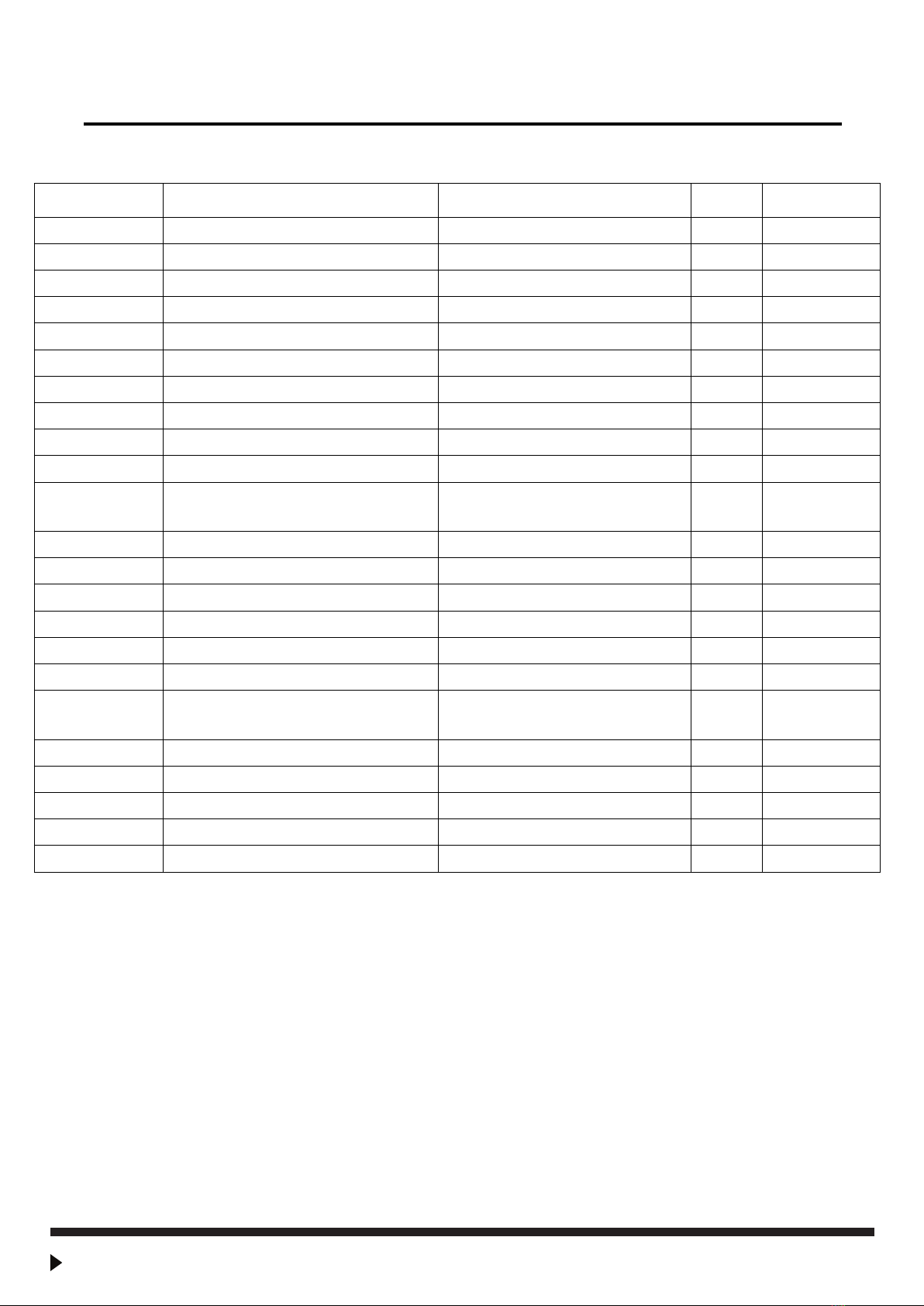

PART NO. S/N. NUMBER PART DESCRIPTION QTYS NOTE

1 050872I.02 COVER 1

2 GB/T 5783-2000 BOLT M8*25 4

3 GB/T 5783-2000 FLAT WASHER D8 6

4 GB/T 93-1987 SPRING WASHER D8 6

5 GB/T 6170-2000 NUT M8 6

6 GB/T 5783-2000 BOLT M12*45 12

7 GB/T 93-1987 SPRING WASHER D12 12

8 GB/T 97.3-2000 FLAT WASHER D12 12

9 050872I.00.01 MOTOR 1

10 050872I.00-09 SPLINED SHAFT 1

11 050872I.00-10 JOINT 2

12 050872I.03 BEARING SEAT 1

13 GB1152 GREASE NIPPLE 1

14 GB299 BEARING 1

15 050872I.00-08 OUTER BLOCK 1

16 GB9877.1-88 SEALING RING 1

17 050872I.00-07 INNER BLOCK 1

18 050872I.00-04 END CAP 1

19 GB/T 70.3-2000 SCREW M8*25 8

20 050872I.01 FRAME 1

21 050872I.00-01 CHAIN BEARING 1

22 GB/T 6170-2000 NUT M8 8

23 050872I.00-02 CHAIN 62

24 0508-DP BLADE 3

25 050872I.04T BLADE BASE 1

26 GB/T 5783-2000 BOLT M24*120 3

www.tmgindustrial.com 8/13TOLL FREE: 1-877-761-2819