Preparation

1. Never use the machine until you have read and completely understand this manual, the skid steer tractor Operator's Manual

and each of the Safety Messages found on the safety signs on the skid steer tractor and machine.

2. Personal protection equipment including hard hat, safety glasses, safety shoes, and gloves are recommended during

assembly, installation, operation, adjustment, maintaining, repairing, removal, cleaning, or moving the unit. Do not allow long

hair, loose fitting clothing or jewelry to be around equipment.

3. PROLONGED EXPOSURE TO LOUD NOISE MAY CAUSE PERMANENT HEARING LOSS!

Power equipment with or without equipment attached can often be noisy enough to cause permanent, partial hearing loss.

We recommend that you wear hearing protection on a full-time basis if the noise in the Operator's position exceeds 80db.

Noise over 85db on a long-term basis can cause severe hearing loss. Noise over 90db adjacent to the Operator over a long-

term basis may cause permanent, total hearing loss. NOTE: Hearing loss from loud noise (from tractors, chain saws,

radios, and other such sources close to the ear) is cumulative over a lifetime without hope of natural recovery.

4. Clear working area of stones, branches or hidden obstacles that might be hooked or snagged, causing injury or damage. 5.

Use only in daylight or good artificial light.

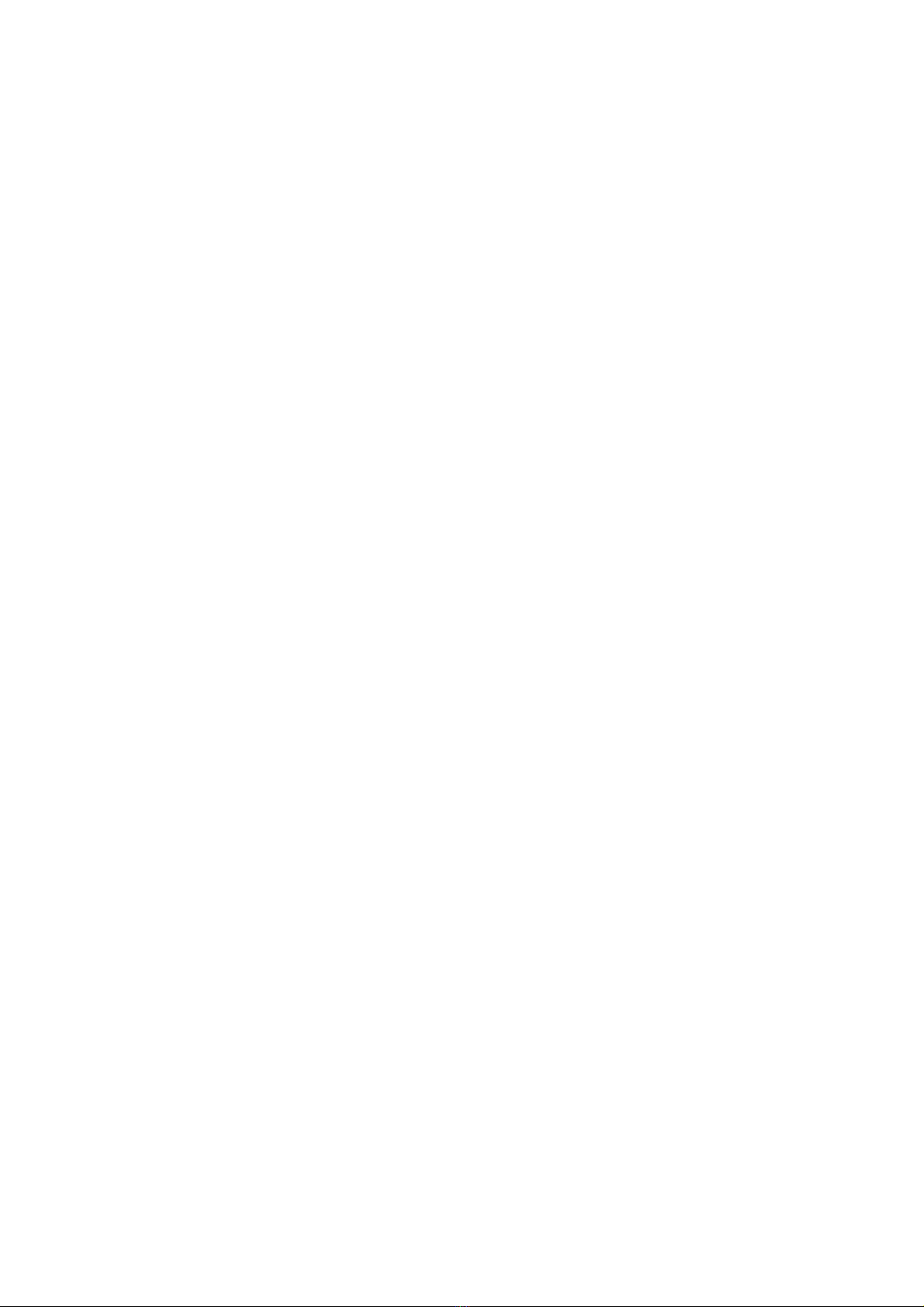

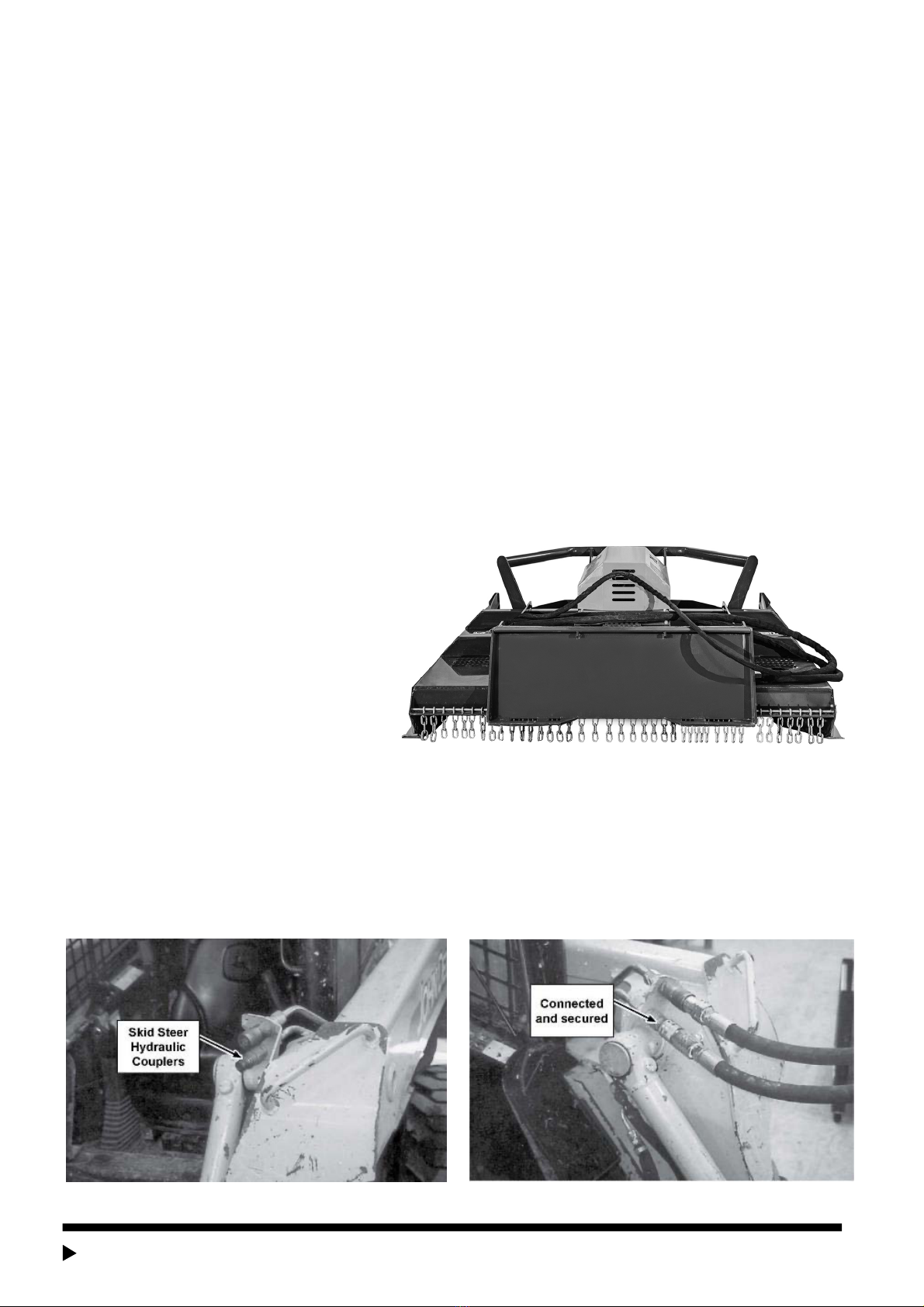

6. Be sure machine is properly mounted, adjusted and in good operating condition.

7. Ensure that all safety shielding, and safety signs are properly installed and in good condition.

Maintenance Safety

1. Good maintenance is your responsibility. Poor maintenance is an invitation to trouble.

2. Follow good shop practices.

- Keep service area clean and dry.

- Be sure electrical outlets and tools are properly grounded.

- Use adequate light for the job at hand.

3. Make sure there is plenty of ventilation. Never operate the engine of the towing vehicle in a

closed building. The exhaust fumes may cause asphyxiation.

4. Before working on this machine, shut off the engine, set the brake, and turn fuel valve off.

5. Never work under equipment unless itis blocked securely.

6. Always use personal protection devices such as eye, hand and hearing protectors, when performing any service or

maintenance work. Use heavy or leather gloves when handling blades.

www.tmgindustrial.com 7 / 15 TOLL FREE: 1-877-761-2819