Tomoe 304YA User manual

R

INSTRUCTION MANUAL

High Performance Butterfly Valve

304YA

Contents Page

FOR YOUR SAFE USAGE 1

1. PRODUCT FEATURES 2

1. 1 About the Product 2

1. 2 Standard Specications 2

1. 3 Pressure - Temperature Rating 3

2. STRUCTURE 4

2. 1 Expanded View and Part List 4

3. PRECAUTIONS FOR USE 5

3. 1 Safety Measures 5

3. 2 Transportation and Storage 6

3. 3 Installation and Working Environment 7

3. 4 Installation Precautions 9

3. 5

Precautions for Safe Handling After Installation

12

3. 6 Maintenance 13

4 INSTALLATION 15

4. 1 Installation Procedure 15

5 MAINTENANCE 17

5. 1.

Seatring Disassembly/Assembly Procedures

17

5. 2 Removal of Valve Body and Actuator 18

5. 3

Disassembly/Assembly Procedures of Gland area

19

5. 4

Assembly Procedure of Valve Body and Actuator

20

5. 5

Valve Body Full-Close Position Adjustment Procedure

21

6. Piping Data 22

6. 1

Minimum Inner Pipe Diameter and Disc

Protruding Dimension at Full-open Position

22

6. 2 Applicable Pipes 22

6. 3 Piping Gasket Dimensions 23

6. 4 Piping Bolt Sizes 24

7. TROUBLESHOOTING 25

7. 1 Troubleshooting 25

WARRANTY PERIOD / SCOPE OF WARRANTY

AND INDEMNITY / CHARGED REPAIR SERVICE

AND SUPPLY OF DISCONTINUED PARTS

/

28

REPLACEMENT TIMING OF SPARE PARTS

/

APPLICABLE APPLICATION CONDITIONS

1

FOR YOUR SAFE USAGE The following instructions should always be followed.

Thank you for purchasing our products.

For safe use of our products over long periods of time, please read this instruction manual (here-

inafter "this document") thoroughly before use, and use the products properly in accordance

with the contents.

The following instructions are for long-lasting service of High Performance Butterfly Valve 304YA

(hereinafter "this product") without loss or injury.

■ In this document, the level of danger or damage caused by neglecting these cautions

will be indicated as follows:

This mark indicates "possibility of death or serious injury".

This mark indicates "possibility of injury to personnel or physical damage

only".

■In this document, the following marks will indicate particular points for your attention.

This mark indicates items that "you must not do".

This mark indicates items "you must do".

■Requests

Be sure to read this document before carrying out transportation, storage, piping installation, operation and main-

tenance work.

This document does not describe all the assumed conditions concerning transportation, storage, piping installa-

tion, operation and maintenance of this product. If you have any questions, please contact our sales department.

Reference values and limit values for operation, maintenance and inspection specified in this document have

been determined in consideration of maintenance management of this product. This product should be used

within the range of the reference values and the limit values.

This product should be used only with the dedicated actuator installed when shipped. Do not use this product

with other actuators.

Be sure to store this document in a readily accessible place for future reference after installation and start of

operation. When a staff in charge is changed, information on the storage place of this document and operation

should be communicated to the next staff.

If this product gets dented or scratched on impact, to ensure safety stop use of the product and replace it.

Details of this document are subject to change without notice.

WARNING

CAUTION

2

1. PRODUCT FEATURES

1. 1 About the Product

This product is a double eccentric butterfly valve, which controls fluid by 90-degrees rotation of the disc.

The valve can be fully opened or closed. In addition, an intermediate valve opening can be used for fluid control.

1. 2 Standard Specifications

<Table-1> 304YA Standard Specifications

Valve Model 304YA

Valve Type Double eccentric (Wafer)

Valve nominal size 1 1/2, 2, 2 1/2, 3, 4, 5, 6, 8, 10, 12inch

40, 50, 65, 80, 100, 125, 150, 200, 250, 300 mm

Max. allowable working pressure 1.0 MPa

Allowable seat leakage standard ISO 5208 leakage rate A (tight shut-off)/ JIS B 2003-2013 rate A

Flow direction Retainer side pressurization

Applicable

standards

Face to face

dimensions JIS B 2002-1987 (series 46)/ ISO 5752 wafer butterfly valve (short)

Applicable flange

connection JIS 5K / JIS 10K / ASME / ANSI CLASS 150

Top flange In compliance with ISO 5211

Standard

materials

Body SCS13A FCD450

Disc SCS13A

Shaft SUS630 SUS420J2

Seatring RPTFE (Carbon and graphite contained)

Gland packing RPTFE (Graphite contained)

Maximum temperature range -29°C - 200°C -20°C - 200°C

Ambient temperature range

1T -20°C - 80°C

2U -10°C - 80°C

7E, 7F, 7G -10°C - 60°C

3U, 3K 0°C - 80°C

4I ,4J -10°C - 50°C

Test pressure Body Shell Working pressure × 1.5 (Water pressure)

Seat leakage Working pressure × 1.1 (Pneumatic pressure)

Actuator

Lock Lever 1T 40 mm - 150 mm

Worm gear 2U 40 mm - 300 mm

Pneumatic cylinder

7E 40 mm - 300 mm

7F, 7G 40 mm - 200 mm

3U, 3K 250 mm, 300 mm

Motorized 4I ,4J 40 mm - 300 mm

Maximum average flow velocity

in piping (Limit value) 6 m/s or less (Valve full-open, continuous operation)

Body color FCD450-body only : Modified silicon resin coating Munsell N7 (Gray)

3

1. 3 Pressure - Temperature Rating

[Fig.-1]

Case of FCD450-body :

-4°F or over ~ less than 392°F

Case of SCS13A-body :

-20°F or over ~ less than 392°F

0 50 100

-29 -20

150 200 250

Temperature [℃]

0.2

0.4

0.6

0.8

1.0

Pressure [MPa]

8

3

13

14

15

16

22

10

11

8

1

21

7

20

5

12

2

17

4

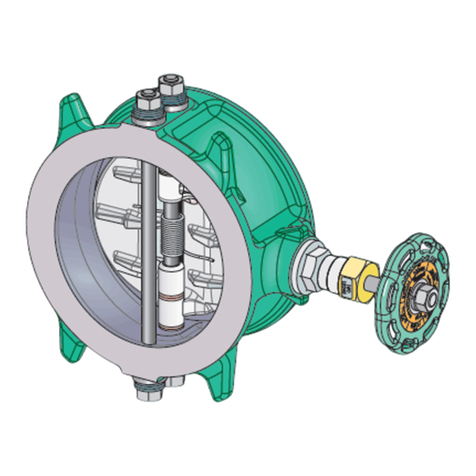

2. STRUCTURE

2. 1 Expanded View and Part List

<Table-2> 304YA Parts List

No. Description Q'ty

Remarks

No. Description Q'ty

Remarks

1 Body 1 14 Gland packing 1 set

2 Disc 1 15 Rough gland 1 set

3 Shaft 1 16 Gland flange 1

5 Seatring 1 17 Hexagon bolt 2

7 Seatring retainer 1 20 Ball 2*1

8 Shaft bearing 3 3 *2

10 Bottom cover 1 21 Hexagon socket set screw 2*1

11 Bottom gasket 1 3*2

12 Taper pin 2 22 Hexagon bolt 4

13 Packing retainer 1 22 Spring washer 4

*1 For nominal sizes of 40 mm to 100 mm, *2 For nominal sizes of 125 mm to 300 mm

Remarks: The

indicates recommended spare parts. They are supplied as “Seatring set” with a small hexagonal spanner to

remove hexagon socket set screw (P.No.21).

[Fig.-2] [Fig.-3]

Gland

Neck

Flange surface

Bottom

Disk stopper

5

3. PRECAUTIONS FOR USE

3. 1 Safety Measures

WARNING

3.1.1 Handling of this product

1) This product should be assembled, operated, maintained, etc. by personnel who have read

this document thoroughly and understood the contents well.

2) The work should be performed while wearing protective gear, such as a helmet, safety belt,

protective glasses, working gloves and safety shoes, in accordance with laws and regulations,

and safety provisions of business establishments.

3) Do not stand or place heavy objects on this product, as this may cause the product to be dam-

aged, resulting in falling accidents.

WARNING

3. 1. 2 Safety check

Equipment should only be dismantled after the following points have been checked to ensure safety.

1) Safety precautions for this product, such as prevention against falling of parts, material or

other accidental happenings, have been taken.

2) The surface temperatures of the product, flanges, and pipes are at a level where the surfaces

can be touched.

3) The pressure in the piping is the atmospheric pressure, and fluid has been drained out from

the inside of the piping.

4) When the fluid flowing through the piping is toxic, flammable or corrosive, adequate safety

measures have been taken.

5) Energy sources of the related facilities, such as power supplies and air sources, have been

shut off.

6) No fluid harmful to the human body is adhered on this product or peripheral piping.

Before restarting of the unit, check the following items.

1) The product and the actuator are secured firmly.

2) There is no failure or damage to the appearance, or loss of parts.

3) Tools have not been left on the product or pipes.

4) Nothing hinders operation of the product (operation of the lever and handle, opening/closing of

the valve).

5) Safe evacuation procedure is already introduced in case of unexpected movements, leakage,

etc.

WARNING

3. 1. 3 Water hammer and steam hammer

1) Should be check whether there is water hammer and steam hammer during operation.

If water hammer or steam hammer occurs, this product and peripheral piping materials may

be damaged.

2) For a lever type, do not open or close the valve abruptly because it causes water hammer.

3) For a pneumatic cylinder valve with a speed controller, the speed controller is fully opened

when shipped. If the opening/closing time is short, water hammer or steam hammer may oc-

cur, resulting in damage of the product. Therefore, be sure to adjust the opening/closing time.

4) Note that piping conditions may cause water hammer or steam hammer which has an influ-

ence on the product by stopping pump operation, opening/closing operations of other valves.

WARNING

3. 1. 4 Cavitation

Design should be performed to prevent cavitation.

This product can be operated at the intermediate valve opening (Opening: 30° or more). However, if

abnormal noise or vibrations are generated by the product or peripheral piping, cavitation may have

occurred.

When this product is used for long periods of time in this state, the product or piping materials may

be damaged. Therefore, prevent cavitation by changing the valve opening, pressure, flow rate, etc.

6

3. 2 Transportation and Storage

WARNING

3. 2. 1 Transportation and Transfer

1) Products with large mass (approx. 20 kg or more) should be transported using equipment or a

machine, not by manpower alone. See the catalog, product drawings, etc. issued by our com-

pany for details on the mass of this product.

2) Qualified personnel should perform work with a forklift or a crane, or slinging work in accor-

dance with laws and regulations, and safety provisions of business establishments. In addition,

observe section 「3. 2. 2

3) Protect this product sufficiently before transportation so that it is not damaged. Damage

causes leakage or corrosion.

4) Use containers for ocean transportation. If containers are not used, this product becomes de-

teriorated due to salty sea breeze.

5) Use a covered vehicle for inland transportation to avoid exposure to wind and rain.

If an uncovered vehicle is used, cover the product with a protective tarp.

6) Do not throw the product and do not apply a heavy load.

WARNING

CAUTION

3. 2. 2 Drop and falling

1) At lifting up and slinging work, perform the work while paying thorough attention to safety.

E.g., check the mass well in advance, and use a lifting tool or equipment corresponding to the

mass, but do not stand under a hung load.

2) Transportation shall be performed under sufficient illumination to secure safety of scaffolding.

Avoid work on unstable pipes, etc.

3) At unloading or transportation between warehouses, this product should be held properly to

prevent it from falling and being damaged.

4) Do not suspend or hoist this product by hanging a hook on the handle. Otherwise, the product

may be damaged or fall, which is very dangerous. Suspend the product by tying down a well-

balanced position, such as the neck section of the valve body, with material that does not dam-

age the product, such as nylon sling.

3. 2. 3 Packing state

This product is shipped in the full-close position, except for the single-acting type air-to-close pneu-

matic cylinder. Be careful not to damage the edge of the disc, Seatring, and flanges.

3. 2. 4 Unpacking

1) Unpack this product immediately before installing it to the piping. Do not leave the product

unpacked for long periods of time to prevent adherence of dust and harmful substances and

deterioration due to ozone or ultraviolet rays. Otherwise, degradation in performance, contami-

nation, discoloration or material deterioration may occur.

2) Be careful not to damage this product with a cutter, etc. when unpacking.

3. 2. 5 Storage

Store this product as follows to prevent degradation in performance, contamination, discoloration,

and material deterioration.

1) Store this product in a place with no dust or water droplets while avoiding direct sunlight, high

temperatures and humidity.

2) Store this product indoors (ambient temperature: 0°C - 50°C, humidity: 70% or less) without

removing the cardboard packaging or the protective material attached to the valve body.

3) For cardboard packaging, high humidity may reduce the strength of the box and the packaging

may be broken, which may result in damage of the product. Be adequately careful not to get

the packaging wet.

4) Do not store this product in an atmosphere that contains corrosive gas. Otherwise, the parts

may be subject to corrosion, resulting in an impairment of functions.

5) Do not drop, overturn or vibrate this product, and do not apply a heavy load to the product dur-

ing storage. Otherwise, functions may be impaired.

6) Do not stack this product at storage. A load collapse may occur, which causes damage to per-

sonnel and/or the product. (Refer to section 3. 2. 2.)

7)

Store this product in the full-close position. Open and close the prod-

uct about once every three months.

8) Store this product while no load is applied to the actuator. Oth-

erwise, the handle shaft, etc. may be deformed.

9) For long-term storage, apply Ferro-Guard (Ferro-Guard

#1009, US Ronco Laboratories, INC.) once a year to the

plated parts (indicator, bolts, nuts, handle shaft, etc.). [Fig.-4]

7

3. 3 Installation and Working Environment

WARNING

3. 3. 1 Installation location and working environment

For installation locations, necessary work space should be provided for expected work and mainte-

nance, such as operation of the actuator, wiring and piping.

In the following installation locations or working environments, special actions, such as compliance

with laws and regulations, may be required in some cases as well as functional conformance to

specifications. If there are any questions, please contact our sales department at the planning stage.

1) Special working environments which are not specified in the specifications

2) In the case where substantial damage to human beings, assets, environments, etc. is predict-

ed if this product fails

E.g.: Facilities related to the High Pressure Gas Safety Act, facilities related to the Industrial

Safety and Health Act, Nuclear power related facilities, medical facilities, vehicles, etc.

CAUTION

3. 3. 2 Atmosphere of installation location

The following measures should be taken depending on the atmosphere of the installation location.

1) Locations which are exposed to gas containing salt, corrosive gas, chemical solution, organic

solvent, steam, salt water, etc. should be avoided.

2) If there is a possibility that this product is exposed to direct radiant heat or chemicals, the

product and attachments should be protected with covers.

3) Do not submerge this product. When it is installed in a place that is usually exposed to water,

such as near a cooling tower, protect the product and attachments with covers.

4) When this product is installed in a salt damage zone, take measures against salt damage.

3. 3. 3 Temperature of installation location and working environment

Using this product out of the allowable working temperature range causes thermal degradation or

hardening of Seatring and O-rings, faulty operation due to thermal expansion of parts or difference

of thermal shrinkage, etc.

1) The ambient temperature of the installation location should be within the ambient temperature

range of the specification (section 「1. 2).

2) When this product is exposed to direct sunlight, maintain the working temperatures of the

product and the actuator under the upper limit.

3) This product should be kept away from heat sources, and should be installed in a location

whose temperature is within the specified ambient temperature range. Not that temperature

near a motor, an engine, an air compressor, a boiler, etc. may exceed the specified ambient

temperature range.

4) When this product is used in an environment where the temperature of the internal fluid

changes significantly, note that leakage tends to occur due to difference in the coefficients of

thermal expansion of materials.

CAUTION

3. 3. 4 Vibration and impact at installation location

The following measures should be taken if there are vibrations or impact at the installation location.

1) When this product is used in the following conditions, check vibration or impact conditions,

such as acceleration values, and contact our sales department.

Location where excessive vibration or impact of more than 9.8 m/s2is expected to be ex-

erted

Location where vibration or impact is exerted continuously

2) Installation sections and connecting sections, etc. should be locked to secure and fasten them

firmly.

3) Vibration isolation measures should be taken to reduce vibrations or impact on the machine.

Piping should be secured with supports, or vibration isolation material should be installed.

4) Joints should be checked periodically against looseness and deformation. In case of abnormal

conditions, bolts should be retightened or parts should be replaced. Coming off of the bolts

may cause falling off or rotation in an unexpected direction of this product.

5) For a gear type, the handle may rotate due to vibrations. Take measures to secure the handle, such

as handle lock, when necessary. Handle lock can be provided as optional at time of order.

8

3. 3 Installation and Working Environment (Continued)

3. 3. 5 Removal and replacement of this product and the actuator

1) The seat sealing performance of this product depends on the full-close adjustment mechanism

of the actuator. Therefore, make alignment marks before removing the actuator, and take care

that its position is not changed at reassembly.

2) Do not remove the actuator and replace it with other actuators or modify the actuator. When

the actuator is replaced or modified, the warranty is no longer applicable.

CAUTION

3. 3. 6 Precautions for installation of thermal insulating material for the valve

If a thermal insulation thickness is 50 mm or less from the pipe outer diameter and the flange outer

diameter, the gland can be retightened. Leakage of fluid from this product to the outside may hap-

pen due to reduction in the tightening force as a result of stress relaxation of the packing during

commissioning and operation. In consideration of leakage, install the thermal insulation so that the

lever and the handle can be operated unhindered.

In addition, install the thermal insulation so that the indication of opening can be seen. For a gear

actuator, there is an option to extend the indication of opening. Please contact our sales.

CAUTION

3. 3. 7 Condensation

Condensation may occur in the actuator when the temperature of the actuator is different from the

ambient temperature.

There is an option to prevent condensation of the actuator. Please contact our sales.

CAUTION

3. 3. 8 Precautions for selection

1) This product has a structure where the body gets wet in contact with the fluid. Pay attention to

corrosion of the body due to the fluid used. Especially, Be careful to FCD450.

2) A pressure direction (flow direction) is specified on the body. Use with pressurization in the op-

posite direction is not guaranteed.

3) The pressure test is performed with water at the factory. When the fluid is gas/vapor and a little

external leakage is a problem, please contact our sales department.

4) This product use RPTFE for seat ring, so it is very weak for rust or jam and easy to get injured.

If get injured, happen leak at during an early stage.

5) If used fluid be powder or slurry, it is piled up on stopper or seal surface for disc. And lifetime

for product might be shorter.

50

50

50

Thermal

insulation

Outside diameter of

the flange

Thermal

insulation

Valve body

[Fig.-5]

9

3. 4 Installation Precautions

3. 4. 1 Precautions before installation

1) The working pressure, fluid and temperature ranges of this prod-

uct depend on the materials of the Seatring and the disc. Prior to

installation to the piping, be sure to check the valve specifications

with nameplates, catalog, drawings, etc. (Materials are described at

the arrow position in [Fig.-6].)

2) Secure scaffolding and illumination required for operation and work

at the installation location.

3) Provide supports to pipes as required so that excessive load is not

applied to the pipes due to weight or operation of this product.

4) Use standard flat-face or raised-face flanges specified in the product specifications (section 1. 2).

5) This product cannot be connected to a lining pipe. Connect the product to a carbon steel pipe

for piping, carbon steel pipe for pressure piping, or stainless steel pipe for piping whose inner

diameter is equal to or bigger than the “minimum pipe inner diameter” shown in the table in

section 6. 1.

3. 4. 2 Precautions at time of installation

When connecting this product to the piping, pay attention to the following points.

If dents or scratches are made on impact, to ensure safety stop use of the product and replace it.

1) Prior to installation to the piping, sufficiently clean piping members to remove shavings, cutting

oil, waste material, etc. from the inside.

2) This product and pipes should not be subjected to extreme force, being hit, or impacted. If the

product is deformed or damaged due to rough handling, leakage or faulty operation may occur.

3) A pressure direction (flow direction) is specified for this product. When installing, make the

pressure direction match the direction indicated by the arrow on the valve body. Pay attention

to the following installation conditions.

①Piping with the actuator facing downward is not allowed.

②If your application involves pressure being applied in both directions, please contact our sales.

③Be careful of the shaft direction when piping conditions are as shown in [Fig.-7].

Specification

name plate

[Fig.-6]

[Fig.-7]

〈Incorrect Installation〉 〈Correct Installation〉 〈Incorrect Installation〉 〈Correct Installation〉

〈Incorrect Installation〉 〈Correct Installation〉

Centrifugal Pump

(Horizontal Shaft) Pump Shaft

(Horizontal)

Pump Shaft (Vertical)

Pump Shaft (Vertical)

Pump Shaft

(Vertical)

Pump Shaft

(Vertical)

Valve Shaft (Horizontal) Valve Shaft (Vertical)

Valve Shaft Valve Shaft

Valve Shaft

(Vertical)

Valve Shaft

(Vertical)

Valve Shaft

(Horizontal)

Valve Shaft

(Horizontal)

Axial Pump (Vertical Shaft)

Pump Discharge Pump Discharge

Pump DischargePump Discharge

Flow

Flow Flow Flow

Valve Shaft

Flow Flow

Valve Shaft

Valve Shaft

Valve Shaft

Valve Shaft

Flow

Flow Flow

Flow

Flow

FlowFlow

Flow

5D or longer

Valve Shaft

5D or longer

Valve Shaft

5D or longer

5D or longer

All the Valve Shafts

have the same orientation.

The orientation of the

Valve Shafts is alternating.

Centrifugal Pump (Horizontal Shaft)

10

3. 4 Installation Precautions (Continued)

4) When installing, do not stand on this product or insert the product by hitting it.

5) Be sure to use gaskets between the pipe flanges and valve. Joint sheet gaskets*1, spiral gas-

kets*2, and PTFE Envelope gaskets can be used. Do not use soft gaskets such as ones made

of rubber. Otherwise, external leakage occurs. For piping gasket sizes, refer to the table in sec-

tion 6. 3.

*1 When the joint sheet gaskets are used, select products whose size is in compliance with

former JIS B 2404-1999 for 65 mm. For the sizes other than 65 mm, JIS standard products

can be used.

*2 For the spiral gaskets, use our special products.

6) For this product, fluid is sealed by the Seatring compressed with the force as a result of the

pipe flange compressing the gasket. When connecting the product to the piping, align the

center of the product with the center of the flange to press the Seatring accurately. The align-

ment for piping work becomes easy by using the alignment rib of this product. If this product

is operated while the centers are not aligned, breakage, faulty operation, external leakage, or

seat leakage may occur.

7) When tightening piping bolts, pay attention to the following precaution. For tightening proce-

dures, refer to section 4. 1. 1.

CAUTION

8) Never weld when this product is in the piping. Installation of

the product immediately after welding the pipe flange will

lead to heat damage to the Seatring, resulting in adverse

consequences. Make sure that the temperature is low and

weld spatters have been removed before installing the

valve.

9) Damage of the Seatring or flange leakage may occur if the flange face that contacts the seat

ring of this product is as shown in [Fig.-9].

Please be careful when using a high-torque impact wrench for piping installation or retighten-

ing piping bolts of butterfly valves. Unless an appropriate impact wrench is used and work with

it is performed properly, deformation or damage of the valve body, Seatring, pipe flanges, pip-

ing bolts, etc. may happen. If you use an impact wrench, use one whose maximum torque is no

more than the “Max. allowable value” in the following table.

<Table-3> Maximum Allowable Torque for Metal Flanges (Unit: Nm)

Bolt Nominal Size M12 M16 M20 M22 M24 M30 M36

Max. allowable value 64

or less

150

or less

300

or less

400

or less

640

or less

1280

or less

2200

or less

Note) Lubricant should be applied to bolts properly

Using an impact wrench

[Fig.-8]

● Excessive weld penetra-

tion, chamfering

The resulting oversized inner

pipe diameter may cause

flange leakage.

● Sharp edge

Sharp angles and burrs may

damage the flange surface.

● Rough surface finishing

Protrusions or indentations

on the sealing surface may

cause flange leakage. flange

leakage. [Fig.-9]

11

3. 4 Installation Precautions (Continued)

10

)Align the primary side pipe with the secondary side pipe properly and make sure that the

pipes are parallel and there is no distortion. If the alignment is not proper, external leakage,

seat leakage, or faulty operation may occur.

11

)When installing a non-return valve, pump, or flexible joint with this product, insert a short pipe

between the part and the product. Not inserting a short pipe may cause the disc to make con-

tact with the other device during operation, resulting in faulty operation, external leakage, and

seat leakage. Refer to section 6. 1 for protruding dimensions of the disc.

12

)Connect this product to the primary side of a bent pipe (elbow, tee). If the product is connected

to the secondary side by necessity, secure a straight pipe distance of 5 times or more of the

pipe diameter from the bent pipe. In addition, the product should be positioned so that the flow

velocities at the right and left sides of the shaft are the same. [Fig.-7]

If the product is closely connected to the secondary side of a bent pipe, etc., flow velocity and

pressure distribution cause unbalanced torque on the disc, which may increase the operating

force or have an adverse effect on the performance and service life of the product.

13

)When this product is connected to the secondary side of a control valve, pump outlet, or re-

ducer, secure a straight pipe distance of 5 times or more of the pipe diameter. In addition, the

valve should be positioned so that the flow velocities at the right and left sides of the shaft are

the same. [Fig.-7]

14

)When replacing a valve with a long face-to-face dimension (e.g. gate valve, globe valve, ball

valve) with this product, you must insert a short pipe and adjust the total length of the short

pipe and the face-to-face dimension of this product to the face-to-face dimension of the origi-

nal valve flange. Use the equation below when making a short pipe. [Fig.-11]

15)After piping work is completed, set this product to the full-open positon and check that the disc does

not make contact with the inner surface of the flange.

16)Also, insulate around the valve body when the valve will be used with high-temperature fluids that

exceed 60°C.

Poor centering alignment

of the pipes

Poor parallel

alignment

Distortion

[Fig.-10]

<Table-4>

Length of short pipe

L2 = L1 – L - t mm

L2 : Length of short pipe mm

L1 : Face-to-face dimension of

existing valve

mm

L : Face-to-face dimension of

TOMOE butterfly valve

mm

t : Thickness of gasket packing mm

[Fig.-11]

L

L2

L1

Butterfly valve

Short pipe Pipe

Piping gasket

Existing valve

L1

t t

t

t

t

Piping gasket

Pipe

12

Check for

any leak

[Fig.-12]

3. 5 Precautions for Safe Handling After Installation

CAUTION

3. 5. 1 Precautions for safe handling after installation

After this product is connected to the piping, perform

checks while paying attention to the following points. If the

checks are not performed, serious accidents may occur,

such as damage of the product.

1) Prior to operating, clean pipes and remove foreign

material from the inside and outside of the pipes.

2) Prior to operating, increase the internal pressure of

the piping and check for leakage from the flanges,

glands, and bottom. Make sure that the internal

pressure does not exceed the rated pressure of the

valve at the leakage check.

3) If leakage from the flanges is observed, reduce the pressure and then retighten the piping

bolts and nuts.

Refer to “Piping bolt tightening procedures” in section 4. 1. 1 10) for the tightening proce-

dures. If leakage from the bottom is observed, check for looseness of the hexagon bolts at the

bottom. If leakage from the glands is observed, retighten the hexagon bolts of the glands. If

leakage does not stop, release the piping internal pressure and remove this product from the

piping. Then replace the glands or spare parts at the bottom.

4) When performing a pressure test of the piping including this product, the pressure should be

the rated pressure of this product × 1.5 times or less.

When performing a pressure test of the piping where the pressure exceeds the rated pressure,

set the product to the full-open positon.

5) After installation, open and close the product about once every two weeks if the product is not

used for long periods of time.

6) Do not use this product as a blank flange by setting the product to the full-close position.

WARNING

WARNING

CAUTION

CAUTION

3. 5. 2 Precautions for operating this product

1) Never loosen the bolts, pins or piping bolts of this product when the inside of the piping is un-

der pressure. Otherwise fluid jets to the outside, which is dangerous.

2) Do not remove the actuator from this product when the inside of the piping is under pressure.

Unexpected abrupt valve operation may occur or the shaft may spring out.

3) When this product is used at the intermediate opening, the opening should be 30° or more. If

the product is used continuously with the opening of 30° or less, damage of sheets, or dam-

age, vibration and noise of the piping may occur due to jet speed increase or cavitation. (Refer

to section 3. 1. 4.)

4) Do not loosen the stopper bolts of the actuator and the

indicator installation bolts of the lever. Otherwise, seat

leakage may occur because the full-close position is

shifted. When the stopper bolts are moved, perform

full-close position adjustment again in accordance with

“Valve Body Full-Close Position Adjustment Proce-

dure” in section 5. 5.

5) For a manual gear type actuator, the stopper works

when the indicator shows full-open or full-close. Do not

apply excessive force to the handle wheel from this

state. Otherwise, the gear box will be damaged.

This product has been adjusted so that the maximum sealing performance can be obtained

at the full-close position adjusted with the stopper bolts. The sealing performance will be dete-

riorated and torque becomes low at a position which is deeper or shallower than the adjusted

position. Therefore, it is not necessary to rotate the handle forcibly.

6) Opening and closing operation of the lever and the handle wheel must be done by hand. When

operating the handle using an ancillary tool, such as a Wilky key, this may cause damage or

failure of the product.

7) After installation and before operation, be sure to open and close the product once or twice.

8) After trial operation or operation over a fixed period, retighten the piping bolts and nuts. Par-

ticularly, in applications involving high-temperature fluids, the tightening force of the bolts may

be reduced due to stress relaxation of the piping gaskets, which may cause flange leakage.

[Fig.-13]

Indicator

Stopper bolt

Hexagon nut

13

3. 6 Maintenance

3. 6. 1 Daily Inspection

Perform daily inspection on the following.

<Table-5> Daily Inspection Procedure

Inspection

Description Inspection Points Inspection

Procedure Countermeasure

Fluid external

leakage

Pipe joints Visual check

Retighten the piping bolts and nuts.

Align the valve center with the pipe center and

retighten the piping bolts.

Bottom, valve surface Visual check

Disassembly and maintenance (Spare parts

replacement*1)

Valve replacement

Gland area Visual check Retighten the bolts.

Abnormal noise,

vibration

Appearance of the valve

and actuator

Piping around the valve

Bolts and nuts

Listening,

Check by touch

Change the valve opening. Review the flow

rate and pressure.

Retighten the bolts and nuts. Remove the

sources of vibrations.

Disassembly and maintenance (Check for

damage of the parts.)

Looseness of the

bolts and nuts Bolts and nuts Visual check,

Check by touch

Retighten the bolts and nuts.

Retighten the pressure part after reducing

pressure.

Seat leakage

Presence or absence of

leakage from the second-

ary side

(Flow meter, pressure

gauge, drain)

Listening,

Visual check,

Measurement

Check that the opening and closing positions

are correct with the indicator.

Remove foreign material by flushing water with

the valve fully open (section 3. 6. 6).

Remove the valve from the piping (section 3. 6.

7) and perform check and cleaning.

Replace *1 pare parts

Valve operation

check

Check of opening and

closing positions

Manual valve: Operability

Automatic valve: Operation

Visual check,

Operational

feeling

Check that the opening and closing positions

are correct with the indicator.

Valve damage

check Valve surface Visual check If any damage is observed, stop use of the

valve and replace it.

*1 Replace the spare parts around after 3000 times of opening and closing (Open - Close - Open: 1 time) or

one year operation at room temperature using fresh water. The replacement timing may become faster de-

pending on the working environment. Please replace the spare parts (refer to the Expanded View in section

2.1) based on the number and term.

3. 6. 2 Periodic inspection

Perform periodic inspection on the following items once every 6 months.

<Table-6> Periodic Inspection Procedure

Inspection

Description Inspection Points Inspection Procedure Countermeasure

Corrosion and

damage of the

disc

Disc

Remove the valve

from the piping and

perform visual check.

Valve replacement

Abrasion and

damage of the

Seatring

Seatring

Remove the Seatring

from the piping and

perform visual check.

Clean the disc and Seatring (section 3. 6. 3).

Replace *1 pare parts

Valve replacement.

Valve operating

condition Valve, actuator Opening/Closing

operation Actuator replacement, valve replacement

*1 Replace the spare parts around after 3000 times of opening and closing (Open - Close - Open: 1 time) or

one year operation at room temperature using fresh water. The replacement timing may become faster de-

pending on the working environment. Please replace the spare parts (refer to the Expanded View in section

2. 1) based on the number and term.

3. 6. 3 Cleaning of the disc and disc stopper

For pneumatic cylinders and motors, before putting your hand in the valve, take precautions, such as shut-

ting off air sources and turning off the power, to prevent the actuation. It is very dangerous if your hand is

caught by the suddenly closing the disc. Particularly, for single-acting cylinder, it is necessary not only to

shut off power supplies but also to check that the operation pneumatic pressure has been released.

1) When removing this product from the piping and cleaning it for periodic inspection, etc., clean

the Seatring using a clean waste cloth/sponge, etc. and a neutral detergent or alcohol, while

avoiding scratches on the Seatring.

2) Clean the edge of the disc with a waste cloth.

3) Check for scratches and wear on the Seatring inner surface and the edge of the disc.

4) Check that no foreign material adheres to the disc stopper.

14

3. 6 Maintenance (Continued)

3. 6. 4 Replacement of spare parts

This product should be disassembled and assembled in a clean location which is free from dirt,

waste material and dust.

Refer to section 2. 1 “Expanded View and Part List” and “MAINTENANCE” in Chapter 5 for type

and replacement procedures of spare parts.

3. 6. 5 Rust prevention procedure

Be sure to use the rust preventive agent specified blow.

<Table-7> Rust Prevention Procedure

To be applied to: Rust preventive agent Product Name (Manufacturer)

Plated parts

Indicator, bolts, nuts and handle shaft Rust preventive agent Ferro-Guard #1009

(US Ronco Laboratories, INC.)

WARNING

3. 6. 6 Countermeasures to address abnormalities

1) The work should be performed while wearing protective gear, such as a helmet, safety belt,

protective glasses, working gloves and safety shoes, in accordance with laws and regulations,

and safety provisions of business establishments.

2) When the fluid which flows through the piping is toxic, flammable or corrosive, adequate safety

measures should be taken.

3) Before retightening the pipe flanges, be sure to reduce the pressure in the piping to the atmo-

spheric pressure.

4) In case of abnormal operation, possible causes are clogging of foreign material, damage of

the Seatring, etc. If you continue to use the valve, serious accidents may occur due to dam-

age. Perform checks in accordance with the following procedures.

①To remove foreign material, keep the disc in the full-open positon and flush fluid to remove

foreign material.

②If normal operation is still not restored through the above procedure, damage of the seat

ring is possible.

Remove the Seatring from the piping and check the Seatring.

WARNING

3. 6. 7 Removal/Installation from/to the piping

1) Before removing this product from the piping, release the residual pressure and remove fluid

from the equipment and the piping completely. Otherwise, jetting of fluid to the outside and

unexpected movements may occur.

2) Take necessary measures so that fluid does not flow into applicable pipes accidentally during

the work.

3) When this product is removed, fluid may leak from the inside. Provide protection as required.

4) Remove/install this product from/to the piping with the product in the full-close position so that

the disc does not protrude from the face. (Refer to section 4. 1. 1 for detailed procedures.)

5) Remove all the bolts and nuts except those on the lower side. Remove the valve. At this time,

use of jack bolts in between the flanges will assist in removing the valve more easily.

3. 6. 8 Disposal

1) Do not dispose of this product by incineration. There is a possibility of generation of toxic gas

from synthetic rubber or nylon resin parts and bursting. Therefore please dispose of this prod-

uct as general industrial waste. The product does not contain materials which cannot be dis-

posed of as general industrial waste.

2) For segregated disposal, classify the parts in accordance with materials specified on drawings.

3) This product should be disposed of in accordance with laws and regulations, local government

ordinances, standards of business establishments, etc.

15

4 INSTALLATION

4. 1 Installation Procedure

4. 1. 1 Installation procedure

At installation, read “Installation Precautions” in sec-

tion 3. 4 thoroughly and then perform installation in

accordance with the following procedures.

When installing a non-return valve, pump, or flexible

joint made of rubber with this product, insert a short

pipe between the part and this product. Otherwise,

the disc may make contact with the other device

during operation, resulting in faulty operation and

leakage.

CAUTION

1) Clean the flange face that will make contact with

this product. If there is rust or some other foreign

material sticking to the flange face, remove it and

clean the flange face with a suitable cleaning fluid

(alcohol, neutral detergent, etc.). [Fig.-14]

Remove foreign material from the piping completely

before connecting this product to the piping.

2) Before installation or removal work, set the valve

disc in the full-close position. [Fig.-15]

3) After aligning both flanges, insert the piping bolts

as shown in the figure and secure the product to

prevent it from dropping. [Fig.-16]

4) Insert jack bolts in the position shown in the figure

to widen the distance between the flanges. Push

the flanges and make the distance between the

flanges 6 to 10 mm longer than the valve face-to-

face dimension. Do not remove the jack bolts until

all the piping bolts are installed. [Fig.-17][Fig.-18]

5) Do not suspend this product by hanging a hook,

etc. on the handle. Suspend the product by tying

down a well-balanced position, such as the neck

section of the product, with material that does not

damage the body, such as a nylon sling.[Fig.-18]

6) A pressure direction (flow direction) is specified for

this product. When installing, make the pressure

direction of the valve match the direction indicated

by the arrow on the valve body. Insert the product

while taking care not to damage the valve flange

face. At installation, if the product is pushed in the

flange forcibly, the flange face will be damaged,

which will cause leakage.

Be sure to widen the distance between the flanges

using jack bolts, etc. before inserting the product.

[Fig.-18]

7) Insert piping gaskets between the end faces of the

valve and the pipe flange faces.

[Fig.-17]

[Fig.-15]

Close

Jack bolt

Face-to-face dimension

+ 6 10mm

[Fig.-18]

Piping gasket

Piping gasket

Jack bolt

Neck

Flow direction indicator

[Fig.-14]

[Fig.-16]

16

4. 1 Installation Procedure (Continued)

8)When this product is inserted completely, insert

the piping bolts to support the alignment rib.

9)After all the piping bolts are installed, remove the

jack bolts.

10

)Align the flanges with the product accurately. Tight-

en the piping bolts with the following procedures so

as not to tighten the bolts on one side too much or

too little. For this product, fluid is sealed by the seat

ring compressed with the force as a result of the

pipe flange compressing the gasket. When con-

necting the product to the piping, align the center

of this product with the center of the flange to press

the Seatring accurately. The alignment for piping

work becomes easy by using the alignment rib. If

this product is operated while the centers are not

aligned, breakage, faulty operation, external leak-

age or seat leakage may occur.

When you use an impact wrench, be sure to

read “section 3. 4. 2”.

11)

For accurate alignment between the flanges and

this product, tighten the flanges at both ends tem-

porarily and tighten this product finally first. [Fig.-21]

12)

After installation, open and close the product to

verify that the operations from/to full-open to/from

full-close are smooth.

[Fig.-21]

Piping bolt tightening procedures

When there is no appropriate tightening procedure in business establishments or

internal standards, tighten the bolts and nuts with the following procedures.

1) Clean the bolts and nuts and apply lubricant to them.

(Do not use rusty or damaged bolts and nuts.)

2) Tighten the bolts and nuts by hand in any desired order.

3) Tighten the bolts and nuts in any desired order with approx. 20% of the speci-

fied tightening torque.

4) Tighten the bolts and nuts, alternate diagonally (refer to the right figure) with

approx. 70% of the specified tightening torque.

5) Tighten the bolts and nuts, alternate diagonally, with approx. 100% of the

specified tightening torque.

6) Tighten the bolts and nuts, alternate diagonally, with approx. 100% of the

specified tightening torque again.

7) Tighten the bolts and nuts clockwise with approx. 100% of the specified tight-

ening torque.

For this product, bolts that are tightened once may become loose due to stress relaxation of the piping gaskets.

Be sure to perform retightening in 6) and 7) repeatedly until the bolts and nuts are tightened evenly.

[Fig.-20]

①

⑤

③

⑦

⑧

②

④

⑥

Example) Bolt tightening sequence

CAUTION

[Fig.-19]

Alignment ribs

Jack bolt

Flange of both ends

Flange of both ends

17

5 MAINTENANCE

5. 1. Seatring Disassembly/Assembly Procedures

5. 1. 1 Seatring disassembly procedure

For periodic inspection or in case of trouble due to

damage and wear of the Seatring, etc., carry out the

following procedures while referring to the expanded

view.

1) Secure the metal section of the body using a

vice so that the flanges are not damaged. Open the

disc approx. 30°. [Fig.-22]

2) Remove the Hex. socket set screws on the front

of the Seatring retainer . [Fig.-22]

3) Carefully grasp the inner side of the Seatring re-

tainer and pull it out toward you by hand. The

ball inserted on the outer side of the retainer

may pop out during removal, so care must be taken

not to lose it. [Fig.-22]

4) Remove the Seatring from the seat ring retainer

. [Fig.-22]

5) Thoroughly clean the Seatring mounting faces of

the body and the Seatring retainer , and the

disc using a suitable cleaning fluid, such as

alcohol or a neutral detergent. [Fig.-23]

5. 1. 2 Seatring assembly procedure

1) Set the disc to the full-close position. [Fig.-24]

2) Install a new Seatring to the Seatring retainer

. Set the ball on the periphery of the Seatring

retainer and install it on the body . [Fig.-24]

3) Screw the set screws into the tap hole provided

on the front face of the Seatring retainer . Make

sure that the Hex. socket set screws is com-

pletely screwed in so that it does not protrude from

the front face of the Seatring retainer . [Fig.-25]

[Fig.-25]

4) Open and close the valve to ensure that the seat

ring retainer is properly secured to the body.

[Fig.-22]

[Fig.-23]

[Fig.-24]

Seatring retainer

Hex. socket set screw

Ball

Seatring

Disc

Hex. socket set screw

Ball

Seatring

Seatring

retainer

Disc

Body

Hex. socket

set screw

Ball

18

5. 2 Removal of Valve Body and Actuator

5. 2. 1 Lever type

1) Secure the metal section of the body using a

vice so that the flanges are not damaged. Set the

valve opening to the full-open position. [Fig.-26]

2) Make alignment marks on the body and indica-

tor

L21

.

3) Remove the Hex. socket set screw

L26

and hexagon

nut

L27

that secure the shaft and lever.

4) Remove the hexagon nuts and spring washers (2

pairs) that secure the body and indicator

L21

.

5) Lift the lever upward and remove it.

6) Be careful not to lose the removed parts.

5. 2. 2 Worm gear

1) Secure the metal section of the body using a

vice so that the flanges are not damaged. Set the

valve opening to the full-open position. [Fig.-27]

2) Make alignment marks on the connecting part be-

tween this product and the actuator.

3) Remove the hexagon bolts and spring washers (4

pairs) that secure the body and actuator.

4) Lift the actuator upward and remove it.

5) Be careful not to lose the removed parts.

[Fig.-26]

[Fig.-27]

Before installing/removing the actuator while this

product is installed to the piping, check that the

pressure in the piping is atmospheric pressure and

the fluid is drained out from the inside.

WARNING

Actuator

Screws

Shaft

Bonnet

Heat insulation sheet

Body

Disc

Lever

Screws

L26

Hex. socket set screw

L21

Notch plate

Shaft

L27

Hexagon nut

Bonnet

Body

19

5. 3 Disassembly/Assembly Procedures of Gland area

5. 3. 1 Disassembly procedure of Gland area

1) Set the disc to the full-close position.

2) Remove the hexagon bolts and then remove the

gland flange .

3) Pull out the rough gland from the body .

4) Remove the gland packing from the body us-

ing a packing tool or a scriber or similar tool. If the

packing retainer can be removed, remove it as

well.

5. 3. 2 Assembly procedure of Gland area

1) Clean the gland packing hole on the body to

remove waste material and other foreign material.

2) Clean the parts before assembly.

3) When the packing retainer was removed, install

it in the gland packing hole of the body .

4) Insert the gland packing into the gland packing

hole on the body and attach the rough gland

onto it. When inserting the gland packing , insert

the male adaptor (c), V rings (3 pcs)(b), and the

female adaptor (a) in that order, one by one, in the

direction shown in [Fig.-29].

5) Attach the gland flange and tighten the hexagon

bolts equally on the left and right.

6) Set the disc to the full-close position.

7) After installing the actuator, open and close the

valve to verify that the operations are smooth.

[Fig.-29]

[Fig.-28]

Rough gland

Packing retainer

Gland packing

Gland flange

Body

Gland packing

a

b

c

a

b

c

Table of contents

Other Tomoe Control Unit manuals

Popular Control Unit manuals by other brands

Leonard

Leonard TM-500A Installation and operating instructions for the installer

Waldorf

Waldorf DVCA1 user manual

BTR

BTR BCR - 2 A Installation and commissioning instructions

turck

turck IO-LINK MASTER user manual

VAT

VAT 162 Series Installation, operating, & maintenance instructions

Telit Wireless Solutions

Telit Wireless Solutions LE910Cx Hardware user's guide