TKO 3R User manual

2

IMPORTANT SAFETY INSTRUCTIONS

•Read this Owner’s Manual and follow it’s instructions carefully before using the

machine. Make sure that it is properly assembled and tightened before each

use.

•Inspect your machine prior to exercise to ensure that all nuts and bolts are fully

tightened.

•Replace the worn parts immediately.

•Most exercise equipment is not recommended for small children. Children

should not use the machine unless they are under adult supervision.

•Exercise equipment has moving parts. In the interest of safety, keep others,

especially children and pets, at a safe distance while exercising.

•Warm up 5 to 10 minutes before each workout and cool down 5 to 10 minutes

afterward. Never hold your breath while exercising.

•Rest adequately between workouts. Muscles tone and develop during these

rest periods. Beginners should work out twice a week and increase gradually to

4 to 5 times per week.

•Remove all jewelry, including rings, chains and pins before commencing exercise.

•Never exercise in bare feet or socks, always wear correct footwear, such as running,

walking, or cross-training shoes.

•Always wear suitable clothing and footwear during exercise. Do NOT wear loose

fitting clothing that could become entangled with the moving parts of your

exercise machine.

MEDICAL WARNING

•Before beginning any exercise program, consult your personal physician.

Evaluate your present fitness level and determine the exercise program that

is most appropriate for your particular age and condition.

•If you experience any pain or tightness in your chest, irregular heartbeats,

shortness of breath, faintness or other unusual discomfort while exercising,

stop and consult your physician before continuing.

Maximum recommended exercise weights not to exceed 270Lbs (123Kgs)

!

3

TKO Fitness products are designed and manufactured to the highest

standards in order to provide you with years of great workouts. We

proudly stand behind all our products with the best customer service in

the fitness industry. If you have any question or need assistance please

contact us at:

Toll free: 866-856-3488 or 713-895-9270

Monday-Friday 8:30am to 4:30pm CT

4

BEFORE YOU BEGIN

Note: Before starting assembly remove all parts and hardware from the

carton, ensure you have everything according to the list.

TOOLS YOU NEED (Included)

ALLEN WRENCH

(5 & 6 mm)

Display Console

HEX WRENCH

(17mm x 2

pcs)

Handlebar

Backrest

(Mesh style)

Console Sleeve

Hand Grip Pulse

Sensor

Upright Post

Upright Bottom

Cover

Seat Adjustment Pull

Handle

Main Frame

e

Front Stabilizer

Foot Pedal

Seat Carriage

Assembly

Knob

Rear Stabilizer

COMBINATION

WRENCH

5

LIST OF COMPONENTS

Display Console

Console Bottom Sleeve

Console Bottom

Sleeve Cover

Upright Post

Assembly

Handlebar

Upright Bottom Cover

Seat Cushion

Backrest Assembly

Seat Rail Cover

Rubber Stopper

Assembly

Foot Pedals

Front Stabilizer

Seat Handlebar

Assembly

Seat Frame

Seat Adjustment

Pull Handle

Rear Stabilizer

Seat Carriage Assembly

Main Frame Assembly

Lock Pin & Bracket

6

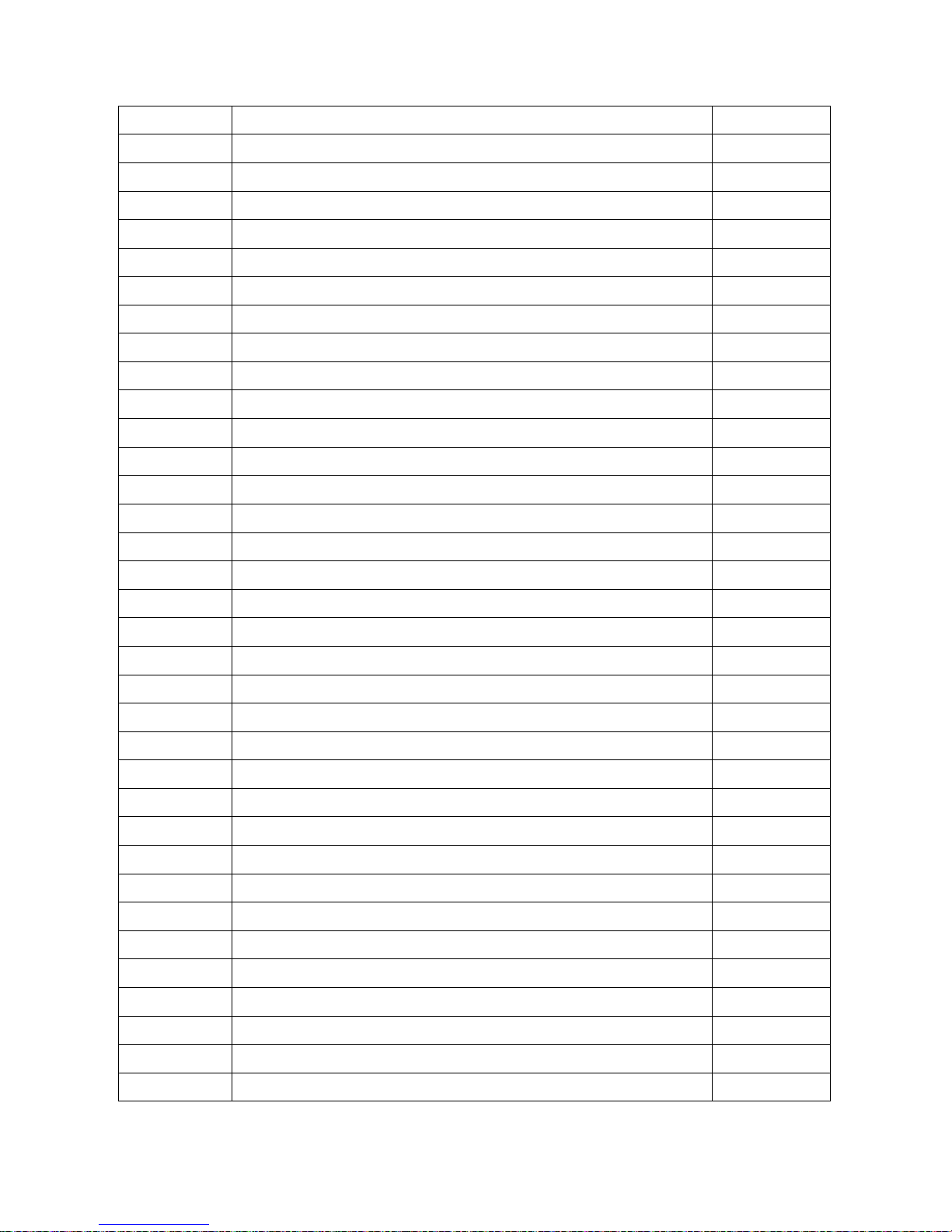

HARDWARE PACK

There are 3 separate hardware pack in the carton (A, B & C)

Assembly step 1: Hardware Pack A

Assembly step 3, 4 & 5: Hardware Pack B

Assembly step 7 to 11: Hardware Pack C

Hardware pack A - Assembly step 1

Part #

Description

Q’TY

88

Lock Washer (M8)

4

90

Flat Washer (8mm x 16mm x 2.0mm t)

4

115

Bolt, Socket Head (M8 x p1.25 x 90mm L)

4

Hardware pack B - Assembly step 3, 4 & 5

Part #

Description

Q’TY

88

Lock Washer (M8)

5

90

Flat Washer (8mm x 16mm x 2.0 t)

5

97

Screw, Pan Head (M5 x p0.8 x 25mm L)

4

99

Screw, Round Head (M5 x p0.8 x 15mm L)

4

111

Bolt, Socket Head (M6 x p1.0 x 15mm L)

4

112

Bolt, Socket Head (M8 x p1.25 x 16mm L)

4

114

Bolt, Socket Head (M8 x p1.25 x 55mm L)

1

Hardware pack C - Assembly step 7 to11

Part #

Description

Q’TY

87

Lock Washer (M5)

2

88

Lock Washer (M8)

10

90

Flat Washer (8mm x 16mm x 2.0 t)

10

93

Self-Tapping Screw, Truss Head (M4 x 16mm L)

1

99

Screw, Round Head (M5 x p0.8 x 15mm L)

2

107

Carriage Bolt (M8 x p1.25 x 50mm L)

2

112

Bolt, Socket Head (M8 x p1.25 x 16mm L)

10

113

Bolt, Socket Head (M8 x p1.25 x 40mm L)

4

119

Bolt, Hex Head (M10 x p1.5 x 90mm L)

1

127

Lock Nut (M8 x p1.25)

2

128

Lock Nut (M10 x p1.5)

1

150

Nylon coated Screw, Round Head (M5 x p0.8 x 15mm L)

2

7

EXPLODED DIAGRAM (A)

8

EXPLODED DIAGRAM (B)

!

!

9

PARTS LIST

NO.

Item Name

Q'TY

1

Main Frame

1

2

Seat Rail Support Bracket (front)

1

3

Seat angle adjustment upper tube

1

4

Seat angle adjustment lower tube

1

5

Front Stabilizer

1

6

Rear Stabilizer

1

7

Upright Post

1

8

Handlebar

1

9

Seat Carriage

1

10

Seat Frame Support

1

11

Seat Frame

1

12

Seat Handlebar

1

13

Chain Cover (Left Front)

1

14

Chain Cover (Right Front)

1

15

Crank Disk (L&R)

2

16

Chain Cover (Left Rear)

1

17

Chain Cover (Right Rear)

1

18

Decoration Cover for Angle Adjustment Lower Tube

1

19

Base Center Cover

1

20

Left foot Pedal

1

21

Right foot Pedal

1

22

Pulley (Sprocket)

1

23

Magnet

1

24

Drive Belt

1

25

Compression Wheel

1

26

Bushing (ψ50.8xψ10) (For Part 3)

2

27

Bushing (ψ60xψ10) (For Part 2 & 4)

4

28

Plastic Sleeve (For Part 4)

1

29

Spring Loaded Lock Pin

1

30

Decorative Cover (For Front & Rear Stabilizer)

2

31

Transport Wheel (L&R)

2

32

Front Stabilizer End Cap

2

33

Rear Stabilizer End Cap

2

10

NO.

Item Name

Q'TY

34

Upright Bottom Cover

1

35

Foam Grip (530mm) (For Part 8)

2

36

Plastic Plug (20x40mm) (For Part 11)

1

37

Display Console

1

38

Console Bottom Sleeve

1

39

Console Bottom Sleeve Cover (Left)

1

40

Console Bottom Sleeve Cover (Right)

1

41

Backrest (Mesh Style)

1

42

Seat Cushion

1

43

Foam Grip (330mm) (For Part 12)

2

44

Hand Grip Pulse Sensor (L&R)

2

45

Plastic Round Plug (31.8mm) (For Part 8 & 12)

4

46

Plastic Plug (25.4mm) (For Part 11)

4

47

Seat Locking Device (For Part 10)

1

48

Seat Carriage Cover (Left)

1

49

Seat Carriage Cover (Right)

1

50

Seat Adjustment Pull Handle (Plastic Handle)

1

51

Guide Wheel (For Part 9)

1

52

Wheels (37.6mm) (For Part 9)

4

53

Rubber Bumper

4

54

Rail Decorative Cover (Left)

1

55

Rail Decoration Cover (Right)

1

56

Flywheel

1

57

Tension Cable

1

58

Tension Control Motor Bracket

1

59

Left Crank

1

60

Right Crank

1

61

Axle (For Crank)

1

62

Bracket for Compression Wheel

1

63

Upright Cover (L&R)

2

64

Seat Rail

1

65

Fixed Bracket for Seat Rail

1

66

Seat Adjustment Pull Handle Mounting Bracket

1

67

Seat Adjustment Pull Handle

1

11

NO.

Item Name

Q'TY

68

Steel Pin (For Part 66)

1

69

Lock Pin (For Part 9)

1

70

Axle for Braking (For Part 9)

1

71

Axle for Backrest Tube (For Part 10)

1

72

Bearing (6004zz) (Pulley)

2

73

Eye Bolt (40mm) (For Flywheel) (Part 56)

2

74

Eye Bolt (50mm)(For Part 62)

3

75

Tension Bracket (For Flywheel) (Part 56)

2

76

Bushing (10.2x14x2mm) (For Part 25)

1

77

Bushing (10.2x14x10mm) (For Part 25)

1

78

Spring (For Part 62)

1

79

Spring (For Seat Adjustment) (For Part 47)

1

80

Spring for Steel Pin (For Part 68)

1

81

Spring (For Seat Adjustment Pull Handle) (Part 66)

1

82

Bushing for Seat Guide Wheel (For Part 51)

2

83

Screw Cap (For Part 10)

2

84

Bushing (8x12x6.5mm) (For Part 52)

4

85

C Ring (20mm) (For Part 72)

1

86

Wave Washer (For Part 72)

1

87

Lock Washer (M5) (For Part 66)

2

88

Lock Washer (M8)

23

89

Washer (6x19x1.5t) (For Part 71)

2

90

Washer (8x16x2.0t)

19

91

Washer (10x23x2.0t) (For Part 4 & 56)

3

92

Washer (21x30x1.0t) (For Part 72)

2

93

Self-Tapping Screw, Truss Head (M4x16mm)

9

94

Self-Tapping Screw, Truss Head (M5x18mm)

27

95

Self-Tapping Screw, Flat Head (M4x20mm) (For Part 44)

2

96

Bolt, Button Head (M6xp1.0x40mm) (For Part 74)

2

97

Screw, Pan Head (M5xp0.8x25mm) (For Part 38)

4

98

Screw, Round Head (1/4’’x20mm) (For Part 41)

4

99

Nylon-Coated Screw, Round Head (M5xp0.8x15mm)

16

100

Screw, Round Head (M5xp0.8x40mm) (For Part 19)

2

101

Bolt, Round Head (M6xp1.0x25mm) (For Part 15)

8

12

NO.

Item Name

Q'TY

102

Bolt, Round Head (M6xp1.0x35mm) (For Part 47 & 66)

2

103

Bolt, Round Head (M6xp1.0x65mm) (For Part 10)

1

104

Screw, Flat Head (M5xp0.8x12mm) (For Part 135)

4

105

Bolt, Pan Head (M8xp1.25x15mm) (For Part 58)

2

106

Bolt, Pan Head (M8xp1.25x25mm) (For Part 52)

4

107

Carriage Bolt (M8xp1.25x50mm) (For Part 12)

2

108

Bolt, Button Head (M10xp1.25x35mm) (For Part 25)

1

109

Bolt, Hex Head (M10xp1.25x45mm) (For Part 62)

1

111

Bolt, Socket Head (M6xp1.0x15mm) (For Part 37)

4

112

Bolt, Socket Head (M8xp1.25x16mm) (For Part 7 & 64)

14

113

Bolt, Socket Head (M8xp1.25x40mm) (For Part 42)

4

114

Bolt, Socket Head (M8xp1.25x55mm) (For Part 8)

1

115

Bolt, Socket Head (M8xp1.25x90mm) (For Part 5 & 6)

4

116

Bolt, Hex Head (M8xp1.25x16mm) (For Part 22)

4

117

Bolt, Hex Head (M8xp1.25x105mm) (For Part 47)

1

118

Bolt, Hex Head (M8xp1.25x115mm) (For Part 53)

2

119

Bolt, Hex Head (M10xp1.5x90mm) (For Part 3)

1

120

Bolt, Hex Head (M10xp1.5x115mm) (For Part 3 & 4)

2

121

Collar Screw (M6) (For Part 80)

2

122

Flange Nut (M10) (For Part 56)

2

123

Nut (M6) (For Part 74)

3

124

Nut (M8) (For Part 53, 67 & 147)

4

125

Nylon Lock Nut (M6) ( For Part 71 & 73)

6

126

Thin Nylon Lock Nut (M8) (For Part 22 & 52)

8

127

Nylon Lock Nut (M8) (For Part 10 & 12)

9

128

Thin Nylon Lock Nut (M10xp1.5) (For Part 3 & 4)

3

129

Nylon Lock Nut (M10xp1.25) (For Part 25 & 62)

2

130

Monitor Display Cable

1

131

Monitor Display Connecting Cable (Inside Upright)

1

132

Power Connecting Cable

1

133

AC/DC Adaptor

1

134

Speed Sensor (Inside Main Frame)

1

135

Tension Control Motor

1

136

Pulse Sensor Cable 1 (Behind Monitor)

1

13

137

Pulse Sensor Cable 2 (Inside Upright)

1

138

Pulse Sensor Cable 3 (Inside Part 2)

1

139

Pulse Sensor Coil Cable (Inside Seat Rail)

1

140

Pulse Sensor Cable 4 (Inside Handlebar)

1

141

Plastic Plug (25x75mm) (For Part 10)

1

142

Flange Nut – Black Color (M10) (For Crank)

2

143

Nut (M5) (For Part 67)

1

144

Bolt, Button Head (M8xp1.25x16mm)

4

145

Washer (8x26x2.0t) (For Part 47)

2

146

Self-Tapping Screw, Button Head (M4x16mm) (For Part 31)

4

147

Floor Leveler

1

148

Backrest Plastic Cover

1

149

Lock Washer (M6) (For Part 41)

4

150

Nylon coated Screw, Round Head (M5xp0.8x15mm) ( For Part 67)

2

14

ASSEMBLY INSTRUCTIONS

STEP 1 – Base Stabilizer

a. Attached the Front Stabilizer (5) to the Main Frame (1). A circular decal (“R”)

should be located on the right side of the Front Stabilizer (5).

b. Secure it using 2 Lock Washers (M8) (88), 2 Regular Washers (8x16x2.0t)(90)

and 2 Bolts, Socket Head (M8xp1.25x90mm) (115).

c. DO NOT tighten these bolts yet.

d. Attached the Rear Stabilizer (6) to the Main Frame (1) using 2 Lock Washers

(M8) (88), 2 Regular Washers (8x16x2.0t) (90) and 2 Bolts, Socket Head

(M8xp1.25x90mm) (115).

e. Securely tighten these 4 Bolts with Wrenches.

f. Install the Floor Leveler (147) to the bottom of the Main Frame Assembly. Adjust

it accordingly.

STEP 2 – Pedal Assembly

a. Attached the Right Foot Pedal (21)to the Right Crank (60) behind the Crank Disk

(15). Threaded clockwise and tighten it securely with Wrench.

b. Attached the Left Foot Pedal (20)to the Left Crank (59) behind the Crank Disk

(15). Threaded counterclockwise and tighten it securely with Wrench.

USE HARDWARE KIT

A

15

STEP 3 – Upright Post Assembly

a. Slide the Upright Sleeve (26) onto the Upright Post Assembly (5)

b. Attach the Upright Post Assembly (5) to the Main Frame (1), using 4 Washers

(8x16x2.0t) (90), 4 Lock Washers (M8) (88), and 4 Bolts, Socket Head

(M8xp1.25x16mm) (112). Securely tighten it with Wrench. Make sure you

place the Lock Washer in between the Bolt and the Regular Washer.

c. Connect the Cable (95A) at the bottom of the Upright to the Motor Cable (98)

inside the Main Frame Assembly.

d. Connect the Cable (95B) to the Adaptor Connection Cable (96).

e. Connect the Cable (95C) to the Sensor Cable (99).

f. Make sure the Cables are securely connected.

g. Make sure you DO NOT pinch the Cable.

h. Securely attached the Upright bottom cover (34) to the Main Frame Assembly

(1)

USE HARDWARE KIT

B

16

STEP 4 – Display Console and Handlebar Assembly

a. Attached to Console Bottom Sleeve (38) to the back of the Display Console (37).

Secure it with 4 Screws, Pan Head (M5xp0.8x25mm) (97).

b. Loosen and remove the Bolt (144), Regular Washer (90) and Lock Washer (88)

from the Handlebar (8). There are 4 of them.

c. Install the Handlebar (8) to the Upright Post Assembly (7) and tighten with 5

Washers (8x16x2.0t) (90), 5 Lock Washers (M8) (88) and 4 Bolts, Button

Head (M8xp1.25x16mm) (144) & 1 Bolt, Socket Head (M8xP1.25x55mm)

(114). Tighten it securely with Wrench.

d. Attached the Display Console Assembly onto the metal plate that welded on the

Upright Assembly (7). Secure it using 4 Bolts, Socket Head

(M6xp1.0x15mm)(111). Tighten it securely with Wrench.

g. Connect the Cable (130) in the back of the Console to the Cable (131) in the

Upright.

h. Connect the Pulse Sensor Cable 1 (136) in the back of the Console and the Pulse

Sensor Cable 2 (137) in the Upright.

i. Make sure the Cables are connected securely and you DO NOT pinch the Cable.

USE HARDWARE

KIT B

17

STEP 5 – Console Sleeve Assembly

a. Slide the Right Console Bottom Sleeve Cover (40) thru the right side Handlebar

(8).

b. Slide the Left Console Bottom Sleeve Cover (39) thru the left side Handlebar (8).

c. Securely tighten it with 4 Screws, Round Head (M5xp0.8x15mm) (99) using

Philips Screwdriver.

d. Display Console angle can be adjusted by pulling it forward or back.

USE HARDWARE

KIT B

18

STEP 6 – Pull Pin Assembly

a. The Seat Rail has 5 angle adjustments. They are, Level 1- 9 degree. Level 2- 18

degree. Level 3- 27 degree. Level 4- 36 degree and Level 5- 45 degree.

b. When changing the seat height, you must first loosen the Spring Loaded Lock

Pin (29) located in the back of the Lower Tube (4) by turn the knob

counterclockwise 3 turns, pull the knob outward to change the seat angle (select

1 of the 5 holes), release the knob reengage the lock pin to the Upper Tube.

c. A CLICK sound should be heard when Lock Pin has engaged to the hole in the

Upper Tube.

d. Tightening the Lock Pin (29) by turn the knob clockwise until it is fully tightened.

e. Once you changed the Rail angle, you can adjust the Seat angle by using the

Leveler located in the back on the Seat Carriage Assembly. There are also 5

adjustments. In normal condition, the Seat should be parallel to the floor.

19

STEP 7 – Bracket for Rail

Attach the Fixed Bracket for Seat Rail (65) to the rear bottom of the Rail, secure it

using 4 Washers (8x16x2.0t) (90), 4 Lock Washers (M8) (88) and 4 Bolts, Socket

Head (M8xp1.25x16mm) (112) (illustration shown above). Tighten it securely with

Wrench.

USE HARDWARE KIT

C

20

STEP 8-a & b

STEP 8-c

STEP 8 – Seat Support Assembly

There are 2 holes approximately one inch apart toward the front of the rail.

a. Install the Rubber Bumper (53) onto the Rail (Hole 1) using 1 Bolt

(M8px1.25x115mm) (118), 1 Nut (M8) (124). Tighten it securely with Philip

Screwdriver.

b. Install the Rail to the Seat Rail Support Bracket (2) (Factory preinstalled) in the

Main Frame Assembly, secure it using 2 Washers (8x16x2.0t) (90), 2 Lock

Washers (M8) (88) and 2 Bolts, Socket Head (M8xp1.25x16mm) (112) in Hole

2. Make sure the Lock Washer are in between the Bolt and the Regular Washer.

DO NOT tighten these 2 Bolts yet.

c. Install 4 Bolts, Socket Head (M8xp1.25x16mm) (112), 4 Lock Washers (M8)

(88) and 4 Regular Washers (8x16x2.0t) (90) to the Main Frame Assembly

from the bottom of the Rail. DO NOT tighten these Bolts yet.

Table of contents

Other TKO Exercise Bike manuals

Popular Exercise Bike manuals by other brands

Proteus

Proteus PEC-4945 owner's manual

BODY BIKE

BODY BIKE SMART+ Do's & don'ts

ergoline

ergoline ergoselect 600 Operator's manual

Skandika Fitness

Skandika Fitness SF-2210 Assembly instructions and user guide

BH FITNESS

BH FITNESS RDX 1.1 H9179N Instructions for assembly and use

Schwinn

Schwinn 120 Assembly manual