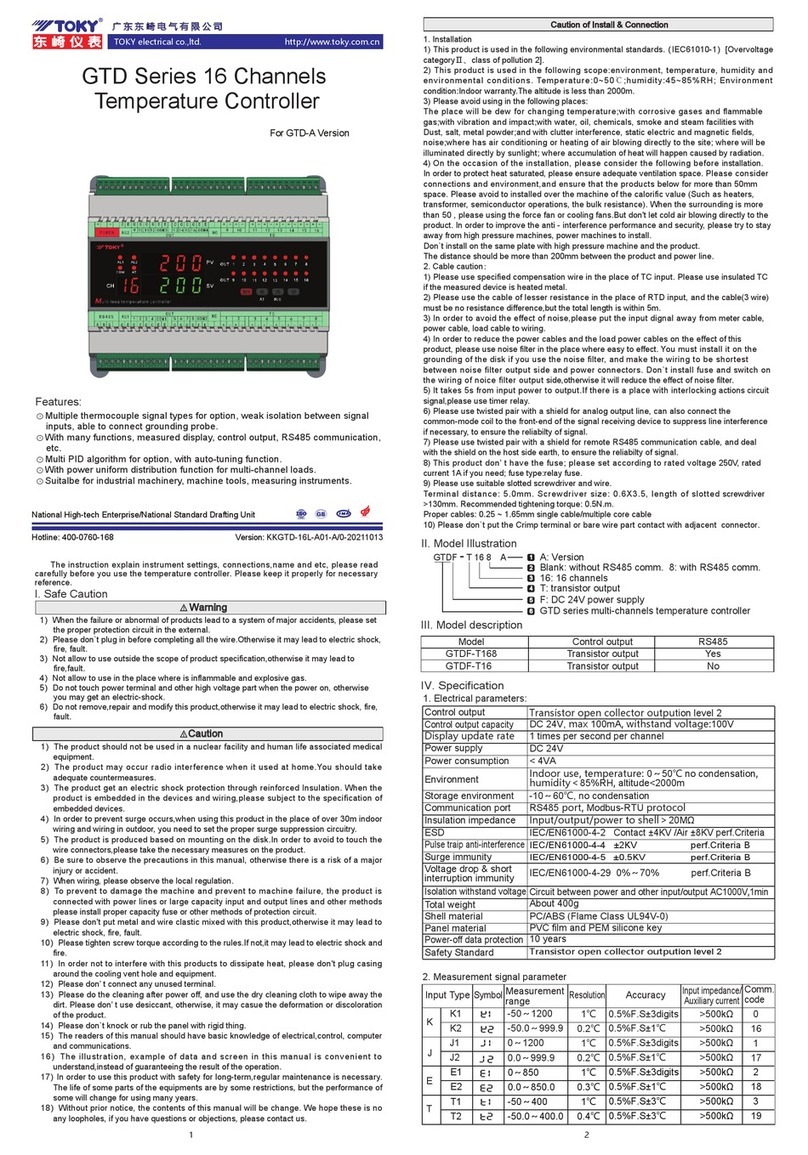

Toky AI808P Series User manual

Page 01 KKAI808PE01-A/0-20130904

AI808P

AI808P Series Intelligent Temperature Controller User Manual

Features:

TC / RTD / Analog signal universal input;

With display, alarm, adjusting and communication function;

Advanced Fuzzy algorithm & Two Degrees

of Freedom PID Arithmetic;

Optional control output, modularization design;

Good anti-interference;

Up to 50 programmable segments control;

Color bar display

AI808 Series Intelligent Temperature Controller (with 50 programmable segment control)

1. Model

Safe Caution

Please comply with the below important points.

Warning

Notice

An accident may happen if the operation does not comply with the instruction.

An operation that does not comply with the instruction may lead to product damage.

For your safty, please read following content carefully before you are using our temperature controller!

The instruction of the symbol in the manual is as below.

An accident danger may happen in a special condition.

Please read the manual carefully before you use the temperature controller.

Warning

1. A safty protection equipment must be installed or please contact with us for the relative information if the product is used under

the circumstance such as nuclear control, medical treatment equipment, automobile, train, airplane, aviation and equipment etc..

Otherwise, it may cause serious loss, fire or person injury.

2. A panel must be installed, otherwise it may cause creepage (leakage).

3. Do not touch wire connectors when the power is on, otherwise you may get an electric shock.

4. Do not dismantle or modify the product. If you have to do so, please contact with us first. Otherwise it may cause electric shock

and fire.

5. Please check the connection number while you connect the power supply wire or input signal, otherwise it may cause fire.

Caution

1. This product cannot be used outdoors. Otherwise the working life of the product will become shorter, or an electric shock accident

may happen.

2. When you connect wire to the power input connectors or signal input connectors, the moment of the No.20 AWG (0.50 mm2)

screw tweaked to the connector is 0.74n.m - 0.9n.m. Otherwise the connectors may be damaged or get fire.

3. Please comply with the rated specification. Otherwise it may cause electric shock or fire, and damage the product.

4. Do not use water or oil base cleaner to clean the product. Otherwise it may cause electric shock or fire and damage the product.

5. This product should be avoid working under the circumstance that is flammable, explosive, moist, under sunshine, heat radiation

and vibration. Otherwise it may cause explosion.

6. In this unit it must not have dust or deposit, otherwise it may cause fire or mechanical malfunction.

7. Do not use gasoline, chemical solvent to clean the cover of the product because such solvent can damage it. Please use some soft

cloth with water or alcohol to clean the plastic cover.

Dimension: 4: 48Wx48H 6: 48Wx96H 7: 72Wx72H 8: 96Wx48H 9: 96Wx96H

16 80W×160H 80 160W×80H

Output function: R: Relay S: Logic (SSR) D: Current (4-20mA)

Alarm function: B: One Alarm Output C: Two Alarm Output

(One more alarm will be added when the heating & cooling control is not used)

Signal input: 10: One signal input without communication

18: One signal input with RS485 communication (please indicate when order)

Page 02 KKAI808PE01-A/0-20130904

1

1

1

1

1

1

Model Alarm (Note 3)

No

No

No

RS485 (Modbus RTU)

RS485 (Modbus RTU)

RS485 (Modbus RTU)

Communication

OUT1 (Note 1) OUT2 (Note 2)

2. Model Illustration

Relay output

Relay output

Relay output

Relay output

Relay output

Relay output

Relay output

SSR output

4-20mA current output

Relay output

SSR output

4-20mA current output

Ambient humidity 45-85%RH

Ambient temperature 0-50

Total current 30mA 220VAC

Power supply AC/DC 100-240V

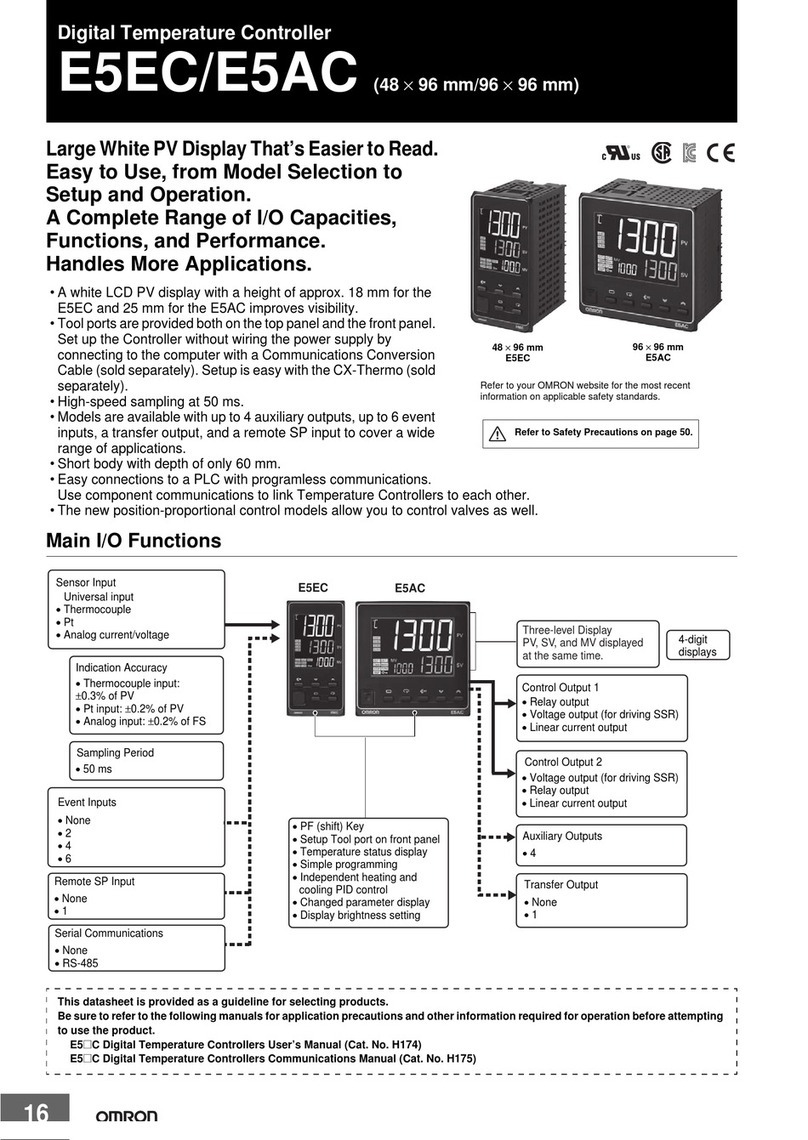

1) Whole controller parameters

Measurement accuracy ±0.3%FS±3digits 25

Control mode ON/OFF control PID heating control PID cooling control PID heating & cooling control

Communication function RS485 communication interface, MODBUS protocol

Panel protection level IP65

Temperature excursion 0.01%FS/

Between the connectors of power supply to relay output, power supply to signal input, relay output to

signal input 2000VDC; Between the low voltage signal isolated with each other 600VDC.

3. Main Technical Parameters

Dielectric strength

AI808P-4-RB10

AI808P-4-SB10

AI808P-4-DB10

AI808P-4-RB18

AI808P-4-SB18

AI808P-4-DB18

AI808P- RC10

AI808P- SC10

AI808P- DC10

AI808P- RC18

AI808P- SC18

AI808P- DC18

2

2

2

2

2

2

Model Alarm (Note 3)

No

No

No

RS485 (Modbus RTU)

RS485 (Modbus RTU)

RS485 (Modbus RTU)

Communication

OUT1 (Note 1) OUT2 (Note 2)

Relay output

Relay output

Relay output

Relay output

Relay output

Relay output

Relay output

SSR output

4-20mA current output

Relay output

SSR output

4-20mA current output

OUT2: Can be workable just under heating-cooling control(OT=3); under other control mode,

worked as alarm 3 (For size:48*48 worked as alarm 2)

Relay output capacity: 1A/250V AC.

OUT3: Alarm 3:

Relay output capacity: 1A/250V AC

Note:

OUT1: 4-20mA current output, load capacity: 600 max.

Relay output capacity: 3A/250V AC

SSR output capacity: 30mA/24V DC

Page 03 KKAI808PE01-A/0-20130904

Signal Input type Measuring range Resolution Input impedance

K type thermocouple

J type thermocouple

E type thermocouple

T type thermocouple

B type thermocouple

R type thermocouple

S type thermocouple

N type thermocouple

Reserved

PT100

JPT100

CU50

CU100

Linear voltage

Linear current

Linear voltage

Linear resistance

-50 1300

-50 1200

-50 1000

-50 400

600 1800

-10 1700

-10 1600

-50 1200

-199.9 850.0

-199.9 500.0

-50.0 150.0

-50.0 150.0

0 50mV

420mA

010V

0400

1

1

1

1

1

1

1

1

0.1

0.1

0.1

0.1

0.01%FS

0.01%FS

0.01%FS

0.01%FS

100K

100K

100K

100K

100K

100K

100K

100K

0.2mA)

0.2mA)

0.2mA)

0.2mA)

100K

<110

100K

0.2mA)

2) Input parameter table

4. Panel indication

SV Value or Parameter Code

PV Value or Parameter Code

AL1:AL1 Indicating Light

OUT2:OUT2 Indicating Light

AL2:AL2 Indicating Light

SET Function Key

OUT1:OUT1 Indicating Light

Shift Function Key

No

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Increase Key

Decrease Key

AL3:AL3 Indicating Light

AT: Auto-turning Indicating Light

Control Output Indicating Color Bar

(AI808P-4 without color bar display)

5. Panel Key Operation

1 key In normal display status, press key to show setting menu, press key for a few seconds

to show advanced setting menu.

2 key press key to make the parameters to flicker the parameters can be changed.

3 , key to change parameters in setting status, after each operation, press key to confirm the modify.

4 In advanced setting menu, press key for a few seconds to quit the menu and back to normal display status.

5 In normal display status, press key for 3 second to start Auto-tuning function at this moment AT indicating

lamp turns on.

(6) In normal display status, press Key to enter into programmable setting menu, press Key to enter into

programmable parameter setting menu.

Page 04 KKAI808PE01-A/0-20130904

6. Operation Sequence

Measuring status

Power on & Reset

Alarm 1

Alarm 2

Alarm 3

PV bias

value

Manual / auto

shift menu

Password lock

Control mode

OUT1 control

cycle

Cooling prportional

coefficient

effective when OT=3

Output function

setting menu

OUT2 control cycle

effective when OT=3

Heating cooling

control dead area

effective when OT=3

Alarm 1 hysteresis

Setting menu

Alarm 1 mode

Alarm 2 hysteresis

Alarm 2 mode

Alarm 3 hysteresis

Alarm 3 mode

Lower limit

of control

output

Upper limit

of control

output

Input signal

mode

Lower limit

of input signal

Upper limit

of input signal

Decimal point (Not effective

for TC / RTD input

Fliter constant

Lower limit of transmit current output

Upper limit of transmit current output

Baud rate

Meter

communication

address

Press SET

for a few

seconds

Press SET key for a few seconds

Proportional coefficient

Integral time

Derivative time

On/Off control

hysteresis

(effective when OT=0)

Press SET key for a few seconds

Press SET key

for a few seconds

Input function

setting menu Communication

setting menu

Change between celsius and fahrenheit

7. Program segment control setting

SET+ Start or stop the program

segment control

Program segment

setting menu

Power on & Reset

Measuring status

Operation Status, for

three types STOP, RUN

and HOLD can be choosed

Program segment control setting method

1) There are total 50 programmable segments. For each segment, there are 2 settable parameters: SV , ST .

2) SV value is the object control value of a segment, for example, if SV 01 is 200, the object control value of

this segment is 200

3) ST value is the control mode parameter of a segment.

When ST setting value is -51, it means it has finished this time’s programmable segment control, reset to single setting

value control mode (refer to example onw)

When ST setting value is -50 -1 it means the current segment will jump to the appointed segment, for example,

if ST -45 it means the current segment will jump to segment no.45 directly, after the control of this

segment is finished.

When ST setting value is 0 it means the program segment will jump to the next segment automatically when the

temperature get to

When ST setting value is 1 1440, unit is Minute, it means when runing within this segment, it will reach the setting value with average

speed; The meter will stop this segment’s operation when this segment’s ST value countdown to 0, if the ST value has already come to 0, but PV

measuring value does not meet with SV setting value, the program will not leave this segment until SV=PV. For example: SV =200

ST =10 the temperature is 30 ,the program will still runing in this segment for 10 minutes and the temperature will rise 17 per minute.

STEP Programmable

setting

SV Program

setting value

ST refer to the

illustration in the following

Press Key to enter into

programmable parameter

setting menu

programmable parameter

setting menu

Page 05 KKAI808PE01-A/0-20130904

Parameter name egnargnitteSnoitacidnI Ex-factory setting

Setting menu

Measured value amendment

OUT2 control cycle ( setting range can )

Dead area for heating & cooling control

Alarm hysteresis 1

Alarm mode 1

Alarm hysteresis 2

Alarm mode 2

Alarm hysteresis 3

Alarm mode 3

8. Menu Parameter

Manual / auto setting: 0 Manual 1: half-auto

Output function setting menu

Integral time

Control mode. 0 ON/OFF control 1 Heating control

Start Auto-tuning manually

2: auto Start Auto-tuning automatically after power on

Alarm 1 setting value

Alarm 2 setting value

Alarm 3 setting value

2Cooling control 3 Heating & cooling control

Proportional coefficient (P=0: ON / OFF control)

ON/OFF control hysteresis

Derivative time

OUT1 control cycle: Current output is 0;

Cooling proportional coefficient

1

1

1

1

1

1

1

SSR output is 1; the setting range of SSR output can

4) In normal display status, press key for a few seconds to show the parameter setting menu of

program segment control.

5) In normal display status, press key for a few seconds to enter into status setting value of program

segment control. You can choose RUN, STOP and HOLD three status in this segment.

Example Here is a control process with below requirement, the relevant setting is on the right side:

1) Temperature raise to 300 SV01=300 ST01=0;

2) Temperature raise from 300 to 500 (raise 10 degrees/ min) SV02=500 ST02=20

3) Temperature falls to 150 SV03=150 ST03=0;

4) Temperature is keep at 150 for 60 minute, and then SV04=150 ST04=60

Program jumps to No.10 segment ST05= -10

6) Temperature falls to 25 at No.10 segment SV10=25 ST10=0;

7) Program control stops running at No.11 segment.

exit the segment and control the temeprature according

to the SV (SV10=25)setting value ST11=-51;

0001, prohibit to modify SV; 0010, prohibit to modify Menu parameter;

0011, prohibit to modify SV and Menu;

Input function setting menu

Communication setting menu

Lower limit of control output

Upper limit of control output

Input signal type Please refer to input signal table

Lower display limit of input signal

Upper display limit of input signal

Decimal point setting. Only effective for analog signal input

Filter constant

Lower limit display for transmit current output

(with current transmit output can workable)

Baud rate

Meter communication address

Please refer to input signal table

Please refer to input signal table

0: unit of celsius, 1: unit of fahrenheit

Higher limit display for transmit current output

(with current transmit output can workable)

Page 06 KKAI808PE01-A/0-20130904

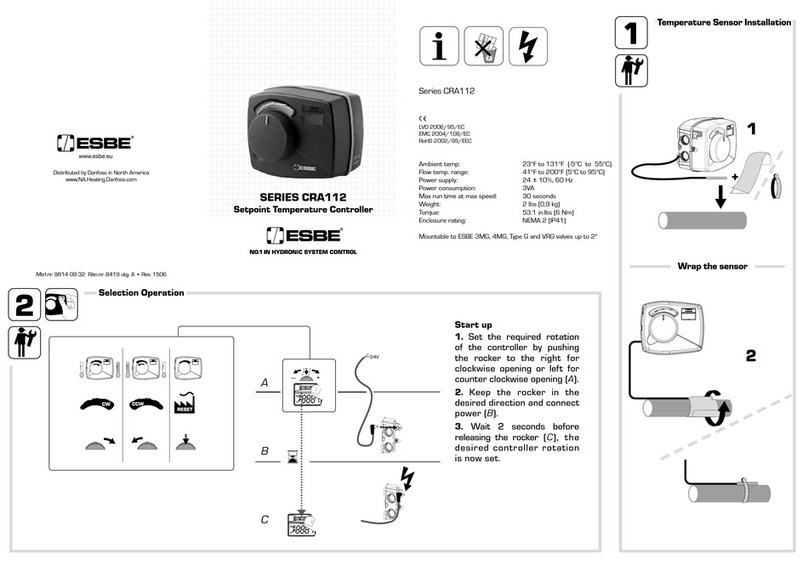

10. Connection Drawing

Model AI808P-6/AI808P-8

Accuracy

±

0.3%FS±3digits 25

Temperature excursion: 0.01%FS/

AI808P Series Temperature Adjustor

Model AI808P-9

Accuracy

±

0.3%FS±3digits 25

Temperature excursion: 0.01%FS/

AI808P Series Temperature Adjustor

Model

Alarm code Alarm mode Alarm output (AL1, AL2 is independent with each other

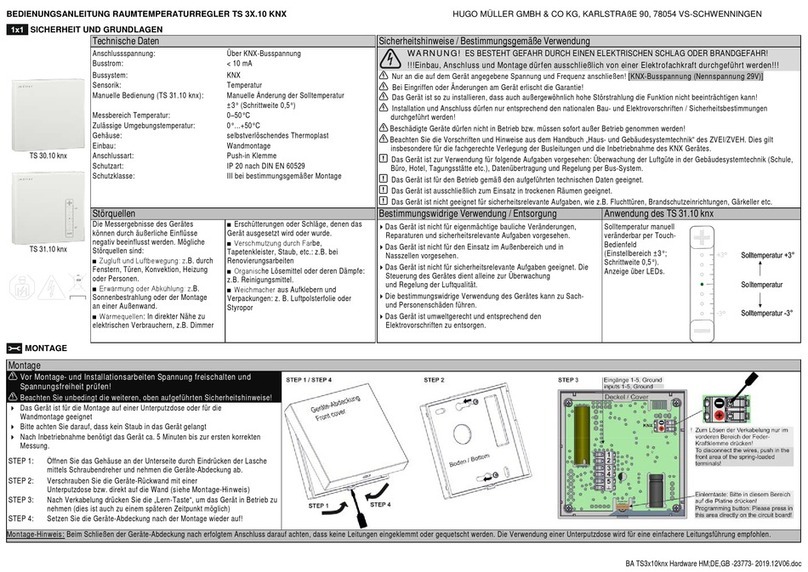

9. Apperance & Mounting Dimension

Alarm function table

Panel size

Side face size Mounting size

0

1

2

3

AL

SV

SV-AL SV

SV+AL

AL

HY

HY

HY

HY

Alarm PV AL

Cancel PV AL-HY

Alarm PV AL

Cancel PV AL+HY

Alarm PV AL+SV

Cancel PV SV+AL-HY

Alarm PV SV-AL

Cancel PV SV-AL+HY

Absolute upper limit alarm

Absolute Lower limit alarm

Upper Limit deviation alarm

Lower Limit deviation alarm

Temperature Raise

Temperature decrease

Temperature Raise

Temperature decrease

Formula

AI808P-4

AI808P-6

AI808P-7

AI808P-8

AI808P-9

AI808P-80

AI808P-16

Unit mm

48

48

72

96

96

160

80

AH(Min)

G

B C D E F

J

48

96

72

48

96

80

160

97.5

97.5

97.5

97.5

97.5

96

96

6.5

9

9

9

9

13

13

91

88.5

88.5

88.5

88.5

83

83

45.5

45

67.5

90

92

155.5

76

25

25

25

25

25

30

30

45.5

90

67.5

45

92

76

155.5

45

89.5

67

44.5

91.5

75.5

155

K

(Min)

25

25

25

25

25

30

30

A

B

C

E

D

F

G

K

J+0.5

-0

+0.5

-0 H

Page 07 KKAI808PE01-A/0-20130904

11. Simple Problem Shooting

Display Message

Display HHHH

Display LLLL

Shooting Method

Input disconnect or over upper limit, please check input signal, FH value and ambient working temperature.

Input disconnect or under lower limit, please check input signal, FL value and ambient working temperature.

11.Communication

AI808P series adjustor follow Modbus RTU communication protocol, and it can run RS485 half-duplex communication.Read

function code is 0x03, write function code is 0x10, 16-bit CRC checking is applied. The coulometer can not return error message.

Start bit Data bit Stop bit Check bit

1 8

2

None

Data Frame flag:

1. Read Multiple Registers

For example: The host computer read the float number AL1 (The value of Alarm 1 is 15.4).The address code of AL1 is 0x0000,

for AL1 is float number (4bits), it will occupy 2 data register. Reference IEEE-574 standard the hexadecimal 16 result of the

decimal float number is

0x41766666

.

Request from the host computer (Read Multiple Registers)

1 2 3 4 5 6 7 8

Unit Address Function code

Start

Address Hi

Start

Address Lo

Data

length Hi

Data

length Lo CRC code Lo CRC code Hi

0x01 0x03 0x00 0x00

0x04 0xE5 0xC9

0x02

Model AI808P-16/AI808P-80

Accuracy 0.3%FS±3digits 25

Temperature excursion: 0.01%FS/

AI808P Series Temperature Adjustor

Note: If there is any change, please subject to the drawing on the meter!

Model AI808P-4

Accuracy 0.3%FS±3digits 25

Temperature excursion: 0.01%FS/

AI808P Series Temperature Adjustor

Model AI808P-7

Accuracy 0.3%FS±3digits 25

Temperature excursion: 0.01%FS/

AI808P Series Temperature Adjustor

Page 08 KKAI808PE01-A/0-20130904

Correct answer from slave unit (Read Multiple Registers)

2 3 4 5 6 7 8 9

code

Function Data byte No. Data1

Hi byte

Data1

Lo byte

Data2

Hi byte

Data2

Lo byte

CRC

Code Lo

CRC

Code Hi

0x03 0x04

0x41 0x76 0x66 0x66 0xE2 0xF4

1

Address

0x01

2. Write Multiple Registers

For example: The host computer write the float number (setting value 600) ,

The address code for SV is 0x0000, for SV is float number (4bits), it will occupy 2 data register. Reference IEEE-574

standard the hexadecimal 16 result of the

decimal float number is

0x41766666

.

Request from the host computer (Write Multiple Registers)

12345678 9

Unit

address

Unit

address

Function

Code

Function

Code

0x01

10 11 12 13

Data

Length Hi

Data

Length Hi

Data

Length Lo

Data

Length Lo

Data

Length

CRC

Lo

CRC

Lo

Start

address Hi

Start address

8 Hi

Start address

8 Lo

Start

address Lo

0x10 61x020x000x0 0x04 0xFD

Data 1

Hi

Data 1

Lo

Data 2

Hi

Data 2

Lo

CRC

Hi

CRC

Hi

0x00 0x00 0x44 0x00 0x00 0xFC

Correct answer from slave unit (Read Multiple Registers)

123456 7 8

0x01 0x10 0x00 0x00 0x00 0x02 0x41 0xC8

AI808P Series table reference address

Code Number of Variable Data

Length

Read & Write

allow Remark

0

2

4

6

8

10

12

14

16

18

0x0000

0x0002

0x0004

0x0006

0x0008

0x000A

0x000C

0x000E

0x0010

0x0012

0x0014

0x0016

0x0018

0x001A

0x001C

0x001E

0x0020

0x0022

0x0024

0x0026

Setting Value SV

Alarm value AL1

Alarm value AL2

Alarm value AL3

Correct value PS

Proportion rate P

Integral time I

Differentia lD

ON/OFF Control Hysteresis HY

Heating & cooling dead district DB

Alarm 1 Hysteresis HY1

Alarm 2 Hysteresis HY2

Alarm 2 Hysteresis HY3

Control output Lo OLL

Control output Hi OLH

Display Lo FL

Display Hi FH

Analog Lo Value

Analog Hi Value

Measuring Value

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R

Reference

address

20

22

24

26

28

30

32

34

36

38

Page 09 KKAI808PE01-A/0-20130904

Code Number of Variable Data

Length

Read & Write

allow Remark

0x0028

0x002A

0x002C

0x002E

0x0030

Lock LCK

Control output OT

Heating control Turn CT

Cooling proportion C_P

1

1

1

1

1

R

R

R

R

R

0x0032

0x0034

0x0036

0x0038

0x003A

0x003C

0x003E

0x0040

0x0042

Cooling control Turn C_CT

Alarm 1 mode AD1

Alarm 2 mode AD2

Alarm 2 mode AD2

Input signal select INP

Decimal DP

Filter FT

Baud rate BAD

Address ADD

1

1

1

1

1

1

1

1

1

R

R

R

R

R

R

R

R

R

Note1

Note1

Note1

Note2

Note3

Reference

address

40

42

44

46

48

50

52

54

56

58

60

62

64

66

68

70

72

74

76

78

80

82

84

86

88

90

92

94

96

98

100

102

104

106

108

110

112

114

116

118

0x0044

0x0046

0x0048

0x004A

Programmable Value STEP

1R

The 1 section setting value SV1 2R/W

The 1 section status setting value ST1 2R/W

The 2 section setting value SV2

The 2 section status setting value ST2

The 3 section setting value SV3

The 3 section status setting value ST3

The 4 section setting value SV4

The 4 section status setting value ST4

The 5 section setting value SV5

The 5 section status setting value ST5

The 6 section setting value SV6

The 7 section setting value SV7

The 8 section setting value SV8

The 6 section status setting value ST6

The 7 section status setting value ST7

The 8 section status setting value ST8

The 9 section status setting value ST9

The 10 section status setting value ST10

The 11 section status setting value ST11

The 9 section setting value SV9

The 10 section setting value SV10

The 11 section setting value SV11

The 12 section setting value SV12

The 13 section setting value SV13

The 12 section status setting value ST12

0x004C

0x004E

0x0050

0x0052

0x0054

0x0056

0x0058

0x005A

0x005C

0x005E

0x0060

0x0062

0x0064

0x0066

0x0068

0x006A

0x006C

0x006E

0x0070

0x0072

0x0074

0x0076

2R/W

2R/W

2R/W

2R/W

2R/W

2R/W

2R/W

2R/W

2R/W

2R/W

2R/W

2R/W

2R/W

2R/W

2R/W

2R/W

2R/W

2R/W

2R/W

2R/W

2R/W

2R/W

2R/W

Auto/Manual free change

Page 10 KKAI808PE01-A/0-20130904

The 14 section setting value SV14

The 15 section setting value SV15

The 16 section setting value SV16

The 13 section status setting value ST13

The 14 section status setting value ST14

The 15 section status setting value ST15

The 16 section status setting value ST16

The 17 section status setting value ST17

The 18 section status setting value ST18

The 19 section status setting value ST19

The 20 section status setting value ST20

The 21 section status setting value ST21

The 22 section status setting value ST22

The 23 section status setting value ST23

The 24 section status setting value ST24

The 25 section status setting value ST25

The 26 section status setting value ST26

The 17 section setting value SV17

The 18 section setting value SV18

The 19 section setting value SV19

The 20 section setting value SV20

The 21 section setting value SV21

The 22 section setting value SV22

The 23 section setting value SV23

The 24 section setting value SV24

The 25 section setting value SV25

The 26 section setting value SV26

The 36 section setting value SV36

Code

Data

Length

Remark

Reference

address

Read & Write

allow

Variable Name

The 27 section status setting value ST27

The 27 section setting value SV27

The 28 section status setting value ST28

The 28 section setting value SV28

The 29 section status setting value ST29

The 29 section setting value SV29

The 30 section status setting value ST30

The 30 section setting value SV30

The 31 section status setting value ST31

The 31 section setting value SV31

The 32 section status setting value ST32

The 32 section setting value SV32

The 33 section status setting value ST33

The33 section setting value SV33

The 34 section status setting value ST34

The 34 section setting value SV34

The 35 section status setting value ST35

The 35 section setting value SV35

The 36 section status setting value ST36

The 37 section setting value SV37

Page 11 KKAI808PE01-A/0-20130904

Note

Note

program Section Operating Status

Output Alarm Status

The 37 section status setting value ST37

The 38 section status setting value ST38

The 38 section setting value SV38

The 39 section status setting value ST39

The 39 section setting value SV39

The 40 section status setting value ST40

The 40 section setting value SV40

The 41 section status setting value ST41

The 41 section setting value SV41

The 42 section status setting value ST42

The 42 section setting value SV42

The 43 section status setting value ST43

The 43 section setting value SV43

The 44 section status setting value ST44

The 44 section setting value SV44

The 45 section status setting value ST45

The 45 section setting value SV45

The 46 section status setting value ST46

The 46 section setting value SV46

The 47 section status setting value ST47

The 47section setting value SV47

The 48 section status setting value ST48

The 49 section status setting value ST49

The 49 section setting value SV49

The 50 section status setting value ST50

The 50 section setting value SV50

The 48 section setting value SV48

Code

Data

Length

Remark

Reference

address

Read & Write

allow

Variable Name

R Read only R/W Read/Write

Parameter setting range , please refering to products user’s manual

Note 1 Alarm Mode

Note 2 Input Signal (please refer to input parameter table)

Note 3

Data value

Baud rate BAD 4.8K 9.6K

01

Upper Alarm Lower Alarm

Upper deviation alarm

Lower deviation alarm

Alarm Mode

Corresponding values

Note 4: Operating Status

Operating Status

Corresponding values

Note 5: Output Alarm Status ( 1 means ON, 0 means OFF)

Parameter bits

Control Status

Page 12 KKAI808PE01-A/0-20130904

unsigned int Get_CRC(uchar *pBuf, uchar num)

{

unsigned i,j;

unsigned int wCrc = 0xFFFF;

for(i=0; i<num; i++)

{

wCrc ^= (unsigned int)(pBuf[i]);

for(j=0; j<8; j++)

{

if(wCrc & 1){wCrc >>= 1; wCrc ^= 0xA001; }

else

wCrc >>= 1;

}

}

return wCrc;

}

16 digit CRC verify program

This manual suits for next models

6

Table of contents

Other Toky Temperature Controllers manuals