Tool-Co BCA350 User manual

OPERATING MANUAL

BCA350

MASONRY SAW

MANUAL

CONTENT

Safety Precautions : Page 1

General Safety Rules : Page 2

Health Warnings : Page 2

Unpack & Inspection : Page 3

Technical Data : Page 3

Assembly & Operation : Page 4

Working Instructions : Page 5

Fault Diagnosis : Pages 6 - 7

Maintenance : Page 8

Exploded Diagram A : Page 9

Diagram A Parts List : Page 10 - 12

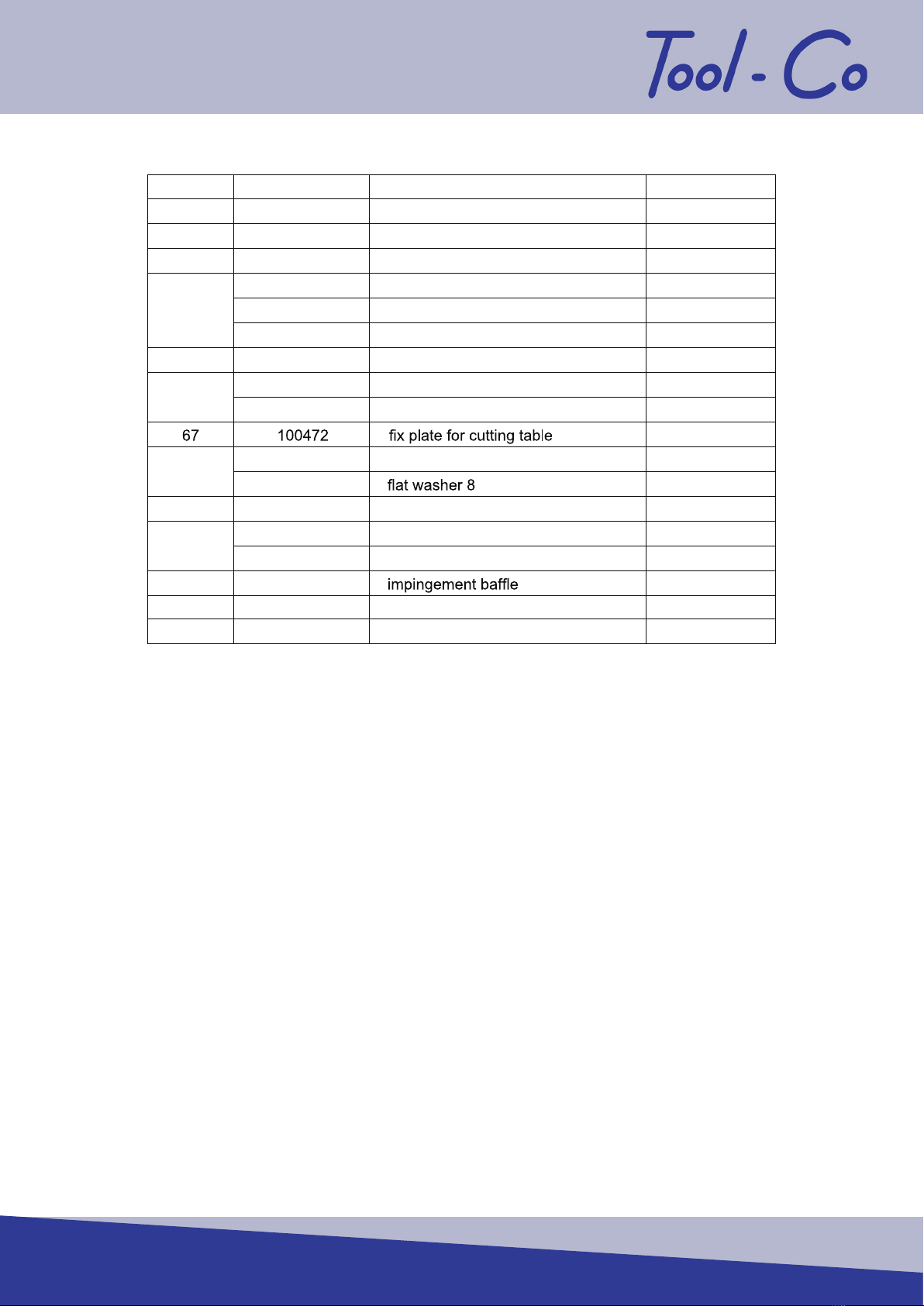

Exploded Diagram B : Page 13

Diagram B Parts List : Page 14

Recommended Blades : Page 15 - 16

BCA350

SAFETY PRECAUTIONS

The saw blade should be inspected daily for excessive wear, core cracks, and

arbor damage. Replace the blade if it shows any signs of damage.

• To mount the blade; clean the arbor and outer fl ange, then tighten the nut

to secure the blade.

• Keep limbs and fi ngers clear from the blade when it is in use.

• To reduce risk of electrical shock, it is recommended to use a Ground Fault

Circuit Interrupter (GFCI) switch

• Always have a qualifi ed technician service the machine.

We recommend that you use the following Personal Protective Equipment

(PPE) when operating the machine:

WEAR HEARING PROTECTION

WEAR EYE PROTECTION

WEAR A DUST MASK

USE A BLADE GUARD WHEN OPERATING THE SAW

Pg.1

MANUAL

Pg.2

GENERAL SAFETY RULES

• Never misuse the machine or work in an unsafe manner.

• Always wear the correct PPE when operating the machine. (See Page1)

• Always remain alert when the machine is in use. Operating the machine

while distracted may lead to serious injury.

• Before you start working, do a basic risk assessment of your environment.

• Take measures to ensure that the machine is in a safe and trouble-free

condition prior to usage. Use the machine only when all protective devices

(i.e. guards, noise absorbers, emergency shut-off devices) are located and

operating as intended.

• A visual check of the machine must be made at least once a shift to ensure

that visible damages or faults are recognized. Any changes (including

changes in the performance or behavior of the machine) must be reported

to the supervisor. If required, cut off the power and correct any faults

before using the machine.

• In the case of a malfunction, stop the machine immediately, then follow

the operating instruction steps and look for any damages or faults.

• Be sure to connect the plug to a properly grounded socket, and that there

is no damage to the cable to reduce the risk of electric shock.

HEALTH WARNINGS

Dust is created when sawing, which could contain harmful particles.

Some examples of these particles include:

• Lead from lead based paints,

• Crystalline silica from bricks, concrete, and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk to these types of exposure varies depending on how often you do

this type of work and your environment.

To reduce your exposure to these chemicals: work in a well ventilated area,

and work with approved safety equipment, such as dust masks that are

specially designed to fi lter out microscopic particles.

BCA350

TECHNICAL DATA

Rated Voltage 230V/50Hz

Rated Power 2.2kW

Cutting Materials Block/Brick

Max Cutting Depth & Angles 90mm (90°) & 50mm (45°)

Cutting Length 650mm

Rated Speed 2800rpm

Blade Diameter 350mm

Arbor Size 25.4mm

Weight 72kg

Dimensions L x W x H 1276 x 736 x 862mm

Pg.3

UNPACK & INSPECTION

After opening the container, carefully lift the saw frame handles and place it on

a fl at, level working area. Be certain that you have the following items before

you discard the container:

• Saw: 1 piece

• Saw frame support: 4 pieces

• Water pump: 1 piece

• Hex Wrench No. 4,6,8: 1 piece/each

• Adjustable Wrench: 1 piece

• Wrench: 1 piece

The Masonry Saw is shipped completely assembled and ready for use

excluding the diamond blade. Inspect the saw for shipping damage. If any

damage is found, contact the shipper immediately and fi le a freight claim.

MANUAL

Pg.4

ASSEMBLY & OPERATION

• After opening the package and confi rming everything has been included,

install the 4 removable legs underneath masonry saw frame by tightening

knobs.

• Plug the rubber block into the drain hole. Please inspect the motor and

wires before powering up the saw.

• DO NOT connect the plug into the power socket before installing blade.

• Keep the blade shaft clean and dry, remove the blade safety guard, install

the blade on the blade shaft, tighten the collar.

• Fill the water pan with clean water and fully submerge the water pump.

• Connect power to the pump and be sure there is enough water fl ow to the

blade before cutting.

• Keep the input hole of water pump clear, check regularly to avoid slurry

block.

• Rotate the blade manually (slowly) to check the blade condition, make

sure it’s rolling smoothly and is properly mounted.

• Always ensure you are using the correct rated voltage.

• Keep the motor rotating in no-load condition for one minute before cutting

in order to check related parts. Listen to the sound of the machine in

operation for abnormal behavior.

• DO NOT use if there is anything wrong or unusual.

• Check pump operation to ensure enough water is fl owing during operation.

• Put the cutting head in the desired position: either for sawing at right

angles or for mitering (90° or 45°). Loosen the bolt slightly by using the

ring wrench then tilt the head into the desired position. Tighten the bolt.

The exact position 90° or 45° can be adjusted by means of the adjustment

bolts.

• When nearing completion of the cut, pull back the cut, and slightly hold

back the conveyor cart. Always keep the blade out of the cutting slot

before turning off the motor.

• Place the cutting material on the conveyor cart, clamp and hold it fi rmly

against the backstop. Align the cutting material line with the blade cut line.

• The motor will stop in an overload condition. This means the overheat

protection device is working as intended.

• Turn off power and unplug the machine after each use. Empty the water

tank, remove dust, debris and slurry from machine. Keep the equipment

clean and dry.

BCA350

Pg.5

WORKING INSTRUCTIONS

• Please study this operating manual carefully and ensure you follow the

safety guidelines before using the BCA350 Masonry Saw.

• Professional training for workers is necessary.

• Always check work area for hidden wires, water or gas pipes before

working.

• Sawing action requires the use of water, since the use of electrical

equipment in wet areas is hazardous, the equipment must be grounded.

Always wear insulated footwear and gloves for extra protection against

shock hazards.

• Always wear safety goggles or glasses with side shields.

• Avoid vibrating or bumping the saw during cutting to insure equipment and

blade lifespan is not reduced.

• Keep any electrical equipment, the motor and cables away from water.

• Keep the blade free from any material when you start the saw.

• DO NOT operate without water. Suffi cient water fl ow is required to cool

blade and remove slurry.

• DO NOT remove the safety guard while the machine is in operation.

• DO NOT use the machine when you are tired, distracted or under the

infl uence of drugs, alcohol and any medication causing decreased

awareness or control.

MANUAL

FAULT DIAGNOSIS

Symptom Possible Cause Action

Machine does not run when

switched on

Power cord not properly

fi xed/plugged in

Check that the machine is

properly connected to the

power supply

Power Cord Defective

Have the power cord

checked or replace if

necessary

Main power switch

defective

Have the main power

switched checked and

replace if necessary by a

qualifi ed electrician

Loose electrical connection

inside the electric system

Have the whole electric

system of the machine

checked by a qualifi ed

electrician

Motor defective

Have the motor checked

and replace if necessary by

a qualifi ed technician

Insuffi cient water fl ow

The water pump or water

pipe is blocked

Check and clean water

pump and water pipe

The water pump or water

pipe is faulty or damaged

Check the water pump

and pipe and replace if

necessary by a qualifi ed

technician

Motor stops (power cut out)

Too much pressure exerted

while cutting

Exert less pressure when

cutting

Incorrect specifi cation for

saw blade

Use a saw blade which

corresponds to the material

being cut

Saw has a defective

electrical system

Have the electrical system

checking by a qualifi ed

electrician

Poor machine performance

(low power)

Power cord or extension

cable is too long or the

cable is still wound up

inside the cable drum

Use a power cord or

extension cable of the

rated length, use a cable

drum with cable fully

extended

Power network is

insuffi cient

Observe the electrical

ratings of the machine and

connect it only to a power

network which is rating

compliant

Drive motor no longer runs

at rated RPM

Have the motor checked

and replaced by a qualifi ed

technician if necessary

Pg.6

BCA350

Symptom Possible Cause Action

Irregular run of the saw

blade

Poor tension in the blade

material

Return the saw blade to the

manufacturer

Saw blade wobbles when

the saw is running

Saw blade is damaged or

bent

Have the saw blade

aligned or fl attened

Clean the receiving fl ange

Flange of the saw blade is

damaged

Replace the saw blade

fl ange

Shaft of the motor is bent Replace the electric motor

Diamond segment becomes

loose

Overheating of the saw

blade

Have the diamond segment

soldered on the blade

again

Coolant is not suffi cient Ensure optimum fl ow of

cooling water

Excessive wear

Wrong type of saw blade Use a harder blade bond

Shaft of motor causes

wobbling

Have bearings of the motor

replaced, or replace the

motor

Overheating Ensure optimum fl ow of

cooling water

Cracks in or near the

diamond segment

Saw blade bond too hard Use a softer blade bond

Fixed fl ange is worn out Have the fi xed fl ange

replaced

Motor shaft bearing is worn Replace the bearing of the

motor shaft

The center hole in the saw

blade has become wider

due to wear

The saw blade has slipped

on the motor shaft when

running

The arbor of the saw blade

must be fi tted with an

adapter ring

Check the receiving fl ange

and have it replaced if

necessary

Appearance of cut is not

optimal

Poor tension in the blade

material

Return the blade to the

manufacturer

Too much load placed on

the saw blade Use a suitable blade

Diamond segments are

blunt

Sharpen the diamond

blade on an abrasive

material

Grinding marks on the saw

blade

Material is not being fed

parallel to the saw blade

Ensure that the direction of

feed is parallel to the blade

Poor tension in the blade

material

Adjust the roller table or

have it adjusted

Too much load on the

blade

Exert less pressure when

cutting, proceed slower

Pg.7

MANUAL

MAINTENANCE

After every use of the machine:

• Remove dirty water from the machine.

• Remove dirt and mud from the bottom of the machine.

• Check and renew worn parts to keep the parts in good condition, and

check belts for wear and proper tension.

• Check and tighten screw nuts and wire connections to Keep them in good

condition.

Before using the machine again:

• Connect the machine to an electrical power outlet equipped with a Ground

Fault Circuit Interrupter (GFCI) switch. If the safety power breaker cuts off

the electrical power supply, DO NOT try to operate the machine before

having it checked by an authorized technician fi rst.

Before storing the machine for a prolonged period of time:

• Clean and lubricate all moving parts.

After not using the machine for a long period, or removing from storage:

• Check that the legs are safely fi xed.

• Check that all screw joints and nuts are fi xed.

• Check that the roller table is in it’s guides and that it moves easily.

• With the saw blade removed, switch on the motor for a moment and switch

it back off again. If the motor does not run, have the machine inspected by

a qualifi ed technician.

WARNING!

For your safety, before performing any maintenance on the

machine, ensure that the power is turned off and unplugged.

Pg.8

BCA350

Pg.9

Pg.10

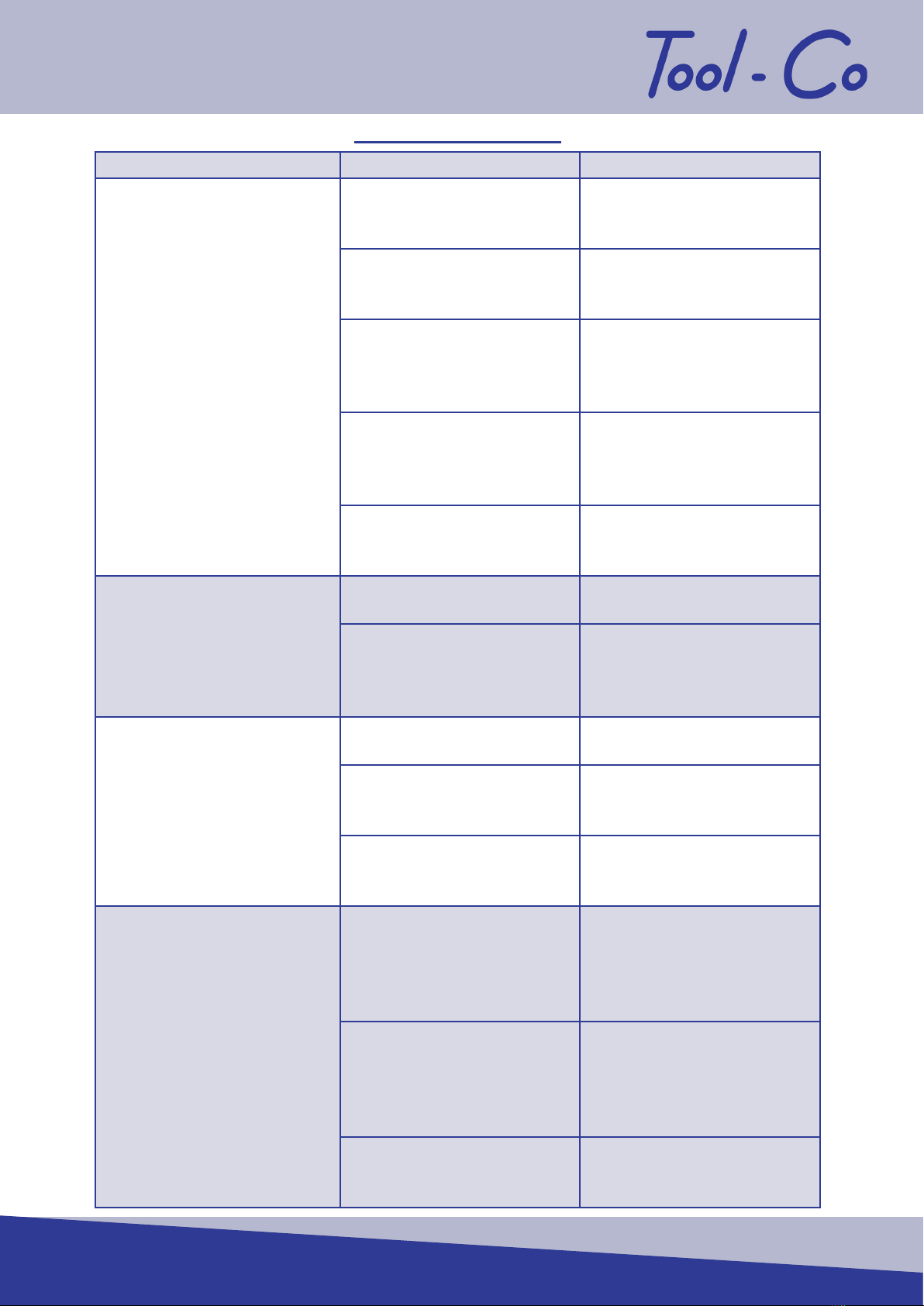

EXPLODED DIAGRAM A

MANUAL

Item No. Part No. Description Qty

1 100222 water tube12×2-2200

2 100399 water valve

3 100400 blade cover

4 100384 tee joint

5 100401 water tube5×1.5(300mm)

6 100402 clamp

7 100403 bolt M8X16

8 100404 plastic part

100405 hex.head bolt M20X120

100406

10 100407 rocker arm assembly

100408 Hex.socket set screws M8X30

100409 hex nut M8

12 100410 bracket for motor

100411 Cross Recess Head Screw M5X45

100412

14 100413 switch

100414 hex. Head bolt M6X20

100415

100416 hex. Lock nut M6

16 100417 water curtain

17 100418 water curtain clamp

18 100419 Hex. head tapping screws

19 100420 spring

20 100421 lathe bed

21 100422 handle

100423 hex.head bolt M20X80

100406

23 100217 jacket for handle

100424 hex.head bolt M8X30

100425 washer 8

100213 hex. Lock nut M8

100408 Hex.socket set screws M8X30

100409 hex nut M8

26 100426 wrench

27 100427 pole for assemble and unassemble

28 100428 water tank

29 100429 rubber stopper

30 100430 screw eye

9

11

13

15

22

24

25

1

1

1

1

2

2

1

2

1

1

1

2

2

1

4

4

1

1

2

1

1

1

2

1

1

1

1

1

1

4

8

4

1

1

1

1

1

1

1

DIAGRAM A PARTS LIST

Pg.10

BCA350

31 100431 ring

32 100432 water pump

33 100433 hex nut M20

34 100434 outside platen

35 100435 inside platen

36 100436 motor

37 100437 dead plate for water curtain clamp

38 100438 water curtain 400X300

100439 Cross Recess Head Screw M4X10

100440 hex nut M4

100441 eyelet bolt M8X50

100305 hex nut M8

100338 hex. Lock nut M8

100442

100443 hex.head bolt M8X65

100444 big washer 8

100109

100445 hex. Lock nut M8

42 100446 wheel

43 100447 axle

100448 socket head screw

100266

45 100449 guide plate

46 100450

47 100451 square nut M10

48 100452 handle for tighten legs

49 100453 guide rail

50 100454 rubber plate

51 100455 cutting table

52 100456 cover for right roller

53 100457 bearing 6201RS

54 100458 right roller

55 100459 retaining ring 32

100460 socket head screw M12X45

100239 hex. Lock nut M12

100218

58 100462 support legs

100463 socket head screw M12X50

100239 hex. Lock nut M12

100218

39

40

41

44

56

59

1

1

1

1

1

1

2

1

3

3

1

1

1

2

2

4

4

4

2

2

4

4

1

1

4

4

2

1

1

2

2

2

8

2

2

2

2

2

2

2

Pg.11

MANUAL

60 100464 left roller

61 100457 bearing 6201RS

62 100465 cover for left roller

63 100466 back stop

100467 round head square neck bolt M10X30

100468 hex.Look nut M10

100469 big washer 10

65 100470 ruler 1

100471 ruler 2

100599 tack rivet 2.5X5

100473 hex.head bolt M8X25

100442

69 100474 half-round head square neck bolt M10X35

100475 hex. Nut M6

100476 spring washer

71 100477

72 100478 rubber hat

73 100551 Cord Sleeve

64

66

68

2

4

2

1

3

3

3

1

1

4

1

2

2

1

1

1

1

1

1

70

Pg.12

BCA350

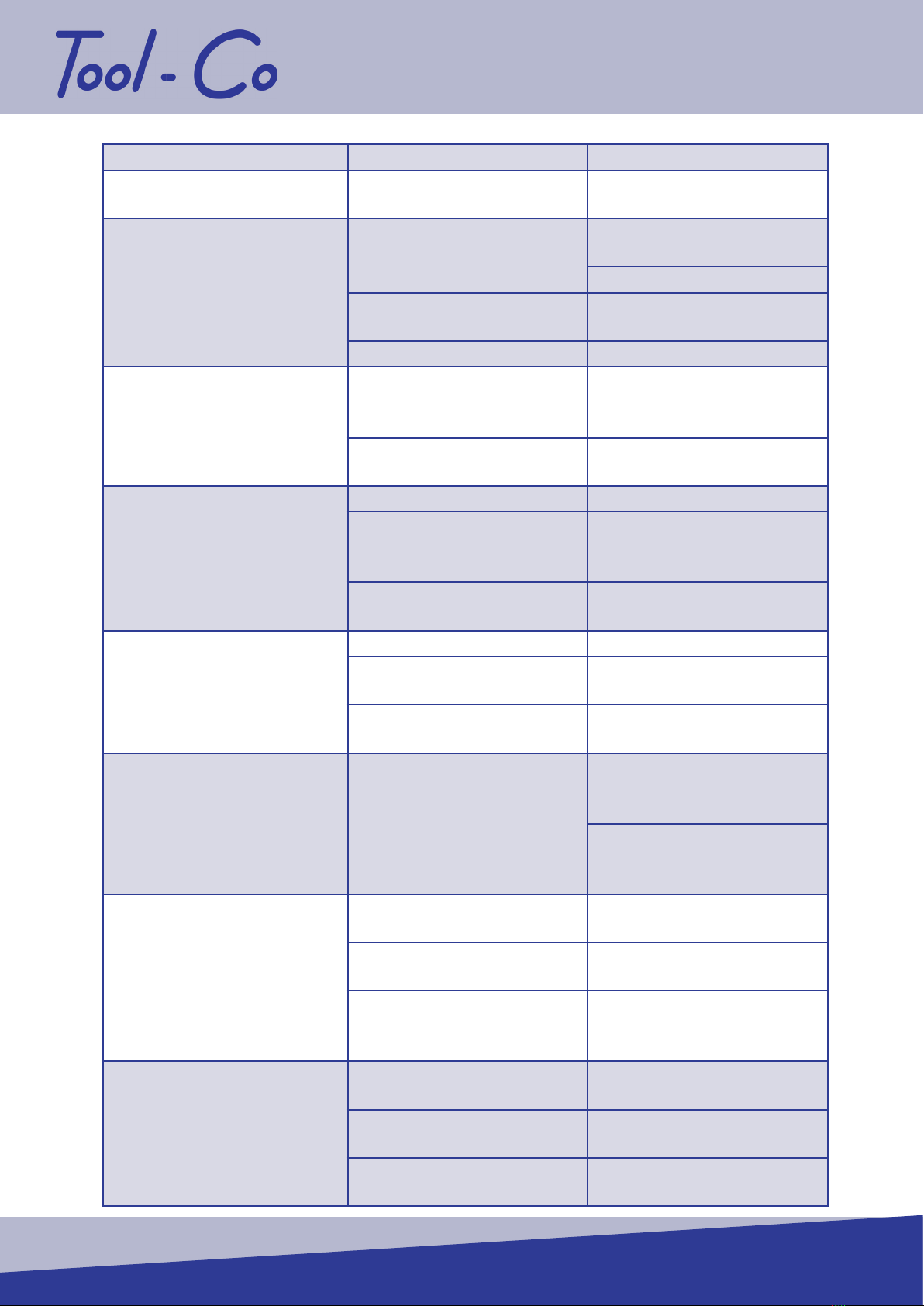

EXPLODED DIAGRAM B

Pg.13

MANUAL

Item No. Part No. Description Qty

3a 100552 blade cover

14a 100553 switch & Swiss plugs

100553 switch

100433-1 plug for South Africa

100554 right angle spring

16a 100555 water curtain

17a 100556 plate

20a 100557 lathe bed

28a 100558 water tank

29a 100559 rubber plug

38a 100454 water curtain

100560 Cross Recess Head Screw M4X10

100440 hex nut M4

100443 hex screw M8

100444 washer 8

100109

100445 hex lock nut M8

42a 100446 wheel

43a 100447 axle

73 100551 sleeve3X1.5

74 100561 angle gage

75 100713 hex nut

76 100562 stellate knob II

77 100442

78 100563 back stop

79 100296 stellate knob I

80 100629 hex lock screw

81 100564 blade cover

82 100109

83 100565 hex screw

84 100662 hex nut

85 100714 nylon wheel

86 100566 hex screw

87 100567 ring

88 100568 hex nut

89 100569 hock

90 100570 water-proof joint

29a

1

1

1

1

3

1

1

1

1

1

1

3

3

2

2

4

2

2

2

1

1

1

1

1

1

1

2

1

7

1

1

1

1

3

1

1

1

41a

14b

DIAGRAM B PARTS LIST

Pg.14

BCA350

1BM300MS 300 x 3.2 x 10 x 25.4mm Masonry Blade

2BM350MS 350 x 3.2 x 10 x 25.4mm Masonry Blade

1LVR300P 300 x 3.1 x 25.4mm Rescue Blade

2LVR350P 350 x 3.1 x 25.4mm Rescue Blade

1HO350TP 350 x 3.2 x 12 x 25.4mm Trade Pro

1LSDC300 300 x 2.4 x 7 x 25.4mm Hard Materials

2LSDC350 350 x 3.2 x 5 x 25.4mm Hard Materials

3LSDC450 450 x 4 x 7 x 25.4mm Hard Materials

RECOMMENDED BLADES

1BO300DA 300 x 3 x 12 x 25.4mm Economy

2BO350DA 350 x 3.2 x 15 x 25.4mm Economy

Pg.15

MANUAL

RECOMMENDED BLADES

1BO300CS 300 x 3 x 12 x 25.4mm Standard Blade

2BO350CS 350 x 3.2 x 15 x 25.4mm Standard Blade

1BO350CH 350 x 3 x 15 x 25mm Premium Blade

Pg.16

BCA350

Pg.17

Table of contents

Popular Saw manuals by other brands

Parkside

Parkside PHKSU 710 A1 translation of original operation manual

Pattfield Ergo Tools

Pattfield Ergo Tools PE-600 MHKS-2 Original instructions

Makita

Makita 5603R instruction manual

Grizzly

Grizzly G1012 parts list

Bosch

Bosch GSA 1200 E Professional Original instructions

Milwaukee

Milwaukee M18 FCS66 user manual