Sercel GRC Spy Pro Operating instructions

© Sercel 2020 - All rights reserved

School of Gauges

Spy Pro ESP Monitoring

Troubleshooting

AUG 9th , 2022

© Sercel 2020 - All rights reserved

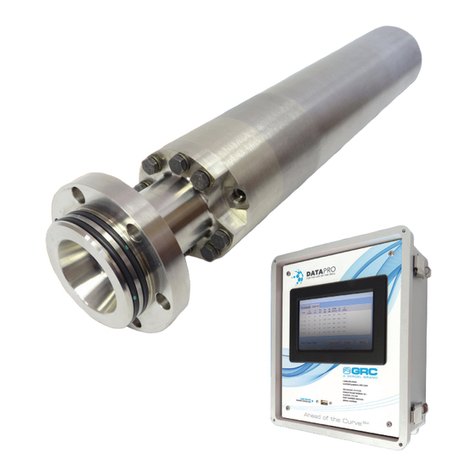

SPS-1500

〉The SPS-1500 may experience communication problems due to noisy

environments, grounding problems, or installation issues. The LCD on the

SPS-1500 will display error codes depending on the failure it is detecting.

Below is a list of common error codes and possible solutions to assist with

troubleshooting the SPS-1500.

2

© Sercel 2020 - All rights reserved

SPS-1500

3

Item Description / Descripción

LCD BEZEL COVER LABEL

FRONT PANEL, FLAT TRANSPARENT

SPS1500 PRODUCT WIRING LABEL

ENCLOSURE

SPS1501 PRODUCT IDENTIFICATION LABEL

LABEL, CE IDENTIFICATION

PCB ASSY, SPS1500L LCD

PCB ASSY, SPS1500L ESP PWR SPLY

CABLES 10P 6 SKT

❶

❷

❸

❹

❺

❻

❼

❽

❾❶

❷

❸

❹

❺

❻

❼

❽

❾

© Sercel 2020 - All rights reserved

SPS-1500

4

© Sercel 2020 - All rights reserved

SPS-1500 Screen Sequence

5

Firmware

Version/Date

Tool

Information

Modbus Information

Tool Communication

Settings

Signal

Levels

Line

Voltage

Packet Count and Run

Time

Status & Error

Message

© Sercel 2020 - All rights reserved

SPS-1500 Screen Sequence

6

Error Message

Tool

Information

© Sercel 2020 - All rights reserved

SPS-1500 Troubleshooting

7

Error

Possible Cause

Troubleshooting Step

DC-DC Bad or DC-DC

Chk - (Voltage measured

by SPS is not matching

what is sourced by SPS)

•Bad Ground Connection

•Low Resistance from Gauge

Signal to Ground

•Excessive Gauge signal line

current

•Faulty SPS

•Check Downhole readings (Phase-Phase & Phase-Ground

(Reverse Polarity Megger))

•Try alternate SPS power supply

•

Use voltmeter to confirm voltage MAX Voltage is over 45VDC.

DC-DC Bad or DC-DC

Chk - (El voltaje medido

por SPS no coincide con

el de SPS)

•Mala conexión a tierra

•Baja resistencia de la señal del

sensor a tierra

•Corriente de línea de señal de

sensor excesiva

•SPS defectuoso

•Verifique las lecturas eléctricas del equipo de fondo (fase-

fase y fase-tierra (megóhmetro con polaridad inversa))

•Pruebe una fuente de alimentación SPS alternativa

•Use un mulltímetro para confirmar que el voltaje MÁX. sea

superior a 45 VCC.

© Sercel 2020 - All rights reserved

SPS-1500 Troubleshooting

8

Error

Possible Cause

Troubleshooting Step

Baud Fast –

(Gauge Data is changing

at a Rate higher than

expected)

•Set voltage is too high

•Motor noise affecting gauge

current modulation

•Disable Auto Baud and raise Max Tool Baud to 8-10

•Reboot or cycle power to restart analyzing stage

•Disable Auto Volt/ Auto Analyze with DataWorks. Set voltage to

~60VDC.

Baud Fast –

(Los datos del sensor

están cambiando a una

velocidad superior a la

esperada)

•El voltaje configurado es

demasiado alto

•Ruido del motor afecta a la

modulación actual del sensor

•Desactive Auto Baud y aumente Max Tool Baud a 8-10

•Reiniciar o apagar y encender para reiniciar la etapa de análisis

•Desactive Auto Volt / Auto Analyze con DataWorks. Establezca

el voltaje en ~ 60 VCC.

© Sercel 2020 - All rights reserved

SPS-1500 Troubleshooting

9

Error

Possible Cause

Troubleshooting Step

Low Amps –

(Gauge current is lower

than expected)

•Disconnected from tool

•High resistance connection at

motor WYE point to gauge

•Blown Signal fuse

•Low amp setting set to high

•Check Downhole readings (Phase-Phase & Phase-Ground

(Reverse Polarity Megger))

•Check all connection(s)

•Check Signal fuse

•Check Setting of Low amp with DataWorks (15VDC Nominal)

•Check Setting of High amp with DataWorks (25VDC Nominal)

Low Amps –

(La corriente del sensor es

mas baja de la esperada)

•Sensor no esta conectado

•Conexión de alta resistencia en el

motor WYE punto a sensor

•Fusible de señal abierto

•Ajuste de amperaje bajo

establecido en alto

•Verifique las lecturas del fondo del pozo (fase-fase y fase-tierra

(megóhmetro con polaridad inversa))

•Verifique todas las conexiones

•Compruebe el fusible de señal

•Verifique el ajuste de amperaje bajo con DataWorks (15 VDC

nominal)

•Verifique la configuración de alto amperaje con DataWorks (25

VDC nominal)

© Sercel 2020 - All rights reserved

SPS-1500 Troubleshooting

10

Error

Possible Cause

Troubleshooting Step

High Amps –

(Gauge current is higher

than expected)

•Poor Wellhead grounding

•Excessive Gauge Signal Line

Current or injection of noise from

motor at wye point.

•Connect to the SPS with “DataWorks” software to manually set

the following current settings for the gauge:

- Check Setting of Low amp (15mA normally for SPS-1500 and 2-

8mA normally for SPS-1501)

- Check Setting of High amp (25mA normally for SPS-1500)

•Verify Downhole readings (Phase to Phase, Phase-Ground

(Reverse Polarity Megger))

•Replace the SPS-1500

High Amps –

(La corriente del sensor es

mas alta de la esperada)

•Conexión a tierra del cabezal de

pozo deficiente

•Corriente de línea de señal del

sensor excesivo o ruido del motor

en el punto estrella.

•Conéctese al SPS con el software "DataWorks" para establecer

manualmente las siguientes:

- Compruebe la configuración de Low Amp (15 mA normalmente

para SPS-1500)

- Compruebe la configuración de High Amp (25 mA normalmente

para SPS-1500 y 22-26 mA normalmente para SPS-1501)

•Verifique las lecturas del equipo de fondo (fase a fase, fase-

tierra (megóhmetro con polaridad inversa))

•Reemplace el SPS-1500

© Sercel 2020 - All rights reserved

SPS-1500 Troubleshooting

11

Error

Possible Cause

Troubleshooting Step

Analyzing–

(SPS is adjusting output

voltage to analyze gauge

signal)

•Normal Operation message unless

message is continuous or

repeating over 5 minutes.

If message is continuous or repeats over 5 minutes:

- Check all wire connections

- Check Phase to Phase and Phase-Ground connection (Reverse

Polarity Megger) (Applies to SPS-1500 only)

- Check Signal fuse

- Adjust Set voltage (Approx. 60+/- for 1500 and Approx. 40+/- for

the SPS-1501). This can be done using “DataWorks” software.

Analyzing–

(SPS se está ajustando el

voltaje de salida para

analizar la señal del

sensor)

•

Mensaje de funcionamiento normal

a menos que el mensaje sea

continuo o se repita durante 5

minutos.

Si el mensaje es continuo o se repite durante 5 minutos:

•Verifique todas las conexiones de los cables

•Compruebe la conexión de fase a fase y de fase a tierra

(megóhmetro con polaridad inversa) (solo se aplica al SPS-1500)

•Comprobar fusible de señal

•Ajuste el voltaje establecido (Aprox. 60 +/- para 1500 y Aprox.

40 +/- para el SPS-1501). Esto se puede hacer usando el

software "DataWorks".

© Sercel 2020 - All rights reserved

SPS-1500 Troubleshooting

12

Error

Possible Cause

Troubleshooting Step

No Tool –

(No Tool indicates there is

no gauge current)

•Blown SPS Fuse

•Blown Surge Protector Fuse/MOV

•Bad SPS to Gauge Signal wire

connection

•No-Tool Current setting incorrect

in SPS

•Read the DC current drawn by the gauge with an ammeter in

series and DC mode. DC current is normally 15-30mA.

•Check all fuses and surface connections.

•If connections and equipment okay error may indicate possible

downhole connection is open.

•Using “DataWorks”, verify “No Tool Amp” value is set to 5.3mA

(default value).

No Tool –

Indica que no hay sensor

conectado

•Fusible SPS abierto

•Fusible / MOV del protector de

sobretensión abierto

•Mala conexión del cable de SPS a

la señal del sensor

•Configuración de corriente No-

Tool Current incorrecta en SPS

•Lea la corriente DC consumida por el sensor con un

amperímetro en serie y modo DC. La corriente DC debe ser

normalmente de 15 a 30 mA.

•Compruebe todos los fusibles y las conexiones de superficie.

•Si las conexiones y el equipo están bien, el error puede indicar

que una posible desconexión en el fondo.

•Usando “DataWorks”, verifique que el valor de “No Tool Amp”

esté establecido en 5.3mA (valor predeterminado).

© Sercel 2020 - All rights reserved

SPS-1500 Troubleshooting

13

Error

Possible Cause

Troubleshooting Step

Line Noisy–

(SPS is unable to measure

current modulation from

gauge)

•Motor WYE phase imbalance

voltage is high

•Check all fuses and surface connections.

•If connections and equipment okay error may indicate possible

downhole problem.

•Check line voltage at wye point on surge protector for motor

noise injection.

Line Noisy–

(SPS no puede medir la

modulación actual del

sensor)

•El voltaje de desequilibrio de fase

en el WYE point del motor es alto

•Compruebe todos los fusibles y las conexiones de superficie.

•Si las conexiones y el equipo están bien, el error puede indicar

un posible problema en el fondo del pozo.

•Verifique el voltaje de línea en el punto estrella del protector

contra sobretensiones (surge protector) para detectar la

inyección de ruido del motor.

© Sercel 2020 - All rights reserved

SPS-1500 Troubleshooting

14

Error

Possible Cause

Troubleshooting Step

No Signal–

(SPS measures gauge

current but no modulation

current)

•Possible SPS/gauge firmware

corruption

•Possible SPS/gauge component

failure

•No-Tool Current setting incorrect

in SPS

•Use DC Ammeter to measure DC current from SPS to gauge.

Gauge current is normally modulated from approximately 15mA

to 25mA. If not modulated, check SPS and connections.

No Signal–

(SPS mide la corriente del

sensor pero no la corriente

de modulación)

•Posible corrupción del firmware

del sensor / SPS

•Posible falla en algún

componente del sensor / SPS

•Configuración de No-Tool

Current incorrecta en SPS

•Utilice un amperímetro de DC para medir la corriente DC de SPS

al sensor. La corriente del sensor normalmente se modula

desde aproximadamente 15 mA a 25 mA. Si no está modulado,

verifique SPS y conexiones.

© Sercel 2020 - All rights reserved

SPS-1500 Troubleshooting

15

Error

Possible Cause

Troubleshooting Step

LINE BAD–•Phase imbalance, short circuit or

damaged equipment

•Check drive, grounding to wellhead, surface cable to wellhead

and system grounds. Check Surge Suppressor MOV, fuses,

surface choke and wiring. Check gauge fuse on SPS-1500. Test

resistance/insulation of the downhole cable at wellhead

LINE BAD–•Desequilibrio de fase,

cortocircuito o equipo dañado

•Verifique el VSD, la conexión a tierra al cabezal del pozo, el

cable de superficie al cabezal del pozo y las tierras del sistema.

•Compruebe el MOV del supresor de sobretensión, los fusibles,

el choke de superficie y el cableado. Verifique el fusible del

sensor en el SPS-1500. Pruebe la resistencia / aislamiento del

cable de fondo de pozo desde la boca del pozo

•Reemplace SPS-1500

© Sercel 2020 - All rights reserved

SPS-1500 Troubleshooting

16

Error

Possible Cause

Troubleshooting Step

Packet Size–•Communication problem as the

SPS-1500 looks for the optimal

voltage to run the gauge

•If AutoAnalisys and AutoVolt are disabled (Manual Mode),

increase the voltage; If AutoAnalisys and AutoVolt are enabled

the SPS-1500, try running in a Manual Mode and increase de Set

Voltage until the gauge is communicating.

Packet Size–•Problema de comunicación ya

que el SPS-1500 busca el voltaje

óptimo para detectar el sensor

•Si AutoAnalisys y AutoVolt están desactivados (modo manual),

aumente el voltaje; Si AutoAnalisys y AutoVolt están habilitados

el SPS-1500, intente ejecutar en modo manual y aumente el

voltaje de ajuste hasta que el sensor se comunique.

© Sercel 2020 - All rights reserved

SPS-1500 Troubleshooting

17

Error

Possible Cause

Troubleshooting Step

OKAY–•Normal Operation, no errors •SPS is communicating with the gauge

•Operación normal, sin errores •El SPS se esta comunicando con el sensor

© Sercel 2020 - All rights reserved

〉Possible Reason(s)

oSend / Receive connections

reversed

oImproper address and Baud Rate

oNot receiving Modbus request

(Magenta LED by Modbus

connector flashes when SPS

receives Modbus request)

No Modbus communication

18

〉Correction

Check for proper Modbus address and Baud rate on SPS-1500 LCD

RS-485 connections

oMake sure jumpers, J6 & J7, are on SPS-1500.

oMake sure same polarity connection is going from SPS-1500 to

RS-485 adaptor board [e.g. ‘TR-’ from SPS-1500 connects to

TD(A) of RS-485 adaptor].

RS-422 connections

oMake sure jumpers, J6 & J7, are not on SPS-1500.

oMake sure all 4 wires are connected with correct polarity. For

example

o‘TR-’ from SPS-1500 connects to TD(A) of RS-422 adaptor and –

TR+’from SPS-1500 connects to TD (B) of RS-422 adaptor.

© Sercel 2020 - All rights reserved

SPS Default Configurations

19

SPS Control Description Default

Power On Voltage Setting Sets initial Line Voltage at startup 40.00

MBWD:Modbus Watchdog Enables 5 Min

Modbus packet timer timeout and

restart

ON

SAFEV: Safe Voltage Measures Signal Levels before gauge power on and

can disable the tool if voltages are too high

ON

Auto Volt Sets optimum line voltage ON

Auto Analyze Analyzes for optimum line communication ON

Auto Baud Toggle Auto Baud ON

Minimum Baud Rate Edit Minimum tool baud rate 3

Baud Rate Edit Maximum tool baud rate 8

Line Voltage Tolerance Edit Line Voltage Tolerance 4

No Tool Amp Edit current threshold while no tool connected 5

Low Current Edit low current threshold 16-18

High Current Edit high current threshold 30-32

© Sercel 2020 - All rights reserved

SPS Default Configurations (Cont..)

20

SPS Control Description Default

LCD Backlight Toggle LCD backlight ON

LCD Time Adjust time between data screens 3

LCD F W Info. Toggle Display: Firmware Version OFF

LCD Tool Information Toggle Display: Tool Information ON

LCD Modbus Information Toggle Display: Modbus Information ON

LCD Wye Imbalance Toggle Display: Wye Voltage Imbalance ON

LCD Comm Settings Toggle Display: SPS Communication Settings ON

LCD Signal Levels Toggle Display: SPS-Tool Signal Levels ON

LCD Line Voltage Toggle Display: Current Line Voltage ON

LCD Run Time Toggle Display: SPS-1500 Power On Time ON

This manual suits for next models

1

Other Sercel Measuring Instrument manuals