TKS AGRI Conveyor TR User manual

TKS

1

Conveyor TR - EN Issue 1, 05-2016 988784

IT_06

Operator’s manual -

Spare parts list

Conveyor TR

TKS

2

Content

1 GENERAL SAFETY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 PREPARING A NEW MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3 MAINTENANCE AND CARE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4 CIRCUIT DIAGRAM - CONVEYOR TR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5 SPARE PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

1 GENERAL SAFETY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 CE - Declaration of conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.2 Guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.4 Technical data - Conveyor TR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.4.1 Model description and area of use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.4.2 Machine identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.4.3 Main dimensions - Conveyor TR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1.5 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

1.5.1 General safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

1.5.2 Additional safety instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

1.5.3 Overview of safety risks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

1.5.4 Lifting the machine with a crane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

1.5.5 New machine – caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

1.5.6 Lifting point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

1.6 Recycling - waste to resource - . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

TKS

3

2 Preparing a new machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.1 Installing the power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

3 Maintenance and care. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.1 Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

3.2 Tightening the belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4 Koblingsskjema - Conveyor TR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5 Spare parts list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

TKS

4

1 General safety instructions

We,

T. Kverneland & Sønner AS,

Kvernelandsvegen 100

N-4355 Kverneland

Norge

declare that the product:

TKS - Conveyor TR

has been built in conformity with the Machine Directive (2006/42/EC) and meets the relevant

fundamental health and safety requirements.

Kverneland, 03-2013

Tønnes Helge Kverneland

General Manager

Enter the serial number

of the machine

T. Kverneland & Sønner AS, manufacturer of agricultural products, reserves the right

to change the design and/ or specifications of its products without prior warning.

This does not imply any obligation to modify previously supplied machines.

1.1 CE - Declaration of conformity

TKS

5

1.2 Guarantee

This TKS product is guaranteed against manufacturing and material defects for one year.

If the owner wishes a defect to be covered by the product guarantee, he or his representative must

inform the dealer of this when ordering parts and/or repairs. Claims must be reported within the

guarantee period.

The dealer must complete a claims form for each case covered by a guarantee and send it to TKS

or TKS’s distributor/importer within the 10th of the month following the one in which the defect was

reported.

The defective parts shall be marked with the claim number and be kept for up to 6 months so that

TKS or TKS’s distributor/importer can inspect them.

Since TKS products are used outside the manufacturer’s control, we can only guarantee the

product quality, and not that it will perform its function, nor are we liable for any resulting damage.

The guarantee is not valid if:

a) third-party spare parts are used, or the product is repaired or altered without the

approval of TKS

b) the operating and servicing instructions have not been followed

c) the machine has been used for other purposes than those for which it is designed

The guarantee does not cover damage due to normal wear and tear.

Official safety regulations specify requirements that apply to the manufacturers of this machine

relating to the careful review of safety hazards that may arise when this type of machine is used

correctly. Therefore, TKS and our importer/distributor are not responsible for the functioning of

components that are not shown in the spare-parts catalogue for this product.

TKS reserves the right to change the design of the product without this implying any obligations in

relation to previously supplied machines.

NB! It must be possible to identify all enquiries relating to this product by the product’s serial

number; see page 7 on Machine identification.

TKS

6

1.3 Introduction

Congratulations on buying your new TKS product. You have chosen a functional, high quality

product. Anetwork of helpful dealers will be able to advise you on its use, as well as provide

servicing and spare parts.

All TKS products are designed, tested and built in close cooperation with farmers and machine

workshops to ensure optimal efficiency and reliability.

Please read this instruction manual carefully and familiarise yourself with the machine’s manner of

operation before starting to use it.

Many different factors and variables can affect the performance and method of operation of the

machine. It is therefore very important to assess all known factors and adapt the way in which the

machine is used accordingly. Agood understanding of the machine’s method of operation and

performance, together with a sound knowledge of feeding and

feed types/consistency will ensure the best results.

By being thorough and making the necessary adaptations to local conditions, you will ensure the

best possible results.

Yours faithfully

T. Kverneland & Sønner AS

T. Kverneland & Sønner AS,

Kvernelandsvegen 100

N-4355 Kverneland

Norway

www.tks-as.no

Phone : + 47 51 77 05 00

Fax : + 47 51 48 72 28

TKS

7

1.4 Technical data - Conveyor TR

1.4.1 Model description and area of use

The universal Conveyor TR with a length of 3–9 metres is a lightweight, flexible structure for the

practical handling of materials, which can be easily adapted to all medium-weight materials such

as: wood, chippings, timber waste, potatoes, onions, root vegetables, pellets, silo feed, ice, fish,

etc.

The Conveyor TR belt and carrier are powered by an electric motor on the drive roller, or by a

worm gear motor at the top end of the belt.

• The carrier belt runs on sheet metal bases.

• Conveyor TR belt of reinforced rubber with carrier.

• Minimum operating temperature -20OC.

Conveyor TR: 600

Belt width in mm 600

Motor power rating in kW with 5-metre 2,2

Belt speed in m/sec 1 m/sek

Carrier height in mm 60mm

Carrier c/c spacing in mm (standard) 750

Available equipment:

Supporting foot

Refilling funnel

TKS

8

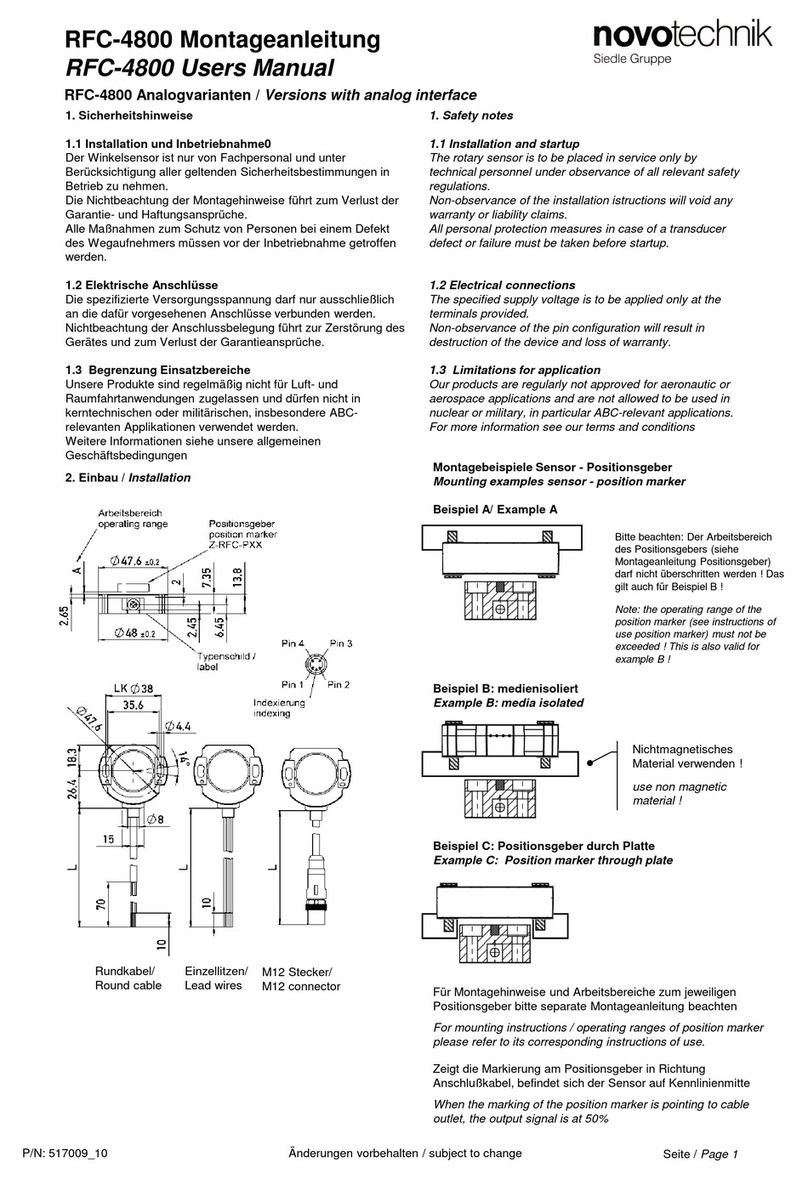

1.4.2 Machine identification

The machine’s serial number and the manufacturer’s address are written on a plate on the

machine. See the illustration on this page. The machine‘s serial number and the delivery year

should be written below.

Please use this information when making any enquiries about spare parts or servicing.

This product is CE marked. This mark, along with the associated written EU confirmation, means

that the product fulfils current health and safety requirements, and complies with the following

directives: Machine Directive, 2006/42/EC.

IT_14

729

412

911

512

1000

404

6000

502

722

832

TKS

9

1.4.3 Main dimensions - Conveyor TR

All measurements are in mm.

IT_01

IT_02

IT_12

TKS

10

The refilling funnel (A) should be used on slopes exceeding 35O. Max slope is 45O.

See extra equipment.

Example:

Conveyor TR length of 6 m. Slope 30O

Height to top end 2,85 m

Length from rear end 5,40 m

IT_02

Slope 40O

Slope 30O

Slope 20O

Length in metres

Height in metres

IT_04

A

TKS

11

TKS

12

1.5

Safety Please pay particular attention to this symbol.

It designates a safety risk, and describes

precautions that must be taken to avoid

accidents

Before operating, adjusting or repairing the

machine, the user, technician or owner should

familiarise himself with the safety instructions

contained in this installation manual.

Using the equipment for the first time:

It is important to drive carefully in the beginning

in order to adjust the driving pattern to local

conditions and to the consistency of the bales.

Please note that this affects functionality / mode

of operation. Proceed carefully.

Safety at work is your responsibility!

1.5.1

General safety

instructions Please read and understand these general

safety instructions.

Use of the machine

The machine must only be used for the purpose

for which it is designed.

The machine’s method of operation

The operator must familiarise himself with the

machine’s method of operation and function so

that the machine can be used in a safe and

appropriate manner.

Keep a safe distance

Mennesker og dyr skal holdes borte fra

maskinen når denne er i drift.

Hold avstand fra arbeidende, roterende og

bevegelige deler.

Think safety at work

Never climb on the machine while it is

operating. If maintenance must be carried out,

the power supply must be disconnected.

Protective screens

Check that all screens are in order and correctly

fitted. Do not start the machine until this has

been done. Damaged screens must be repaired

or replaced immediately.

Spare parts

For safety reasons we recommend that you

only use original spare parts. The use of

third-party spares invalidates the product

guarantee.

TKS

13

Maintenance

Make sure that the machine is maintained satis-

factorily and kept in good condition.

Never make alterations to the machine’s struc-

tures.

The machine’s working area

This must be physically cordoned off or locked

in order to prevent hazards for

people and animals.

988010

TKS

14

1.5.2

Additional safety-

instructions

The machine is marked with a warning

signs. If these signs are damaged, they must

be replaced. The order number is shown on the

illustrations in this section.

Fig. 4 for their location on the machine.

Warning sign UH220532 (Fig. 1)

Ensure that you read and understand the

instruction manual before using the machine,

and before making any adjustments or

performing any maintenance.

Warning sign UH220539 (Fig. 2)

Finger fracture warning sign. Risk of finger

fracture if fingers are trapped between the

carrier and lower frame.

Warning sign 988010 (Fig. 3)

NB! The carrier on the elevator belt and the

chain on the elevator must be kept tight. It is

therefore important and necessary to retighten

the screws regularly.

Fig. 1

Fig. 2

Fig. 3

UH220532

UH220539

988010

TKS

15

1.5.3 Overview of safety risks

IT_07

Fig. 4

IT_15

TKS

16

1.5.4

Lifting the machine

with a crane

Only use approved lifting equipment.

The machine must be lifted from the points

marked with a lifting symbol. See Fig. 5

Caution!

Ensure that no-one is under or close to the

machine when it is being lifted.

Lift the machine using a strap attached to the

main frame of the machine, so that the lift is

balanced.

Check that the straps are properly fixed before

starting the lift.

Use an extra strap to help keep the machine in

position.

1.5.5

New machine –

caution Read the operator’s manual

Be particularly careful when starting a new

machine for the first time. Installation faults.

Be particularly careful when starting a new

machine for the first time. Installation faults,

incorrect operation, etc. may lead to expensive

repairs and loss of earnings. The TKS product

guarantee does not cover damage resulting

from failure to follow the recommendations

contained in the instruction manual.

Please pay particular attention to this symbol.

It is used to highlight important information, to

help prevent incorrect installation and

operation.

Pay particular attention to the following

when commissioning a new machine:

Check that the machine is correctly installed

and that it is not damaged.

Lubricate the machine where shown on

Fig. 8 in Section 3 on Maintenance

Remember that the operator is

responsible for the product being properly

packed.

220307

TKS

17

IT_15

Fig. 5

1.5.6 Lifting point

The indicated lifting point must be used when lifting.

TKS

18

1.6 Recycling

- waste to resource -

TKS’s products rely on electrical and electronic components in order to work.

These fall under the generic term of EE products. TKS’s products use typical components such as

cables, switches, motors, control units, etc.

When TKS products are thrown away those components containing contaminants should be

treated and sorted in such a way that they do not pollute the environment. Contaminants should be

taken care of safely.

Distributors are obliged to accept EE waste from products in the range of goods they sell.

This waste should be kept safe and sent on to an approved waste recipient or treatment plant.

EE waste must be sorted and transported in such a way that it is not damaged or destroyed.

If you need further information on the treatment of EE waste, please contact your distributor.

Regards

TKS AS

TKS

19

TKS

20

Fig. 6

IT_08

2 Preparing a new machine

A

E

B

D

F

G

C

Table of contents

Popular Accessories manuals by other brands

Taurus

Taurus COMFORT THERM CPH-20 manual

Soehnle Professional

Soehnle Professional 3700 BASIC user manual

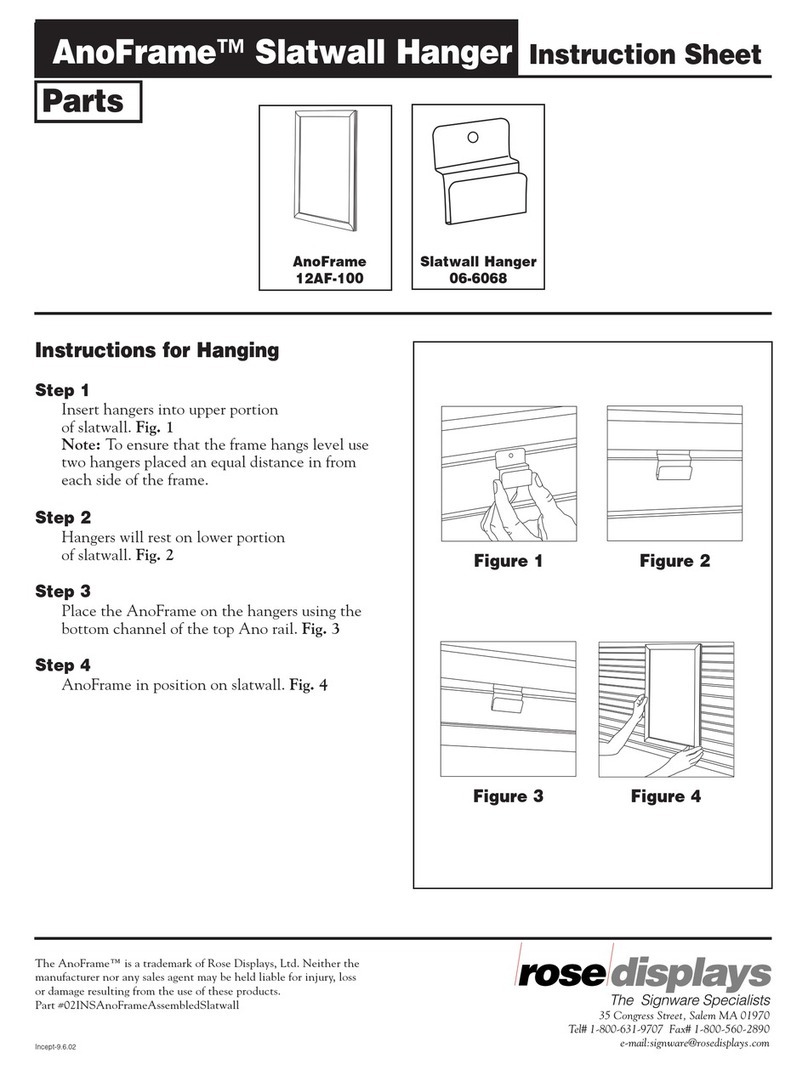

ROSE DISPLAYS

ROSE DISPLAYS ANOFRAME ROUND ASSEMBLED-SLATWALL manual

Omega Engineering

Omega Engineering Wireless Sensor System zSeries user guide

ring

ring chime Quick install guide

texet

texet PowerPack TPB-2112 user guide