Toho Electronics TRM-10C User manual

TRM-10C

HYBRID RECORDER

(MULTIPOINT TYPE RECORDER)

INSTRUCTION MANUAL

TOHO ELECTRONICS INC.

HXPRM10mnCT001E

AUG. 2022 (8th Edition)

Copyright © 2000-2022 TOHO ELECTRONICS INC. All Rights Reserved.

―1―HXPRM10mnCT001E

For safety using

Thank you for purchasing our TRM-10C Hybrid Recorder.

In order to this instrument to exhibit all of its functions effectively and correctly, read and understand this

instruction manual thoroughly before using the instrument.

Don't use this product in any method not specification by manufacturer. The protective features of this

product may be impaired if it is used in a method not specified in the operation manual.

The symbols below are used on this instrument for the cautioning information.

Symbols used on the instrument

This shows “Caution for handling”. This symbol is used on the parts need to

reference the instruction manual for saving human body and the instrument.

This shows “Protective grounding”. Be sure to provide protective grounding prior

to operate this instrument.

AC

This shows “Risk of electric shock”. This symbol is used on the parts, which has

a risk of electric shock.

Be sure to observe the following warnings/cautions and those provided in the text

in order to secure safety in handling the instrument.

WARNING

(1) In order to prevent electric shock; be sure to disconnect this instrument from the main

power source when wiring it.

(2) When the effect on the system is expectedby the error occurs due to external factors

or failure the instruments, take precautions to ensure the overall safety of your

system.

(3) Take precautions to so that an alien substance does not get into the instruments

aperture.

(1) In order to prevent an electric shock; be sure to provide protective grounding prior to

turning on this instrument.

(2) Do not cut a protective grounding conductor or disconnect protective grounding.

(1) Make sure that the supply voltage for this instrument conforms to the voltage of the

supply source.

Rated power voltage range :100-240VAC

Working supply voltage range :85-264VAC

Rated power frequency :50/60Hz

Power consumption :30VA max

(2)Attach a protective cover prior to turning on this instrument.

(3) Power module that is used in the instruments conform to EN60950

(1) Do not operate this instrument in the environment where it is exposed to a

combustible/explosive/corrosive gas or water/steam.

(2) Please use in an environment that is shown in the following.

Installation features :Indoor

Altitude :2000m or less

Ambient temperature :0-50℃

Ambient humidity :20-80%RH(Non condensing)

Overvoltage category :Category Ⅱ

Allowable pollution degree :Pollution degree 2

Vibration :10~60Hz 0.2m/s2

Impact :The impact is not allowed.

Provide input and output wiring after turning off the power.

Input and Output Wiring

General

Protective Grounding

Power Source

Working Environment

―2―HXPRM10mnCT001E

CAUTION

Do not use empty terminals for other purposes such as relaying, etc.

Do not touch the switches, etc. inside this instrument. Also, do not replace the

main unit or PRINTed circuit boards. When this is neglected, we cannot

guarantee functioning of the instrument. Contact our dealer where you

purchased the instrument, or our sales representative.

When transporting this instrument or the equipment with this instrument

incorporated in it, take measures to prevent opening the door and falling out

the inner module.

[Note]

(1) Deliver this instruction manual to an end user.

(2) Prior to handling this instrument, be sure to read this manual.

(3) If you have any questions on this manual or find any errors or omissions in

this manual, contact our sales representative.

(4) After reading this manual, keep it carefully by the instrument.

(5) When the manual is lost or stained, contact our sales representative.

(6) It is prohibited to copy or reproduce this manual without our permission.

(1) When installing this instrument, put on a protective gear such as safety

shoes, helmet, etc. for your safety.

(2) Do not put your foot on the installed instrument or get on it, because it is

dangerous.

Only our serviceman or persons authorized by TOHO are allowed to remove

and take the inner module, the main unit and PRINTed circuit boards apart.

(1) Dispose the replaced batteries in a correct way.

(2) Do not incinerate plastics of maintenance parts and replacement parts. A

harmful gas may be produced.

(1) Use dry cloth to clean the surface of this instrument.

(2) Do not use any organic solvent.

(3) Cleaning the instrument after turning off the power.

This instruction manual is subject to change without prior notice.

Manufacturer:TOHO ELECTRONICS INC.

Address :2-4-3 Nishihashimoto, Midori-Ku, Sagamihara-Shi, Kanagawa 252-0131 Japan

Input and Output Wiring

Transportation

Inside of Instrument

Instruction Manual

Installation

Maintenance

Disposal

Cleaning

Revisions

―3―HXPRM10mnCT001E

Using procedure for this manual

1. Using procedure

This instruction manual consists of “For safety using”, “Contents” and “Chapter 1 to Chapter 11” as bellow.

Read the applying sections for your purpose to use this instrument.

Chapter and TITLE

For purchase

and install

For initial

setting and

change setting

For daily

operation

For using

communication

For

maintenance

and

trouble-shootin

g

For safety using (page 1)

◎

◎

◎

◎

◎

1. INTRODUCTION

◎

2. CONSTRUCTION

○

○

○

○

3. INSTALLATION

◎

○

4. WIRING

◎

○

○

○

○

5. PREPARATIONS FOR

OPERATION

○

◎

6. OPERATION

○

◎

7. DEVICE SETTING

◎

○

○

8.COMMUNICATIONS

◎

9. MAINTENANCE

◎

10. TROUBLESHOOTING

○

◎

11. SPECIFICATIONS

○

○

○

◎:Be absolutely certain to read this.

○:Be certain to read this if you need.

The symbols below are used on the warning and cautioning information in this manual.

Symbols used on this manual

WARNING

Failure to observe this information could result in death or injury.

Be absolutely certain to read this.

CAUTION

Failure to observe this information could damage the instrument.

Be certain to read it.

[Note]

This is cautionary information for correct use of the instrument.

Be certain to read it.

[Reference]

This is information to help youuse the functions of this instrument more

effectively.

2. Guide of Instruction manual

The instruction manuals of this instrument are as the table below.

Name

Part No.

Outline

1

TRM-10C Hybrid Recorder

(Multipoint type) instruction

manual

HXPRM10mnCT001E

Explanation for installing, wiring,

standard operation. And setting

or operation for using this

instrument.

2

TRM-10C Hybrid Recorder

Communication Command

instruction manual

HXPRM10mnCT005E

Explanation for reading and

writing data of the recorder by

communication function.

This

manual

―4―HXPRM10mnCT001E

CONTENTS

1. INTRODUCTION...................................................................6

1.1 HybridRecorder...........................................................................6

1.2 CheckingtheAccessories............................................................6

1.3 CheckingtheTypeandSpecifications........................................7

1.4 TemporaryStorage.......................................................................8

1.5 IndicationCard..............................................................................8

2. CONSTRUCTION..................................................................9

2.1 Appearance ................................................................................9

2.2 DisplayScreenandOperationKeys.........................................10

2.2.1 DisplayScreen.....................................................................10

2.2.2 OperationKeys.....................................................................11

3. INSTALLATION.................................................................. 12

3.1 OutsideDimensionsDrawingandPanelCuttingDimensions.........12

3.2 MountingtothePanel................................................................13

3.2.1 ProcedureforMountingtothePanel..................................13

3.2.2 MountingtothePanelincompliance withtheIP65............14

4. WIRING................................................................................ 15

4.1 TerminalLayoutandPowerWiring...........................................15

4.1.1 Terminal Layout....................................................................15

4.1.2 PowerWiring........................................................................15

4.1.3 WiringProcedure..................................................................16

4.2 InputWiring.................................................................................17

4.2.1 WiringProcedure..................................................................18

4.3 DI/AlarmOutputWiring(Option)................................................20

4.3.1 DI/AlarmOutputWiringExample........................................20

4.3.2 AlarmOutputWiringProcedure..........................................21

4.3.3 DI WiringProcedure.............................................................21

4.4 CommunicationWiring...............................................................22

4.4.1 RS-232CWiring...................................................................22

4.4.2 RS-485Wiring......................................................................22

5. PREPARATIONS FOR OPERATION .............................. 23

5.1 SettingtheChartPaper..............................................................23

5.2 SettingtheRibbonCassette......................................................29

6. OPERATION....................................................................... 31

6.1 Operation....................................................................................31

6.1.1 StatusafterInitialScreen.....................................................31

6.2 Recording...................................................................................32

6.2.1 RecordingColors..................................................................32

6.3 HowtoRecord............................................................................32

6.3.1 Starting/StoppingRecordingOperation..............................32

6.3.2 Feedthe ChartPaper..........................................................32

6.3.3 PrintSample.........................................................................33

6.4 DigitalPrint..................................................................................34

6.4.1 ManualPrint..........................................................................34

6.4.2 ListPrint................................................................................35

6.4.3 EngineeringListPrint...........................................................37

6.4.4 RecordStart/EndPrint ........................................................39

6.4.5 DIManualPrint.....................................................................39

6.4.6 DI Date/TimePrint................................................................39

6.4.7 DI CommentPrint.................................................................40

6.5 ChangingtheDisplay ...............................................................41

6.5.1 AutoDisplay< >....................................................41

6.5.2 ManualDisplay< >....................................................41

6.5.3 Date Display< >....................................................41

6.5.4 TimeDisplay< >....................................................41

6.5.5 DisplayOff < >...........................................................41

7. DEVICE SETTING.............................................................42

7.1 SettingtheSetupMode............................................................. 42

7.1.1 Settingthe Range................................................................ 45

(1) Settingmethod..................................................................... 45

(2) (Current/Voltage), (Thermocouple),

(ResistanceTemperatureDetector)........................ 46

(3) (Scaling)............................................................48

(4) (SquareRoot).......................................................50

(5) (Decade)........................................................... 52

(6) (Difference),(Sum),

(Average)..............................................................54

(7) (Skip).....................................................................55

7.1.2 SettingtheAlarm..................................................................56

7.1.3 Settingthe Unit.....................................................................58

(1) Character CodeTable..........................................................59

7.1.4 Settingthe ChartSpeed...................................................... 60

7.1.5 Settingthe DateandTime...................................................61

7.1.6 CopyingtheSettingData.....................................................62

7.1.7 SettingOtherFunctions.......................................................63

(1) (PrintingCycle).................................................64

(2) (ZoneRecording).................................................64

(3) (PartialCompression/Expansion).......................65

(4) (DigitalPrint).....................................................66

(5) (Tag)..........................................................................67

(6) (CommentWords)...............................................68

7.2 SettingtheEngineeringMode...................................................69

7.2.1 AlarmHysteresis..................................................................72

7.2.2 BurnoutON/OFF.................................................................72

7.2.3 ChannelOffset.....................................................................72

7.2.4 ReferenceJunctionCompensation....................................73

7.2.5 ChangingthePrintingColor ............................................... 74

7.2.6 SettingsRelatedtoRecording............................................75

(1) Recordingstart/stoptriggersetting.....................................75

(2) Tag/channelprintselection..................................................75

(3) AlarmprintON/OFF.............................................................76

(4) LoggingprintON/OFF......................................................... 76

(5) ScaleprintON/OFF............................................................. 77

(6) LoggingprintSynchronous/Asynchronous........................ 78

7.2.7 Settingthe Communication Function..................................78

7.2.8 InitializingtheSetupData ...................................................79

7.2.9 DIFunctions......................................................................... 79

7.2.10 TemperatureUnit...............................................................80

7.2.11 Point Calibration.................................................................80

7.2.12 DataCalibration.................................................................82

7.3 TerminatingtheEngineeringMode...........................................84

―5―HXPRM10mnCT001E

8. COMMUNICATIONS......................................................... 85

8.1 GeneralDescription....................................................................85

8.1.1 GeneralDescriptionofFunctions........................................85

8.1.2 TransmissionSpecifications................................................85

8.2 OriginalProtocol.........................................................................86

8.2.1 DataConstruction.................................................................86

8.2.2 Opening/ClosingtheLink.....................................................86

8.2.3OutputtingtheProcessVariableData.................................87

8.2.4 OutputtingtheUnitandDecimalPointPositionData.........90

8.2.5OutputtingtheStatus............................................................91

8.2.6DataReceptionExample.....................................................92

8.3ModbusRTUProtocol...............................................................93

8.3.1 DataConstruction.................................................................93

8.3.2 Function Codes....................................................................93

8.3.3ErrorResponse....................................................................93

8.3.4 Reading fromtheInputRegisterArea................................94

8.3.5Reading fromorWritingtotheHoldingRegisterArea......97

9. MAINTENANCE................................................................. 98

9.1 Inspection....................................................................................98

9.2 Cleaning......................................................................................98

9.3 ReplacingConsumables............................................................99

9.4 Adjust Dot PrintingPosition(PointCalibration).........................99

9.5 Calibration(DataCalibration).....................................................99

(1) CalibrationofVoltage.........................................................100

(2) CalibrationofResistanceTemperatureDetector..............100

(3) CalibrationofReferenceJunctionCompensation............101

10. TROUBLESHOOTING.................................................. 102

10.1 Troubleshooting.....................................................................102

10.1.1 TroubleItems...................................................................102

10.1.2 WhentheRecorderDosenotWork atAll......................102

10.1.3 WhenthereisaBigError................................................103

10.1.4 WhentheTrendRecordingDeflected............................103

10.1.5 WhenRecordsNothing...................................................104

10.1.6 WhenRecordingisFaint.................................................104

10.1.7 WhentheChartPaper isnotfedatAll............................105

10.1.8 WhentheChartPaper isnotfedProperly......................105

10.2 Self DiagnosticsFunction(ERROR)....................................106

10.2.1 SelfDiagnosticItems.......................................................106

10.2.2 ErrorDisplay.....................................................................107

11. SPECIFICATIONS.......................................................... 108

11.1 CommonSpecifications.........................................................108

11.1.1 InputSignal.......................................................................108

11.1.2 PerformanceandCharacteristics....................................108

11.1.3 Structure...........................................................................109

11.1.4 PowerSource...................................................................109

11.1.5 Normal OperatingConditions..........................................109

11.1.6 Alarm(RelayOutputisOptional)......................................110

11.1.7 SafetyStandardandEMIStandard.................................110

11.1.8 DIFunction (Option)..........................................................110

11.1.9 Paper-emptyDetectingFunction(Option).......................110

11.2 StandardSettingSpecifications.............................................111

11.2.1 MeasurementRange........................................................111

11.2.2 TheAccuracyattheComputation....................................114

(1) Scaling..................................................................................114

(2) SquareRootComputation..................................................114

(3) Decade.................................................................................115

(4) Difference,Sum,andAverage............................................115

11.2.3 IndividualSpecifications....................................................116

11.2.4 StandardFunctions...........................................................117

11.3 StandardSetting Functions....................................................118

11.3.1 StandardSettingFunctions..............................................118

11.4 OptionalFunctions..................................................................118

11.4.1 RemoteFunctionofDI......................................................118

11.4.2 AlarmBoard......................................................................118

11.4.3 Communication Unit.........................................................118

―6―HXPRM10mnCT001E

1. INTRODUCTION

1.1 Hybrid Recorder

The values of the measured variable are recorded with dot point type recording, and indicates data in the

digital display. The Hybrid recorder has also Alarm function that indicates, records event data and outputs by

relays, and Communicationfunction for datatransmission.

1.2 Checking the Accessories

Upon delivery of this instrument, unpack and check its accessories andappearance.

If there are any missing accessories or damages on the appearance, contact our dealer where you

purchased the instrument, or our sales representative.

Following accessories should beattached.

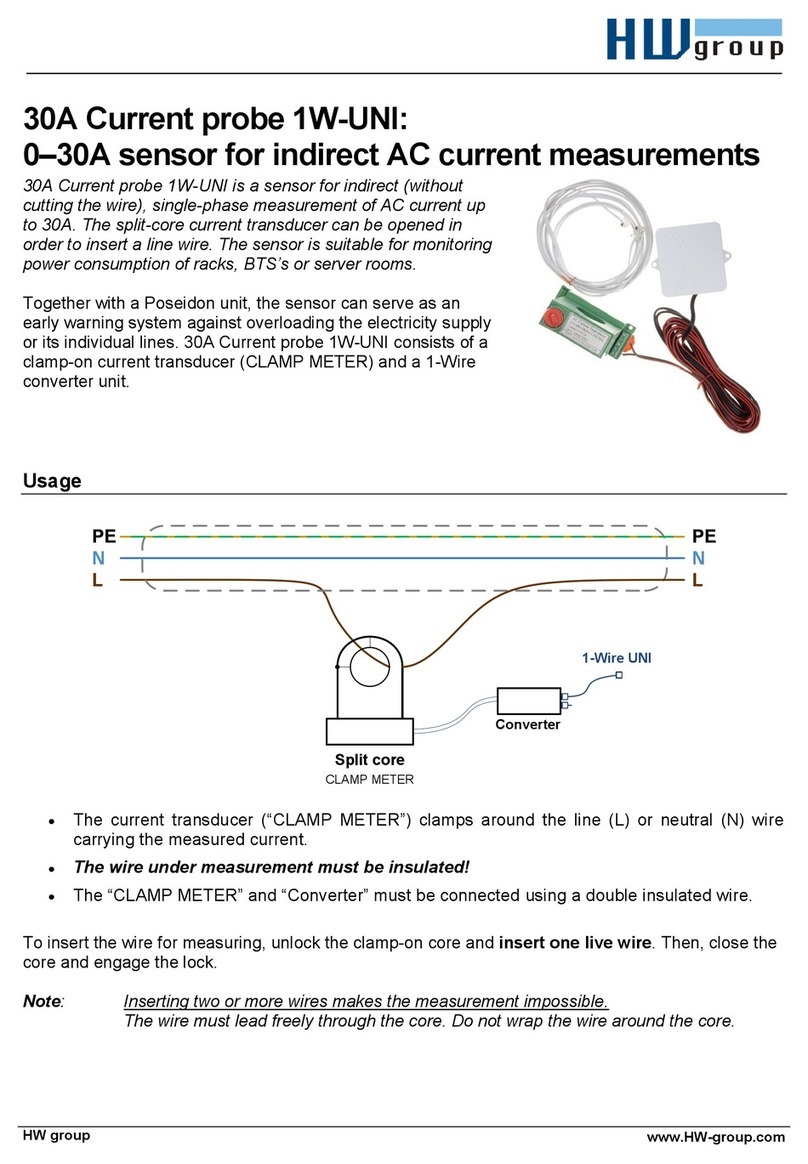

①Chartpaper ②Ribboncassette ③Mountingbracket

④Instruction manual ⑤Packing

Fig. 1.1 Accessories

Table 1.1 List of Accessories

No.

Part Name

Type

Quantity

Remarks

1

Chartpaper

HZCGA0105EL001

1

50equaldivisions

2

RibbonCassette

WPSR188A000001A

1

3

Mountingbracket

H4A14175

2

Panel mounting bracket

4

Instruction manual

HXPRM10mnCT001E

1

This manual

5

Packing

H4H14900

1

ForIP65

[Note]

The ribboncassette hasbeen set in the instrument upon shipment.

―7―HXPRM10mnCT001E

1.3 Checking the Type and Specifications

A nameplate is affixed to the inside of the instrument. Remove the chart holder and make sure that the

nameplate is affixed to the middle far side of the instrument.

Make sure that this instrument meetsyour requested specification, seeingthe following tables.

Table 1.2 Type

06 6-Multipoint type recorder

①Model

0RS-232C(Standard)

②Communication

1RS-485(Option)

③DI/DO(Option)

1

2

3

9

7

4

5

6

11

8

10

T

R

M

-

1

0

0

C

①

②

③

④Paper-emptySensor(Option)

0None

1Yes

④

0None

16Relay output

23DI

33DI+

6 Relay output

12

6

13

T

―8―HXPRM10mnCT001E

1.4 Temporary Storage

Store the instrument inthe following environment.

When incorporated in theequipment, store it in the following environment as well.

1.5 Indication Card

An indicationcard has been affixed to the door upon delivery. Enter anameas required.

CAUTION

Storage in a poor environment may damage the appearance, functions, andservice life of theinstrument.

Storage Environment

・Aplace with little dust.

・Aplace free from combustible, explosive, or corrosive gases ( SO2, H2S, etc.).

・Aplacefree fromvibrationsorshocks.

・Aplace frees from water or steam or highhumidity (95% RHmax.).

・Aplace free from direct sunshine orhigh temperature (50℃max.).

・Aplace free from an extremely low temperature ( -20℃min. ).

CAUTION

Note that ifa non-original nameplate is attached, it may damage thedoor or mounting part.

―9―HXPRM10mnCT001E

2. CONSTRUCTION

2.1 Appearance

Fig. 2.1 Appearance

Ribboncassette

Door

Chartholder

Display keyboard

Terminalblock

Printer

Case

Mountingbracket

Indicationcard

―10―HXPRM10mnCT001E

2.2 Display Screen and Operation Keys

2.2.1 Display Screen

The following describes the display screen. Since the channel numbers and data are indicated by a

7-segmentLED,alphabetsaresymbolizedtorepresentthem.

For theLED display, see" SymbolizedAlphabets forDisplay" at[Reference] below.

Fig.2.2 Display

[Reference] SymbolizedAlphabets for Display

Display

Alphabet

A

B

C

D

E

F

G

H

h

I

J

K

L

l

Display

Alphabet

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

RUN ALM

CH.No DATA

RUN MENU PRINT FEED ENT

ESC ▲

▲

Alarm Type Display

Indicates an alarmtype inred.

"H"isilluminatedwhen thealarmisHigh.

And “L”is illuminated when the alarm is

Low. Neither ofthemisilluminatedwhen

thereis noalarm.

Channel No. Display

Indicatesachannel

number in orange.

Data Display

Indicates the process

variable, time,setting

screen,etc.inorange.

Operation Keys

Use these keys for setting and

otheroperations.

Status Display

The "RUN"lamp (orange) is illuminatedwhen

recording. The"ALM" lamp(red) is illuminated

whenthealarmisbeingactivated. denotes

that the lamp goes out and denotes that it

isilluminated.

H

L

―11―HXPRM10mnCT001E

2.2.2 Operation Keys

The following describes each operationkey.

This manual represents the actualoperationkeys as shown in the figurebelow.

Fig. 2.3 Actual Display and Operation Keys

Table 2.1 Names of Operation Keys and Their Functions

Key

Name

Function

“RUN”key

Starts/stops recording.

Tostop,holddownthe“RUN”keyfor 3secondsormore.

(Goneoutthe “RUN”lamp.) Tostart,press the“RUN”key.

(Illuminates the“RUN”lamp.)

“MENU”key

MENUfunction

Selects engineering list print and change to the

settingmode.

“ESC”key

ESCfunction

Exitsthatmenuhalfwayselectinga function.

“PRINT”key

PRINT function

Used to perform manual printorlistprint.

“△”key

△function

Used to select a setting parameter (numeral or

built-incommand)(ascendingdirection).

“FEED”key

FEEDfunction

The chart paper is fed while the key is pressed, and

stoppedwhenreleased.

“”key

function

Used to shifta digit insetting anumeral.

“ENT”key

Used for registering a setting parameter (numeral or built-in command)

after selecting it, or executing a function. Pressing this key executes the

setting.

RUN

ESC

MENU

PRINT

FEED

ENT

RUN ALM

CH.No. DATA

RUN MENU PRINT FEED ENT

ESC ▲

▲

RUN

PRINT

FEED

ENT

ESC

MENU

H

L

―12―HXPRM10mnCT001E

3. INSTALLATION

3.1 Outside Dimensions Drawing and Panel Cutting Dimensions

Fig. 3.1 Outside Dimensions and Panel Cutting Dimensions

CAUTION

For maintenance andsafety of the instrument, it is recommended to securethe spacing larger than the

parenthesized dimensions per unit.

Unit: mm

<Front>

<Rear>

<Side>

<PanelCutting>

(56)

144

144

3.5

2.5

(100)

RUN

ALM

RUN

MENU

PRINT

FEED

ESC

CH, NO.

ENT

DATA

137

137

200 min

1

3

8

+

1

-

0

138+1

-0

(128)

7 MAX

(Panel thickness)

2

5

1

5

0

200 min

(128)

Dimension required

when the door is fully

opened(135゜).

(Wall on the left side).

―13―HXPRM10mnCT001E

3.2 Mounting to the Panel

3.2.1 Procedure for Mounting to the Panel

1) Assemble the mounting bracket refer to Fig.3.2.

2) Fit in this instrument through thefront of the panel.

3) Fit the claws of the mounting bracket into the square holes in the top and bottom surfaces of the

case.

4) Tighten the screw of the mounting bracket with a screwdriver to attach it to the panel. When the

mounting unit doesnot move back andforth any more, tighten ascrew by180゚.

Fig. 3.2 Mounting bracket

[Note]

If it istightened with an excessive force, thecase may be distortedand the mounting bracket may be

deformed. An adequate tightening torque isabout 0.2to 0.3 N・m(2~3kgf・cm).

WARNING

Do not install the instrument in aplace exposed toa combustible, explosive, or corrosive gas (SO2, H2S,

etc.).

CAUTION

Installthe instrument in the followingplaces

・Aplacefree fromwherehumidity often changes.

・Aplace of normal temperature (25℃orso).

・Aplace exposed to as little mechanical vibrations as possible.

・Aplacewithas little dusts as possible.

・Aplace affected by the electromagnetic field as little as possible.

・Aplace not directlyexposed to highradiant heat.

・Aplace where the altitude is upto 2000m.

・Humidity has an effect on the chart paper and ink. Use the instrument in a humidity range of20 to

80%RH(60%RHisoptimum).

・This instrument needsthe inside installation.

Mountingto the Panel

・Asteel plate not thinner than 1.2mm is recommended as a mountingpanel.

・The maximum thickness of the mounting panel is 7mm.

Inclination

・Install the instrument horizontally.

・The instrument should be installed so that its inclination should be 0゜at the front and within 30゜at the

rear.

Assemble in such a manner

that the screw nose will be

almost aligned with the plate

surface.

MountingClaw

Body

MountingClaw

―14―HXPRM10mnCT001E

Fig. 3.3 Mounting to the Panel

3.2.2 Mounting to the Panel in compliance with the IP65

Prior to mounting the instrument to the panel, attach apacking tothe position shown inthe figure.

The rest of the procedure is the same.

Fig. 3.4 Mounting to the Panel(in compliance with the IP65)

Mounting of Packing

Packing

Panel

Mountingbracket

Packing

Panel

Screw

Panel

Mountingbracket

Screw

―15―HXPRM10mnCT001E

4. WIRING

4.1 Terminal Layout and Power Wiring

4.1.1 Terminal Layout

Fig. 4.1 Terminal Layout (Rear view)

4.1.2 Power Wiring

Powersource

terminal block

Communication

terminal block (RS-232C)

Input terminal block

6Relay outputs

Communication

terminal block (RS-485)

3DIterminalblock

L N

1A 2C2A1C 3A 4C4A3C 5A 6 C6 A5 C

4+

B

4-

B

4

A

5+

B

5-

B

5

A

6+

B

6-

B

6

A

1+

B

1-

B

1

A

2+

B

2-

B

2

A

3+

B

3-

B

3

A

SG

RDTD

+

-

DI

COM DI

3DI

2

DI

1

WARNING

①In order to prevent an electric shock, be sure to provide protective grounding prior to turning on the

instrument.

②Do not cut aprotective grounding conductor ordisconnect protective grounding.

③Make sure that thesupply voltage for the instrument conforms to the voltage of the supply source.

④Attach a transparent protective cover prior to turning onthe POWER of the instrument.

⑤Any interruption of the protective conductor inside or outside the apparatus or disconnection of the

protective grounding terminal is likely to make the apparatus dangerous under some fault conditions.

Intentional interruption is prohibited.

―16―HXPRM10mnCT001E

4.1.3 Wiring Procedure

1) Put your fingers on the left and right (both sides) hooks of the transparent protective cover on the

power source terminal block. Pushing them inside,take out the cover to this side.

2) Connect the power source electric wire refer to Fig. 4.2. Connect the protective grounding to the

terminal. Connect the non-grounding side of the power source to "L" terminal. Connect the

grounding side to the "N" terminal.

3) Put back the transparent protective cover.

4) Make sure that protective grounding is properly provided.

Fig. 4.2 Power source Terminal block

LN

CAUTION

Thetransparentprotectivecovershould surelyremovethe leftandright(both sides)hookssimultaneously.

If it removes by turns, there is a possibility that it may damage.

Powersupply voltage

Rated power voltagerange :100-240VAC

Workingsupplyvoltage range :85-264VAC

Rated power frequency :50/60Hz

CAUTION

①Asanelectricwireforthepowersource,usea600Vvinylinsulatedwire(AWG20to 16, IEC60227-3)

or its equivalent orabove.

②Attach aring terminal with insulatedsleeve (for M3.5) tothe end ofthe electric wire.

③Please installa protective ground terminal on the device to which the recorder is installed. It is

necessary to connect terminal to the protective ground terminal provided on the device.

④Connect a protective grounding (resistance:100Ωor lower, a minimum diameter of a grounding

conductor:1.6mm)tothe protectivegrounding terminal.

⑤If other instrument shares the protective grounding conductor, there may be an effect caused by

noise comingfromthe grounding conductor. It is recommended not to share it withother instrument.

⑥In orderto comply with therequirements of safety standard EN61010-1, the recorder shall haveone

ofthefollowingasadisconnectingdevice, fittedwithineasyreachoftheoperator, andlabeledasthe

disconnecting device.

a.Acircuit breaker whichcomplies with the requirements of IEC60947-1,IEC60947-3

(Rated current 1A).

b.Aseparable couplerwhich can be disconnected without the useof a tool.

c.Aseparable plug, without a locking device, tomate with asocket outlet in the building.

⑦This product has designed to conformto EN61010-1 installation CategoryⅡand pollution

degree 2.

⑧Please usethe main power supply by the change within 10% of the rated voltage.

⑨Transitional current might flow to the main power supply when the power supply is turned on.

―17―HXPRM10mnCT001E

4.2 Input Wiring

CAUTION

①Precautions forthe input electric wire

⚫See that no noise is mixed in input wiring. For input wiring, it is recommended touse a shielding

wire or twisted wire effectivefor noise.

⚫In case of thermocouple input, connecta thermocouple wire directly or use a compensating lead

wire. It is recommended to use ashielded input line.

⚫In case of resistance temperature detector input, dispersion of 3-wire lineresistance should be

less than the below mentioned values. It is recommendedto use ashielded input line.

ForPt100,JPt100;50mΩmax.

⚫Whenitislikelytobeaffectedbyinductionnoise,particularly whenwiringnearthehigh-frequency

power source, it is recommended tousea shielded twisted wire.

⚫Attach a ring terminal with insulated sleeve (for M3.5) tothe end of theelectric wire.

②Precautionsforwiring

⚫The wiring between the instrument and measurement point should be kept away from the power

circuit (25V or higher circuit or DO circuit).

⚫Short-circuit unused input terminals. (Short-circuit between "+"and"-" in case of mV, V, or

thermocouple input, andshort-circuit amongA, B, and B in case of resistance temperature

detector input.)

⚫Ground the shield of connecting wire.

―18―HXPRM10mnCT001E

4.2.1 Wiring Procedure

Fig. 4.3 Input Wiring

1) Put your fingers on the left and right (both sides) hooks of the transparent protective cover on the

input terminal block. Pushing them inside,take out the cover to this side.

2) Wire the input lines refer to Fig. 4.3, Fig. 4.4(Page 18) and Fig.4.5.(Page 19)

3) Put back the transparent protective cover.

Fig. 4.4 Input Wiring ( mV, V, TC )

CAUTION

Thetransparentprotectivecovershould surelyremovethe leftandright(both sides)hookssimultaneously.

If it removes by turns, there is a possibility that it may damage.

DC Voltage

Thermocouple

RTD

4channel

5channel

6channel

4 +

B

4 -

B

4

A

5 +

B

5 -

B

5

A

6 +

B

6 -

B

6

A

DI

COM

DI

3

DI

2

DI

1

TD

RD

SG

1 +

B

1 -

B

1

A

2 +

B

2 -

B

2

A

3 +

B

3 -

B

3

A

1channel

2channel

3channel

A

B

B

+

-

+

-

A

B

B

+

-

+

-

A

B

B

+

-

+

-

+

-

DCCurrent

+

-

+

-

+

-

B

B

A

+

-

B

B

A

+

-

+

-

①mV,V input

②TCinput

―19―HXPRM10mnCT001E

Fig. 4.5 Input Wiring ( RTD,mA )

CAUTION

①Attach the shunt resistor to the input terminal block of the instrument.

②Input accuracy is effected with the shunt resistor. Use the following recommended resistor.

Resistance:250Ω, Ratedpower:1/4W, Tolerance:±0.1% max.

Temperaturecoefficient:±50ppm max.

+

-

B

B

A

+

-

B

B

A

B

B

A

Shuntregistor

+

-

①RTDinput

②mAinput

Other manuals for TRM-10C

2

Table of contents

Other Toho Electronics Measuring Instrument manuals