TMCON FT803 User manual

Economical Smart Temperature Controller

1 2 3

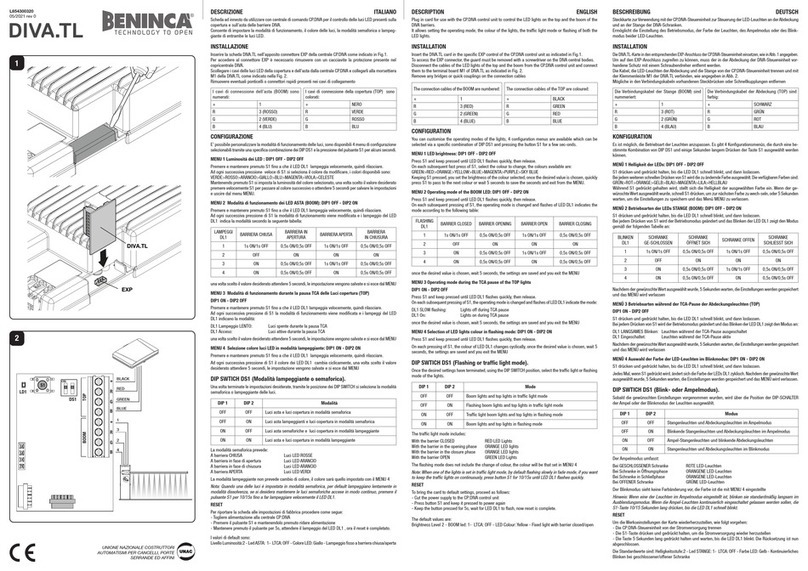

4 Wiring diagram、

4

21

Operating Ambient Temperature:0~60°C;Humidity≤90%RH

Response time ≤0.5Sec(when digital filter parameter InF=0)

Relay output

SSR Voltage output

TRIAC no contact discrete output

3A/250VAC 5A/30VDC

0.2A (continuous), 2A (20mS instantaneous, repeat period≥5s) /100~240VAC

12VDC/50mA(Used to drive SSR)

Electromagnetic compatibility (EMC) IEC61000-4-4(Electrical Fast Transient Burst)±4KV/5KHz;IEC61000-4-5(Surge),4KV

R

FT803

1、main features

2、Model defined

FT803

AC/DC100 240V , or AC/DC12-24V(~-15%, +10%/50-60HZ)

0.3% FS ± 1 measurement unit

48X48mm 72X72mm 96X96mm 48X96mm 96X48mm

45 X45

+0.6 +0.668 X68

+0.6 +0.692 X92

+0.6 +0.6

Measurement accuracy

Panel size(W*H)

Panel cutout size

3、Technical parameters

size code G D A E F

Output mode

Power consumption Approx. 5.2 VA at 100 to 240 VAC, Approx. 3 VA at 12 to 24 VDC

Operation Manual

Gross weight Approx. 177 g Approx. 272 g Approx. 419 g Approx. 286 g

FT803,The temperature controller belongs to the economy,The operation is simple, easy to

learn and use.

Use digital calibration technology for input Measurement accuracy:0.3%FS,Support

standard thermocouples and platinum resistance,maximum resolution is 0.1℃.

Use advanced artificial intelligent control algorithm, no overshoot and with the function of

auto tuning (AT) and self-adaptation.

With worldwide power supply of AC/DC100-240V or AC/DC12-24V and various installation

dimensions for users to choose.

Power supply voltage

5

45 X92

+0.6 +0.692 X45

+0.6+0.6

Relay contacts output

Code OUT(Master output)

R

QSSR voltage output

W1 TRIAC no contact

normally open output

W2 TRIAC no contact

normally closed output

NNone

2

48X48mm

Code Panel size(W*H)

G

D72X72mm

A96X96mm

E

F

48X96mm

96X48mm

1

Light gray

Code Shell color

Black

B

None

4

AC/DC100~240V

Code Power

AC/DC12-24V

D

None

5

None

Code ALM Alarm)(

1 relay contact output

1

N

3

22 relay contact output

Panel back depth 86mm

89mm

99mm 99mm

72mm

K(-50~+1300°C),E(0~800°C),J(0~1000°C),N(0~1300°C),

Pt100(-200~+600°C)

0、0.0

Decimal point

Input type and

Measuring range

+

ABB

-

12

10

9

8

76

11

12

13

345

AL1

-

+

OUT

COM

N/O

AL2

+

AB

-

12

109

8

3

B

14

13

12

11

18

4567

COM

-

+

OUT

AL1 AL2

N/O

N/OCOM N/C

POWER

COM

N/CN/O

COM N/OCOM N/O

POWER

15

16

17

+

A

B

B

-

OUT

-+

AL2

1

2

9

8

3

4

5

6

7

13

12

11

10

14

15

16

17

18

+

A

B

B

-

1

2

14

13

12

11

8

3

4

5

6

7

15

16

OUT

AL2

+

AL1

-

9

10

POWER

COM

N/ON/C

N/O

COM

N/C

N/O

COM

POWER

AL1

COM N/C

N/ON/OCOM

COM N/O

N/C

Wiring graph for G(48X48mm) size Wiring graph for G(72X72mm) size

Wiring graph for G(96X96mm) size Wiring graph for

E(48X96mm) ,F(96X48mm) size

5.Panel Description

Upper display window

1

Lower display window

2

To the parameter key, the Enter key

3

Data shift key

4

Increase keythe

5

Reduce the key

6

OUT Lamp

7

6、Display the status and basic operation

7、Parameter list and function

press and hold key 2 seconds, LOC parameter appears, set the LOC = 800,Then press

the key to confirm and enter the system parameter setting state.

Parameter

code

Meaning of

parameters Explain Setting

range

LOC Parameter

lock

LOC<9000, will automatically for 0, allowed to modify the SV Set

Value.

LOC≥9000, are not allowed to modify the SV Set Value.

Set the LOC = 800, then press key to confirm, can enter the

following system parameters.

0~9999

3 4

OUT

AUT

A L 1

TF800

TMCON

PV

SV

A L 2

1

2

3

46

7

8

5

PV

SV

Press 2 SEC

+

The next

parameter

2 SEC,Return to the

previous parameter

For example:

measuring a value of 600.0

Set value 600.5

The basic display state

6.1.System parameter setting

PV

SV

LOC parameter

appears,

Set the LOC = 800,

Then Press

Instrument power

Access to the system parameter setting state

In the basic display state, press and hold key 2 seconds, LOC parameter appears, set the

LOC = 800,Then press the button to confirm and enter the system parameter setting state.

, , Key can directly modify the parameter values. Press the key to reducing

the data, press the to increase the data,Waiting to modify the value of the decimal

point will flash (like a cursor).press key and hold, you can quickly increase / decrease in value,

And the speed will be automatically accelerated. also press the key to move to modify the

data location (cursor), the operation is more efficient. Key can be stored to modify

parameter values and display the next parameter,press and hold key 2 seconds,and can

return to the previous parameter; and hold key and then press the key can

immediately exit the parameter setting state.

key

press

6.2 Set Value Setting

In basal display status, if the parameter lock “Loc” isn't locked, we can set setpoint (SV) by

pressing first、then can press , or to adjust value. Press key to decrease

the value, key to increase the value, and key to move to the digit expected to modify.

Keep pressing or , the speed of decreasing or inscreasing value get quick. The range

of setpoint is between the parameter SPL and SPH.

6.3 “At”PID Parameter auto-tuning

"At" parameter "OFF" is set to "ON" and then press the KEy to confirm instrument can start

the implementation of the auto-tuning Given function,the instrument in the basic display state

display will flash the word "At", the instrument after 2 oscillation cycle ON-OFF control can

automatically calculate the PID parameters.If you want to advance to give up auto-tuning , "At"

parameter “ON” is set to “OFF” and then press key to confirm.

Given tuning parameter values obtained are not identical, to perform auto-tuning function,

9

AL1 Lamp

8

AL2 Lamp

9

should be first given value set in The most commonly used value or middle value, if the system

is good insulation properties of the furnace, the given value should be set in the system uses

the maximum, and then Execute the start of the operation of auto-tuning function. Reasons to

learn, auto-tuning after the initial use, the effect may not be the best, you need a period of time

(usually the same time auto-tuning control) before they can get the best results.

AL1 high

limit alarm

value

AL1 low

limit alarm

value

-999~

+32000

“HAL1” is the absolute value alarm or deviation value alarm, by

“ALtd” parameter definition.

When the value set to Max. will disable this function.(3200)

“LAL1” is the absolute value alarm or deviation value alarm, by

“ALtd” parameter definition.

When the value set to Min. will disable this function.(-999)

AL2 high

limit alarm

value

AL2 low

limit alarm

value

“HAL1” is the absolute value alarm or deviation value alarm, by

“ALtd” parameter definition.

When the value set to Max. will disable this function.(3200)

“LAL1” is the absolute value alarm or deviation value alarm, by

“ALtd” parameter definition.

When the value set to Min. will disable this function.(-999)

HAL2

LAL2

HAL1

LAL1

Alarm

hysteresis

Alarm mode

Avoid frequent alarm on-off action because of the fluctuation of PV

ALtd=0,AL1is the is the

.

deviation value alarm,AL2 absolute

value alarm

ALtd=1,AL1 and AL2 is the absolute value alarm.

ALtd=2,AL1 and AL2 is the deviation value alarm.

Control

mode

onoF: on-off control. For situation not requiring high precision.

FPId: advanced artificial intelligence ”FUZZY PID“ control.

0~2000

0~2

OFF: close the function.

ON: start a function.

finish will automatically returns to the OFF state.

auto-tuning

auto-tuning

auto-tuning

auto-tuning ON

OFF

onoF

FPId

onr: Reverse acting. Increase in measured variable causes a

decrease in the output, such as heating control.

ond: Direct acting. Increase in measured variable causes an

increase in the output, such as refrigerating control.

Selection of

heating

refrigeration

AHYS

ALtd

CntL

At

orEv onr

ond

Proportional

band

Integration

time

No integral effect when I=0

1~32000

1~9999

seconds

Proportional band in PID and APID control. Instead of percentage

of the measurement range, the unit is the same as PV.

Generally, optimal P, I, D and CP can obtained by auto tuning. They

can also be manually inputted if you already know the correct

values.

P

I

6

8、Note

!

Read this manual before using, to prevent the error operation

caused by the failure to Fully understand the operating

procedures, and retain the manual for ready reference.

( )

( )

1 Can not normally display measured values in the display window alternating show:

"orAL" character, indicating that the input of the measurement signal abnormalities or Out of

range; check Int parameter settings, and then the input sensor signals are the same category,

if it is determined the same, check the input sensing Signal not pick the wrong line, if it is

determined to not pick the wrong line, check whether the sensor problem, replace another

sensor to try.

2 The instrument used by the local environmental temperature and humidity can not

exceed the scope of the provisions, the instrument around should allow sufficient space for

CP Control cycle CP reflect the instrument operator to adjust the speed, the size of

the CP that affect the control accuracy.

With SSR, SCR output control cycle preferable to shorter, usually

0.5-3.0 Seconds. The relay switch output is generally in 15-40

seconds.

When the output relay switches , the CP will be limited to

3 seconds, And self-tuning At will automatically set the CP as the

appropriate value, taking into account the control accuracy And

mechanical switch life.

When the control mode CntL = onoF, the action of the CP as an

output disconnect or power-on output ON Delay time.

0.2~

300.0

Int Input Signal Input spec:

K、E、J、N、Pt(Pt100)

dp Decimal

point

0 (no decimal), 0.0 (one decimal place).

InF

dU

SvL

SvH

-9990~

+30000

SC Input Shift

Adjustment

Sc is used to shift input to compensate the error caused by

transducer, input signal, or auto cold junction compensation of

thermocouple.

PV after compensation=PV before compensation + Sc It is generally

set to 0. The incorrect setting will cause measurement inaccurate.

-1999~

+4000

PV

input filter

The value of InF will determine the ability of filtering noise.

When a large value is set, the measurement input is stabilized but

the response speed is slow. Generally, it can be set to 1 to 3.

If great interference exists, then you can increase parameter “InF”

gradually to make momentary fluctuation of measured value less

than 2 to 5.

When the instrument is being metrological verified, “InF” s can be

set to 0 or 1 to shorten the response time.

Temperature

unit selection

°C:

°F:fahenheit equals

celsius equals

Low limit

of SV

Minimum value that SV is allowed to be.

Upper limit

of SV

Maximum value that SV is allowed to be.

0~40

°C

°F

HYS Control

hysteresis

0~2000

HYS is used for on-off control to avoid frequent on-off action of relay.

For a reverse acting (heating) system, when PV > SV, output turns

off; when PV<SV-HYS, output turns on.

For a direct acting (cooling) system, when PV<SV, output turns off;

when PV>SV+HYS, output turns on.

Differential

time

No derivative effect when d=0 0~3200

seconds

dheat dissipation, instrument internal temperature rise due to thermal radiation will lead to a

result of the measurement accuracy and service life of the affected. In this Case, to be taken

to a forced cooling fan or other measures to reduce the ambient temperature.

3 the extension or connection then the thermocouple leads should be used with the

thermocouple type to match the compensation conductor; extend or connect the

thermoelectric Resistance of the lead, you should use the minimal resistance of the wire and

cable away from power lines and load connection, in order to avoid signal interference.

( )

5

Guangzhou Tmcon Electronic Technology Co., Ltd.

R

Sales Hotline: -020 34273933 Technical Hotline:020-34273900

Http://www.china-tmcon.com E-mail:chinatmcon@163.com

Made in Guangzhou, China

0

0.0

Parameter code

*

* solid state relay output type factory is set to ,

the relay contact output type factory set to .

factory setting Parameter code Parameter code

factory setting factory setting

9、default settings.

Popular Controllers manuals by other brands

Kenwood

Kenwood KCA-R10 instruction manual

Murphy

Murphy EMS547 Specifications

Voicebird

Voicebird Voicebird Mini user guide

Becker

Becker Centronic UnitControl UC52 Assembly and operating instructions

Watersports Innovations

Watersports Innovations The Boost Box WS 1107 Installation & operation instructions

UCS

UCS QUASAR AC user manual