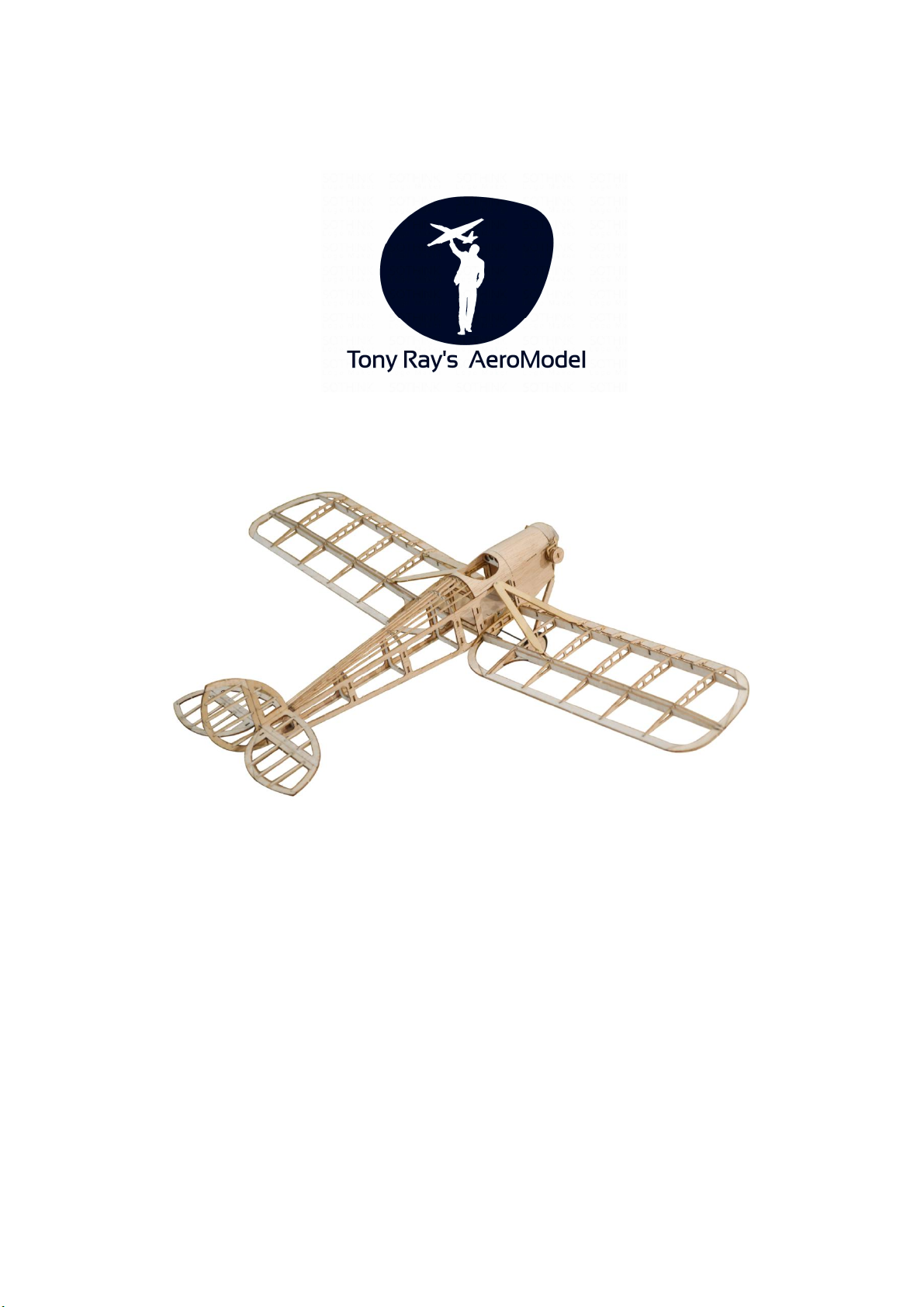

This is a small model but don’t underestimate its complexity. It is suggested that this

should not be a first build of a model aircraft. Some prior knowledge would be

helpful. However, I’ve tried to point out any pitfalls and ease the way to making a

successful model of the DH53 Humming Bird.

1. Before you start

oSome items you may find helpful

•A sharp, fine modelling knife or scalpel and additional blades

•Fine nosed pliers or strong tweezers

•A very fine cross head screw driver for miniature screws

•A couple of clear plastic containers for holding small parts. Keep your clear

plastic, takeaway food containers, they’re ideal.

•Pins and a small building board.

•In the main it is recommended to use thin cyano acrylate (super glue) for the

well-fitting joints and thinly spread aliphatic resin (yellow glue) for sheet to

sheet bonds

•A capillary tube extension for the cyano acrylate bottle to reach awkward glue

joints

•A small sanding board (make one by gluing pieces of 1/16 balsa, 3inch x

1. 5inch with grain crossed at 90deg. You can stick a different grade of

sandpaper to each side to make a really handy small sanding block)

•A flat building board which can take pins to build on. A5 size is adequate but

somewhat larger will give more room for tools etc.

oRead through this help sheet in conjunction with the pictorial build document.

oThere are 6 small circular magnets in the kit. To ease things later on, mark them all on

the same pole before you start. I found the easiest way was to put them all together and

mark one magnet face with a “sharpie” pen. Then remove that magnet and mark the

next one… and so on. This means that you can easily identify which way round they

need to be during the build.

oCheck each “Step” before you start it. Study the photos in the pictures

oIdentify all the parts for each step and remove only these from the relevant sheet by

cutting through the tabs in the laser cuts around each item. Use a plastic container to

hold them until needed in the step.

oAny offcuts containing other pieces (like the centre of a former etc.) can be stored in

another plastic container

oRemember, the parts are extremely small and leave very little room for recovery if you

get things wrong. However, the standard of the kit makes it less likely that you will make

that mistake in the first place.