asta asta

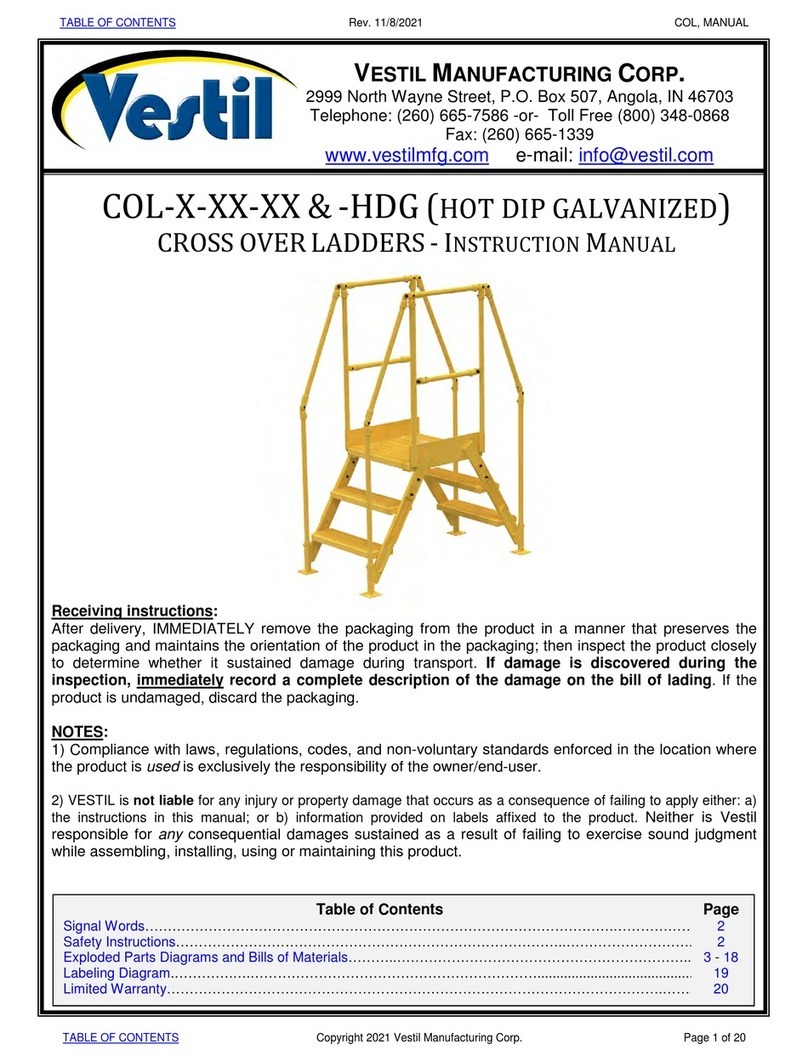

SELF-ASSEMBLY STAIRS SELF-ASSEMBLY STAIRS

GUIDELINES CONCERNING INSTALLATION, SERVICING AND UTILISATION OF ASTA STAIRS

TECHNICAL INFORMATION

TECHNICAL PARAMETERS

Duck board permissible load 2kN/m2

Load per step 125kg

Useable width 900mm

External width 962mm

Steps dimensions 900x260mm

Stairs height (H) depending on the number of steps 340-2800mm

Height of a step (S) 170-200mm

Material Steel S355JR, S235JR, 420MC

Anticorrosion coating

1. Stairs supporting structure and balustrades:

- hot dip galvanising

- hot dip galvanising and powder paint: Black RAL9005

- abrasive blasting and

powder paint: Black RAL9005

2. Steps (welded grating and perforated sheet)

- hot dip galvanising

3. Step substructure (outdoor and indoor board)

- hot dip galvanising

- hot dip galvanising and powder paint: Black RAL9005

- abrasive blasting and

powder paint: Black RAL9005

STEPS MAXIMUM HEIGHT

In modular stairs ASTA it is possible to adjust step height, in accordance with the regulations and depending on the type

and intended use of the room.

Limits of the height of steps in fixed stairs used in buildings of various utility functions are presented in the table below.

OCCUPATIONAL HEALTH AND SAFETY GUIDELINES CONCERNING THE INSTALLATION

The self-assembly of modular stairs may be performed by a person who read the guidelines included in this instructions.

A person performing the assembly should:

• check the technical conditions of the structure or devices used in the assembly works

• make sure that electric tools that are to be use in the assembly are in good technical condition allowing their safe

use and that they do not threaten the environment

• make sure that clothing and its elements do not pose a threat during the performance of assembly works

• protect oneself against the fall from a height or the fall of tools or structure elements

After completing all works, the person performing the assembly should:

• make sure that all electric devices are unplugged,

• make sure that all tools are put back and secured so that the would not pose a threat for the user and environment.

It is forbidden to:

• use the stairs that are incomplete or assembled not in accordance with the instructions

• installation of the structure not in accordance with guidelines included in the instructions

• replacing structure fasteners

GUIDELINES ON PERIODIC INSPECTIONS

TLC recommends performing ongoing inspection from utility level of the stairs, and in the case of irregularities, and

not less than once a year, also the inspection of ground level under the property and next to it. Ongoing inspection of

engineering structure is a visual inspection (survey) made within an ad hoc inspection of the structure performed to see

if there are any damages directly threatening the safety of users.

The purpose of the ongoing inspection is the verification whether there are:

• damages directly threatening the safety of users

• damages significantly decreasing the comfort of using the structure or its surroundings

TRANSPORT AND STORAGE

The elements of stairs system ASTA were prepared in packages, which considerably facilitate the transport and protect

the elements from being damaged. While loading make sure that packages were placed and secured so that they do

not pose a threat to any transporting persons. Secure the packages so that they could not move during the transport. If

at the same time you transport other items, secure them in the same way. Otherwise there is a risk that the elements of

the stairs will be damaged and that there will be a direct threat to the transporting persons. All elements of the system

should be stored is dry spaces, both before and after unpacking.

UTILISATION

Packaging and used devices should be stored, managed or disposed according to applicable recommendations and

requirements defined in Act on waste of 27 April 2001 (Dz. U. [Journal of Laws] 2001 no. 62 item 628 as amended).

TYPE OF BUILDING STEP MAXIMUM HEIGHT (MM)

Single family and farm residential buildings, two-level apartments 190

Built-in and separate garages (for many vehicles) and service buildings, where is

employed more than 10 people. 190

All buildings, regardless their intended use for stairs to the basement, technical rooms

and non-habitable attics. 200

TORQUE FOR SCREW CONNECTIONS

It is recommended to tighten screw connections in accordance with optimum values of torques presented in the table below.

FASTENER RECOMMENDED TORQUE (Nm)

Screw M8 (strength class 8.8 thread pitch 1.25mm) 27

Screw M10 (strength class 8.8 thread pitch 1.5mm) 46

Screw M12 (strength class 8.8 thread pitch 1.75mm) 79

14 15