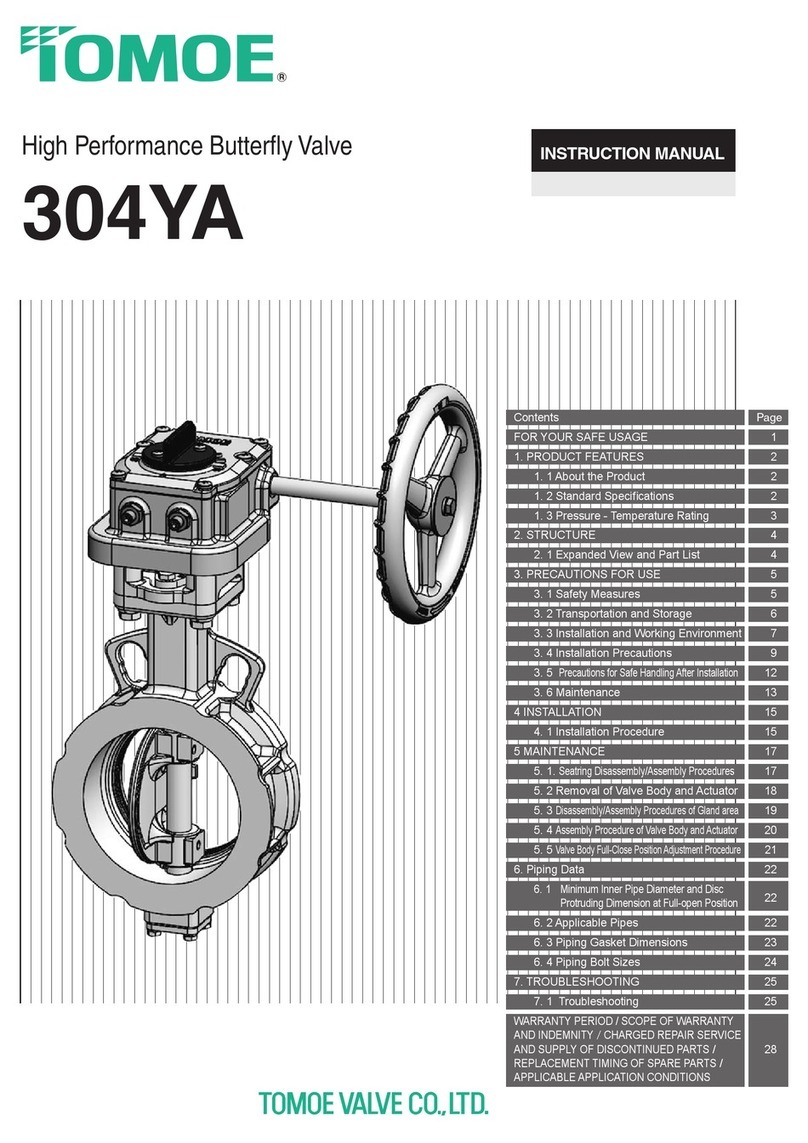

Tomoe MKT Series User manual

MKT Series Standard Specifications

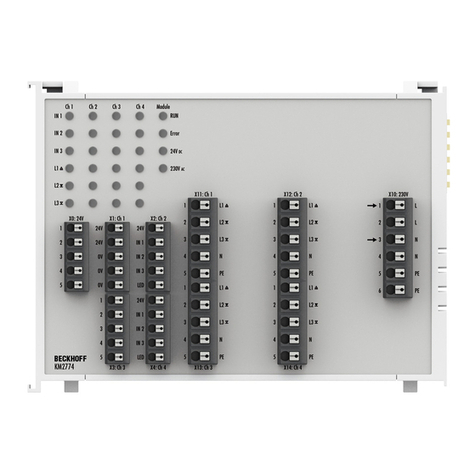

Expanded View

Precaution for Use

Installation Procedure

Precautions for Safe Handling After Installation

Inspection and Countermeasures

Disassembly/Assembly Procedures

Pressure Loss, Flow Characteristics

Valve Specifications and Standards for Selecting Springs

Available Pipe List

Cracking Pressure (Opening Pressure)

Quantity and Dimensions of Piping Bolts

Before Placing an Order

2

3

4

10

12

12

13

18

19

20

21

21

22

Contents Page

(907T・908H)

MKT Series Standard Specifications

Valve structure

Valve nominal diameter

Valve type

Applicable flange standard

Face-to-face dimensions

Max. working pressure

Allowed flow velocity

Allowable valve seat

leakage standard

Test

pressure

Working temperature range

(without freezing)

Standard

materials

Pipe gasket

Coating

Pressure

resistance

of body

Valve seat

leakage

Main body*2

Plate

Pin

Spring

Seat*3

Wafer-type double-plate check valve

Check valve with bypass

JIS 10K, 16K, 20K ASME B16.5 Class125/150

JV8-1 (stainless steel valves, wafer-type check valves), SAS358

2.0MPa

0.5 m/s to 10 m/s (Max. 12 m/s)

Tight shut

3.0MPa

High-pressure test 2.2 MPa (hydraulic)

A351 CF8 (stainless cast steel)

304 stainless steel

304 stainless steel

NBR, EPDM

Required (please purchase a commercially available gasket that satisfies the flange standards)

907T = Resin baked finish (Tomoe Green)

908H = No coating

NBR seat

EPDM seat

: 0 to 60℃

: 0 to 100℃

907T

50, 65, 80, 100, 125, 150, 200, 250, 300, 350, 400 mm

*1

908H

50, 65, 80, 100, 125, 150, 200, 250, 300 mm

A536 Gr.65-45-12 (ductile cast iron) A351 CF8 (equivalent to SCS13)

*1. 250A and 300A types include rubber sleeves. (Compared to the types without rubber sleeves, loss of pressure increases by approx. 8%.)

350mm & 400mm do not include bypass as a rule, and are made to order. Please contact our sales team.

*2. The rubber seat is vulcanized to the valve body valve seat surface.

*3.

With fluid containing chlorine, the seat ring may deteriorate earlier than expected, depending on the concentration and temperature conditions.

Please contact our sales team for details.

* Never use an EPDM rubber seat if the valve is being used for oil or for a fluid containing even a trace of oil.

When a chemical agent containing calcium is charged to protect the piping, EPDM seat ring is recommended.

Incorrect selection of the valve specifications according to the fluid conditions and installation conditions may

cause vibration noise during operation.

Refer to "MKT Valve Specifications and Standards for Selecting Springs" and "Handling Precautions".

2

FOR YOUR SAFETY IN USE The following instructions should always be followed.

Warning This sign indicates “possibility of death or serious injury”.

This symbol indicates items that "you must not do".

This symbol indicates items "you must do".

This sign indicates “possibility of injury to personnel or

physical damage to property only”.

■The levels of danger and damage when these cautions are neglected and the

product is used incorrectly are classified and described below.

■

The types of advisories to be observed are classified and indicated with the symbols below

(The following symbols are examples.)

Caution

■Introduction

1

Thank you for purchasing our products.

For proper use of our products over long periods of time, please read this instruction manual thor-

oughly before use, and use the products properly in accordance with its contents.

The instructions in this document are to promote the correct use of the check valve MKT series

(hereinafter "this product") and to help prevent injury or damage.

●Be sure to read this instruction manual before transportation, storage, piping and installation, operation, mainte-

nance and inspection.

●This instruction manual does not describe all the assumed conditions concerning transportation, storage,

installation, operation, maintenance and inspection of this product. If there are any questions, please contact

our sales representative.

●Reference values and limit values for operation, maintenance and inspection, which are specified in this

instruction manual, have been determined in consideration of maintenance management of this product. This

product should be used within the range of the reference values and the limit values.

●Be sure to store this instruction manual in a readily accessible place for future reference after installation and

when operation starts.

If a staff member in charge is changed, information concerning the storage place of this document and opera-

tion should be given to the member of staff taking over responsibility.

●If dents or scratches are caused by an impact, etc., for safety’s sake you should stop using and replace the

product.

●The contents of this instruction manual are subject to change without notice.

MKT Series Standard Specifications

Valve structure

Valve nominal diameter

Valve type

Applicable flange standard

Face-to-face dimensions

Max. working pressure

Allowed flow velocity

Allowable valve seat

leakage standard

Test

pressure

Working temperature range

(without freezing)

Standard

materials

Pipe gasket

Coating

Pressure

resistance

of body

Valve seat

leakage

Main body*2

Plate

Pin

Spring

Seat*3

Wafer-type double-plate check valve

Check valve with bypass

JIS 10K, 16K, 20K ASME B16.5 Class125/150

JV8-1 (stainless steel valves, wafer-type check valves), SAS358

2.0MPa

0.5 m/s to 10 m/s (Max. 12 m/s)

Tight shut

3.0MPa

High-pressure test 2.2 MPa (hydraulic)

A351 CF8 (stainless cast steel)

304 stainless steel

304 stainless steel

NBR, EPDM

Required (please purchase a commercially available gasket that satisfies the flange standards)

907T = Resin baked finish (Tomoe Green)

908H = No coating

NBR seat

EPDM seat

: 0 to 60℃

: 0 to 100℃

907T

50, 65, 80, 100, 125, 150, 200, 250, 300, 350, 400 mm

*1

908H

50, 65, 80, 100, 125, 150, 200, 250, 300 mm

A536 Gr.65-45-12 (ductile cast iron) A351 CF8 (equivalent to SCS13)

*1. 250A and 300A types include rubber sleeves. (Compared to the types without rubber sleeves, loss of pressure increases by approx. 8%.)

350mm & 400mm do not include bypass as a rule, and are made to order. Please contact our sales team.

*2. The rubber seat is vulcanized to the valve body valve seat surface.

*3.

With fluid containing chlorine, the seat ring may deteriorate earlier than expected, depending on the concentration and temperature conditions.

Please contact our sales team for details.

* Never use an EPDM rubber seat if the valve is being used for oil or for a fluid containing even a trace of oil.

When a chemical agent containing calcium is charged to protect the piping, EPDM seat ring is recommended.

Incorrect selection of the valve specifications according to the fluid conditions and installation conditions may

cause vibration noise during operation.

Refer to "MKT Valve Specifications and Standards for Selecting Springs" and "Handling Precautions".

2

FOR YOUR SAFETY IN USE The following instructions should always be followed.

Warning This sign indicates “possibility of death or serious injury”.

This symbol indicates items that "you must not do".

This symbol indicates items "you must do".

This sign indicates “possibility of injury to personnel or

physical damage to property only”.

■The levels of danger and damage when these cautions are neglected and the

product is used incorrectly are classified and described below.

■

The types of advisories to be observed are classified and indicated with the symbols below

(The following symbols are examples.)

Caution

■Introduction

1

Thank you for purchasing our products.

For proper use of our products over long periods of time, please read this instruction manual thor-

oughly before use, and use the products properly in accordance with its contents.

The instructions in this document are to promote the correct use of the check valve MKT series

(hereinafter "this product") and to help prevent injury or damage.

●Be sure to read this instruction manual before transportation, storage, piping and installation, operation, mainte-

nance and inspection.

●This instruction manual does not describe all the assumed conditions concerning transportation, storage,

installation, operation, maintenance and inspection of this product. If there are any questions, please contact

our sales representative.

●Reference values and limit values for operation, maintenance and inspection, which are specified in this

instruction manual, have been determined in consideration of maintenance management of this product. This

product should be used within the range of the reference values and the limit values.

●Be sure to store this instruction manual in a readily accessible place for future reference after installation and

when operation starts.

If a staff member in charge is changed, information concerning the storage place of this document and opera-

tion should be given to the member of staff taking over responsibility.

●If dents or scratches are caused by an impact, etc., for safety’s sake you should stop using and replace the

product.

●The contents of this instruction manual are subject to change without notice.

Precaution for Use

1. Handling of this product

Safety Measures

4

(1) This product should be assembled, operated, maintained, etc. by personnel who have read the

instruction manual (hereinafter "this document") thoroughly and understood the contents well.

(2) The work should be performed while wearing protective gear, such as a helmet, safety belt, protective

glasses, working gloves and safety shoes, in accordance with laws and regulations, and safety

provisions of business establishments.

(3) Do not stand or place heavy objects on this product, as this may cause the product to be damaged,

resulting in falling accidents.

2. Safety check

Never attempt to handle the machine and the system or remove the equipment before safety is ensured.

Before removing the equipment, check the following items are in place to ensure safety.

(1) Safety precautions for this product have been taken, such as prevention of falling of any parts or

materials, or other accidental events.

(2) The surface temperatures of this product, flanges, and pipes are at a safe level for surfaces to be

touched.

(3) The pressure in the piping is atmospheric pressure, and fluid has been drained from the interior of the

piping.

(4) Where the fluid flowing through the piping is toxic, flammable or corrosive, adequate safety measures

have been taken.

(5) Energy sources for the facilities related to this product, such as power supplies and air sources, have

been shut off.

(6) No fluid harmful to the human body is adhering to the product or to the peripheral piping.

Before restarting the unit, check the following items.

(1) There is no failure or damage to this product visible, and no parts are missing.

(2) No tools have been left on this product or on the pipes.

(3) Nothing can hinder operation of this product.

(4)

A safe evacuation procedure is already in place in case of unexpected equipment movement, leakage, etc.

3. Water hammer

This product can be used with the purpose of preventing water hammer due to water level reduction, by

closing the valve when the pump is stopped. However, water hammer may still occur, depending on

installation conditions such as opening/closing operations of other valves and piping height from the ground.

Design should take into account prevention of water hammer.

Occurrence of water hammer may damage this product and the peripheral piping materials.

4. Cavitation

Design should take into account prevention of cavitation.

This product can be operated at a maximum fluid velocity of 10m/s. However, cavitation may occur when

the product is used at a velocity of 10m/s or less. If abnormal noise or vibrations are generated by the

product or peripheral piping during fully-open operation, cavitation may have occurred. If the product is

used for long periods of time in this state, the product or piping materials may be damaged. Cavitation

should therefore be prevented, by changing the flow rate, etc.

Warning

Warning

Caution

Caution

7

26

4

5

99

10

1

8

9

30

30

8

9

6

26

7

3

2L

2R

16

51

20

13

12

29

23

21

15

15 14

9

30

30

9

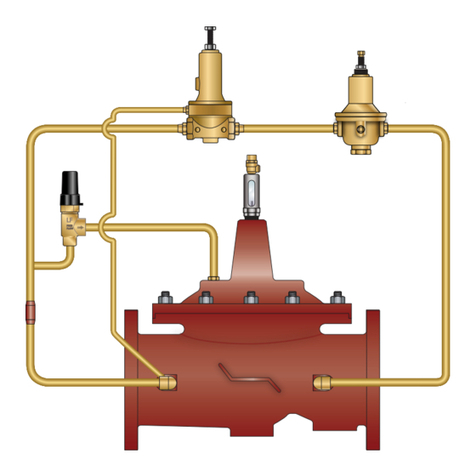

■MKT Body Parts List (50 to 300 mm)

No. Q'ty RemarksPart Name

1

2L

2R

3

4

5

6

7

8

9

10

12

13

14

15

16

20

21

23

26

29

30

51

99

Body

Left plate

Right plate

Spring

Hinge pin

Stop pin

Seat

Hexagon nut

Washer

Washer

Eye bolt

Handle

Lock bolt

Stopper

Hexagon socket set screw

O-ring

Spindle

Hexagon nut

Collar

Seal washer

Spring washer

Bearing

Rubber valve seat

Rubber sleeve

1

1

1

1

1

1

1

4

2

4

1

1

1

1

2

1

1

1

1

4

1

4

1

1

200, 250, 300 mm:2 pcs

Same part as part No. 4.

Vulcanized to body

Only 150, 200, 250, 300 mm

Only 250, 300 mm

3

Expanded View

Precaution for Use

1. Handling of this product

Safety Measures

4

(1) This product should be assembled, operated, maintained, etc. by personnel who have read the

instruction manual (hereinafter "this document") thoroughly and understood the contents well.

(2) The work should be performed while wearing protective gear, such as a helmet, safety belt, protective

glasses, working gloves and safety shoes, in accordance with laws and regulations, and safety

provisions of business establishments.

(3) Do not stand or place heavy objects on this product, as this may cause the product to be damaged,

resulting in falling accidents.

2. Safety check

Never attempt to handle the machine and the system or remove the equipment before safety is ensured.

Before removing the equipment, check the following items are in place to ensure safety.

(1) Safety precautions for this product have been taken, such as prevention of falling of any parts or

materials, or other accidental events.

(2) The surface temperatures of this product, flanges, and pipes are at a safe level for surfaces to be

touched.

(3) The pressure in the piping is atmospheric pressure, and fluid has been drained from the interior of the

piping.

(4) Where the fluid flowing through the piping is toxic, flammable or corrosive, adequate safety measures

have been taken.

(5) Energy sources for the facilities related to this product, such as power supplies and air sources, have

been shut off.

(6) No fluid harmful to the human body is adhering to the product or to the peripheral piping.

Before restarting the unit, check the following items.

(1) There is no failure or damage to this product visible, and no parts are missing.

(2) No tools have been left on this product or on the pipes.

(3) Nothing can hinder operation of this product.

(4)

A safe evacuation procedure is already in place in case of unexpected equipment movement, leakage, etc.

3. Water hammer

This product can be used with the purpose of preventing water hammer due to water level reduction, by

closing the valve when the pump is stopped. However, water hammer may still occur, depending on

installation conditions such as opening/closing operations of other valves and piping height from the ground.

Design should take into account prevention of water hammer.

Occurrence of water hammer may damage this product and the peripheral piping materials.

4. Cavitation

Design should take into account prevention of cavitation.

This product can be operated at a maximum fluid velocity of 10m/s. However, cavitation may occur when

the product is used at a velocity of 10m/s or less. If abnormal noise or vibrations are generated by the

product or peripheral piping during fully-open operation, cavitation may have occurred. If the product is

used for long periods of time in this state, the product or piping materials may be damaged. Cavitation

should therefore be prevented, by changing the flow rate, etc.

Warning

Warning

Caution

Caution

7

26

4

5

99

10

1

8

9

30

30

8

9

6

26

7

3

2L

2R

16

51

20

13

12

29

23

21

15

15 14

9

30

30

9

■MKT Body Parts List (50 to 300 mm)

No. Q'ty RemarksPart Name

1

2L

2R

3

4

5

6

7

8

9

10

12

13

14

15

16

20

21

23

26

29

30

51

99

Body

Left plate

Right plate

Spring

Hinge pin

Stop pin

Seat

Hexagon nut

Washer

Washer

Eye bolt

Handle

Lock bolt

Stopper

Hexagon socket set screw

O-ring

Spindle

Hexagon nut

Collar

Seal washer

Spring washer

Bearing

Rubber valve seat

Rubber sleeve

1

1

1

1

1

1

1

4

2

4

1

1

1

1

2

1

1

1

1

4

1

4

1

1

200, 250, 300 mm:2 pcs

Same part as part No. 4.

Vulcanized to body

Only 150, 200, 250, 300 mm

Only 250, 300 mm

3

Expanded View

6

Installation and Working Environment

1. Installation location and working environment

In installation locations, sufficient work space should be planned and provided for anticipated work and mainte-

nance.

In certain installation locations or working environments there may be extra requirements, such as compliance with

laws and regulations, as well as functional conformance to specifications. If there are any questions, please

contact our sales team at the planning stage. These special installation environments may include:

(1)Special working environments which are not specified in the specifications

(2)Environments where failure of the product would be expected to cause substantial damage to human beings,

assets, surroundings etc.

e.g.: Facilities covered by the High Pressure Gas Safety Act, facilities covered by the Industrial Safety and Health

Act, Nuclear power related facilities, vehicles, medical facilities, etc.

2. Atmosphere of installation location

The following measures should be taken, depending on the atmosphere of the installation location for this product.

(1)Locations which are exposed to salt-laden atmospheres, corrosive gases, chemical solutions, organic solvents,

steam, salt water, etc. should be avoided.

(2)If there is a possibility that this product may be exposed to direct radiant heat or chemicals, the product and its

attachments should be protected with covers.

(3)Do not submerge this product. If it is installed in a place that is regularly exposed to water, such as near a

cooling tower, protect the product and its attachments with covers.

3. Temperature of installation location

Using this product out of the allowable working temperature range causes thermal degradation or hardening of

seat rings and O-rings, faulty operation due to thermal expansion of parts or differential thermal contraction, etc.

(1)The ambient temperature of the installation location should be within the ambient temperature range of 0°C to

60°C.

(2)If this product is exposed to direct sunlight, ensure that the working temperature remains below the upper limit

of the above ambient temperature range.

(3)This product should be kept away from heat sources, and should be installed in a location whose temperature

is within the specified ambient temperature range. Please note that siting the product near a motor, an engine,

an air compressor, a boiler, etc. may cause conditions to exceed the specified ambient temperature range.

4. Vibration and shock at installation location

The following measures should be taken if vibration or shock are factors at the installation location of this product.

(1)When this product is used in the following conditions, check for factors potentially causing vibration or shock,

such as acceleration values, and consult our sales team.

1) Locations where excessive vibration or shock is anticipated

2) Locations where vibration or shock is exerted regularly or continuously

(2)Mounting and connecting sections of this product should be secured to prevent loosening as a result of

vibration or shock.

(3)Anti-vibration measures should be taken to isolate or reduce vibration or shock to the machine. Piping should

be secured with firm supports, and where necessary vibration isolation materials should be used.

(4)Connections should be checked periodically for looseness or deformation. If there is any abnormality, the bolts

should be re-tightened or the parts should be replaced. A bolt working loose may cause the product to fall or

rotate suddenly in an unexpected direction.

Warning

Caution

Caution

1. Transportation and Transfer

Transportation and Storage

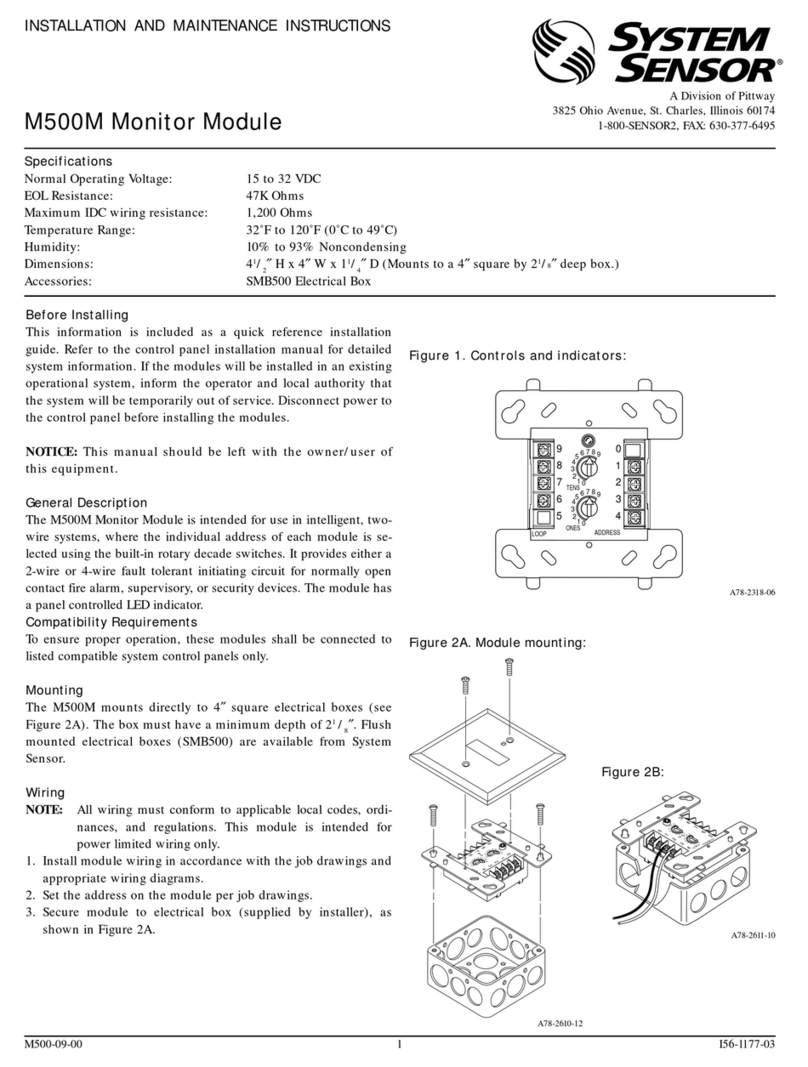

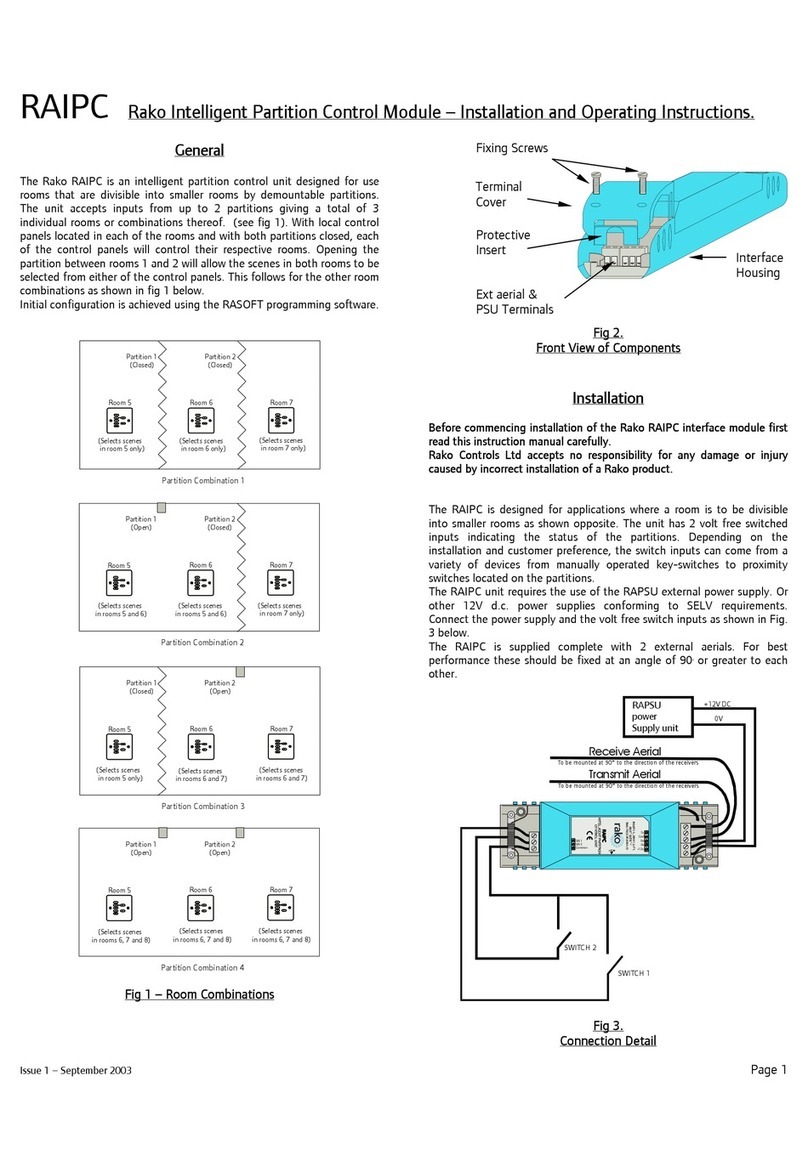

[Fig.-1]

5

(1)Products with large mass (150 mm or more) should be transported using suitable equipment or machinery, not by manpower alone.

See the catalog, product drawings, etc. issued by our company for details on the mass of this product. Qualified personnel should

perform work with a forklift, crane or sling in accordance with laws and regulations, and safety provisions of business establishments.

In addition, please observe the instructions in "Dropping and falling” below.

(2)While transporting this product, be careful not to damage the coated surface. If the surface is damaged, repair the coated film.

Leaving surface damage unrepaired may result in corrosion.

(3)Use shipping containers for ocean transportation. If the product is not sealed within a shipping container, it will deteriorate from

contact with salt-laden wind and spray.

(4)Use a covered vehicle for inland transportation to avoid exposure to wind and rain. If an open vehicle is used, cover the product with

a protective tarpaulin and secure against the effects of weather.

(5)Do not throw the product and do not apply a heavy load.

(1)When lifting or using a sling to hoist this product, pay thorough attention to safety. For example, check the mass well in advance, and

use lifting machinery or equipment rated to be safe for the mass. Ensure that no personnel ever stand or walk under or close to a

suspended load.

(2)Lighting during transportation must be sufficient to ensure safe operation, including lighting related to scaffolding to ensure its safe

use. The stability of piping must be ensured before any work takes place on it.

(3)During unloading or transportation between warehouses, this product should be secured properly at all times to prevent it from falling

and sustaining or causing damage.

(4)Do not use the product’s handle to suspend or hoist this product. The handle may break off or fail and the product may be damaged,

which is very dangerous.

If the nominal diameter of this product is 150 mm or more, use the hanger ring on the MKT body for hook attachment when hoisting.

(1)If the nominal diameter of this product is 50 mm to 200 mm, the product is packed in a cardboard box. For other products, protective

panels made of materials such as plywood are attached to the flange faces (pipe flange contact faces) of the body to protect the

interior.

(2)For the FCD body, rust prevention oil is applied thinly to the inner face of the body.

(3)A name plate is attached. Nominal diameter, materials, etc. can be checked on the plate.

Unpack this product only when ready to connect it to the piping. Do not leave the product unpacked for long periods of time. This will

prevent adherence of dust and harmful aerosols, and deterioration due to ozone or ultraviolet rays.

Otherwise, degradation in performance of this product, contamination, discoloration or materials deterioration may occur.

Store this product as follows to prevent its degradation in performance, contamination, discoloration, and material deterioration.

Store this product in a place with no dust or water droplets while avoiding direct sunlight, high temperatures and excessive humidity.

(1)Store this product in a cool and dark indoor area (ambient temperature:

-10°C - 40°C, humidity: 70% or less) without removing the cardboard

packaging or the protective material attached to the valve body.

[Fig.-1]

(2)With cardboard packaging, high humidity may reduce the strength of

the box and the packaging may deteriorate or separate, which may

result in damage to the product. Be careful not to let the packaging

become damp or wet.

(3)Do not store this product in an atmosphere that contains corrosive gas.

Otherwise, the parts may be subject to corrosion, resulting in an

impairment of functions.

(4)Do not drop or overturn this product or subject it to vibration, and do

not apply a heavy load to the product during storage. Otherwise,

functions may be impaired.

(5)Do not stack more than one item when storing this product. A load

collapse may occur, which could cause damage to personnel and/or

the product. (Refer to Transportation and Storage Section 2: "Dropping

and Falling".)

(6) Individual parts of this product, such as the handle, axle shaft etc., are

not designed to carry the weight of the valve. The products must be

stored so that no load is applied to such parts. Otherwise, the handle,

axle shaft, etc. may become deformed or fail.

2. Dropping and falling

3. Packing state

4. Unpacking

5. Storage

Warning

Warning

6

Installation and Working Environment

1. Installation location and working environment

In installation locations, sufficient work space should be planned and provided for anticipated work and mainte-

nance.

In certain installation locations or working environments there may be extra requirements, such as compliance with

laws and regulations, as well as functional conformance to specifications. If there are any questions, please

contact our sales team at the planning stage. These special installation environments may include:

(1)Special working environments which are not specified in the specifications

(2)Environments where failure of the product would be expected to cause substantial damage to human beings,

assets, surroundings etc.

e.g.: Facilities covered by the High Pressure Gas Safety Act, facilities covered by the Industrial Safety and Health

Act, Nuclear power related facilities, vehicles, medical facilities, etc.

2. Atmosphere of installation location

The following measures should be taken, depending on the atmosphere of the installation location for this product.

(1)Locations which are exposed to salt-laden atmospheres, corrosive gases, chemical solutions, organic solvents,

steam, salt water, etc. should be avoided.

(2)If there is a possibility that this product may be exposed to direct radiant heat or chemicals, the product and its

attachments should be protected with covers.

(3)Do not submerge this product. If it is installed in a place that is regularly exposed to water, such as near a

cooling tower, protect the product and its attachments with covers.

3. Temperature of installation location

Using this product out of the allowable working temperature range causes thermal degradation or hardening of

seat rings and O-rings, faulty operation due to thermal expansion of parts or differential thermal contraction, etc.

(1)The ambient temperature of the installation location should be within the ambient temperature range of 0°C to

60°C.

(2)If this product is exposed to direct sunlight, ensure that the working temperature remains below the upper limit

of the above ambient temperature range.

(3)This product should be kept away from heat sources, and should be installed in a location whose temperature

is within the specified ambient temperature range. Please note that siting the product near a motor, an engine,

an air compressor, a boiler, etc. may cause conditions to exceed the specified ambient temperature range.

4. Vibration and shock at installation location

The following measures should be taken if vibration or shock are factors at the installation location of this product.

(1)When this product is used in the following conditions, check for factors potentially causing vibration or shock,

such as acceleration values, and consult our sales team.

1) Locations where excessive vibration or shock is anticipated

2) Locations where vibration or shock is exerted regularly or continuously

(2)Mounting and connecting sections of this product should be secured to prevent loosening as a result of

vibration or shock.

(3)Anti-vibration measures should be taken to isolate or reduce vibration or shock to the machine. Piping should

be secured with firm supports, and where necessary vibration isolation materials should be used.

(4)Connections should be checked periodically for looseness or deformation. If there is any abnormality, the bolts

should be re-tightened or the parts should be replaced. A bolt working loose may cause the product to fall or

rotate suddenly in an unexpected direction.

Warning

Caution

Caution

1. Transportation and Transfer

Transportation and Storage

[Fig.-1]

5

(1)Products with large mass (150 mm or more) should be transported using suitable equipment or machinery, not by manpower alone.

See the catalog, product drawings, etc. issued by our company for details on the mass of this product. Qualified personnel should

perform work with a forklift, crane or sling in accordance with laws and regulations, and safety provisions of business establishments.

In addition, please observe the instructions in "Dropping and falling” below.

(2)While transporting this product, be careful not to damage the coated surface. If the surface is damaged, repair the coated film.

Leaving surface damage unrepaired may result in corrosion.

(3)Use shipping containers for ocean transportation. If the product is not sealed within a shipping container, it will deteriorate from

contact with salt-laden wind and spray.

(4)Use a covered vehicle for inland transportation to avoid exposure to wind and rain. If an open vehicle is used, cover the product with

a protective tarpaulin and secure against the effects of weather.

(5)Do not throw the product and do not apply a heavy load.

(1)When lifting or using a sling to hoist this product, pay thorough attention to safety. For example, check the mass well in advance, and

use lifting machinery or equipment rated to be safe for the mass. Ensure that no personnel ever stand or walk under or close to a

suspended load.

(2)Lighting during transportation must be sufficient to ensure safe operation, including lighting related to scaffolding to ensure its safe

use. The stability of piping must be ensured before any work takes place on it.

(3)During unloading or transportation between warehouses, this product should be secured properly at all times to prevent it from falling

and sustaining or causing damage.

(4)Do not use the product’s handle to suspend or hoist this product. The handle may break off or fail and the product may be damaged,

which is very dangerous.

If the nominal diameter of this product is 150 mm or more, use the hanger ring on the MKT body for hook attachment when hoisting.

(1)If the nominal diameter of this product is 50 mm to 200 mm, the product is packed in a cardboard box. For other products, protective

panels made of materials such as plywood are attached to the flange faces (pipe flange contact faces) of the body to protect the

interior.

(2)For the FCD body, rust prevention oil is applied thinly to the inner face of the body.

(3)A name plate is attached. Nominal diameter, materials, etc. can be checked on the plate.

Unpack this product only when ready to connect it to the piping. Do not leave the product unpacked for long periods of time. This will

prevent adherence of dust and harmful aerosols, and deterioration due to ozone or ultraviolet rays.

Otherwise, degradation in performance of this product, contamination, discoloration or materials deterioration may occur.

Store this product as follows to prevent its degradation in performance, contamination, discoloration, and material deterioration.

Store this product in a place with no dust or water droplets while avoiding direct sunlight, high temperatures and excessive humidity.

(1)Store this product in a cool and dark indoor area (ambient temperature:

-10°C - 40°C, humidity: 70% or less) without removing the cardboard

packaging or the protective material attached to the valve body.

[Fig.-1]

(2)With cardboard packaging, high humidity may reduce the strength of

the box and the packaging may deteriorate or separate, which may

result in damage to the product. Be careful not to let the packaging

become damp or wet.

(3)Do not store this product in an atmosphere that contains corrosive gas.

Otherwise, the parts may be subject to corrosion, resulting in an

impairment of functions.

(4)Do not drop or overturn this product or subject it to vibration, and do

not apply a heavy load to the product during storage. Otherwise,

functions may be impaired.

(5)Do not stack more than one item when storing this product. A load

collapse may occur, which could cause damage to personnel and/or

the product. (Refer to Transportation and Storage Section 2: "Dropping

and Falling".)

(6) Individual parts of this product, such as the handle, axle shaft etc., are

not designed to carry the weight of the valve. The products must be

stored so that no load is applied to such parts. Otherwise, the handle,

axle shaft, etc. may become deformed or fail.

2. Dropping and falling

3. Packing state

4. Unpacking

5. Storage

Warning

Warning

Butterfly valve

Flow

Short pipe

Check valve

Gaskets

Be sure to attach gaskets to both sides.

Material

Shape

Dimension

Note

Nominal Diameter

mm inch R A F

29.0

36.3

43.2

53.3

66.0

78.9

104.2

129.8

154.5

50

65

80

100

125

150

200

250

300

2

2 1/2

3

4

5

6

8

10

12

30.0

36.0

40.5

38.0

47.5

53.5

72.0

83.5

110.0

0.0

0.0

0.0

8.4

11.0

17.5

25.7

37.7

35.0

Plate Protruding Amount

[Fig.-4]

[Fig.-5]

Do not use the connection of this product when

correcting problems with the flange center,

parallelism or distortion.

8

Installation Precautions(Continued)

(7)Be sure to use gaskets for piping. Do not use soft gaskets

such as types made of soft rubber. This could cause faulty

operation because the gasket could protrude to partially

cover the interior face of the pipe, or could obstruct the

bypass valve aperture. Select the correct gaskets referring

to the following:

(8)When this product is connected with other piping equip-

ment, the plate protrudes to the downstream side. Therefore

care must be taken that there is no interference with the

plate. (Table to the left)

: Non-asbestos, fluorine resin, hard rubber

: Ring gasket (flat gasket), flat face gasket (with bolt hole),

envelope gasket, spiral gasket, etc.

: Use commercial products conforming to the flange

standards in use.

: Use a gasket with the correct inner diameter so that the

bypass aperture is not restricted by the gasket, as shown

in the figure on the right. Importantly, soft gaskets such as

types made of rubber or fluorine resin must not be used,

because the gasket could deform and obstruct the bypass

aperture. Ensure the gasket inner diameter is correct and

the gasket is not misaligned.

(9)When a butterfly valve is connected to this product, be sure

to install a short pipe in between. The disc of the butterfly

valve would otherwise contact this product when in use,

which would cause faulty operation. When a butterfly valve

is connected to this product using a short pipe, install

piping so that the valve stem of the butterfly valve and the

hinge pin of this product intersect at right angles. [Fig.-4]

(10)Align the center of this product accurately with the center

of the flange. Operating this product with the centers

misaligned may cause clogging of the bypass valve,

leakage to the outside or vibration.

(11)Align the primary side pipe accurately with the secondary

side pipe and make sure that the pipes are parallel and

there is no distortion. If the alignment is not accurate,

external leakage or faulty operation may occur. [Fig.-5]

Poor centering

alignment

of the pipes

Poor parallel

alignment Distortion

Bypass aperture

Gasket Bypass valve

Left rotation: Open

Right rotation: Close

1. Precautions before installation

2. Precautions at installation

Using an impact wrench

Installation Precautions

<Table 1> Maximum Allowable Torque for Metal Flanges (Nm)

Note) Lubricant should be correctly applied to bolts.

Bolt Nominal

Size

Valve Nominal

Diameter Bolt Nominal

Diameter

40 - 100mm

125 - 200mm

250 - 350mm

400 - 500mm

550 - 900mm

Recommended

Torque

M16

M20

M22

M24

M30

40

80

100

130

250

M12

64

or

less

150

or

less

300

or

less

400

or

less

640

or

less

1280

or

less

2200

or

less

M16 M20 M22 M24 M30 M36

Max.

allowable

value

<Table 2> Maximum Allowable Torque for Resin Flanges

and Resin Lining Pipe (Nm)

[Fig.-2]

[Fig.-3]

7

(1) The working pressure, fluid and temperature ranges of this

product depend on the materials of the seat ring.

Prior to connection to the piping, be sure to check the valve

specifications with nameplates, catalog, drawings, etc.

(2) Ensure the safety of scaffolding and lighting required for

machinery operation and working at the installation location

of this product.

(6) Welding must never take place when the product is

connected to the piping. Installation of the product must not

take place immediately after the pipe flange has been

welded, as the residual welding heat will cause thermal

damage to the seat ring, resulting in adverse

consequences. Before the valve is installed, ensure that the

component temperature has reduced to ambient

temperature, and weld spatters have been removed.[Fig.-3]

Please be careful when using a high-torque impact wrench for installation to the piping or retightening piping bolts on this

product. Unless an appropriate impact wrench is used and it is employed correctly, there may be deformation of or

damage to the body, seat rings, pipe flanges (particularly, flanges made of resin and resin lining), piping bolts, etc.

If you use an impact wrench, use one whose maximum torque is no more than the "Maximum Allowable Torque” value in

the following table.

For flanges made of resin and resin lining, the torque should be equal to or less than the recommended torque in Table 2.

When connecting this product to the piping, pay attention to the

following points.

To ensure safety, if dents or scratches are caused by an impact,

stop using the product and replace it.

(1) When installing piping, ensure that the fluid flow direction

matches the direction of the casting arrow indicated on the

body of this product. [Fig.-2]

(2) Prior to installation to the piping, clean piping components

thoroughly to remove dust, shavings, cutting oil, waste

material, etc. from the interior.

(3) This product and pipes must not be subjected to extreme

force or impact. If this product is deformed or damaged

due to rough handling, leakage or faulty operation may

occur.

(4) When installing, do not stand on this product or apply undue

pressure to force components into position.

(5) When tightening piping bolts, pay attention to the following

precaution.

Flow

direction

Flow

direction

Butterfly valve

Flow

Short pipe

Check valve

Gaskets

Be sure to attach gaskets to both sides.

Material

Shape

Dimension

Note

Nominal Diameter

mm inch R A F

29.0

36.3

43.2

53.3

66.0

78.9

104.2

129.8

154.5

50

65

80

100

125

150

200

250

300

2

2 1/2

3

4

5

6

8

10

12

30.0

36.0

40.5

38.0

47.5

53.5

72.0

83.5

110.0

0.0

0.0

0.0

8.4

11.0

17.5

25.7

37.7

35.0

Plate Protruding Amount

[Fig.-4]

[Fig.-5]

Do not use the connection of this product when

correcting problems with the flange center,

parallelism or distortion.

8

Installation Precautions(Continued)

(7)Be sure to use gaskets for piping. Do not use soft gaskets

such as types made of soft rubber. This could cause faulty

operation because the gasket could protrude to partially

cover the interior face of the pipe, or could obstruct the

bypass valve aperture. Select the correct gaskets referring

to the following:

(8)When this product is connected with other piping equip-

ment, the plate protrudes to the downstream side. Therefore

care must be taken that there is no interference with the

plate. (Table to the left)

: Non-asbestos, fluorine resin, hard rubber

: Ring gasket (flat gasket), flat face gasket (with bolt hole),

envelope gasket, spiral gasket, etc.

: Use commercial products conforming to the flange

standards in use.

: Use a gasket with the correct inner diameter so that the

bypass aperture is not restricted by the gasket, as shown

in the figure on the right. Importantly, soft gaskets such as

types made of rubber or fluorine resin must not be used,

because the gasket could deform and obstruct the bypass

aperture. Ensure the gasket inner diameter is correct and

the gasket is not misaligned.

(9)When a butterfly valve is connected to this product, be sure

to install a short pipe in between. The disc of the butterfly

valve would otherwise contact this product when in use,

which would cause faulty operation. When a butterfly valve

is connected to this product using a short pipe, install

piping so that the valve stem of the butterfly valve and the

hinge pin of this product intersect at right angles. [Fig.-4]

(10)Align the center of this product accurately with the center

of the flange. Operating this product with the centers

misaligned may cause clogging of the bypass valve,

leakage to the outside or vibration.

(11)Align the primary side pipe accurately with the secondary

side pipe and make sure that the pipes are parallel and

there is no distortion. If the alignment is not accurate,

external leakage or faulty operation may occur. [Fig.-5]

Poor centering

alignment

of the pipes

Poor parallel

alignment Distortion

Bypass aperture

Gasket Bypass valve

Left rotation: Open

Right rotation: Close

1. Precautions before installation

2. Precautions at installation

Using an impact wrench

Installation Precautions

<Table 1> Maximum Allowable Torque for Metal Flanges (Nm)

Note) Lubricant should be correctly applied to bolts.

Bolt Nominal

Size

Valve Nominal

Diameter Bolt Nominal

Diameter

40 - 100mm

125 - 200mm

250 - 350mm

400 - 500mm

550 - 900mm

Recommended

Torque

M16

M20

M22

M24

M30

40

80

100

130

250

M12

64

or

less

150

or

less

300

or

less

400

or

less

640

or

less

1280

or

less

2200

or

less

M16 M20 M22 M24 M30 M36

Max.

allowable

value

<Table 2> Maximum Allowable Torque for Resin Flanges

and Resin Lining Pipe (Nm)

[Fig.-2]

[Fig.-3]

7

(1) The working pressure, fluid and temperature ranges of this

product depend on the materials of the seat ring.

Prior to connection to the piping, be sure to check the valve

specifications with nameplates, catalog, drawings, etc.

(2) Ensure the safety of scaffolding and lighting required for

machinery operation and working at the installation location

of this product.

(6) Welding must never take place when the product is

connected to the piping. Installation of the product must not

take place immediately after the pipe flange has been

welded, as the residual welding heat will cause thermal

damage to the seat ring, resulting in adverse

consequences. Before the valve is installed, ensure that the

component temperature has reduced to ambient

temperature, and weld spatters have been removed.[Fig.-3]

Please be careful when using a high-torque impact wrench for installation to the piping or retightening piping bolts on this

product. Unless an appropriate impact wrench is used and it is employed correctly, there may be deformation of or

damage to the body, seat rings, pipe flanges (particularly, flanges made of resin and resin lining), piping bolts, etc.

If you use an impact wrench, use one whose maximum torque is no more than the "Maximum Allowable Torque” value in

the following table.

For flanges made of resin and resin lining, the torque should be equal to or less than the recommended torque in Table 2.

When connecting this product to the piping, pay attention to the

following points.

To ensure safety, if dents or scratches are caused by an impact,

stop using the product and replace it.

(1) When installing piping, ensure that the fluid flow direction

matches the direction of the casting arrow indicated on the

body of this product. [Fig.-2]

(2) Prior to installation to the piping, clean piping components

thoroughly to remove dust, shavings, cutting oil, waste

material, etc. from the interior.

(3) This product and pipes must not be subjected to extreme

force or impact. If this product is deformed or damaged

due to rough handling, leakage or faulty operation may

occur.

(4) When installing, do not stand on this product or apply undue

pressure to force components into position.

(5) When tightening piping bolts, pay attention to the following

precaution.

Flow

direction

Flow

direction

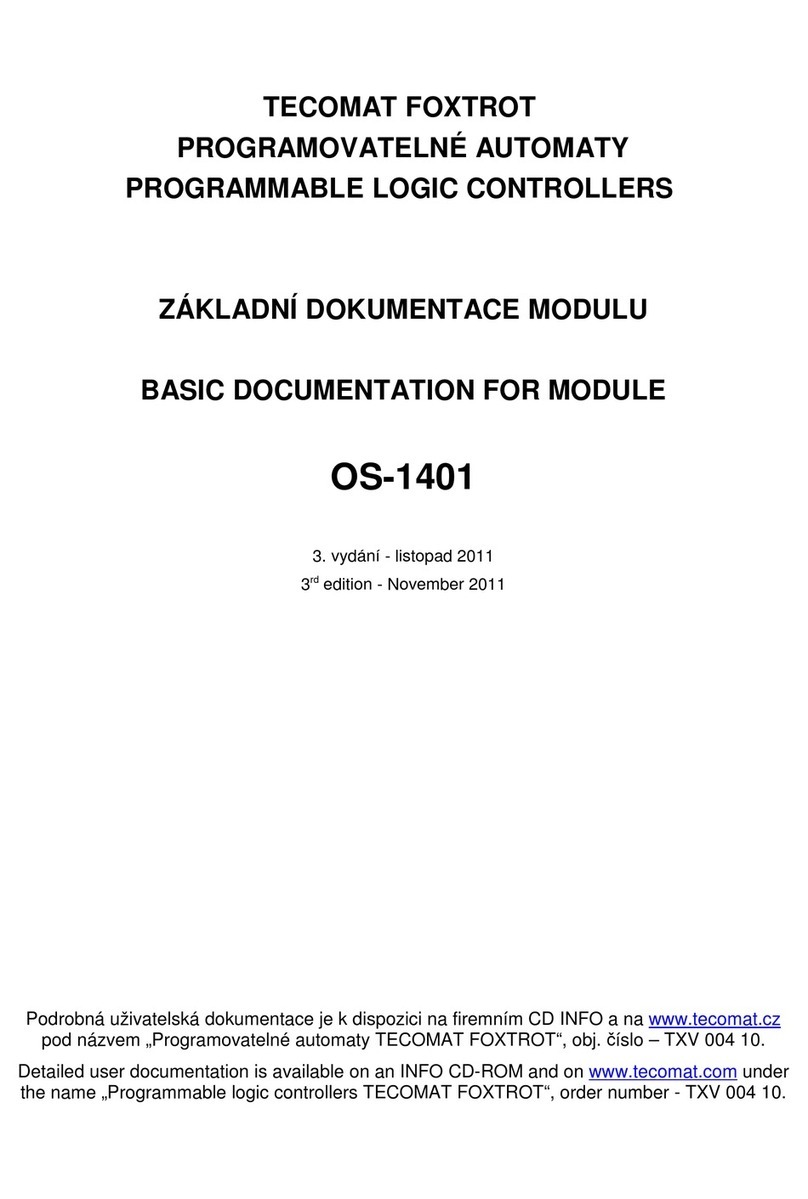

[Fig.-10]

Installation Procedure

[Fig.-9]

Jackbolt

[Fig.-11]

Bolt

10

(1)Clean the flange face that is going to make contact

with the check valve by air purging. If there is rust or

any other foreign substance sticking to the flange

face, clean the face with a suitable cleaning fluid

(alcohol, neutral detergent, etc.). [Fig.-9]

To clean the interior of a pipe, if possible, temporarily

attach a short pipe with the same diameter as the

check valve, and blast air through the interior of the

pipe to remove foreign substances completely.

(2)After aligning the centers of the pipes, insert the

piping bolts into the positions shown and secure the

check valve to prevent it from dropping. [Fig.-10]

(3)Set the jack bolts in the positions shown, and widen

the distance between the flanges. Push the flanges

and ensure a clearance consisting of the check

valve width 3 to 5 mm with each jack bolt. [Fig.-11]

○×

×

Plate

Plate

Check valve Low flow velocity

Low flow velocity High flow velocity

High flow velocity

○×

Check valve

Shaft

Hinge pin

(Top)

(Bottom)

Installation Precautions (Continued)

[Fig.-6]

[Fig.-7]

[Fig.-8]

9

(12)This product can be installed directly to a pump. In that

case, follow the precautions below.

①When the product is installed at an uneven flow velocity

distribution point, such as just after a centrifugal pump,

install the product as shown in [Fig.-6] so that both

plates of the check valve receive uniform flow.

②Use the product with an average pump outlet flow

velocity of 10 m/s or less (for fresh water).

③When the fluid is liquid and the flow velocity exceeds 5

m/s, this product may cause cavitation. To protect

against this, install a valve or equipment on the

downstream side in a position at least 2 x pipe diameter

away from the product.

④Be careful to avoid pressure loss at the check valve.

(Refer to "Table of Pressure Loss, Flow

Characteristics".)

(13)When installing this product to a pipe, the installation

orientation should be as shown below.

①For horizontal installation, install the product so that the

hinge pin is in an upright position. [Fig.-7]

②When installing the product to a bent pipe or at a pump

outlet, install the product so that the flow has a uniform

effect on the plates, as shown in [Fig.-8].

(14)If fluid is liquid and the flow velocity exceeds 10 m/s,

consult our sales team.

(15)When the product is used with a differential pressure of

0.04 MPa or less (water head pressure of 4 m or less),

leakage may occur at the seating location.

(16)Ensure that no solvent adheres to the seat ring of this

product. Perform the work while also being careful not

to allow machine oil to adhere to EPDM. Adherence of

oil may cause swelling of the EPDM seat ring, resulting

in damage.

[Fig.-10]

Installation Procedure

[Fig.-9]

Jackbolt

[Fig.-11]

Bolt

10

(1)Clean the flange face that is going to make contact

with the check valve by air purging. If there is rust or

any other foreign substance sticking to the flange

face, clean the face with a suitable cleaning fluid

(alcohol, neutral detergent, etc.). [Fig.-9]

To clean the interior of a pipe, if possible, temporarily

attach a short pipe with the same diameter as the

check valve, and blast air through the interior of the

pipe to remove foreign substances completely.

(2)After aligning the centers of the pipes, insert the

piping bolts into the positions shown and secure the

check valve to prevent it from dropping. [Fig.-10]

(3)Set the jack bolts in the positions shown, and widen

the distance between the flanges. Push the flanges

and ensure a clearance consisting of the check

valve width 3 to 5 mm with each jack bolt. [Fig.-11]

○×

×

Plate

Plate

Check valve Low flow velocity

Low flow velocity High flow velocity

High flow velocity

○×

Check valve

Shaft

Hinge pin

(Top)

(Bottom)

Installation Precautions (Continued)

[Fig.-6]

[Fig.-7]

[Fig.-8]

9

(12)This product can be installed directly to a pump. In that

case, follow the precautions below.

①When the product is installed at an uneven flow velocity

distribution point, such as just after a centrifugal pump,

install the product as shown in [Fig.-6] so that both

plates of the check valve receive uniform flow.

②Use the product with an average pump outlet flow

velocity of 10 m/s or less (for fresh water).

③When the fluid is liquid and the flow velocity exceeds 5

m/s, this product may cause cavitation. To protect

against this, install a valve or equipment on the

downstream side in a position at least 2 x pipe diameter

away from the product.

④Be careful to avoid pressure loss at the check valve.

(Refer to "Table of Pressure Loss, Flow

Characteristics".)

(13)When installing this product to a pipe, the installation

orientation should be as shown below.

①For horizontal installation, install the product so that the

hinge pin is in an upright position. [Fig.-7]

②When installing the product to a bent pipe or at a pump

outlet, install the product so that the flow has a uniform

effect on the plates, as shown in [Fig.-8].

(14)If fluid is liquid and the flow velocity exceeds 10 m/s,

consult our sales team.

(15)When the product is used with a differential pressure of

0.04 MPa or less (water head pressure of 4 m or less),

leakage may occur at the seating location.

(16)Ensure that no solvent adheres to the seat ring of this

product. Perform the work while also being careful not

to allow machine oil to adhere to EPDM. Adherence of

oil may cause swelling of the EPDM seat ring, resulting

in damage.

Check for

any leakage.

[Fig.-15]

[Fig.-14]

Warning

Precautions for Safe

Handling After Installation

Inspection and

Countermeasures

12

Jack bolt

Check

After this product is connected to the piping, perform checks

while paying attention to the following points.

If the checks are not performed, serious accidents may occur,

such as damage to the product.

(1) Before starting operation, remove foreign substances from

the interior and exterior of the pipes for ensure cleanliness.

(2) Prior to operating, increase the internal pressure of the

piping and check for leakage from the flanges, bypass

valve, and nuts of the hinge pins/stop pins.

(3) When performing a pressure test of the piping including

this product, the pressure should be no more than 150%

of the rated pressure for this product.

(4) Never loosen the bolts, nuts or piping bolts of this product

while water is flowing or when the fluid in the piping is

under pressure. Fluid may otherwise escape under

pressure as a jet, which would be dangerous.

(5) If an external coating is applied to this product, be careful

not to erase the warning indications, nameplate and flow

direction indication arrow.

(1) Perform an annual check to detect any corrosion of the

disc, check the seat ring for abrasion, and ensure smooth

operation of the plates.

(2) If valve seat leakage is observed when fluid circulation

has stopped, check that the bypass valve is closed

properly. Then check that the water head pressure head

at the downstream side of this product is 4 m or more (on

a vertical installation). If leakage does not stop even

though the head pressure is correct, damage to the seat

ring or malfunction of the plates should be assumed.

Disconnect this product from the piping and check the

seat ring and plate operation.

(3) If leakage from the flanges is observed, reduce the

pressure and then retighten the piping bolts and nuts.

Refer to "Piping bolt tightening procedures" on page 11 for

the tightening procedures. If leakage does not stop after

retightening, reduce the internal pressure in the piping

and drain water, and disconnect this product from the

piping. Then check for any abnormality on the flange

faces and piping flanges.

(4) If leakage from the nut of the hinge pin/stop pin is

observed, retighten the nut using the torque specified on

page 17. If leakage does not stop after retightening,

replace the seal washer.

(5) If abnormal noise is heard during operation while water is

circulating, there are the following possibilities: If the noise

sounds like metallic contact, the cause may be fluttering

of the plates due to unexpected drift. If the noise is

continuous, the cause may be cavitation. Consider

changing the installation position to reduce drift (refer to

"Installation Precautions") or changing the flow rate.

①

②

④

③

⑤

⑥

⑧

⑦

Example) Bolt tightening

sequence

[Fig.-12]

Piping bolt

[Fig.-13]

Piping bolt tightening procedures

11

(4) Insert the check valve so that its flange faces are not

damaged, as shown. Note that if the check valve is

pushed in between the pipes flanges forcibly at

installation, the flange faces will be damaged, which

will cause leakage. Be careful that the fluid flow

direction matches the (casting) arrow direction on the

check valve body. [Fig.-12]

(5) When the check valve is inserted completely, insert

piping gaskets and then insert the piping

bolts.[Fig.-12]

*Suspend the check valve with a crane, etc. when

performing the work. When lifting the check valve, lift

the eyebolt (nominal diameter: 150 mm or more)

using a nylon sling.

(6) Install all the piping bolts, and remove the jack bolts.

Then tighten the piping bolts with even force to avoid

uneven tightening according to the following

procedures until the piping flange face makes

contact with the side of the body. If you use an

impact wrench, be sure to read "Using an impact

wrench" in "2. Precautions at installation" in this

manual.[Fig.-13]

If there is no appropriate tightening procedure in place in business establishments, or there

are no internal standards, tighten the bolts and nuts using the following procedures.

Bolts that have been tightened once may become loose due to compression of the gaskets when another bolt is

tightened. Be sure to perform retightening in (6) and (7) repeatedly until the bolts and nuts are tightened evenly.

(1) Clean the bolts and nuts and apply lubricant to them. (Do not use rusty or damaged bolts and nuts.)

(2) Tighten the bolts and nuts by hand in any desired order.

(3) Tighten the bolts and nuts in any desired order with approx. 20% of the specified tightening torque.

(4) Tighten the bolts and nuts, alternate diagonally (refer to the right figure) with approx. 70% of the

specified tightening torque.

(5) Tighten the bolts and nuts, alternate diagonally, with approx. 100% of the specified tightening torque.

(6) Tighten the bolts and nuts, alternate diagonally, with 100% of the specified tightening torque again.

(7) Tighten the bolts and nuts clockwise with 100% of the specified tightening torque.

Caution

Caution

Check for

any leakage.

[Fig.-15]

[Fig.-14]

Warning

Precautions for Safe

Handling After Installation

Inspection and

Countermeasures

12

Jack bolt

Check

After this product is connected to the piping, perform checks

while paying attention to the following points.

If the checks are not performed, serious accidents may occur,

such as damage to the product.

(1) Before starting operation, remove foreign substances from

the interior and exterior of the pipes for ensure cleanliness.

(2) Prior to operating, increase the internal pressure of the

piping and check for leakage from the flanges, bypass

valve, and nuts of the hinge pins/stop pins.

(3) When performing a pressure test of the piping including

this product, the pressure should be no more than 150%

of the rated pressure for this product.

(4) Never loosen the bolts, nuts or piping bolts of this product

while water is flowing or when the fluid in the piping is

under pressure. Fluid may otherwise escape under

pressure as a jet, which would be dangerous.

(5) If an external coating is applied to this product, be careful

not to erase the warning indications, nameplate and flow

direction indication arrow.

(1) Perform an annual check to detect any corrosion of the

disc, check the seat ring for abrasion, and ensure smooth

operation of the plates.

(2) If valve seat leakage is observed when fluid circulation

has stopped, check that the bypass valve is closed

properly. Then check that the water head pressure head

at the downstream side of this product is 4 m or more (on

a vertical installation). If leakage does not stop even

though the head pressure is correct, damage to the seat

ring or malfunction of the plates should be assumed.

Disconnect this product from the piping and check the

seat ring and plate operation.

(3) If leakage from the flanges is observed, reduce the

pressure and then retighten the piping bolts and nuts.

Refer to "Piping bolt tightening procedures" on page 11 for

the tightening procedures. If leakage does not stop after

retightening, reduce the internal pressure in the piping

and drain water, and disconnect this product from the

piping. Then check for any abnormality on the flange

faces and piping flanges.

(4) If leakage from the nut of the hinge pin/stop pin is

observed, retighten the nut using the torque specified on

page 17. If leakage does not stop after retightening,

replace the seal washer.

(5) If abnormal noise is heard during operation while water is

circulating, there are the following possibilities: If the noise

sounds like metallic contact, the cause may be fluttering

of the plates due to unexpected drift. If the noise is

continuous, the cause may be cavitation. Consider

changing the installation position to reduce drift (refer to

"Installation Precautions") or changing the flow rate.

①

②

④

③

⑤

⑥

⑧

⑦

Example) Bolt tightening

sequence

[Fig.-12]

Piping bolt

[Fig.-13]

Piping bolt tightening procedures

11

(4) Insert the check valve so that its flange faces are not

damaged, as shown. Note that if the check valve is

pushed in between the pipes flanges forcibly at

installation, the flange faces will be damaged, which

will cause leakage. Be careful that the fluid flow

direction matches the (casting) arrow direction on the

check valve body. [Fig.-12]

(5) When the check valve is inserted completely, insert

piping gaskets and then insert the piping

bolts.[Fig.-12]

*Suspend the check valve with a crane, etc. when

performing the work. When lifting the check valve, lift

the eyebolt (nominal diameter: 150 mm or more)

using a nylon sling.

(6) Install all the piping bolts, and remove the jack bolts.

Then tighten the piping bolts with even force to avoid

uneven tightening according to the following

procedures until the piping flange face makes

contact with the side of the body. If you use an

impact wrench, be sure to read "Using an impact

wrench" in "2. Precautions at installation" in this

manual.[Fig.-13]

If there is no appropriate tightening procedure in place in business establishments, or there

are no internal standards, tighten the bolts and nuts using the following procedures.

Bolts that have been tightened once may become loose due to compression of the gaskets when another bolt is

tightened. Be sure to perform retightening in (6) and (7) repeatedly until the bolts and nuts are tightened evenly.

(1) Clean the bolts and nuts and apply lubricant to them. (Do not use rusty or damaged bolts and nuts.)

(2) Tighten the bolts and nuts by hand in any desired order.

(3) Tighten the bolts and nuts in any desired order with approx. 20% of the specified tightening torque.

(4) Tighten the bolts and nuts, alternate diagonally (refer to the right figure) with approx. 70% of the

specified tightening torque.

(5) Tighten the bolts and nuts, alternate diagonally, with approx. 100% of the specified tightening torque.

(6) Tighten the bolts and nuts, alternate diagonally, with 100% of the specified tightening torque again.

(7) Tighten the bolts and nuts clockwise with 100% of the specified tightening torque.

Caution

Caution

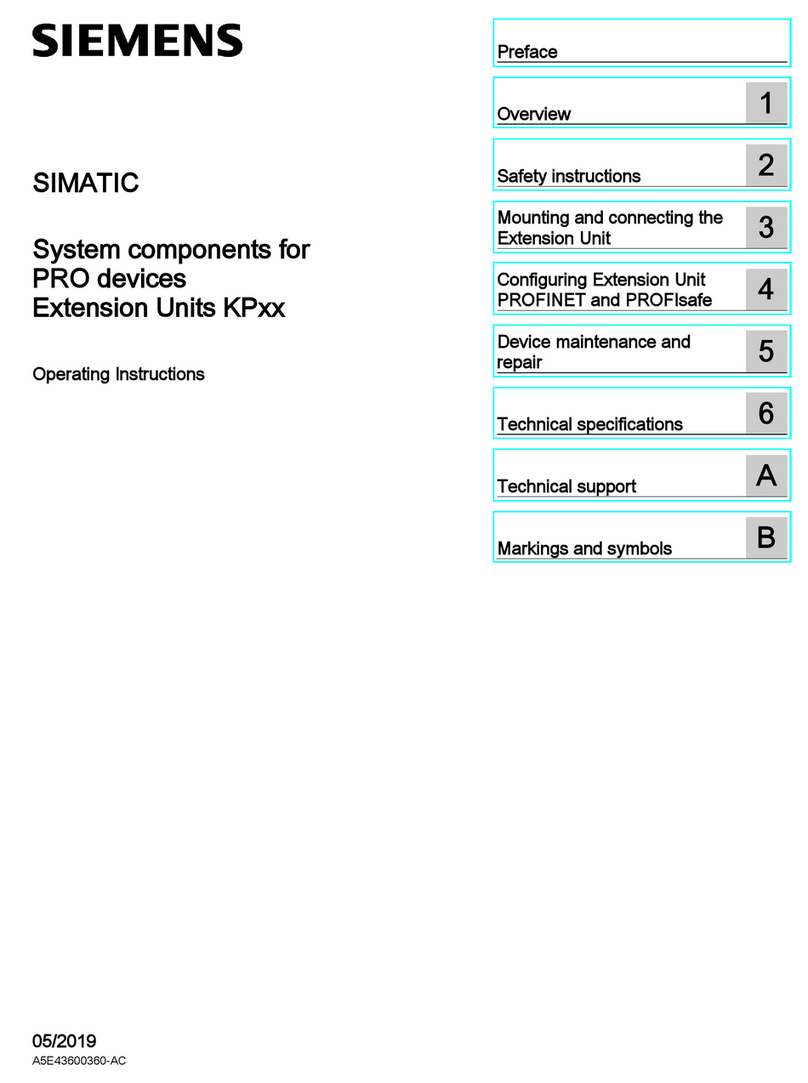

[Fig.-20]

[Fig.-21]

Be careful of

possible

spring rebound

Washer ⑨

Plate ②

Washer ⑨

Hinge pin④

Washer ⑨

Bearing ㉚

Bearing㉚

Bearing ㉚

Washer ⑧

Washer ⑧

14

(5) Pull out the hinge pin ④and the stop pin ⑤from the

side of the body while holding the spring ③by hand.

It should be noted that the spring ③will fly out if you

remove the pins without holding the spring ③by hand.

Next, remove the spring ③by slowly raising the hand

holding the spring ③.[Fig.-20]

(6) Remove the plate ②. [Fig.-21]

*Note that scratches on the protrusion of the rubber

seat and on the seat contact face of the plate can

cause seat leakage.

(7) Remove 2 washers ⑧, 4 washers ⑨, and 4 bearings

㉚from the plate hole. [Fig.-21]

(8) For disassembly of the bypass valve parts, loosen the

handle ⑫a few turns and remove the lock bolt ⑬

. Then the bolt ⑬and the spindle ⑳can be removed.

[Fig.-19]

Disassembly/Assembly

Procedures

Disassembly procedures

Hexagon nut ⑦

Seal washer

㉖

[Fig.-16]

[Fig.-17]

[Fig.-18]

Stop pin ⑤

Stop pin ⑤

Hinge pin ④

Body

①

Spring ③

Stop pin ⑤

Hinge pin ④

Nominal Diameter Nut Size

mm mminch

50

65

80

100

125

150

200

250

300

350

400

2

2 1/2

3

4

5

6

8

10

12

14

16

M6

M6

M8

M8

M8

M10

M12

M16

M16

M20

M20

[Table-2]

13

(1) Place the check valve on a horizontal place with its

secondary side (the side where the pin can be seen)

facing up. [Fig.-16]

(2) Remove 4 hexagon nuts ⑦from the side of the body

with a spanner. Remove the seal washers ㉖from the

hinge pin ④and the stop pin ⑤. [Fig.-16]

(3) Remove the stop pin ⑤(upper pin) from the side of the

body ①. [Fig.-17]

For products with a nominal diameter of 200 - 300 mm,

one end of two springs ③is held by the stop pin ⑤. Be

very careful of rebound of the spring when removing the

stop pin ⑤. [Fig.-18]

(4) Hold the spring ③lightly by hand (2 pieces for a

nominal diameter of 200 mm or more, and 1 piece for a

nominal diameter of 150 mm or less). Then insert the

previously removed stop pin ⑤into the hole in the side

of the body and push out the hinge pin ④until half of

the hinge pin ④protrudes.[Fig.-19]

Nominal Diameter: 200 - 300 mm

[Fig.-20]

[Fig.-21]

Be careful of

possible

spring rebound

Washer ⑨

Plate ②

Washer ⑨

Hinge pin④

Washer ⑨

Bearing ㉚

Bearing㉚

Bearing ㉚

Washer ⑧

Washer ⑧

14

(5) Pull out the hinge pin ④and the stop pin ⑤from the

side of the body while holding the spring ③by hand.

It should be noted that the spring ③will fly out if you

remove the pins without holding the spring ③by hand.

Next, remove the spring ③by slowly raising the hand

holding the spring ③.[Fig.-20]

(6) Remove the plate ②. [Fig.-21]

*Note that scratches on the protrusion of the rubber

seat and on the seat contact face of the plate can

cause seat leakage.

(7) Remove 2 washers ⑧, 4 washers ⑨, and 4 bearings

㉚from the plate hole. [Fig.-21]

(8) For disassembly of the bypass valve parts, loosen the

handle ⑫a few turns and remove the lock bolt ⑬

. Then the bolt ⑬and the spindle ⑳can be removed.

[Fig.-19]

Disassembly/Assembly

Procedures

Disassembly procedures

Hexagon nut ⑦

Seal washer

㉖

[Fig.-16]

[Fig.-17]

[Fig.-18]

Stop pin ⑤

Stop pin ⑤

Hinge pin ④

Body

①

Spring ③

Stop pin ⑤

Hinge pin ④

Nominal Diameter Nut Size

mm mminch

50

65

80

100

125

150

200

250

300

350

400

2

2 1/2

3

4

5

6

8

10

12

14

16

M6

M6

M8

M8

M8

M10

M12

M16

M16

M20

M20

[Table-2]

13

(1) Place the check valve on a horizontal place with its

secondary side (the side where the pin can be seen)

facing up. [Fig.-16]

(2) Remove 4 hexagon nuts ⑦from the side of the body

with a spanner. Remove the seal washers ㉖from the

hinge pin ④and the stop pin ⑤. [Fig.-16]

(3) Remove the stop pin ⑤(upper pin) from the side of the

body ①. [Fig.-17]

For products with a nominal diameter of 200 - 300 mm,

one end of two springs ③is held by the stop pin ⑤. Be

very careful of rebound of the spring when removing the

stop pin ⑤. [Fig.-18]

(4) Hold the spring ③lightly by hand (2 pieces for a

nominal diameter of 200 mm or more, and 1 piece for a

nominal diameter of 150 mm or less). Then insert the

previously removed stop pin ⑤into the hole in the side

of the body and push out the hinge pin ④until half of

the hinge pin ④protrudes.[Fig.-19]

Nominal Diameter: 200 - 300 mm

[Fig.-25]

[Fig.-26] [Fig.-27]

[Fig.-28] [Fig.-29]

Washer ⑨

Washer ⑨

Hinge pin ④

Spring ③

Hinge pin ④

Plate ②

Spring ③

Hinge pin ④

Stop pin ⑤

Stop pin ⑤

Washer ⑧

Stop pin ⑤

16

(7) Insert the washers ⑨(both sides are processed to be

flat) between the plates and the inside of the plate,

and pass the hinge pin ④through the fluororesin

washers ⑨. [Fig.-25]

(8) Place the spring ③in the center of the plate ②, and

pass the hinge pin ④through the spring ③. Be

careful of the installation orientation of the spring ③.

(There are 2 springs, for 350 and 400 mm.) [Fig.-26]

(9) Insert the stop pin ⑤into the lower hole on the back

side of the body until the stop pin ⑤goes through

three washers ⑧and ⑨which are attached to the

plate.

(10) While holding the spring ③lightly by hand from

above, press in the hinge pin ④to push out the stop

pin ⑤. [Fig.-28]

(11) Insert the stop pin ⑤into the upper hole on the side

of the body and through the equivalent hole on the

other side of the casing. [Fig.-29]

Assembly procedures

Hinge pin ④

Plate

Body ①

②

[Fig.-22]

[Fig.-24]

[Fig.-23]

Washer ⑧

Washer ⑨

Plate ②

Washer ⑨

Washer ⑨

Bearing ㉚

Bearing ㉚

Bearing ㉚

Washer ⑧

Washer ⑧

15

(1) Before reassembly, clean the parts thoroughly with a

suitable cleaning fluid (alcohol, neutral detergent, etc.)

and ensure that there is no damage or abnormality. In

particular, conduct a thorough check on the projection

of the seat and the seat contact face of the plate. If any

damage or abnormality is found in any part,

replacement is recommended.[Fig.-22]

When cleaning, be careful to avoid organic solvent

adhering to the rubber seat. Organic solvent may cause

deterioration of rubber or degradation of the rubber’s

adhesive strength.

If the rubber seat material is EPDM, do not allow oil or

grease to make contact with the rubber. Adherence of

oil may cause swelling of the seat ring, resulting in

damage.

(2) Do not reuse parts which are not intended to be

reusable. For washers ⑧and ⑨, bearing ㉚, seal

washer ㉖and O-ring ⑯if there has been deterioration

over time, even though the abrasion is minor, do not

reuse these components but replace them with new

parts. [Fig.-23] [Fig.-30]

(3) Place the body ①on a horizontal surface with the same

orientation as at disassembly. [Fig.-24]

(4) Insert a bearing ㉚into each shaft hole of the plate ②.

[Fig.-23]

(5) Place 2 plates ②into the original positions while

aligning them to the center beam of the body. [Fig.-23]

(6) Insert the washer ⑧(spherical side should be body

side) between the body ①and the plate ②, and pass

the hinge pin ④through the first plate hole from the

lower hole on the side of the body. [Fig.-24]

[Fig.-25]

[Fig.-26] [Fig.-27]

[Fig.-28] [Fig.-29]

Washer ⑨

Washer ⑨

Hinge pin ④

Spring ③

Hinge pin ④

Plate ②

Spring ③

Hinge pin ④

Stop pin ⑤

Stop pin ⑤

Washer ⑧

Stop pin ⑤

16

(7) Insert the washers ⑨(both sides are processed to be

flat) between the plates and the inside of the plate,

and pass the hinge pin ④through the fluororesin

washers ⑨. [Fig.-25]

(8) Place the spring ③in the center of the plate ②, and

pass the hinge pin ④through the spring ③. Be

careful of the installation orientation of the spring ③.

(There are 2 springs, for 350 and 400 mm.) [Fig.-26]

(9) Insert the stop pin ⑤into the lower hole on the back

side of the body until the stop pin ⑤goes through

three washers ⑧and ⑨which are attached to the

plate.

(10) While holding the spring ③lightly by hand from

above, press in the hinge pin ④to push out the stop

pin ⑤. [Fig.-28]

(11) Insert the stop pin ⑤into the upper hole on the side

of the body and through the equivalent hole on the

other side of the casing. [Fig.-29]

Assembly procedures

Hinge pin ④

Plate

Body ①

②

[Fig.-22]

[Fig.-24]

[Fig.-23]

Washer ⑧

Washer ⑨

Plate ②

Washer ⑨

Washer ⑨

Bearing ㉚

Bearing ㉚

Bearing ㉚

Washer ⑧

Washer ⑧

15

(1) Before reassembly, clean the parts thoroughly with a

suitable cleaning fluid (alcohol, neutral detergent, etc.)

and ensure that there is no damage or abnormality. In

particular, conduct a thorough check on the projection

of the seat and the seat contact face of the plate. If any