Tolomatic STAC6 User manual

STAC6 Drives and

Microstepping Motors

LINEAR SOLUTIONS MADE EASY

LINEAR SOLUTIONS MADE EASY

User Manual

STAC6 DRIVES AND

MICROSTEPPING MOTORS

are DISCONTINUED.

Replacements are not

available. For legacy

STAC6 drives and

Microstepping Motors use

this manual for reference

only.

3600-4645_02_AMPSTEP-OBS

© 2022 Tolomatic

Tolomatic, Incorporated. All rights reserved.

Tolomatic and Excellence In Motion are registered

trademarks of Tolomatic Incorporated. All other

products or brand names are trademarks of their

respective holders.

202204130849

STAC6 Drives and Microstepping Motors: User Manual (Discontinued Product)

• i •

Contents

Contents............................................................................................................... i

List of Figures.................................................................................................ii -iii

Overview

Technical Specifications .................................................................................iv - vi

Control Options...................................................................................................vii

Block Diagram ...................................................................................................viii

Drive Dimensions ................................................................................................ ix

Chapter 1: Hardware

Safety Instructions.................................................................................... 1.1 - 1.2

Introduction.......................................................................................................1.3

Getting Started .................................................................................................1.4

Error Codes / Status LED..................................................................................1.5

RS 232 Communications ..................................................................................1.6

RS 485 Communications ......................................................................... 1.7 - 1.8

RS 422 Wiring............................................................................................1.9

RS 485 Wiring..........................................................................................1.10

Connecting AC Power.....................................................................................1.11

Connecting the Motor .....................................................................................1.12

Connecting the Encoder ...................................................................... 1.13 - 1.15

Connecting to In/Out 1....................................................................................1.16

Wiring Digital Inputs to In/Out 1 .................................................... 1.16 - 1.24

Wiring Digital Outputs to In/Out 1 ................................................. 1.25 - 1.26

Wiring Analog Signals to In/Out 1 ................................................. 1.27 - 1.28

Connecting to In/Out 2....................................................................................1.29

Wiring Digital Inputs to In/Out 2 .................................................... 1.29 - 1.32

Wiring Digital Outputs to In/Out 2 ................................................. 1.33 - 1.35

Wiring Analog Signals to In/Out 2 ................................................. 1.36 - 1.37

Regeneration Clamp ............................................................................ 1.38 - 1.39

Chapter 2: Recommended Motors

General Motor Data...........................................................................................2.1

Size 23 Motors..................................................................................................2.1

Size 34 Motors..................................................................................................2.2

Rec. Motor Dimensions............................................................................ 2.4 - 2.5

Chapter 3: Configuration

STAC6 Configurator Software .................................................................. 3.1 - 3.3

Configuring the Motor .............................................................................. 3.4 - 3.7

Input and Outputs.................................................................................. 3.8 - 3.10

Status Monitor ................................................................................................3.11

Chapter 4: Standard Accessories & Options

Breakout Box for In/Out Connectors .................................................................4.1

HUB [SiNET™ HUB 444] Multi-Axis Motion Hub with I/O ............................. 4.2 - 4.13

Chapter 5: Contacting Tolomatic....................................................................5.1

STAC6 Drives and Microstepping Motors: User Manual (Discontinued Product)

• ii •

Figure Description Page

1 DS[STAC6-S] and SI[STAC6-Si] Block Diagram ............................................................viii

2 DS[STAC6-S] and SI[STAC6-Si] Drive Mounting Dimensions ...........................................ix

1.1 STAC6 Applied Motion Products (Motor Control) ..........................................................1.3

1.2 STAC6 Error Codes....................................................................................................1.5

1.3 422 Wiring................................................................................................................1.9

1.4 485 Wiring..............................................................................................................1.10

1.5 AC Connection ........................................................................................................1.11

1.6 Motor Cable Wiring..................................................................................................1.12

1.7 HD 15 Pinouts.........................................................................................................1.13

1.8 Encoder Dialog........................................................................................................1.14

1.9 Connections In/Out 1...............................................................................................1.16

1.10 Step Source............................................................................................................1.17

1.11 Step Sink................................................................................................................1.17

1.12 Step Differential ......................................................................................................1.17

1.13 Connecting the Master Encoder ...............................................................................1.18

1.14 Connecting to PLC with Sourcing (PNP) Outputs........................................................1.18

1.15 PLC Sinking ............................................................................................................1.19

1.16 Mechanical Switches...............................................................................................1.19

1.17 Inside Inputs ...........................................................................................................1.20

1.18 INP Relay................................................................................................................1.21

1.19 Si1 .........................................................................................................................1.21

1.20 INP NPN In/Out 1 ....................................................................................................1.21

1.21 INP PNP In/Out 1.....................................................................................................1.21

1.22 STAC6 Limit Input Diagram......................................................................................1.22

1.23 Mechanical Limit Switch..........................................................................................1.23

1.24 NPN Limit Sensor....................................................................................................1.23

1.25 PNP Limit Sensor ....................................................................................................1.24

1.26 Connections In/Out 1...............................................................................................1.25

1.27 STAC6 Outputs .......................................................................................................1.25

1.28 STAC6 Outsinking ...................................................................................................1.26

1.29 STAC6 Relay...........................................................................................................1.26

1.30 Connections In/Out..................................................................................................1.27

1.31 Analog Single Ended Signal .....................................................................................1.27

1.32 Analog Pot..............................................................................................................1.28

1.33 In/Out 2 Connections...............................................................................................1.29

1.34 Inputs SI[STAC6-Si] ................................................................................................1.30

1.35 Switch In/Out 2.......................................................................................................1.31

1.36 Step Source............................................................................................................1.31

1.37 NPN Proximity In/Out 2............................................................................................1.32

1.38 PNP Proximity In/Out 2 ............................................................................................1.32

1.39 In/Out 2 Connections...............................................................................................1.33

1.40 Outputs SI[STAC6-Si] ..............................................................................................1.34

(Continued)

List of Figures

STAC6 Drives and Microstepping Motors: User Manual (Discontinued Product)

• iii •

Figure Description .....................................................................................Page

1.41 Sourcing Out...........................................................................................................1.34

1.42 SI[STAC6-Si] Out Sinking ........................................................................................1.35

1.43 SI[STAC6-Si] Relay .................................................................................................1.35

1.44 In/Out 2 Connections...............................................................................................1.36

1.45 Connecting an Analog Input to an Active Signal .........................................................1.37

1.46 STAC6 Internal Regen..............................................................................................1.38

1.47 Regen Resistor Connection ......................................................................................1.39

1.48 STAC6 External Regen.............................................................................................1.39

2.1 General Motor Data Table...........................................................................................2.1

2.2 Size 23 Motors..........................................................................................................2.1

2.3 HT 23 Torque Curves.................................................................................................2.2

2.4 Size 34 Motors..........................................................................................................2.2

2.5 HT 34 Torque Curves.................................................................................................2.3

2.6 HT23 Step Motors.....................................................................................................2.4

2.7 HT34 Step Motors.....................................................................................................2.5

3.1 STAC6 Configurator...................................................................................................3.1

3.2 Motor Dialog .............................................................................................................3.4

3.3 Add New Motor Dialog...............................................................................................3.6

3.4 Lead Angle Graph......................................................................................................3.7

3.5 I/O Dialog .................................................................................................................3.8

3.6 Status Monitor ........................................................................................................3.11

4.1 HUB [SiNET™ HUB 444] .........................................................................................4.2

4.2 HUB [SiNET™ HUB 444] Features............................................................................4.5

4.3 Connecting the HUB [SiNET™ HUB 444] ..................................................................4.6

4.4 Programmable Input Circuit Schematic Diagram..........................................................4.9

4.5 Connecting an Si Drive ............................................................................................4.10

4.6 Connecting an NPN Type Prox. Sensor ......................................................................4.10

4.7 Connecting an PNP Type Prox. Sensor ......................................................................4.10

4.8 Output Circuit Schematic Diagram............................................................................4.11

4.9 Sinking Output ........................................................................................................4.11

4.10 Sourcing Output......................................................................................................4.11

4.11 Driving a Relay........................................................................................................4.12

4.12 Mechanical Outline..................................................................................................4.12

4.13 Pin Assignments .....................................................................................................4.13

LIST OF FIGURES

STAC6 Drives and Microstepping Motors: User Manual (Discontinued Product)

• iv •

Technical Specifications

POWER AMPLIFIER SECTION: DS[STAC6-S], SI[STAC6-Si]

Amplifier Type MOSFET, Dual H-Bridge, 4 Quadrant

Current Control 4 state PWM at 20 Khz

Output Current 0.5 — 6.0 in 0.01 amp increments

Power Supply Line Operated Nominal 120 VAC, 50/60 Hz

DC Bus Voltage Nominal 165 VDC

AC Input Voltage 94—135VAC, 50/60Hz

Protection Over-Voltage, Under voltage, Over-Temp, External Output Shorts (Phase

to-Phase, Phase-to-Ground), Inter Amplifier Shorts

Idle Current Reduction Reduction to any integer percent of full-current after delay selectable in

milliseconds

POWER AMPLIFIER SECTION: DS[STAC6-S-220], SI[STAC6-Si-220]

Amplifier Type MOSFET , Dual H-Bridge, 4 Quadrant

Current Control 4 state PWM at 20 Khz

Output Current 0.5 — 3.0 in 0.01 amp increments

Power Supply Line Operated Nominal 120-240 VAC, 50/60 Hz

DC Bus Voltage Nominal 330 VDC (at 240 VAC line input)

AC Input Voltage 94—265VAC, 50/60Hz

Protection Over-Voltage, Under voltage, Over-Temp, External

Output Shorts (Phase to-Phase, Phase-to-Ground),

Inter Amplifier Shorts

Overview

STAC6 Drives and Microstepping Motors: User Manual (Discontinued Product)

• v •

OVERVIEW

Idle Current Reduction Reduction to any integer percent of full-current after delay

selectable in milliseconds.

CONTROLLER SECTION

Non-Volatile Storage Configurations are saved in FLASH memory

aboard the DSP.

Mode of Operation Step & Direction, CW/CCW, Encoder Following, Joystick:

Step & Direction Inputs Optically Isolated: 5-12 Volt. Minimum pulse width = 200 ns.

Maximum pulse frequency = 2 MHz

Speed Range Depends upon selected resolution. Amplifier is

suitable for speeds up to 50 rps

Analog Input Range Software selectable: 0-5V, ±5V, 0-10V, ±10V

Analog Input Resolution 12 bits (with ±10V signal range)

11 bits (with 0-10V or ±5V signal range)

10 bits (with 0-5V signal range)

Microstep Resolution Software selectable from 200 to 50800 steps/rev in

increments of 200 steps/rev

Anti-Resonance Raises the system damping ratio to —0.3-to-0.5.

Eliminates midrange instability and allows stable

operation to 50 rps.

Waveform Allows for fine adjustment of phase current waveform harmonic

content to reduce low-speed torque ripple in the range

0.25 to 1.5 rps

Auto Setup Measures motor parameters and configures tuning and observer

parameters

Self Test Identifies the presence of an encoder and determines resolution.

Diagnoses miswires and open phases

STAC6 Drives and Microstepping Motors: User Manual (Discontinued Product)

• vi •

OVERVIEW

Microstep Emulation Performs low resolution stepping by synthesizing coarse steps from fine

microsteps.

Dynamic Smoothing Software configurable filtering (4th order, elliptic) for

use in removing spectral components from the

command sequence. Reduces jerk and excitation of

extraneous system resonances.

Encoder Option Employs encoder (hi or low resolution) to provide stall

detection, stall prevention and perform position

verification and maintenance.

Interface RS-232 and RS-485 Bus

Encoder Differential line receivers suitable for 200 KHz or greater

Ambient Temperature 0 to 55°C (32 - 158°F)

Humidity 90% non-condensing

STAC6 Drives and Microstepping Motors: User Manual (Discontinued Product)

• vii •

OVERVIEW

Motion Control Options

!

DS[ ]

• Basic drive; analog, digital and host command input.

• Pulse & direction with electronic gearing.

• Encoder following with electronic gearing.

• CW and CCW pulse.

• Multi-axis Si programming if used with a HUB [SiNET™ HUB 444].

• "Host" commands for real time control from a host PC or

PLC using RS-232 or RS-485 serial communication.

!

SI[ ]

• SI[STAC6-Si] can be programmed for stand-alone operation with

the easy to use Si Programmer™ Windows software with integrated

tuning (software and programming cable included).

• Graphical point and click format combines motion, I/O,

and operator interface functionality for simple machine

sequencing.

• Easily integrates with other devices on the machine

(Sensors, PLCs etc).

STAC6 Drives and Microstepping Motors: User Manual (Discontinued Product)

• viii •

OVERVIEW

Figure 1: DS[STAC6-S], SI[STAC6-Si] Block Diagram

STAC6 Drives and Microstepping Motors: User Manual (Discontinued Product)

• ix •

OVERVIEW

Figure 2: DS[STAC6-S], SI[STAC6-Si] Drive Mounting Dimensions

1

STAC6 Drives and Microstepping Motors: User Manual (Discontinued Product)

• 1.1 •

Safety Instructions

Only qualified personnel are permitted to transport, assemble,

commission, and maintain this equipment. Properly qualified personnel

are persons who are familiar with the transport, assembly, installation,

commissioning and operation of motors, and who have the

appropriate qualifications for their jobs. The qualified personnel must

know and observe the following standards and regulations:

IEC 364 resp. CENELEC HD 384 or DIN VDE 0100

IEC report 664 or DIN VDE 0110

National regulations for safety and accident prevention or VBG 4

To minimize the risk of potential safety problems, follow all applicable

local and national codes that regulate the installation

and operation of your equipment. Since codes vary from area to

area it is the users responsibility to determine which codes should be

followed, and to verify that the equipment, installation, and operation

are in compliance with the latest revision of these codes.

Equipment damage or serious injury to personnel can result from the

failure to follow all applicable codes and standards. We do not

guarantee the products described in this publication are suitable for

your particular application, nor do we assume any responsibility for

your product design, installation, or operation.

Read all available documentation before assembly and commissioning.

Incorrect handling of products in this manual can result in injury and

damage to persons and machinery. Strictly adhere to the

technical information on the installation requirements.

It is vital to ensure that all system components are connected to earth

ground. Electrical safety is impossible without a low-resistance earth

connection.

!

The STAC6 contains electrostatically sensitive components that can

Hardware

STAC6 Drives and Microstepping Motors: User Manual (Discontinued Product)

• 1.2 •

1: HARDWARE

be damaged by incorrect handling. Discharge yourself before touching

the product. Avoid contact with high insulating materials (artificial

fabrics, plastic film, etc.). Place the product on a conductive surface.

During operation keep all covers and cabinet doors shut. Otherwise,

there are deadly hazards that could possibly cause severe bodily

damage or damage to the product.

In operation, depending on the degree of enclosure protection, the

product can have bare components that are live or have hot surfaces.

Control and power cables can carry a high voltage

even when the motor is not rotating.

Never pull out or plug in the product while the system is live. There is a

danger of electric arcing and danger to persons and contacts.

After powering down the product, wait at least ten minutes before

touching live sections of the equipment or undoing connections (e.g.,

contacts, screwed connections). Capacitors can store dangerous

voltages for long periods of time after power has been switched off. To

be safe, measure the contact points with a meter before touching.

Be alert to the potential for personal injury. Follow the recommended

precautions and safe operating practices.

Safety notices in this manual provide important information. Read and

be familiar with these instructions before attempting installation,

operation, or maintenance. The purpose of this section is to alert users

to possible safety hazards associated with this equipment and the

precautions that need to be taken to reduce the risk of personal injury

and damage to the equipment.

Failure to observe these precautions could result in serious bodily injury,

damage to the equipment,or operational difficulty.

STAC6 Drives and Microstepping Motors: User Manual (Discontinued Product)

• 1.3 •

1: HARDWARE

Introduction

Figure 1.1: STAC6 Applied Motion Products (Motor Control)

Thank you for selecting an Applied Motion Products motor control from

Tolomatic. We are committed to making your motion control project

successful.

If there’s anything we can do to help you service or troubleshoot your

system. Contact our technical support department at

(800) 325-2174 or you can reach us by fax at (763) 478-8080.

STAC6 Drives and Microstepping Motors: User Manual (Discontinued Product)

• 1.4 •

1: HARDWARE

Getting Started

For all STAC6 Drive models, you must have the following:

• 120VAC or 220VAC single phase power

• A compatible stepper motor

• A small flat blade screwdriver for tightening the connectors (included).

• A personal computer running Microsoft Windows 98, NT, Me, 2000

or XP.

• The "Software, Manuals & More" CD that was included with your

STAC6 Stepper drive

• A programming cable (included)

Familiarize yourself with the drive and the software before deploying

the system in your application.

Recommended Procedures:

1. Install the Configurator™ software from the CD.

2. Launch the software by clicking Start...Programs...Applied Motion

Products...Configurator.

3. Connect the drive to your PC using the programming cable supplied.

4. Connect the drive to the AC power source (may be switched).

5. Connect the drive to the motor.

6. Apply power to the drive.

7. Follow the instructions in the Configurator™ help screens.

(On the CD)

STAC6 Drives and Microstepping Motors: User Manual (Discontinued Product)

• 1.5 •

1: HARDWARE

Error Codes / Status LED

The STAC6 includes a bi-color (red/green) LED to indicate status.

Normal status is indicated by a solid green LED. If the LED changes to

red, an error has occurred. The errors are indicated by combinations of

red and green "flashes" as follows:

Figure 1.2: STAC6 Error Codes

STAC6 Drives and Microstepping Motors: User Manual (Discontinued Product)

• 1.6 •

1: HARDWARE

RS 232 Communications

CONNECTING TO THE PC USING RS - 232

Locate your computer within 6 feet of the STAC6 Stepper drive.

The drive is shipped with a black adapter plug. A telephone style

jack is at one end and a larger 9-pin connector at the other. Plug

the large end into the COM1 serial port of your PC. Secure the

adapter with the screws on the sides. If the COM1 port on your PC

is already in use, the COM2 port may be used for the drive. On

some PCs, COM2 will have a 25 pin connector that does not fit the

black adapter plug. If this is the case, purchase a 25-to-9 pin serial

adapter sold at local computer stores.

The drive is also shipped with a 7 foot telephone line cord. Plug one

end into the black adapter plug attached to your PC, and the other

end into the RS-232 jack on the drive. If the drive needs to be

located farther from the PC, replace the 7 foot phone cord with a

longer one. Do not use cords in excess of 50 feet.

Never connect a STAC6 drive to a telephone circuit. It uses the

same connectors and cords as telephones and modems, but the

voltages are not compatible.

STAC6 Drives and Microstepping Motors: User Manual (Discontinued Product)

• 1.7 •

1: HARDWARE

RS 485 and RS 422 Communications

CONNECTING TO THE PC USING RS-485

RS-485/422 allows connection of more than one drive to a single

host PC, PLC or other computer. It also accommodates a longer

cable (more than 1000 feet) for devices that have a RS-485/422 port.

A SHORT TUTORIAL ON RS-485 & RS-422

RS-485 in the strictest definition is a "2-wire" interface that

allows multi-node connections limited to "Half-duplex" serial

communications. Up to 32 nodes that both transmit and receive

can be connected to the network. RS-422 in the strictest definition

is a "4-wire" point-to-point connection that allows "Full-duplex"

serial communications when connected to a single node. RS-422

has one node that is the driver or transmitter and up to 10 nodes

that are receivers. RS-422 was not designed for a true multi-node

network.

2- wire interfaces require a network node, master or slave, must be

able to tristate its transmitter to allow other nodes to use the

network when required. For high speed baud rates this must be

done very quickly to avoid communications collisions.

4-wire interfaces can go beyond the simple point-to-point and

accommodate multi-node networks if the slave node is capable of

tri-stating their transmitters as required in the 2-wire networks.

Some RS-485 devices are setup to do this and can be used in a

4-wire configuration.

On the AMP Servo drives, the RS-485 can be implemented

with either "2-wire" or "4-wire" interfaces. In both cases,

communications are still limited to "Half-duplex" because of

the nature of the serial communications protocols used. 4-wire

implementations can sometimes be easier due to the greater

number of Host RS-232 to RS-485 adapters that support the 4-wire

interface. 2-wire implementations may require special Host adapters

that support

STAC6 Drives and Microstepping Motors: User Manual (Discontinued Product)

• 1.8 •

1: HARDWARE

"Auto enable" of the adapter transmitter. Host adapters are required

as PC software typically doesn’t support tri-stating the output of the

serial adapters.

In both 2-wire and 4-wire systems one extra wire is always required

to connect the "Grounds" of all the nodes on the network. Even

though 2-wire and 4-wire systems send differentially, a command

ground connection is absolutely required.

In addition, proper cable shielding is a must. High voltage, high

frequency, high current signals that are present on servo motor

cables can emit a significant amount of electrical interference.

Without proper shielding these signals can disrupt even "noise

tolerant" differential line drivers.

4-Wire RS-485-422 Network

The RS485 implementation is a 4-wire multi-drop network with

separate transmit and receive wires. One pair of wires connects

from the host computer’s TX+ and TX- signals to each of the drive’s

RX+ and RX- terminals. Another pair connects the TX+ and TX-

drive terminals to the host computer’s RX+ and RX- signals. A

common ground terminal is provided on each drive and can be

used to keep all drives at the same ground potential. This terminal

connects internally to the DC power supply return (V-), so if all the

drives on the RS485 network are powered from the same supply, it

is not necessary to connect the logic grounds. Connection of one

drive’s GND terminal to the host computer ground is still required.

Before wiring the entire system, connect each drive individually to

the host computer so a unique address can be assigned to each

drive. Proceed as follows: (Also see figure below)

1. Connect the drive TX+ to the PC’s RX+ terminal.

2. Connect the drive TX- to PC RX-.

3. Connect RX+ to TX+.

4. Connect RX- to TX-.

5. Connect GND to GND.

Getting and Connecting a RS485 4-wire adapter to your

STAC6 Drives and Microstepping Motors: User Manual (Discontinued Product)

• 1.9 •

1: HARDWARE

PC

A 25-pin serial port is recommended. The Jameco Electronics (800-

831-4242) Model 1117701 is a good choice. If a 9-pin serial port is on

your PC, a Jameco cable Model 31721 is also required.

Connect as follows:

adapter drive

1 RX+

2 RX-

3 TX-

4 TX+

Set the switches for DCE and TxON,RxON. Plug in the DC power

adapter that comes with the unit.

Figure 1.3: RS - 422 Wiring

The drive can also be connected to the Host computer using only a

2-wire interface. In this case, first connect the TX+ to the RX+ and the

TX- to the RX- on the servo drives before connecting to the Host

adapter. Usually RS-485 2-wire interfaces are labeled "A" & "B".

Getting and Connecting a RS485 2-wire adapter to your PC

The RS485 2-wire adapter (Model 485-25E) from Integrity Instruments

(800-450-2001) is recommended.

adapter drive

B TX+/RX+

A TX-/RX-

Table of contents

Popular Engine manuals by other brands

SEW-Eurodrive

SEW-Eurodrive MOVIMOT MM..D Series operating instructions

Vanguard

Vanguard Series 432447 Operating and maintenance instructions

AutomationDirect

AutomationDirect IronHorse HGR-37-005-A user manual

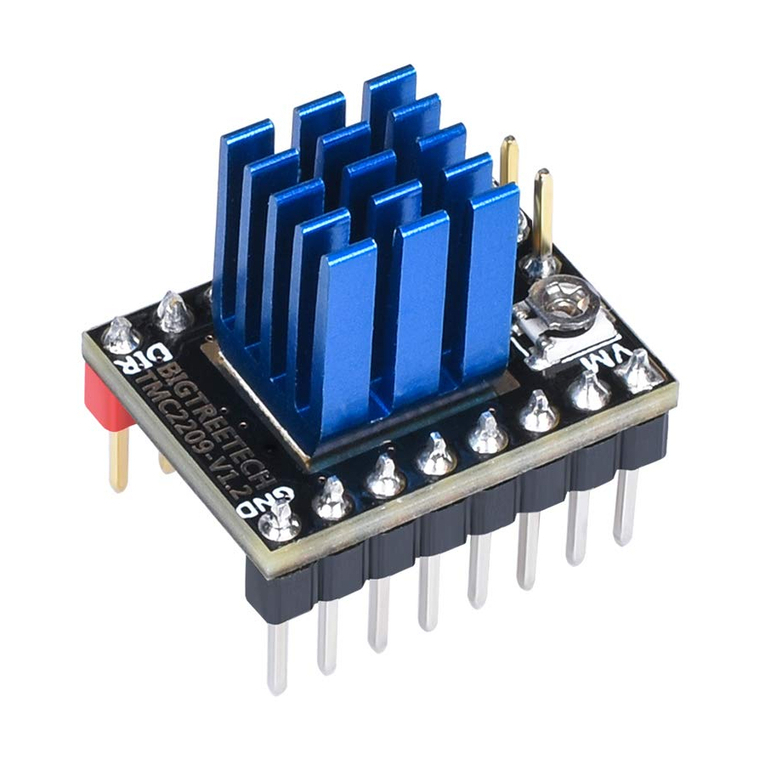

BIG TREE TECH

BIG TREE TECH TMC2209-V1.2 manual

Oriental motor

Oriental motor BLM230 operating manual

Oriental motor

Oriental motor World K Series operating manual

AOK

AOK A M25 PLUS L USB manual

woodmizer

woodmizer D42 Safety, Operation, Maintenance & Parts Manual

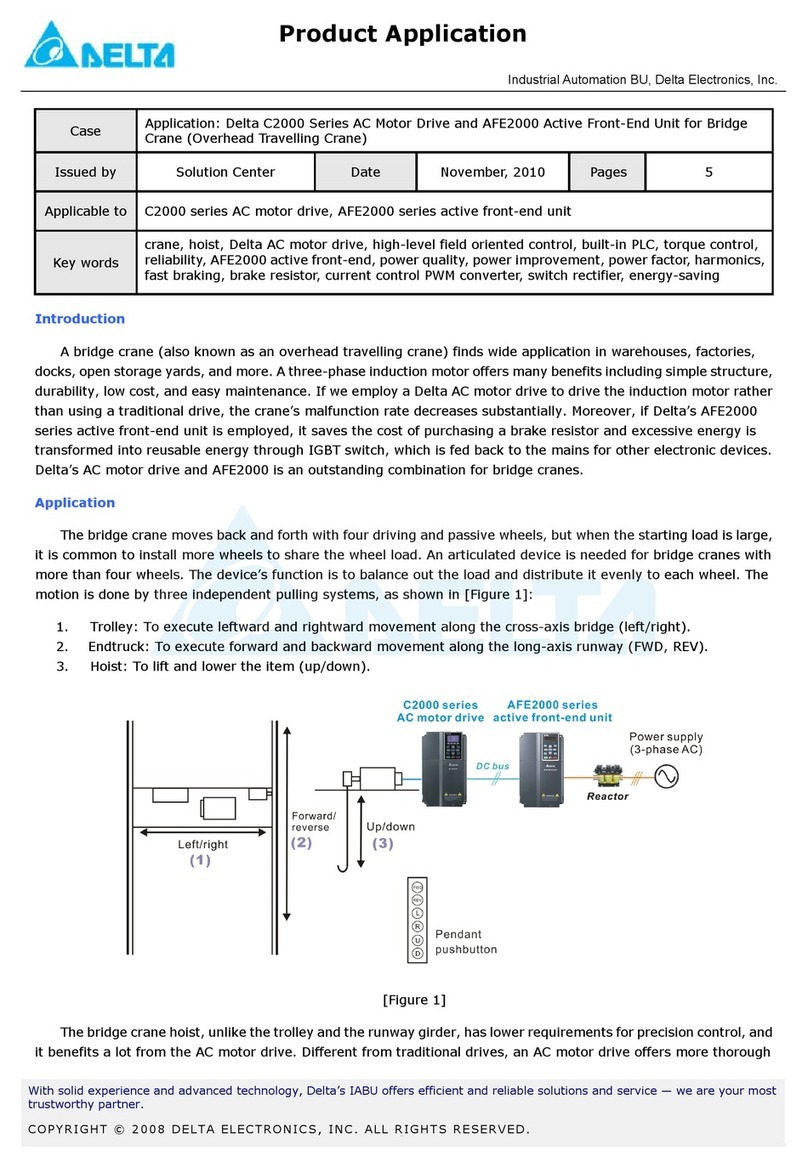

Delta

Delta C2000 Series Product application

Oriental motor

Oriental motor BMU Series quick start guide

Oriental motor

Oriental motor PK Series operating manual

Tecnoautomazione

Tecnoautomazione GPS Series Instructions and warnings