Chopin AlveoPC User manual

20, avenue Marcellin Berthelot - Z.I. du Val de Seine

92396 Villeneuve La Garenne cedex - France

Tél. : 33 (0)1 41 47 50 88 - Fax. : 33 (0)1 47 92 28 27 www.chopin.fr

AlveoPC

Maintenance manual

2016/02

AlveoPC

3

Maintenance manual

IMPORTANT

The technical elements that constitute this manual (text and illustrations) are not contractual,

their only target being to bring assistance for troubleshooting and repairing the equipment

AlveoPC.

Use, duplication or disclosure of subject data, for any purpose other than relating to the

servicing or repair of the equipment, is strictly prohibited without the written authorization of

CHOPIN Technologies.

AlveoPC

4 Maintenance manual

AlveoPC

5

Maintenance manual

Table of contents

Chapter 1 Use and maintenance:

reminders and further information 7

1. Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2. Precautions relating to tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3. Inspection and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4. Control chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 2 Trouble-shooting . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1. Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2. Failure modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3. Repair instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4. Interconnection diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Chapter 3 Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

2. Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Chapter 4 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

1. Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

2. Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

3. List of Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

AlveoPC

6 Maintenance manual

7

Maintenance manual

2016/02

AlveoPC

Chapter 1 USE AND MAINTENANCE:

REMINDERS AND FURTHER

INFORMATION

8Maintenance manual

2016/02

AlveoPC

Chapter 1 Use and maintenance: reminders and further information 9

Maintenance manual

2016/02

AlveoPC

Chapter 1. Use and maintenance: reminders and

further information

This chapter summarizes the most important instructions concerning the use and maintenance of the

AlveoPC.

For more detailed information, please refer to the corresponding user instructions.

This part also includes additional information intended exclusively for persons authorized to carry out

maintenance operations on the instruments.

1. Operating conditions ■ Installation

Use of the instruments requires a flat, clean and unobstructed work

surface. The instruments must be set level using their adjustable

legs, in particular the Alveograph (level supplied).

The surrounding area should be suitable for relating handling oper-

ations (preparation of pieces of dough in particular).

❏ For water line connections:

The water line cooling circuit must be installed very carefully:

- hard wall hoses must be used,

- these must be fixed with pipe supports,

- drain pipe fixed.

❏ For recirculating cooler connections:

Device must be connected as per manufactures recommendation.

Water temperature : 18°c to 20°c.

■ Electrical connections

The electrical connection of each instrument must be compliant with

IEC standard 1010 - installation category: II.

❏ Characteristics of the power source:

• 220-240V~ - 50/60 Hz -1.3 kVA

• Power sockets 2P + E/16 A

• The electricity network must include a DDR with a sensitivity

d30 mA class AC upstream of the instruments.

10 Chapter 1 Use and maintenance: reminders and further information Maintenance manual

2016/02

AlveoPC

■ Computer connection

The AlveoPC cannot function without a connection to a computer to

extract and view results and for calibration and maintenance pur-

poses.

IMPORTANT The mixer's frequency inverter induces leakage current of roughly

10 mA.

❏ A 2-phase + ground plug must only be connected to a power

socket having a protective grounding conductor.

This is a safety measure: if the connection is impossible, under no

circumstances should you attempt to force it; have a suitable socket

installed by a specialist.

■ Environment

❏ Operating temperature:

Laboratory temperature: 18°C to 22°C

❏ Humidity in use: 50% to 80%

❏ Pollution:

AlveoPC instruments are designed to be used in pollution-free con-

ditions, only dry and non-conductive pollution.

2. Precautions relating

to tests

■ Tests with an alveograph must always be conducted with great

care.

The relevant instructions (test conditions, handling, cleaning) are

given in the instrument's user instructions must be followed pre-

cisely, at the risk of:

❏ obtaining incorrect results,

❏ irreparably damaging the equipment.

■ When handling, take care not to damage any components, in par-

ticular:

❏ the mixing blade,

❏ the extraction passage.

Chapter 1 Use and maintenance: reminders and further information 11

Maintenance manual

2016/02

AlveoPC

3. Inspection and

maintenance

■ Maintenance Menu

On the main menu, click the [Maintenance] tab.

From here you can access:

❏ Meters (A):

- number of tests on the day,

- total number of tests (since the database was last archived),

- number of tests since the mixing blade was replaced.

❏ Calibration menus (accessible with the code 1234):

- calibration of the Alveograph's pressure sensor (B- See Operation

A10-10, page 107.),

- calibration of Alveograph measurements, on the basis of listed

flours (C- See Operation A10-11, page 109.).

■ General recommendations

For more efficient maintenance work on the instruments, it is advis-

able to date, record and update all information concerning the life of

the instrument.

A

B

C

12 Chapter 1 Use and maintenance: reminders and further information Maintenance manual

2016/02

AlveoPC

■ Periodic actions

USER Users are advised that, in addition to daily or weekly checks, adjust-

ments and cleaning, they should personally carry out a number of

operations on a regular basis:

ACCREDITED REPAIRMAN Users are also advised to have a full servicing operation carried out

on the AlveoPC by an authorized CHOPIN Technologies engineer.

Recommended frequency: 1 year, possibly 2 years if it is not used

intensively.

Minimum recommended operations:

These operations must be concluded by a full functional verification

(leak test, control tests on known flour).

Operation Frequency

❏ Control test on a control sample

(see 4. "Control chart")

❏ Cleaning the Alveograph

(burette, resting chamber)

100 tests

or

1 month

❏ Leak test (See Operation A10-

3, page 100.)1 year

❏ Alveograph:

- clean the piston, replace seals and springs,

- check the lower plate, 3-part plate

- replace hoses and quick pneumatic couplers,

- (if necessary) replace the EPROMs for software updates.

❏ Mixer:

- check the extraction passage,

- replace the mixing blade,

- check mixing blade-bowl alignment,

- (if necessary) replace the EPROM for software update.

Chapter 1 Use and maintenance: reminders and further information 13

Maintenance manual

2016/02

AlveoPC

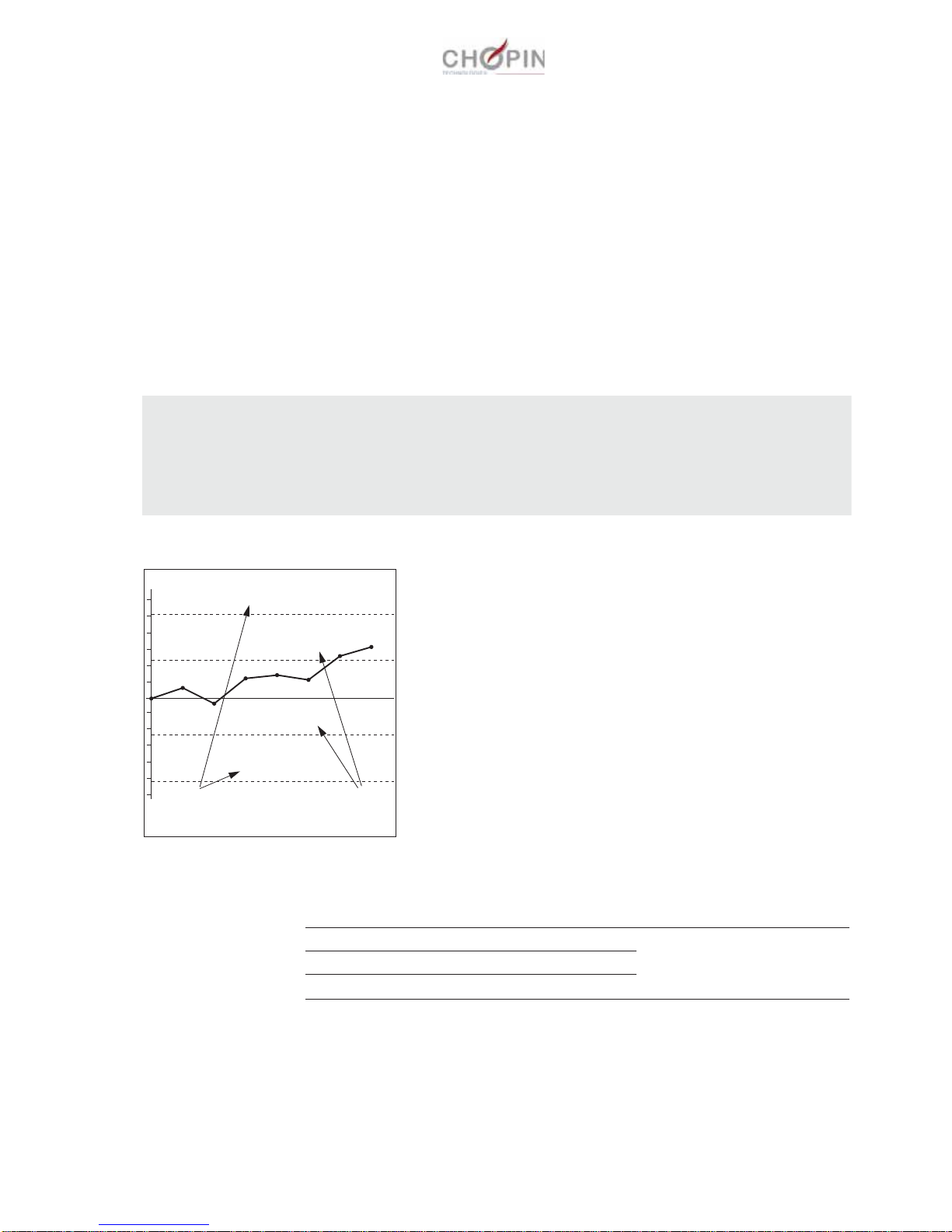

4. Control chart ■ To guarantee optimal alveographic measurement accuracy,

and to detect an incident as soon as possible, carry out regular

control tests with a control flour, in identical testing conditions.

❏ Regular monitoring of the results of these control tests will more

particularly help pinpoint any deviation caused by a disturbance,

wear, fouling, deterioration…

❏ It should be noted that when speaking of “Abnormal results” (see

fault detection tables in this manual or the user manual), this verdict

is assumed to be based on a control test.

❏ We recommend drawing up “control charts” for each instrument.

METHOD

■ Each control chart should include:

❏ its date of creation (the date of the first test),

❏ the reference of the sample,

❏ its humidity,

❏ a results monitoring graph:

- parameters/date,

- indication of tolerances.

Note: This control chart can advantageously be created by com-

puter (a spreadsheet for instance).

■ Alveograph control chart:

The parameters to record on the control chart are:

Note: The information below in no way constitutes a procedure for preparing control charts;

this is the task of the customer's Quality Assurance services, whether or not in connec-

tion with a certification process.

It simply offers instructions that CHOPIN Technologies recommends bearing in mind

when drawing up control charts.

measurement

time

boundary value alarm threshold

Parameter Practical

tolerance

limit

ISO standard 5530

P Persistence ±8% see the repeatability and

reproducibility limits

recommended by the ISO

5530 standard

L (or G) Extensibility ±5%

W Baking strength ±8%

14 Chapter 1 Use and maintenance: reminders and further information Maintenance manual

2016/02

AlveoPC

FREQUENCY ■ All the control test results (curves and computed values) must be

precisely kept.

We recommend keeping a hard copy in addition to a backup on the

PC.

■ The following frequency for these control tests is recommended:

❏ Every 100 tests or after 1 month (whichever is the earlier).

Note: Users of Alveo instruments are strongly recommended to

be members of a laboratory comparison round robin such

as BIPEA, AACC,…; in which case the rules of this circuit

should be observed.

❏ After a major overhaul of instruments, for instance after:

- replacing the mixing blade,

- adjusting the extraction passage,

- realigning the mixer's bowl and gear motor,

- replacing the Alveo spacers,

- cleaning the Alveo pneumatic measuring circuit,

- replacing an Alveograph pressure sensor.

❏ If in doubt about any measurements.

CONTROL SAMPLE ■ Quantity

An adequate quantity of sample flour must be kept for a sufficient

period to monitor the performance of the instruments.

■ Storage conditions

❏Initial characterization

The characteristics of the sample must be measured carefully. In

particular, accurately measure:

❏ the moisture content of the sample,

❏ its alveographic characteristics (a minimum of 3 tests),

Reminder:The milled sample must be stored for at least 6 days after

production, and for no more than 15 days, at room tem-

perature (20°C) in a well-ventilated environment.

■ Storage

The control sample must be kept:

❏ In a clean, dry container made of inert material, in a refrigerated

room at constant temperature, and must be labelled,

❏ for a period not exceeding admissible limits1.

Note: It can be stored at low temperature

(–20°C for instance); to that end, the usual freezing rules

must be observed.

1. The maximum storage time is 2 months at 4°C.

Chapter 1 Use and maintenance: reminders and further information 15

Maintenance manual

2016/02

AlveoPC

CONTROL TEST ■ Conducting the test

Alveo tests must be conducted at constant hydration

❏ The control test must always be conducted using the same proto-

col, and with the usual degree of care for any test (see in particular

“Precautions relating to tests”, page 10).

❏ If the flour is taken from a sample stored at low temperature, you

should obviously ensure that it is at laboratory temperature before

the test, and make sure the moisture content is not altered.

Notes: 1. The sample's bottle must be removed from cold storage

and left in the laboratory for at least 24 hours before use.

2. Check the temperature of the sample with a thermome-

ter.

3. Also measure the moisture content first, using a certi-

fied process.

❏ Alveographic control tests are only valid of course if the Alveo-

Mixer combination is properly maintained.

■ Results

If we rule out cases of poor testing conditions (incorrect handling,

unstable temperatures, etc.), any result outside the specified toler-

ances means that:

❏ the equipment is incorrectly adjusted, worn or damaged (refer to

Chapter 2 "Trouble-shooting"), or

❏ the flour sample has been altered (change in moisture content),

or has even deteriorated through an increase in its acidity (fatty

acidity in particular).

16 Chapter 1 Use and maintenance: reminders and further information Maintenance manual

2016/02

AlveoPC

17

Maintenance manual

2016/02

AlveoPC

Chapter 2 TROUBLE-SHOOTING

18 Maintenance manual

2016/02

AlveoPC

Chapter 2 Trouble-shooting 19

Maintenance manual

2016/02

AlveoPC

Chapter 2. Trouble-shooting

This chapter helps you determine the cause of a given fault and possibly quarantine the faulty component or

subassembly; in which case the requisite actions are specified.

When contacting CHOPIN Technologies After-Sales, always state the serial number of the instrument.

1. Method ■ Conceivable failures are listed in § 2. "Failure modes". These

failures are categorized:

- A. Error messages,

- B. Abnormal results,

- C. Other faults.

❏ Other abnormal events are possible and it is up to the repairman

to resolve the problem through analysis and comparisons. Simpli-

fied interconnection diagrams are provided in § 4. of this chapter,

which may help the trouble-shooting process.

Naturally, in case of difficulty or if in doubt, CHOPIN Technologies

After-Sales is at your disposal to try and resolve the problem, by tel-

ephone, fax or e-mail.

Failing which, the instrument will have to be returned to CHOPIN

Technologies for repairs.

■ Before starting to trouble-shoot, be sure to record all relevant

evidence.

❏ In the event of an abnormal result, checking the control chart (if it

exists) could provide an immediate explanation (the case of a per-

manent deviation for instance).

❏ The PC's software interface can provide some relevant informa-

tion on the life of the instrument:

- the test number and total working time,

- the calibration dates.

❏ Irrespective of the failure, we recommend carefully noting the

conditions in which it occurred.

If a failure occurs during a test, it is advisable whenever possible to

keep a record of graphs and test results (printout).

■ For most failure modes, the table in § 3. "Repair instructions"

gives the isolation process that should be followed chronologically.

20 Chapter 2 Trouble-shooting Maintenance manual

2016/02

AlveoPC

2. Failure modes A Error messages

■ Error message on Mixer

These are displayed on the Mixer screen to help detect common

problems

A-1 ERR: 1 The temperature of the Mixer's chamber is outside acceptable lim-

its.

A-2 ERR: 2 The Alveograph chamber temperature is out of limits.

A-3 ERR: 3 Bus timeout exceeded.

A-4 ERR: 4 Bus frozen.

A-5 ERR: 5 Mixer motor command problem; this error causes a warning beep.

A-6 ERR: 6 Open Mixer cover detected before the motor stopped.

A-7 ERR: 7 Start Mixer attempted while the cover was open.

A-8 ERR: 8 Incorrect control voltage on the Alveograph pump.

A-9 ERR: 9 Inverter return status problem.

Mixer

temperature Alveograph

temperature

Error message

Table of contents

Other Chopin Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

RDS Technology

RDS Technology Master Driers MMM 100 Installation, Calibration and Operation

BRUEL & KJAER

BRUEL & KJAER 2240 instruction manual

Blue-White

Blue-White ProSeries SONIC-PRO S4 Series Installation and operating manual

Hanna Instruments

Hanna Instruments HI 93734 instruction manual

Bell and Howell

Bell and Howell 770 manual

SIGRIST

SIGRIST TurBiScat 2 Ex operating manual

Keysight Technologies

Keysight Technologies M981 AS Series quick start guide

Knick

Knick Stratos Evo A402 user manual

Hanna Instruments

Hanna Instruments HI 99131 instruction manual

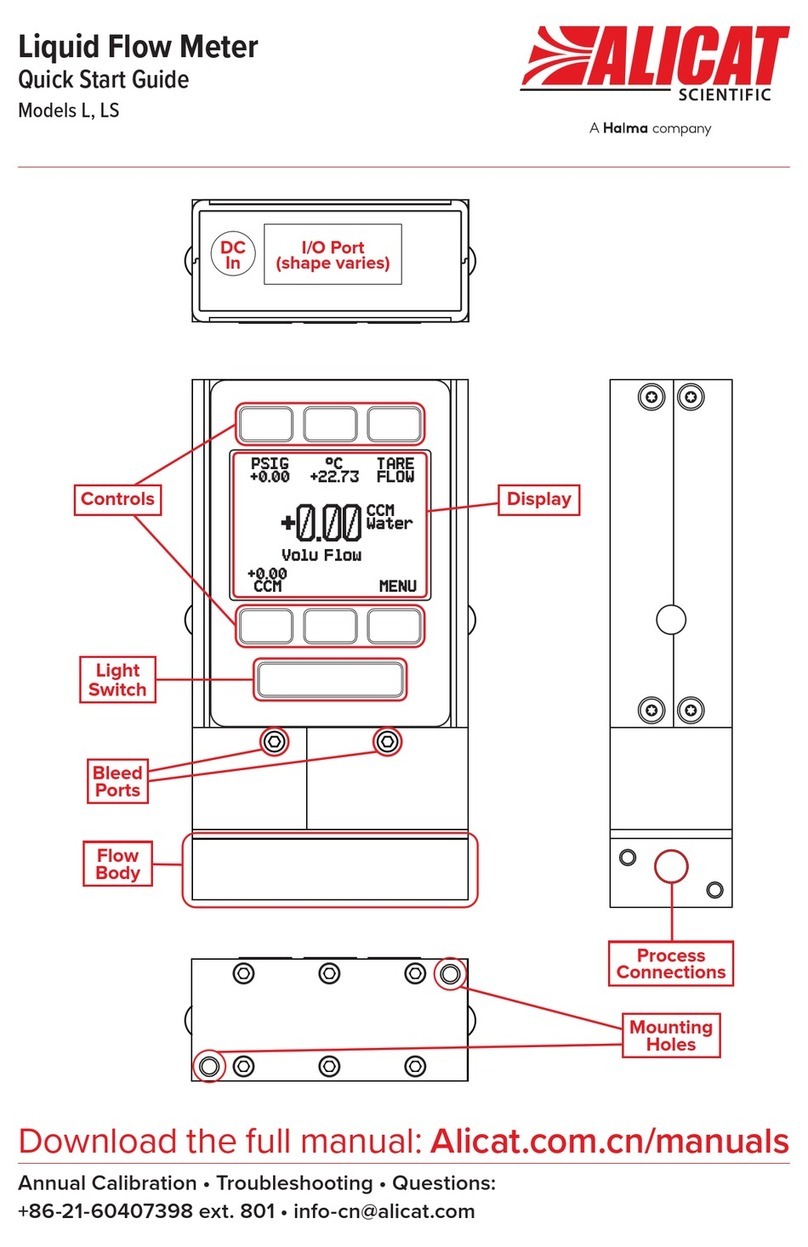

Halma

Halma ALICAT SCIENTIFIC L quick start guide

C-LOGIC

C-LOGIC 8730 instruction manual

Felix Storch

Felix Storch F-750 quick start guide