler

side facing away from your body and clothes.

Use your unit as a blower for:

DSweeping debris or grass clippings from

driveways, sidewalks, patios, etc.

DBlowing grass clippings, straw, or leaves into

piles, around joints, or between bricks.

Use your unit as a vacuum for:

DPicking up dry material such as leaves, grass,

small twigs, and bits of paper.

DFor best results during vacuum use, operate

your unit at high speed.

DMove slowly back and forth over the material

as you vacuum. Avoid forcing the unit into a

pile of debris as this can clog the unit.

DKeep the vacuum tube about an inch above

the ground for best results.

Use unleaded petrol and two

-- 4 --

GENERAL SAFETY PRECAUTIONS

PLAN AHEAD

WARNING: This machine produces

an electromagnetic field during operation. Under

some circumstances, this field may interfere

with active or passive medical implants. To re-

duce the risk of serious or fatal injury, we recom-

mend persons with medical implants to consult

their physician and the medical implant

manufacturer before operating this machine.

DAlways wear eye and ear protection when

operating, servicing, or performing

maintenance on unit. Wearing eye protection

will help to prevent rocks or debris from being

blown or ricocheting into eyes and face which

can result in blindness and/or serious injury.

Eye protection should be marked Z87.

DAlways wear foot protection. Do not go

barefoot or wear sandals.

DAlways wear respirator or face mask when

working with unit in dusty environments.

DSecure hair above shoulder length. Secure or

remove jewelry, loose clothing, or clothing

with loosely hanging straps, ties, tassels, etc.

They can be caught in moving parts.

DDo not operate unit when you are tired, ill,

upset, or if you are under the influence of

alcohol, drugs, or medication.

DKeep children, bystanders, and animals away

from work area a minimum of 15 meters when

starting or operating unit. Do not point blower

nozzle in the direction of people or pets.

HANDLE FUEL WITH CAUTION

DEliminate all sources of sparks or flame

(including smoking, open flames, or work that

can cause sparks) in the areas where fuel is

mixed, poured, or stored.

DMix and pour fuel in an outdoor area; store

fuel in a cool, dry, well ventilated place; use an

approved, marked container for all fuel

purposes.

DDo not smoke while handling fuel or while

operating the unit.

DMake sure the unit is properly assembled and

in good operating condition.

DDo not fill fuel tank while engine is hot or

running.

DAvoid spilling fuel or oil. Wipe up fuel spills

before starting engine.

DMove at least 3 meters away from fuel and

fueling site before starting engine.

DAlways store petrol in a container approved

for flammable liquids.

OPERATE YOUR UNIT SAFELY

WARNING: Stop the engine before

opening the vacuum inlet door. The engine

must be stopped and the impeller blades no

longer turning to avoid serious injury from the

rotating blades.

WARNING: While vacuuming or

blowing debris, hold the unit with the muffler

side facing away from your body and clothes.

DThis garden blower/vacuum is only designed

for blowing away or removal of leaves and

other debris on the ground.

DInspect unit before each use for worn, loose,

missing, or damaged parts. Do not use until

unit is in proper working order.

DKeep outside surfaces free of oil and fuel.

DNever start or run engine inside a closed

room or building. Breathing exhaust fumes

can kill.

DMufflers fitted with catalytic converters get

very hot during use and remain so for some

time after stopping. This also applies at idle

speed. Contact can result in burns to the skin.

Remember the risk of fire!

DTo avoid static electricity shock, do not wear

rubber gloves or any other insulated gloves

while operating unit.

DDo not set unit on any surface except a

clean, hard area while engine is running.

Debris such as gravel, sand, dust, grass,

etc. could be picked up by the air intake and

thrown out through discharge opening,

damaging unit, property, or causing serious

injury to bystanders or operator.

DAvoid dangerous environments. Do not use in

unventilated areas or where explosive vapors

or carbon monoxide build up could be

present.

DDo not overreach or use from unstable

surfaces such as ladders, trees, steep

slopes, rooftops, etc. Keep firm footing and

balance at all times.

DNever place objects inside the blower tubes;

always direct the blowing debris away from

people, animals, glass, and solid objects such

as trees, automobiles, walls, etc. The force of

air can cause rocks, dirt, or sticks to be

thrown or to ricochet which can hurt people or

animals, break glass, or cause other damage.

DNever run unit without the proper equipment

attached. When using your unit as a blower,

always install blower tubes. When using your

unit as a vacuum, always install vacuum

tubes and vacuum bag assembly. Make sure

vacuum bag assembly is completely zipped.

DCheck air intake opening, blower tubes,

vacuum tubes, and elbow tube frequently,

always with engine stopped and spark plug

disconnected. Keep vents and discharge

tubes free of debris which can accumulate

and restrict proper air flow.

DNever place any object in the air intake

opening as this could restrict proper air flow

and cause damage to the unit.

DNever use for spreading chemicals, fertilizers,

or other substances which may contain toxic

materials.

DTo avoid spreading fire, do not use near leaf or

brush fires, fireplaces, barbecue pits,

ashtrays, etc.

DUse only for jobs explained in this manual.

MAINTAIN YOUR UNIT PROPERLY

DHave all maintenance other than the

recommended procedures described in the

instruction manual performed by an

authorise service dealer.

*(1(5$/ 6$)(7< 35(&$87,216

-'LVFRQQHFW VSDUN SOXJ EHIRUH SHUIRUPLQJ

PDLQWHQDQFH H[FHSW IRU FDUEXUHWRU

DGMXVWPHQWV

-

PHQW SDUWV XVH RI DQ\ RWKHU SDUWV PD\ YRLG

\RXU ZDUUDQW\ DQG FDXVH GDPDJH WR \RXU XQLW

-(PSW\ IXHO WDQN EHIRUH VWRULQJ WKH XQLW 8VH

XS IXHO OHIW LQ FDUEXUHWRU E\ VWDUWLQJ HQJLQH DQG

OHWWLQJ LW UXQ XQWLO LW VWRSV

-'R QRW XVH DQ\ DFFHVVRU\ RU DWWDFKPHQW

RWKHU WKDQ WKRVH UHFRPPHQGHG E\

PDQXIDFWXUHU IRU XVH ZLWK \RXU XQLW

-'R QRW VWRUH WKH XQLW RU IXHO LQ D FORVHG DUHD

ZKHUH IXHO YDSRUV FDQ UHDFK VSDUNV RU DQ

RSHQ IODPH IURP KRW ZDWHU KHDWHUV HOHFWULF

PRWRUV RU VZLWFKHV IXUQDFHV HWF

-6WRUH LQ D GU\ DUHD RXW RI UHDFK RI FKLOGUHQ

-6HFXUH WKH PDFKLQH GXULQJ WUDQVSRUW

6$)(7< 127,&( ([SRVXUH WR YLEUDWLRQV

KDQG WRROV FRXOG FDXVH EORRG YHVVHO RU QHUYH

GDPDJH LQ WKH ILQJHUV KDQGV DQG MRLQWV RI SHR

SOH SURQH WR FLUFXODWLRQ GLVRUGHUV RU DEQRUPDO

VZHOOLQJ 3URORQJHG XVH LQ FROG ZHDWKHU KDV

EHHQ OLQNHG WR EORRG YHVVHO GDPDJH LQ RWKHU

ZLVH KHDOWK\ SHRSOH ,I V\PSWRPV RFFXU VXFK DV

QXPEQHVV SDLQ ORVV RI VWUHQJWK FKDQJH LQ VNLQ

FRORU RU WH[WXUH RU ORVV RI IHHOLQJ LQ WKH ILQJHUV

KDQGV RU MRLQWV GLVFRQWLQXH WKH XVH RI WKLV WRRO

DQG VHHN PHGLFDO DWWHQWLRQ $Q DQWLYLEUDWLRQ

V\VWHP GRHV QRW JXDUDQWHH WKH DYRLGDQFH RI

WKHVH SUREOHPV 8VHUV ZKR RSHUDWH SRZHU WRROV

RQ D FRQWLQXDO DQG UHJXODU EDVLV PXVW PRQLWRU

FORVHO\ WKHLU SK\VLFDO FRQGLWLRQ DQG WKH FRQGLWLRQ

RI WKLV WRRO

,'(17,),&$7,21 :+$7 ,6 :+$7"

:+$7 ,6 :+$7"

6WDUWHU

9DFXXP KDQGOH

)XHO WDQN

3ULPHU EXWWRQ

9DFXXP KDQGOH

)XHO WDQN

3ULPHU EXWWRQ

3ULPHU EXWWRQ

1.Starter

2.Vacuum handle

3.Fuel tank

4.Primer button

5.Choke lever

6.Spark plug

7.Throttle trigger

8.Stop switch

9. Upper blower tube

10.Lower blower tube

11.Lower vacuum tube

12.Nut

14.Upper vacuum tube

15.Elbow tube

16.Vacuum bag

Use only recommended replace-

TITAN

WKURXJK SURORQJHG XVH RI SRZHUHG

petrol

13.Bolt

Tool kit bag

Mix Bottle

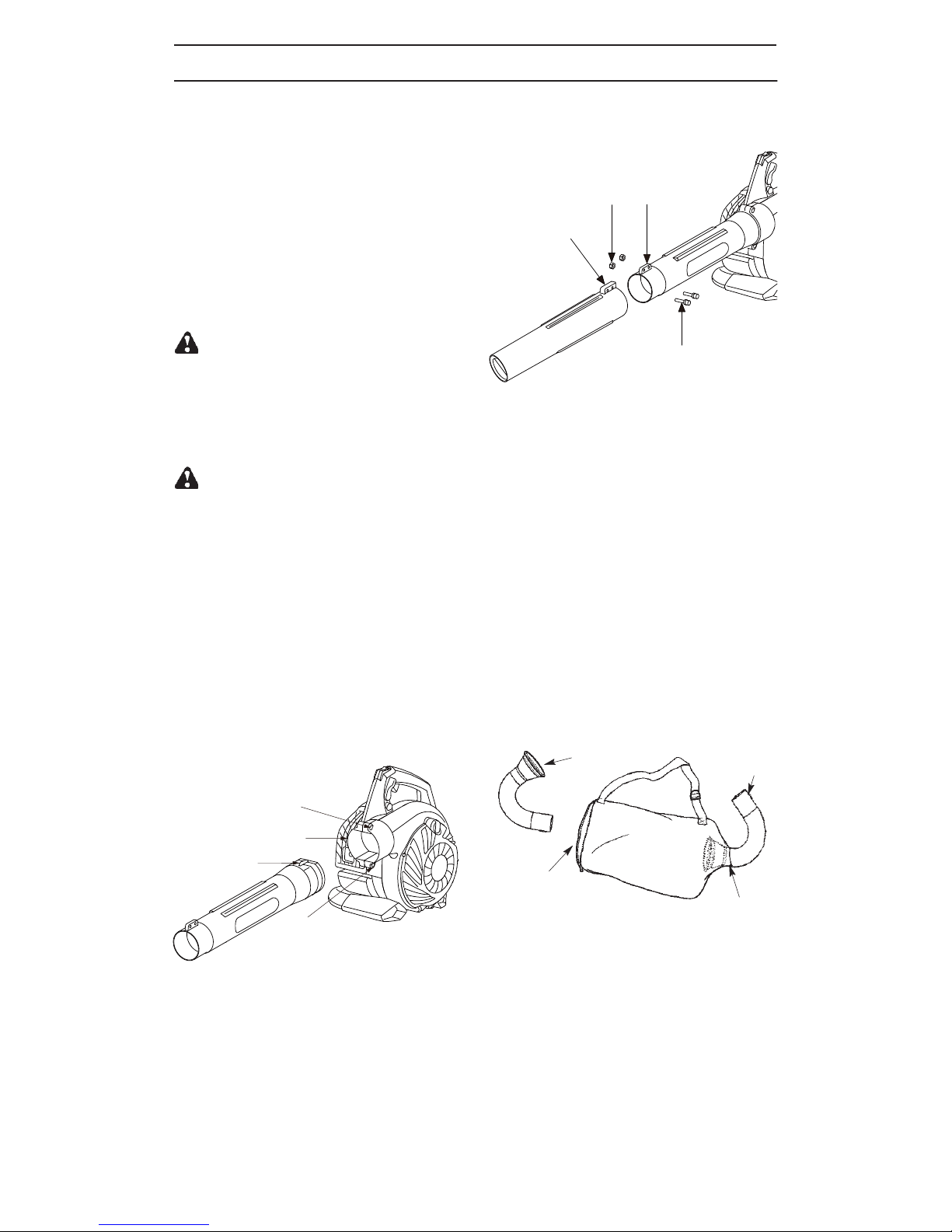

Blower Outlet

Rib

Rib

Rib

Nut

Bolt

5. Secure the tube by turning the bolts clock-

( up-right )

Clamp Bolt

( upper )

Clamp Bolt

( lower )

The tube clamp bolts must be loose

the clamp bolt ( upper ) in the blower outlet;

slide the tube into place.

5. Secure the tube by turning the bolts clock-

2. Secure the tube by turning the bolts clock-

wise

3. Align the rib on the lower blower tube

with the rib on the upper blower tube.

● Blower

● Upper blower tube

● Lower blower tube

● Elbow tube

● Vacuum bag

● Upper Vacuum tube

● Lower Vacuum tube

● Tool kit bag

● Mix Bottle

2. Secure the tube by turning the bols clock-

wise

3. Align the rib on the lower blower tube

with the rib on the upper blower tube.

4. Slide the lower blower tube onto the upper

blower tube.

5. Secure the tube by turning the bolts clock-

wise.

6. To remove the tubes, turn the bolt counter-

clock wise toloosen the tubes.

Clamp Bolt

(upper)

Nut Rib

Rib

Bolt

Blower Outlet

Rib

(Up-right)

Clamp Bolt

(lower)

Tool kit bag

Mix Bottle

Blower Outlet

Rib

Rib

Rib

Nut

Bolt

5. Secure the tube by turning the bolts clock-

( up-right )

Clamp Bolt

( upper )

Clamp Bolt

( lower )

The tube clamp bolts must be loose

the clamp bolt ( upper ) in the blower outlet;

slide the tube into place.

5. Secure the tube by turning the bolts clock-

2. Secure the tube by turning the bolts clock-

wise

3. Align the rib on the lower blower tube

with the rib on the upper blower tube.

BOX

box

anti-

clockwise

Rib

(up-right)

Clamp Bolt

( upper )

Clamp Bolt

( Lower )

Blower Outlet

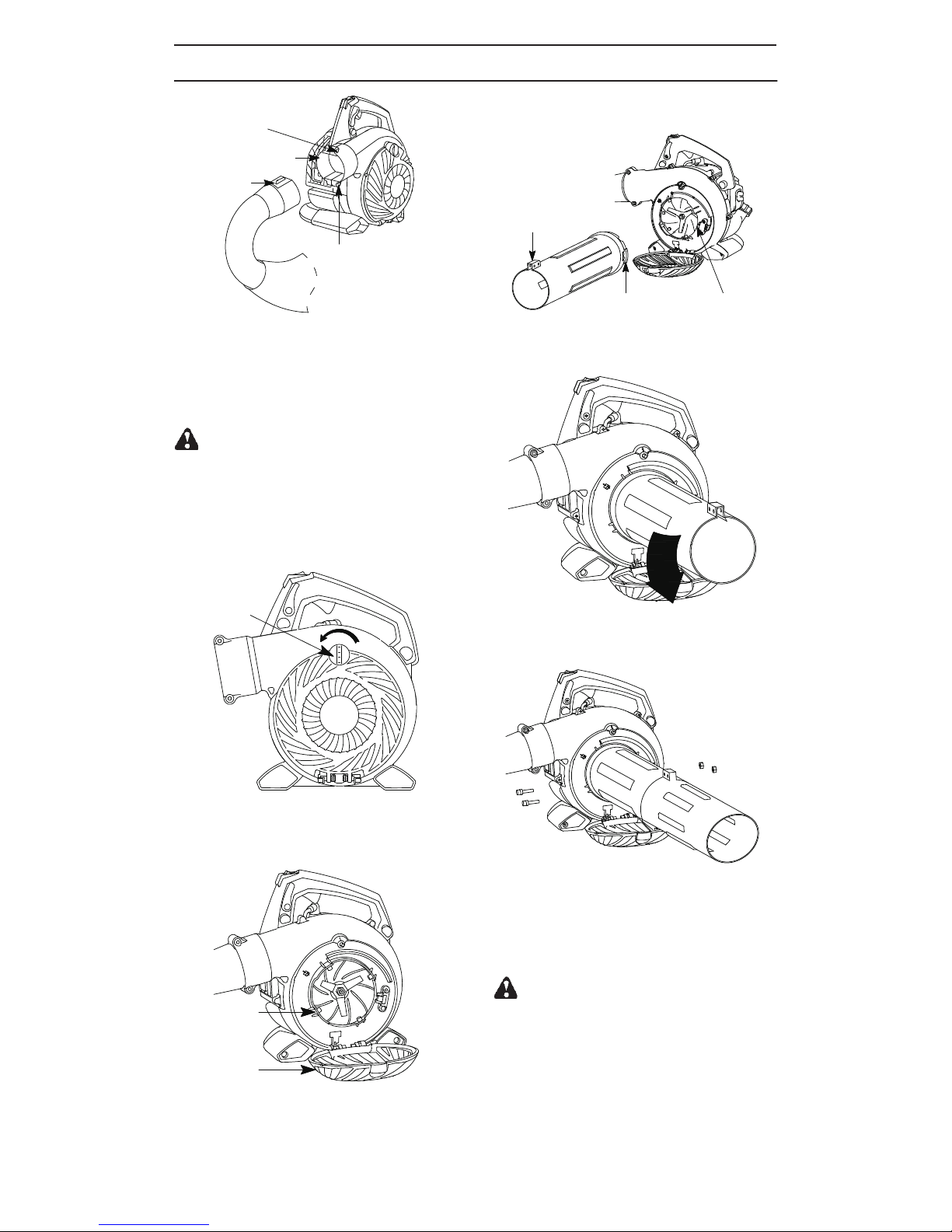

the blower outlet clamp bolt (upper).

6. Secure the elbow tube by turning the bolts

clockwise.

Knob

knob loosed completely.

2. Pulling up the vacuum inlet cover with your hand.

4. Align the switch on the inside of the vacuum

inlet with the slot on the upper vacuum tube.

side switch

slot

rib( up-right )

5. Push the upper vacuum tube into the vac-

uum inlet. Turn the tube counterclockwise

to secure the tube to the blower unit.

6. Align the rib on the lower blower tube

with the rib on the upper blower tube. Sli-

de the lower vacuum tube on to the upper

vacuum tube.

assemble the two tubes together with

the supplied screws.

1. Remove the elbow tube and vacuum bag

Clamp Bolt

(upper)

rib(up-right)

slot side switch

Clamp Bolt

(Lower)

Blower Outlet

Knob

Vacuum Inlet

Vacuum

Inlet

Cover

Rib

(up-right)

Knob loosed completely.

2. Pulling up the vacuum inlet cover with your

hand.

3. Hold the vacuum inlet cover open until up-

per vacuum tube is installed.

5. Push the upper vacuum tube into the vacu-

secure the tube to the blower unit.

6. Align the rib on the lower blower tube with

the rib on the upper blower tube. Slide the

lower vacuum tube on to the upper vacuum

tube.

ssemble the two tubes together with the s-

upplied screws.

4. Align the switch on the inside of the vacuum

inlet with the slot on the upper vauum tube.

anticlockwise

1. Turning the knob till the

um inlet. Turn the tube to

anticlockwise

by turning the bolts to lo

anticlockwise osen

the elbow tube.

7. When vacuum tubes are fitted together a-

Eye

protection

Blower Vacuum

authorise

2-stroke

starter

primer bulb

choke level

1. Slide the self-lock to non-integrated state.

2. Move the stop switch to "1" position.

3. Slowly press the primer bulb 6 times.

Blower

choke level

primer bulb

starter

Vacuum

2. Move the stop switch to “1” position.

3. Slowly press the primer bulb 6 times.

1. Ensure the throttle lock lever is in the vertical

position.

4. Move the choke lever to the "OFF" choke

position

5. Pull starter rope handle sharply until engine

6. Squeeze the throttle trigger, the choke lever

7. Pull starter rope sharply until engine runs.

8. Once the engine runs, allow it to run 10 se-

conds;

1. Slide the self-lock to non-integrated state.

2. Move the stop switch to "1" position.

3. Push starter rope sharply until engien runs.

Stop Switch

Self-lock

osition.

5. Pull starter rope handle sharply until engine

sounds as if it is trying to start, but do not p-

ull rope more than 6 times

8. Once the engine runs, allow it to run 10 se-

conds.

2. Move the stop switch to “1” position.

3. Push starter rope sharply until engine runs.

STARTING A WARM ENGINE

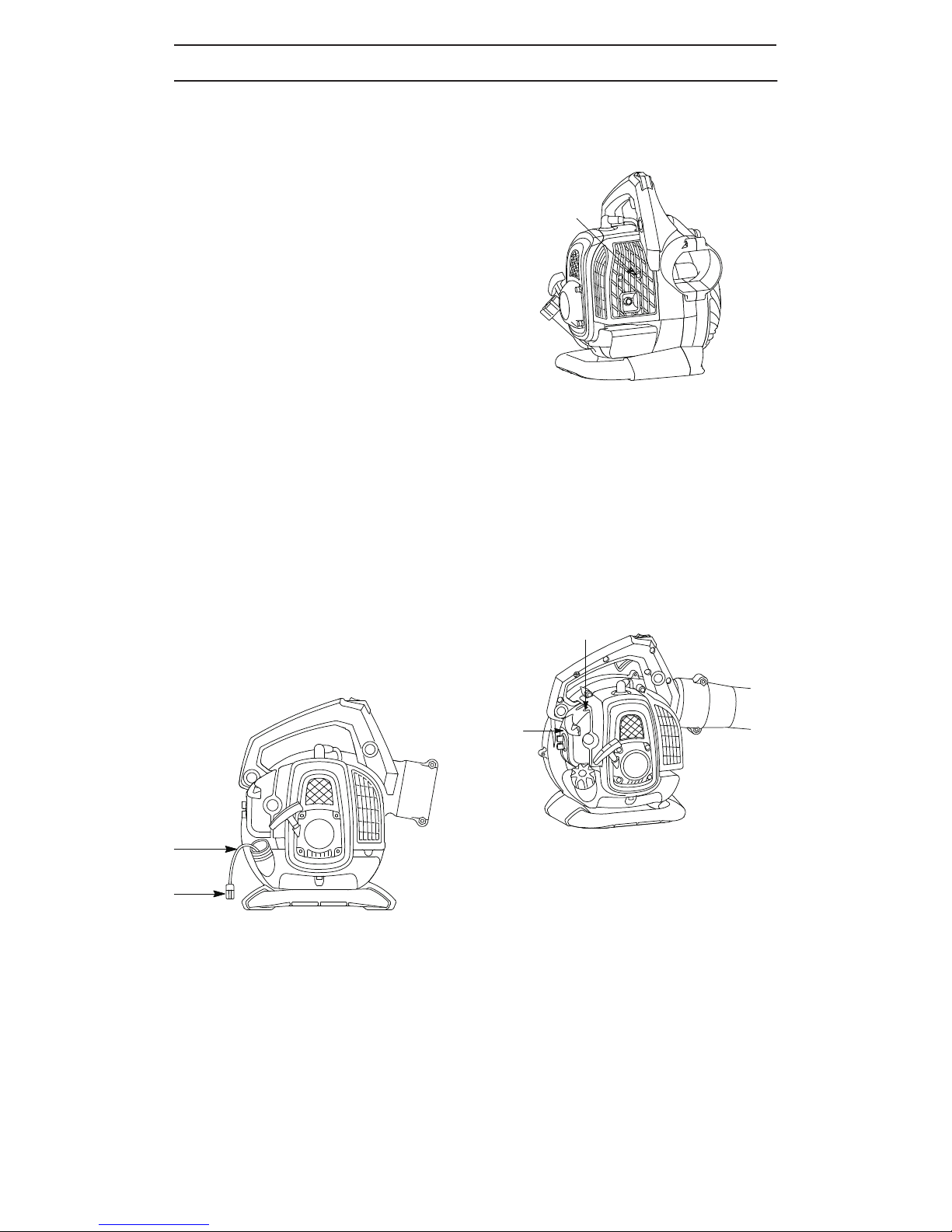

Stop Switch

Air Filter

Cover

Air Filter

position.

1. Ensure the throttle lock lever is in the vertical

4. Move the choke lever to the “Full” choke p-

will move to “ ” choke position.

RUN

6. Squeeze the throttletrigger, the choke lever

7. Pull starter rope sharply until engine runs.

authorise

Throttle lock

lever

Fuel Line

Muffler

Mounting

Screw

Idle Speed Screw

Air

Filter

Cover

Fuel Filter

petrol

anticlockwise

authorise

-- 12 --

STORAGE

WARNING: Prepare unit for storage at

end of season or if it will not be used for 30 days

or more.

SAllow engine to cool, and secure the unit be-

fore storing or transporting.

SStore unit and fuel in a well ventilated area

where fuel vapors cannot reach sparks or

open flames from water heaters, electric mo-

tors or switches, furnaces, etc.

SStore unit with all guards in place. Position unit

so that any sharp object cannot accidentally

cause injury.

SStore unit and fuel well out of the reach of chil-

dren.

EXTERNAL SURFACES

SIf your unit is to be stored for a period of time,

clean it thoroughly before storage. Store in a

clean dry area.

SLightly oil external metal surfaces.

INTERNAL ENGINE

SRemove spark plug and pour 1 teaspoon of

spark plug opening. Slowly pull the starter

rope 8 to 10 times to distribute oil.

SReplace spark plug with new one of recom-

mended type and heat range.

SClean air filter.

SCheck entire unit for loose screws, nuts, and

bolts. Replace any damaged, broken, or worn

parts.

SStart each season using only fresh fuel hav-

OTHER

S

another.

S

1.See “Fueling Your Unit.”

2.Replace with correct spark plug.

TROUBLE CAUSE REMEDY

Engine will not

start.

1.Engine flooded.

2.Fuel tank empty.

3.Spark plug not firing.

4.Fuel not reaching carburetor.

5.Compression low.

1.See “Starting Instructions.”

2.Fill tank with correct fuel mixture.

3.Install new spark plug.

4.Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

Engine will not

idle properly.

1.Fuel not reaching carburetor.

2.Carburetor requires adjustment.

3.Crankshaft seals worn.

4.Compression low.

1.Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

1.Air filter dirty.

2.Fuel not reaching carburetor.

3.Spark plug fouled.

4.Spark arresting screen clogged.

5.Carburetor requires adjustment.

6.Carbon build up.

7.Compression low.

Engine will not

accelerate,

lacks power, or

dies under a

load.

1.Clean or replace air filter.

2.Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

3.Clean or replace spark plug; re-gap.

4.Replace screen.

Engine

smokes

excessively.

1.Choke partially on.

2.Fuel mixture incorrect.

3.Air filter dirty.

4.Carburetor requires adjustment.

1.Adjust choke.

2.Empty fuel tank and refill with

correct fuel mixture.

3.Clean or replace air filter.

Engine

runs hot.

1.Fuel mixture incorrect.

2.Spark plug incorrect.

3.Carburetor requires adjustment.

4.Carbon build up.

TROUBLESHOOTING TABLE

WARNING: Always stop unit and disconnect spark plug before performing any of the

recommended remedies below other than remedies that require operation of the unit.

engine oil (air cooled) through the

2-stroke

ing the proper to oil ratio.

Do not store from one season to

Replace your can if it starts to rust.

petrol

petrol

petrol

5.Contact an service dealer.

authorised

2.Contact service dealer.an authorised

3.Contact an service dealer.

authorised

4.Contact an service dealer.

authorised

5.Contact an service dealer.

6.Contact an service dealer.

7.Contact an service dealer.

authorised

authorised

authorised

4.Contact an service dealer.

authorised

3.Contact an service dealer.

4.Contact an service dealer.

authorised

authorised

-- 13 --

TECHNICAL DATA

MODEL:

ENGINE

Engine displacement, cm3

Idle Speed +/-- 400, rpm 3000

Catalytic converter muffler Yes

IGNITION SYSTEM

Spark plug

Electrode gap, mm 0,6

FUEL AND LIBRICATION SYSTEM

Fuel tank capacity, cm3400

WEIGHT

Weight without fuel and tubes, kg 4,7

NOISE EMISSIONS

(see Note 1)

Soundpowerlevel,measureddB(A)

Sound power level, guaranteed LWA dB(A)

SOUND LEVELS

(see Note 2)

Equivalent sound pressure level at the operator s ear, measured

according to ISO 22868, dB(A)

Equipped with blower tubes and nozzle (original) 96,7

Equipped with vacuum tubes (original) 98,6

VIBRATION LEVELS

(see Note 3)

Equivalent vibration levels (ahv,eq) at handles, measured

according to ISO 22867, m/s2

Equipped with blower tubes and nozzle (original), right 10,1

Equipped with vacuum tubes (original), left/right 8,2/10,4

Note 1: Noise emissions in the environment measured as sound power (LWA) in conformity

with EC directive 2000/14/EC. Reported sound power level for the machine has been mea-

sured with the original cutting attachment that gives the highest level. The difference between

guaranteed and measured sound power is that the guaranteed sound power also includes

dispersion in the measurement result and the variations between different machines of the

same model according to Directive 2000/14/EC.

Note 2: Reported data for equivalent sound pressure level for the machine has a typical

statistical dispersion (standard deviation) of 1 dB(A).

Note 3: Reported data for equivalent vibration level has a typical statistical dispersion (stan-

dard deviation) of 1 m/s2.

TT-BV3405

25.4

Rated Power , KW

Bosch

For technical support in the UK please contact

Sherpa Tools on 01522 283020.

Table of contents