WWW.TMGINDUSTRIAL.COM P05/18 Toll Free:1-877-761-2819

Failure to respect the above precaution can lead to dispersion of dangerous material in

transit,or emission of flammable vapours,which, besides constituting serious violations of

environmental and traffic regulations, ,can represent danger regarding the formation of

potentially explosive atmosphere or fire triggers.

Avoid in any case of overfilling the tank: always leave an adequate minimum vacuum

that allows the free liquid expansion

4. EMPTYING

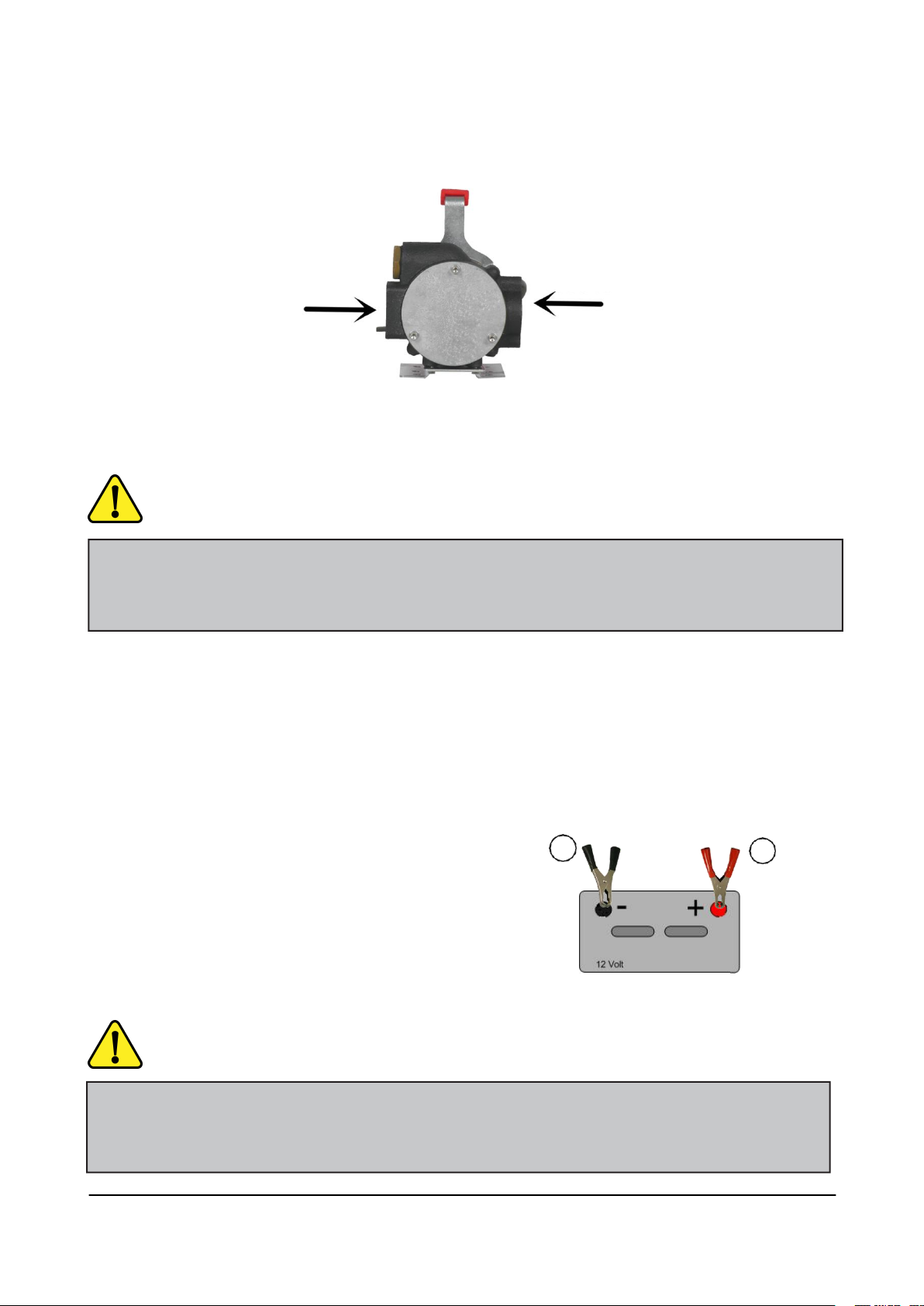

Before you start emptying it is appropriate to provide a good electrical connection (equipotential)

between the metal frame of the transfer unit and the other metal container in which you want to

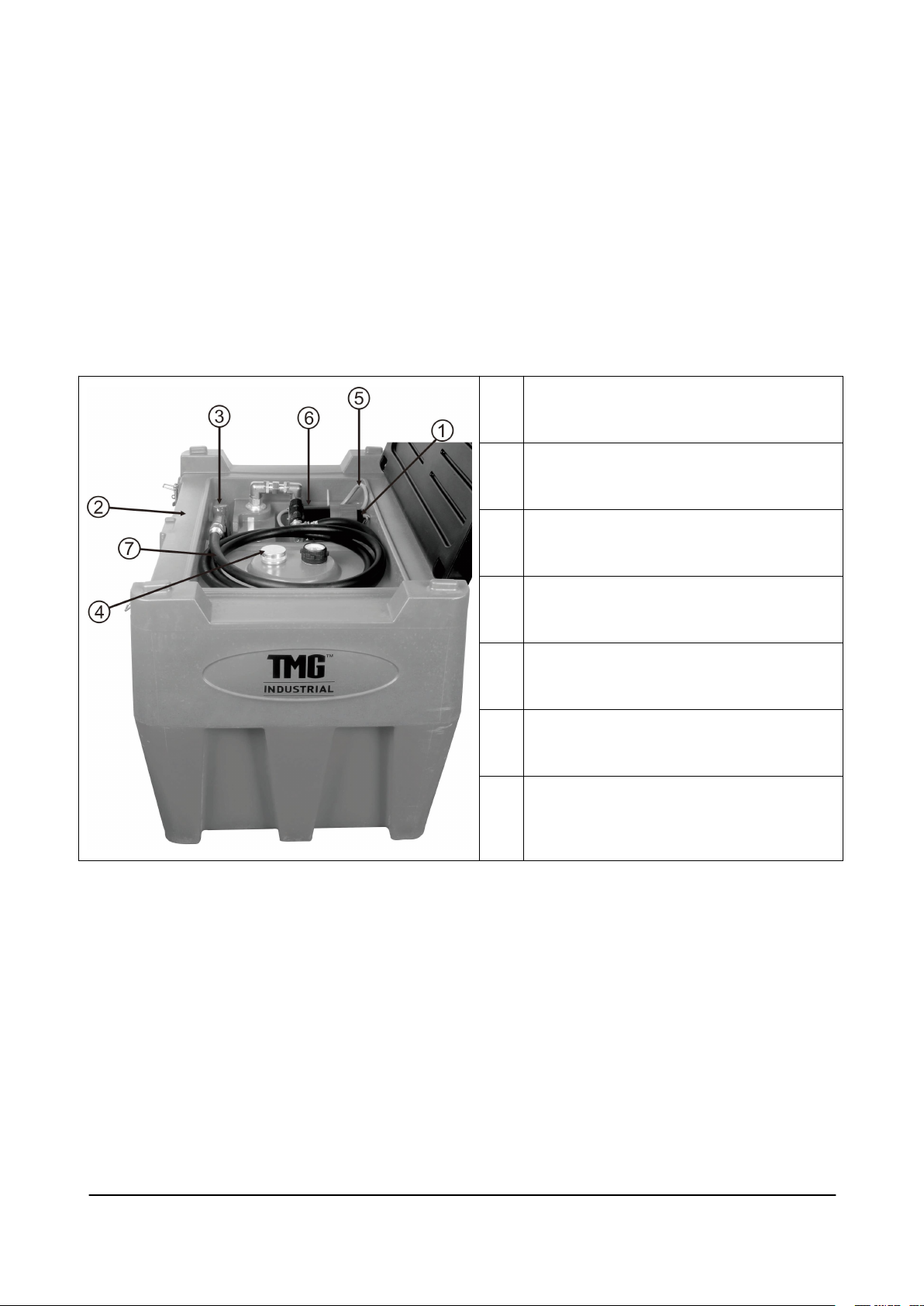

dump the fuel, using, for example,a cable with pliers. For ease of understanding, the operations

are proposed with the indication in () of the component highlighted in Picture

*

Check that the switch of the electric pump (6) is switched to"O".

*

Enable the power line connecting the clamps to the terminals of the battery, respecting the

polarities(red+, black-).

*

Unroll the hose (7) and insert the gun (3) in the destination tank,after locking the lever in the "open"

position.

*

Start the electric pump by placing the pump switch to "I".

*

Proceed with transferring within max.2 minutes after the switch on of the electric pump

*

Monitor the achievement of the desired degree of filling, or wait for the overflow stop in case

of automatic gun. After completing emptying, perform the operations described in sequence:

*

Switch off the pump switch on the pump body(pos. "0").

*

Drain liquid still pressing down for a few moments the gun handle(3), in order to discharge any

residual pressure in the discharge pipe.

*

Store the hose (7) properly rolled in the position shown in the photo(see Picture ), placing the

gun (3) into the recessed area of the tank.

*

Disconnect the power supply by disconnecting the clamps from the terminals of thebattery.

5.PRECAUTIONS

Each type of operation should be avoided/suspended in stormy weather in place or imminent, The

employer is responsible, pursuant to art, to prepare appropriate risk assessment in this regard. It is

considered useful to provide in each case the following minimum safety information:

Each object with an elevation predominant compared with the surrounding area has a greater chance