Tonghui Electronics TH2810D User manual

OPERATION MANUAL

TH2810D LCR Meter

TONGHUI (CHANGZHOU) Electronic Co., Ltd.

Second Edition

www.tonghui.com.cn

1-2

CHAPTER 1 PREPARATION....................................................................................................................1-8

1.1 UNPACKING AND INSPECTION.................................................................................................................1-8

1.2 POWER REQUIREMENTS .........................................................................................................................1-8

1.3 LINE VOLTAGE AND FUSE SELECTION ...................................................................................................1-8

1.4 OPERATION ENVIRONMENT ....................................................................................................................1-9

1.5 USE TEST FIXTURE .................................................................................................................................1-9

1.6 WARM-UP AND CONTINUOUS WORKING TIME.....................................................................................1-10

1.7 OTHER FEATURES .................................................................................................................................1-10

CHAPTER 2 PANEL DESCRIPTION..................................................................................................... 2-11

2.1 ATOUR OF THE FRONT PANEL ............................................................................................................. 2-11

2.2 ATOUR OF THE REAR PANEL ...............................................................................................................2-13

2.3 DISPLAY AREA DEFINITION...................................................................................................................2-14

CHAPTER 3 OPERATION.......................................................................................................................3-17

3.1 POWER ON............................................................................................................................................3-17

3.2 THE PRIMARY FUNCTION OPERATION .................................................................................................3-17

3.2.1 MEASUREMENT FUNCTION ................................................................................................................3-17

3.2.2 TEST FREQUENCY.............................................................................................................................. 3-18

3.2.3 TEST SIGNAL LEVEL...........................................................................................................................3-19

3.2.4 PRIMARY PARAMETER DISPLAY MODE .............................................................................................3-19

3.2.5 MEASUREMENT SPEED......................................................................................................................3-20

3.2.6 MEASUREMENT RANGE .....................................................................................................................3-20

3.3 THE SECONDARY FUNCTION OPERATION............................................................................................3-23

3.3.1 CORRECTION......................................................................................................................................3-23

3.3.2 COMPARATOR FUNCTION...................................................................................................................3-25

3.3.2.1 Comparator Function ON/OFF ....................................................................................................... 3-25

3.3.2.2 Input the Low/High Limits..............................................................................................................3-25

3.3.3 SIGNAL SOURCE OUTPUT IMPEDANCE .............................................................................................3-27

3.3.4 BEEP FUNCTION.................................................................................................................................3-28

3.3.5 MEASUREMENT MODE .......................................................................................................................3-28

3.3.6 EQUIVALENT CIRCUIT.........................................................................................................................3-29

3.3.6.1 Series and Parallel Circuit Setup.....................................................................................................3-29

3.3.6.2 How to Select the Measurement Circuit Mode ...............................................................................3-29

3.3.7 RS232 SERIAL INTERFACE................................................................................................................3-30

CHAPTER 4 HANDLER INTERFACE .................................................................................................. 4-31

4.1 INTRODUCTION ......................................................................................................................................4-31

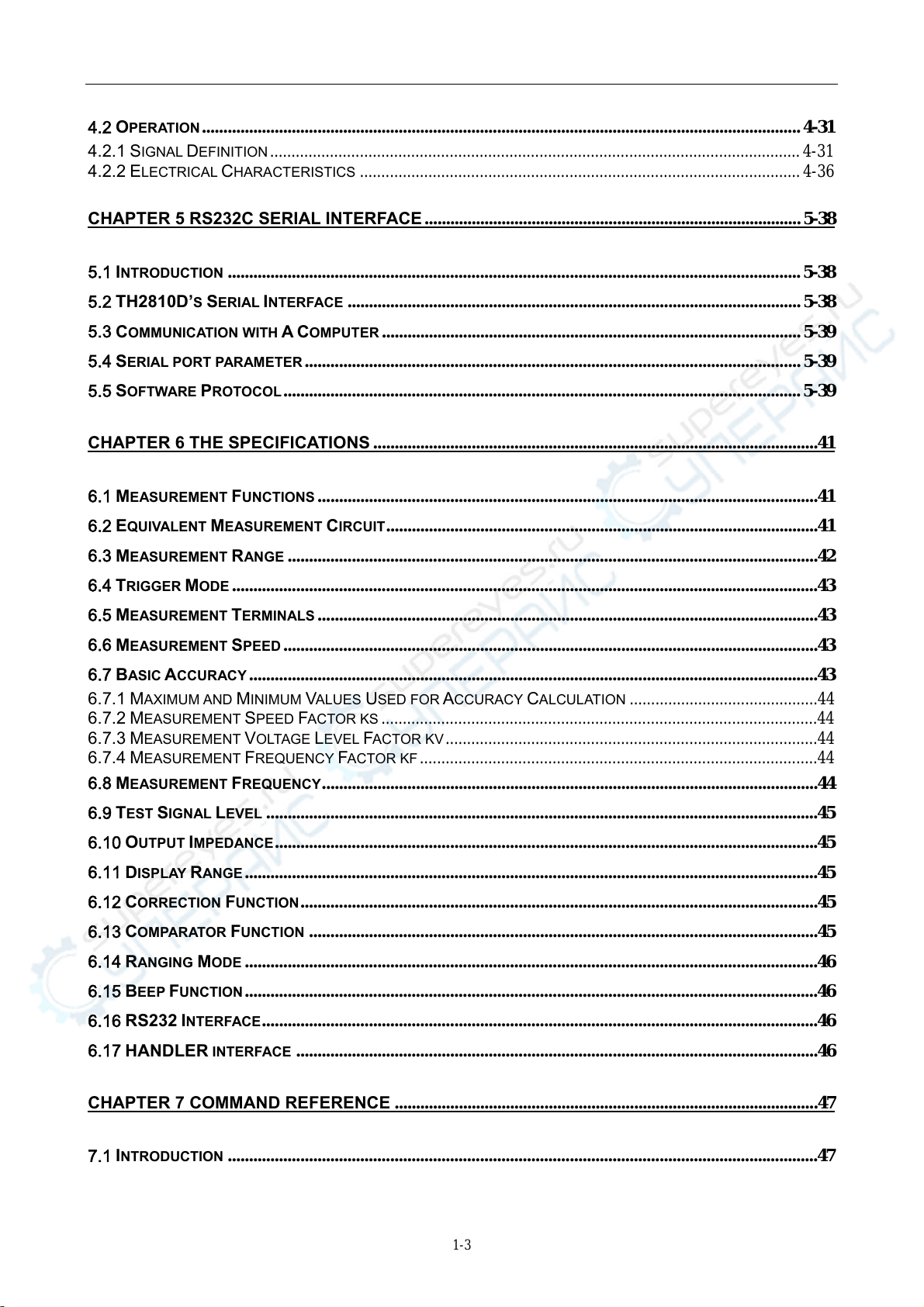

1-3

4.2 OPERATION............................................................................................................................................4-31

4.2.1 SIGNAL DEFINITION ............................................................................................................................4-31

4.2.2 ELECTRICAL CHARACTERISTICS ....................................................................................................... 4-36

CHAPTER 5 RS232C SERIAL INTERFACE........................................................................................5-38

5.1 INTRODUCTION ......................................................................................................................................5-38

5.2 TH2810D’S SERIAL INTERFACE ..........................................................................................................5-38

5.3 COMMUNICATION WITH ACOMPUTER ..................................................................................................5-39

5.4 SERIAL PORT PARAMETER....................................................................................................................5-39

5.5 SOFTWARE PROTOCOL.........................................................................................................................5-39

CHAPTER 6 THE SPECIFICATIONS ........................................................................................................41

6.1 MEASUREMENT FUNCTIONS .....................................................................................................................41

6.2 EQUIVALENT MEASUREMENT CIRCUIT.....................................................................................................41

6.3 MEASUREMENT RANGE ............................................................................................................................42

6.4 TRIGGER MODE .........................................................................................................................................43

6.5 MEASUREMENT TERMINALS .....................................................................................................................43

6.6 MEASUREMENT SPEED .............................................................................................................................43

6.7 BASIC ACCURACY .....................................................................................................................................43

6.7.1 MAXIMUM AND MINIMUM VALUES USED FOR ACCURACY CALCULATION ............................................44

6.7.2 MEASUREMENT SPEED FACTOR KS ......................................................................................................44

6.7.3 MEASUREMENT VOLTAGE LEVEL FACTOR KV .......................................................................................44

6.7.4 MEASUREMENT FREQUENCY FACTOR KF .............................................................................................44

6.8 MEASUREMENT FREQUENCY....................................................................................................................44

6.9 TEST SIGNAL LEVEL .................................................................................................................................45

6.10 OUTPUT IMPEDANCE...............................................................................................................................45

6.11 DISPLAY RANGE ......................................................................................................................................45

6.12 CORRECTION FUNCTION.........................................................................................................................45

6.13 COMPARATOR FUNCTION .......................................................................................................................45

6.14 RANGING MODE ......................................................................................................................................46

6.15 BEEP FUNCTION......................................................................................................................................46

6.16 RS232 INTERFACE..................................................................................................................................46

6.17 HANDLER INTERFACE ..........................................................................................................................46

CHAPTER 7 COMMAND REFERENCE ...................................................................................................47

7.1 INTRODUCTION ..........................................................................................................................................47

1-4

7.2 NOTATION CONVENTIONS AND DEFINITIONS ...........................................................................................47

7.3 COMMAND STRUCTURE ............................................................................................................................47

7.4 COMMAND ABBREVIATIONS......................................................................................................................49

7.5 HEADER AND PARAMETERS .....................................................................................................................49

7.6 COMMAND DESCRIPTION..........................................................................................................................50

7.6.1 SPEED COMMAND ................................................................................................................................50

7.6.2 DISPLAY COMMAND ..............................................................................................................................50

7.6.3 FREQUENCY COMMAND .......................................................................................................................51

7.6.4 PARAMETER COMMAND........................................................................................................................51

7.6.5 LEVEL COMMAND ..................................................................................................................................52

7.6.6 SRESISTOR COMMAND.........................................................................................................................53

7.6.7 TRIGGER COMMAND .............................................................................................................................53

7.6.8 CORRECTION COMMAND......................................................................................................................54

7.6.9 COMPARATOR COMMAND.....................................................................................................................54

7.6.10 EQUIVALENT COMMAND .....................................................................................................................55

7.6.11 RANGE COMMAND ..............................................................................................................................55

7.6.12 ALARM COMMAND ..............................................................................................................................56

7.6.13 LIMIT SUBSYSTEM ...............................................................................................................................57

7.6.14 FETCH?QUERY ..................................................................................................................................58

1-5

Manual Print History

The manual print history shown below lists all the printing dates and editions. The printing

date changes when a new edition is released. The latest editions can be downloaded from

our website.

March 2006 ………………………………… First Edition

December 2007 …………………………… Second Edition

1-6

Warranty

This Tonghui instrument product is warranted against defects in material and workmanship

for a period of two years from the date of shipment. Other items such as test fixtures, test

cables are warranted for 90 days from the date of shipment. During the warranty period, we

will, at our option, either repair or replace products which prove to be defective.

For warranty service or repair, this product must be returned to a service facility designated

by Tonghui. Purchaser shall prepay shipping charges to Tonghui and Tonghui shall pay for

the return of the product to Buyer. However, Buyer shall pay all shipping charges, duties,

taxes, and any other charges for products returned to Tonghui from another country.

Limitation of Warranty

This warranty does not apply to defects resulting from improper or inadequate maintenance

and care by Buyer, Buyer-supplied software or interfacing, unauthorized modification or

misuse, operation outside of the environmental specifications for the product, or improper

site preparation or maintenance.

No other warranty is expressed or implied. Tonghui specially disclaims the implied

warranties of merchantability and fitness for a particular use.

Tonghui’s responsibility to repair or replace defective products is the sole and exclusive

remedy provided to the customer for breach of this warranty. Tonghui shall not be liable for

any direct, indirect, special, incidental, or consequential damages, whether based on

contract, tort, or any other legal theory.

1-7

Safety Precautions

The following safety precautions must be observed to avoid injury and prevent damage

to this product or any products connected to it. To avoid potential hazards, read the

operating information carefully before using the product and use this product only as

specified.

NOTE: This product complies with INSTALLATION CATEGORY I as well as

POLLUTION DEGREE 2. This product is an INDOOR USE product.

zGround the Instrument

Before operating the instrument, make sure the instrument chassis is grounded with the

3-pole power cable.

zDon’t operate in an explosive atmosphere

To prevent explosion or file, don’t operate the instrument in the presence of

inflammable gases or fumes.

zUse the proper fuse

Replace the broken fuse with the same type and rating for continuous protection

against fire hazard.

zKeep away from live circuits

Don’t remove the instrument covers when operating the instrument. Component

replacement and internal adjustment can only be done by qualified personnel. Don’t

replace components with the power cable connected. Dangerous voltage may remain

even after the power cable has been disconnected. Always remove the power cable

from the instrument and discharge circuits before touching them.

1-8

Chapter 1 Preparation

This chapter provides the information necessary for performing an incoming inspection and

setting up the instrument before operation.

1.1 Unpacking and Inspection

Thank you for purchasing and using our product. Inspect the shipping container for damage.

If the shipping container or cushioning material is damaged, it should be kept until the

contents of the shipment have been checked for completeness and the TH2810D has been

checked mechanically and electrically. The contents of the shipment should be as listed in

the packing list. If the contents are incomplete, if there is mechanical damage or defect, if

the instrument does not work normally, notify our company or our local representative.

Keep the shipping container and packing material for future use such as returning for

re-calibration or service.

1.2 Power Requirements

(1) Voltage: 198 to 242 Vac, or 99 to 121Vac

(2) Frequency: 47.5 to 63 Hz

(3) Power: 20 VA maximum

(4) In accordance with internal safety standards, this instrument is equipped with a three-

wire power cable. When connected to an appropriate ac power outlet, this cable

grounds the instrument frame.

(5) The instrument is carefully designed in order to reduce the disturbance induced by AC

power supply, however, low noise environment is recommended. Sometimes a power

source filter is needed.

Warning: For protection from electrical shock, the power cable ground must not be

defeated. The power plug must be plugged into an outlet that provides a

protective earth ground connection.

1.3 Line Voltage and Fuse Selection

Figure 1-1 illustrates the line voltage selection switch on the instrument’s rear panel. Before

connecting the instrument to the power source, make sure that the correct fuse has been

installed and the Line Voltage Selection Switch is correctly set.

1-9

200V~ operation 110V~ operation

Figure 1-1 Line Voltage Selector

The instrument has been equipped with the 200 mA fuse before leaving factory. Use only

fuses with the required current rating and of the specified type as replacements. Do not use

a mended fuse or short-circuit the fuse-holder in order to by-pass a blown fuse. Find out

what caused the fuse to blow!

1.4 Operation Environment

(1) The Please do not operate the instrument in places where there is dusty, vibrant, under

direct sunlight, or where there is corrosive air.

(2) In order to maintain good measurement accuracy, the TH2810D must be operated

under the following environment conditions:

Temperature: 0°C ~ 40°C

Humidity: ≤75% RH at 40°C.

(3) The instrument is carefully designed in order to reduce the disturbance induced by AC

power supply, however, low noise environment is recommended. Sometimes a power

source filter is needed.

(4) Please store the instrument in the place where the temperature is between 5°C and

40°C, humidity is less than 85% RH. If the instrument will not be put in use for a time,

please have it properly packed with its original box or a similar box for storage.

(5) The instrument, especially the test leads, should be kept far away from strong

electromagnetic field to avoid interference with measuring precision.

1.5 Use Test Fixture

Original test fixture and test clip leads should be used in order to ensure correct and

accurate measuring results. At the same time, test fixture, test clip leads and pins of DUT

should be kept clean in order to connect well between DUT and test fixture. Test fixture and

test clip leads are connected to Hcur、Hpot、Lcur and Lpot 4 terminals on the front panel.

1-10

For DUT which has shield, please connect the shield to the ground terminal “┴” of the

instrument.

1.6 Warm-up and Continuous Working Time

Warm up the instrument for a minimum time of 15 minutes in order to ensure measuring

precision.

Continuous working time should be less than 16 hours.

1.7 Other features

(1) Power consumption:≤20VA

(2) Dimension(W*H*D):350mm*110mm*340mm

(3) Weight: about 3.5kg

2-11

Chapter 2 Panel Description

This chapter provides information including a tour of the front and rear panel and display

area definition, which will help you to quickly learn how to operate the TH2810D.

2.1 A Tour of the Front Panel

Figure 2-1 shows the brief description of each key on the TH2810D’s front panel.

CLEAR LIMITS BUZZER

RS-232

30/100

CALSER/PARCOMP

PARA LEVEL DISP SPEED

FREQ DOWN RANGE UP

SHIFT

ESC ▲ ENTER

▼

▼

▲

HCURHPOTLPOTLCUR

UNKNOWN

NG P1 P2 P3 AUX

TH2810D LCR Meter 100Hz 10kHz

~

Figure 2-1 Front panel Overview

(1) Brand and Model

Mark and model of instrument

(2) LCD

Display the measurement results and test conditions, etc.

(3) Comparator Indication

Display the comparator sorting results: NG, P1, P2, P3, and AUX.

(4) Power on/off

Power on/off switch. In the “ON” position all operating voltages are applied to the

instrument. In the “OFF” position NO operating voltages are applied to the instrument.

(5) Keys

a) PARA key:

The primary function is the setup key of test parameter.

The secondary function is the zero correction key CLEAR.

b) FREQ key:

The primary function is the setup key of test frequency.

The secondary function is the comparison function key COMP.

2-12

c) LEVEL key:

The primary function is the setup key of test voltage level.

Under input status (“ENTRY”is lighted), it is the exit key [ESC].

The secondary function is the sorting limits setup key LIMITS.

d) DISP key:

The primary function is the setup key of main parameter display mode.

Under input status (“ENTRY”is lighted),it is the up cursor key or increase key

[▲].

The secondary function is signal source output impedance setup key 30/100.

e) SPEED key:

The primary function is the setup key of measurement speed.

Under input status(“ENTRY” is lighted),it is the [ENTER] key.

The second function is buzzer’s beep status setup key BUZZER.

f) SHIFT key:

The secondary function enable key.

g) TRIGGER key:

The primary function is the trigger key.

The secondary function is continuous and single measurement switch key

CONT/TRIG.

h) DOWN key:

The primary function is the measurement range selection key.

Under input status (“ENTRY” is lighted), it is the left cursor key [

▲

].

The secondary function is the equivalent circuit setup key SER/PAR.

i) RANGE key:

The primary function is the setup key of range HOLD or AUTO.

Under input status (“ENTRY” is lighted), it is the down cursor or decrease key [▼].

The secondary function is the RS232 interface on/off key RS232.

j) UP key:

The primary function is the measurement range selection key.

Under input status (“ENTRY” is lighted), it is the right cursor key [

▼

].

The secondary function is the calibration function key CAL.

2-13

(6) UNKNOWN Terminals

There are 4 unknown terminals used to connect a 4-terminal test fixture or test leads for

measuring the device under test.

HCUR:High current

HPOT:High potential

LPOT:Low potential

LCUR:Low current

(7) Frame Terminal

This is the frame terminal which is tied to the instrument’s chassis and which can be

used for measurements that require guarding.

2.2 A Tour of the Rear Panel

Figure 2-2 shows a brief description of the TH2810D’s rear panel.

!

RS-232C HANDLER

~LINE VOLTAGE FUSE

110V/60Hz

220V/50Hz

250V T200mAL

250V T200mAL

19 36

118

96

51

CAUTION:

2.FOR

CONTINUED

PROTECTION

AGAINST

FIRE

HAZARD,REPLACE

ONLY

WITH

THE

SAME

TYPE

AND

RATING

O F

FUSE

A S

SPECIFIED

FOR

THE

LINE

VOLTAGE

BEING

UTILIZED.

1.DO NOT CONNECT A DC CURRENT/VOLTAGE SOURCE OR A

CHARGED

CAPACITOR

T O

THE

UNKNOWN

TERMINALS,

DOING

S O

WILL

DAMAGE

THE

INSTRUMENT

.

WARNING:NO OPERATOR SERVICEABLE PARTS INSIDE,

REFER SERVICING TO QUALIFIED PERSONNEL.

S/N: W1-46-****

Figure 2-2 Rear panel Overview

(1) Name Plate

Name plate is used to provide the information of date, model, lot number and

manufacturer etc.

(2) Line Input Receptacle

AC power cord receptacle.

(3) Fuse Holder and Line Voltage Selector

Fuse holder and Line voltage selector for TH2810D line input.

(4) RS232C Interface

This is the RS232C interface connector used when operating through the serial

interface.

(5) Hand

l

This i

s

handl

e

proce

s

throu

g

2.3

Di

s

Figure 2-

3

(1) The

S

“SHIF

T

“SHIF

T

(2) Displ

a

Indic

a

“DIR”

“%⊿”

“A

B

⊿

(3) Com

p

“CO

M

“CO

M

(4) Alar

m

“”is

“”is

(5) Com

p

“NG”

i

“P1” i

s

“P2” i

s

l

er Interfa

c

s

the H

AN

e

r to full

y

s

sing. TH

2

g

h the HA

N

s

play Are

a

3

shows t

h

S

econdar

y

T

” is on: T

h

T

” is off: T

h

a

y Mode

o

a

te the cur

r

is on: Dir

e

is on: Pe

r

B

S” is on:

A

p

arator Fu

M

P” is on:

T

M

P” is off:

T

m

Indicati

o

on:

A

larm

off:

A

larm

p

arison R

e

i

s on: No

g

s

on: Bin 1

s

on: Bin 2

c

e

N

DLER in

t

y

automa

t

2

810D rec

e

N

DLER int

e

a

Definitio

n

h

e display

a

F

y

Function

h

e current

h

e current

o

f The Pri

m

r

ent prima

r

e

ct reading

r

cent devi

a

A

bsolute d

e

nction In

d

T

he comp

a

T

he compa

o

n

buzzer is

buzzer is

e

sults Ind

i

g

ood bin

.

.

t

erface c

o

t

e compo

e

ives the

T

e

rface.

n

a

rea defini

F

igure 2-3

D

Indicatio

key functi

o

key functi

o

m

ary Par

a

r

y parame

t

display m

a

tion displ

a

e

viation di

s

d

ication

a

rator func

t

rator func

t

turned on.

turned off.

i

cation

2-14

o

nnector u

nent test

i

T

rigger si

g

tion of the

D

isplay Ar

e

n

o

n is the s

e

o

n is the p

r

a

meter In

d

t

er display

ode.

a

y mode.

s

play mod

e

t

ion is turn

e

t

ion is turn

e

sed when

i

ng, sorti

n

g

nal and

o

TH2810D

e

a Definitio

n

e

condary

f

r

imary fun

c

d

ication

mode.

e

.

e

d on.

e

d off.

operatin

g

n

g, and

q

o

utputs th

e

LCD scre

e

n

f

unction.

c

tion.

g

with a

c

q

uality co

e

compari

s

e

n.

c

omponen

t

n

trol dat

a

s

on result

s

t

a

s

2-15

“P3” is on: Bin 3.

“AUX” is on: Auxiliary bin.

(6) Unit of The primary Parameter Indication

Indicate the current unit of measurement result of the primary parameter.

Unit of inductance:μH, mH, H.

Unit of capacitance:pF, nF, μF, mF.

Unit of resistance/impedance:Ω, kΩ, MΩ.

(7) Signal Source Output Impedance Indication

“30Ω” is on:Signal source output impedance is 30 Ω.

“100Ω” is on:Signal source output impedance is 100 Ω.

(8) Calibration Measurement Indication

“CAL” is on:The instrument is under calibration measuring status.

“CAL” is off:The instrument is under normal measuring status.

(9) Handler Interface indication

“Handler” is on: Handler interface is on, signal output is enabled.

“Handler” is off: Handler interface is off, signal output is disabled.

(10) RS232 Interface Indication

“RS232” is on:RS232 interface is enabled.

“RS232” is off:RS232 interface is disabled.

(11) The primary Parameter Indication

Indicate the current measuring primary parameter user selected.

“L:” is on:Inductance is measured and displayed.

“C:” is on:Capacitance is measured and displayed.

“R:” is on:Resistance is measured and displayed.

“Z:” is on:Impedance is measured and displayed.

(12) Test Signal Frequency Indication

“100 Hz” is on:The current test signal frequency is 100 Hz.

“120 Hz” is on:The current test signal frequency is 120 Hz.

“1 kHz” is on:The current test signal frequency is 1 kHz.

“10 kHz” is on:The current test signal frequency is 10 kHz.

(13) Test Signal Level Indication

“0.1 V” is on:The current test signal voltage is 0.1 V.

“0.3 V” is on:The current test signal voltage is 0.3 V.

“1.0 V” is on:The current test signal voltage is 1.0 V.

(14) The Primary Parameter Display

2-16

Display the current measurement result of the primary parameter.

(15) Measurement Speed Indication

“FAST” is on: Fast measurement speed

“MED” is on: Medium measurement speed

“SLOW” is on: Slow measurement speed

(16) The Secondary Parameter Indication

Indicate the current measuring secondary parameter user selected.

(17) Measurement Mode Indication

“CONT” is on: Continuous measurement mode

“TRIG” is on: Single measurement mode

(18) Equivalent Circuit Mode Indication

“SER” is on: Series equivalent circuit mode.

“PAR” is on: Parallel equivalent circuit mode.

(19) Range Indication

Indicate the current ranging mode and the current range number.

“AUTO” is on:Range AUTO

“AUTO” is off:Range HOLD

(20) The Secondary Parameter Display

Display the current measurement result of the secondary parameter.

3-17

Chapter 3 Operation

3.1 Power On

1) Press power switch to turn on the instrument.

2) Version number of the instrument is first displayed on the LCD screen.

3) The instrument enters the measurement status after a short delay. Figure 3.1

shows the information displayed in measurement status. It maybe different with the

actual display due to different measurement setup.

Figure 3.1 LCD Display in Measurement Status

Description of Measuring LCD Display:

①Primary parameter: C

②Display mode: DIR

③Measuring frequency: 1 kHz

④Primary parameter measurement result display

⑤Measurement speed: FAST

⑥Primary parameter unit: pF

⑦Continuous, serial equivalent circuit and range AUTO (0)

⑧Secondary parameter: D (dissipation factor)

⑨Signal source output impedance: 100Ω

⑩Secondary parameter measurement result display

3.2 The Primary Function Operation

3.2.1 Measurement Function

TH2810D measures two components of the complex impedance parameters at the same

time in a measurement cycle. The primary and secondary measurement parameters are

listed as follows.

Primary Parameter

L: Inductance

C: Capacitance

R: Resistance

|Z|: Absolute value of impedance

3-18

Secondary Parameter

D: Dissipation factor

Q: Quality factor

|Z| is the absolute value of impedance, so it is always a positive value; While L/ C/ R maybe

a positive value or sometimes a negative value.

When measurement function is C-D and the primary parameter measurement result is

negative, this means the component under test is probably an inductor.

When measurement function is L-Q and the primary parameter measurement result is

negative, this means the component under test is probably a capacitor.

When measurement function is R-Q and the measurement result of resistor is negative, this

is due to over zero correction, please perform open and short correction correctly.

TH2810D provides 4 combinations of primary and secondary parameters:

L-Q

C-D

R-Q

Z-Q

Perform the following steps to set the measurement function.

1. Assume that current measurement function is L-Q. Primary parameter indication is “L:”,

secondary parameter indication is “Q:”.

2. Press PARA key, measurement function is changed to C-D. Primary parameter

indication is “C:”, secondary parameter indication is “D:”.

3. Press PARA key, measurement function is changed to R-Q. Primary parameter

indication is “R:”, secondary parameter indication is “Q:”.

4. Press PARA key, measurement function is changed to Z-Q. Primary parameter

indication is “Z:”, secondary parameter indication is “Q:”.

5. Keep on pressing PARA key, until the measurement function required is indicated.

3.2.2 Test Frequency

TH2810D provides 4 typical frequency points: 100 Hz, 120 Hz, 1 kHz and 10 kHz. The

current test frequency is displayed on the bottom area of LCD.

Perform the following steps to set the test frequency.

1. Assume the current test frequency of the instrument is 100Hz. “100Hz” is indicated on

the bottom of LCD.

2. Press FREQ key, test frequency is changed to 120 Hz, and “120Hz” is indicated on the

bottom of LCD.

3. Press FREQ key, test frequency is changed to 1 kHz, and “1kHz” is indicated on the

bottom of LCD.

4. Press FREQ key, test frequency is changed to 10 kHz, and “10kHz” is indicated on the

bottom of LCD.

3-19

5. Press FREQ key, test frequency is changed back to 100Hz, and “100Hz” is indicated

on the bottom of LCD.

6. Keep on pressing FREQ key, until the test frequency required is indicated on the

bottom of LCD.

3.2.3 Test Signal Level

TH2810D provides 3 kinds of test signal voltage levels: 0.1VRMS, 0.3 VRMS and 1.0 VRMS.

Perform the following steps to set the test signal level.

1. Assume the current test signal level 1.0V, and “1.0V” indicated on the bottom of LCD.

2. Press LEVEL key, test signal level is changed to 0.1V, and “0.1V” is indicated on the

bottom of LCD.

3. Press LEVEL key, test signal level is changed to 0.3V, and “0.3V” is indicated on the

bottom of LCD.

4. Press LEVEL key, test signal level is changed back to 1.0V, and “1.0V” is indicated on

the bottom of LCD.

5. Keep on pressing LEVEL key, until the test signal level required is indicated on the

bottom of LCD.

3.2.4 Primary Parameter Display Mode

TH2810D provides three kinds of display modes for the primary parameter:

DIR: Direct reading display mode

ABS⊿: Absolute deviation display mode

%⊿: Percent deviation display mode

ABS⊿deviation display mode:

The difference between the measured value of the DUT and a previously stored

reference value are displayed. The formula used to calculate the deviation is as follows.

ABS = X⊿– Y

Where, X: The measured value of DUT

Y: The stored reference value

%⊿deviation display mode:

The difference between the measured value of the DUT and a previously stored

reference value are displayed as a percentage of the reference value. The formula

used to calculate the percent deviation is as follows.

% =⊿(X – Y)/ Y×100 [%]

Where, X: The measured value of the DUT

Y: The stored reference value

3-20

Perform the following steps to set the primary parameter display mode.

1. Assume the current display mode of the primary parameter is DIR, and “DIR” is

indicated on the top of LCD.

2. Press DISP key, the display mode is changed to ABS mode⊿, and “ ABS⊿” is indicated

on the top of LCD.

3. Press DISP key, the display mode is changed to % mode⊿, and “ %⊿” is indicated on

the top of LCD.

4. Press DISP key, the display mode is changed back to DIR mode again, and “DIR” is

indicated on the top of LCD.

5. Keep on pressing DISP key, until the display mode required is indicated on the top of

LCD

.

3.2.5 Measurement Speed

TH2810D provides 3 kinds of measurement speeds: FAST, MED and SLOW. Generally, a

slow measurement speed will result in more stable and accurate measurement results.

FAST: 10 meas/sec

MED: 4.0 meas/sec

SLOW: 2.5 meas/sec

Perform the following steps to set the measurement speed

1. Assume the current measurement speed is FAST, and “FAST” is indicated on the

bottom of LCD.

2. Press SPEED key, the measurement speed is changed to MED, and “MED” is indicated

on the bottom LCD.

3. Press SPEED key, the measurement speed is changed to SLOW, and “SLOW” is

indicated on the bottom of LCD.

4. Press SPEED key, the measurement speed is changed back to FAST, and “FAST” is

indicated on the bottom of LCD.

5. Keep on pressing SPEED key, until the measurement speed required is indicated on

the bottom of LCD.

3.2.6 Measurement Range

When signal source output impedance is 100Ω, TH2810D provides 5 measurement ranges:

30Ω, 100Ω, 1kΩ, 10kΩand 100kΩ. Table 3-1 shows the effective measuring range for each

measurement range.

When signal source output impedance is 30Ω, TH2810D provides 6 measurement ranges:

10Ω, 30Ω, 100Ω, 1 kΩ, 10 kΩand 100 kΩ. Table 3-2 shows the effective measuring range

for each measurement range.

Table of contents

Other Tonghui Electronics Measuring Instrument manuals