Toolkraft 910A Use and care manual

·OPERATING

INSTRUCTIONS

AND

PARTS LIST

BEFORE

ATTEMPTING TO

DO

ANY

WORK

WITH YOUR RADIAL ARM SAW

READ

THESE

INSTRUCTIONS

CAREFULLY

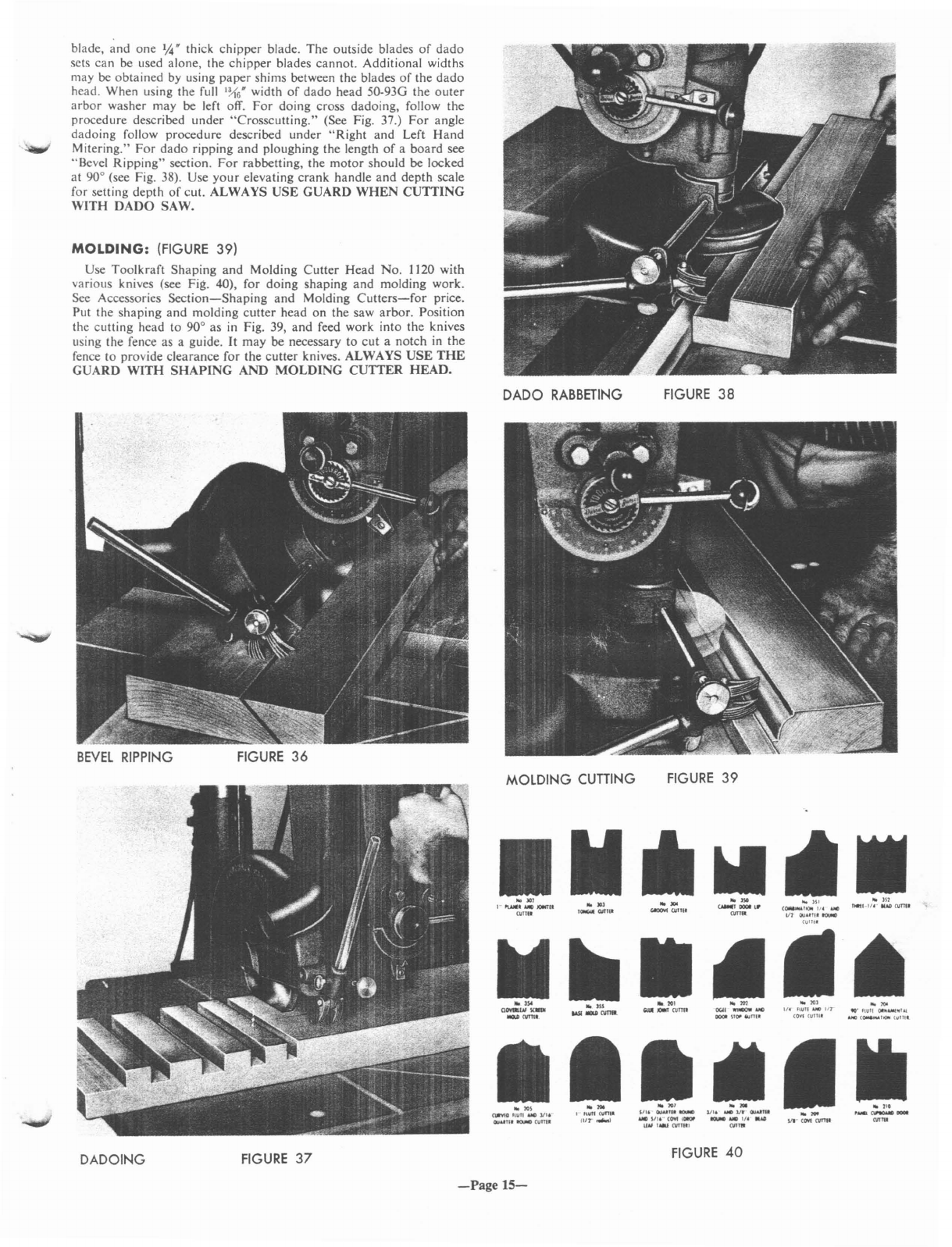

-

MODEL

910A

THE

ABOVE MODEL NUMBER

IS

ON

THE

NAMEPLATE OF YOUR MACHINE

Always

use

this

Number

and

Serial

Number

in

correspondence

with

us

regarding

this

machine

or

when

ordering

parts.

HOW

TO

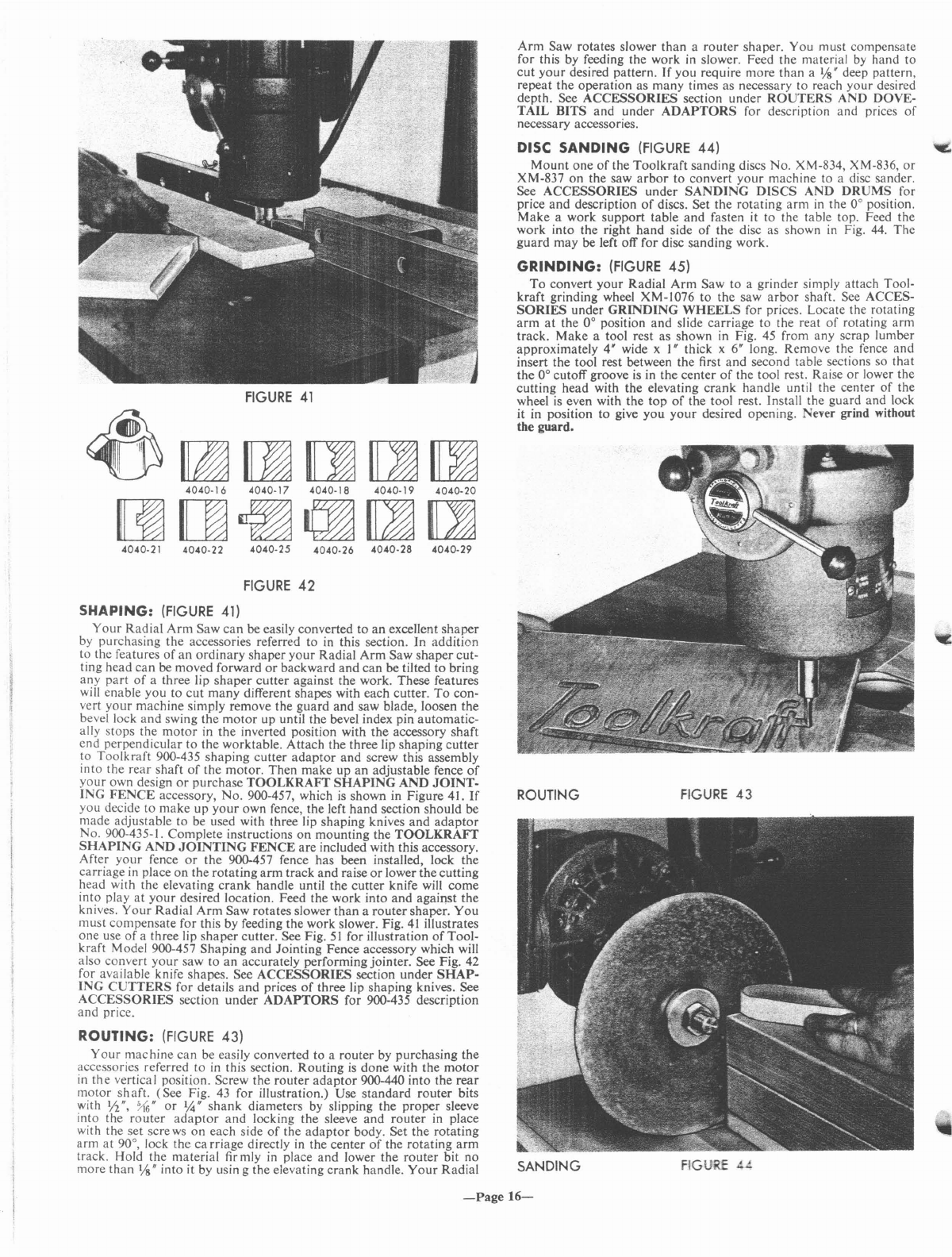

ORDER

PARTS

All

parts

can be ordered from the factory.

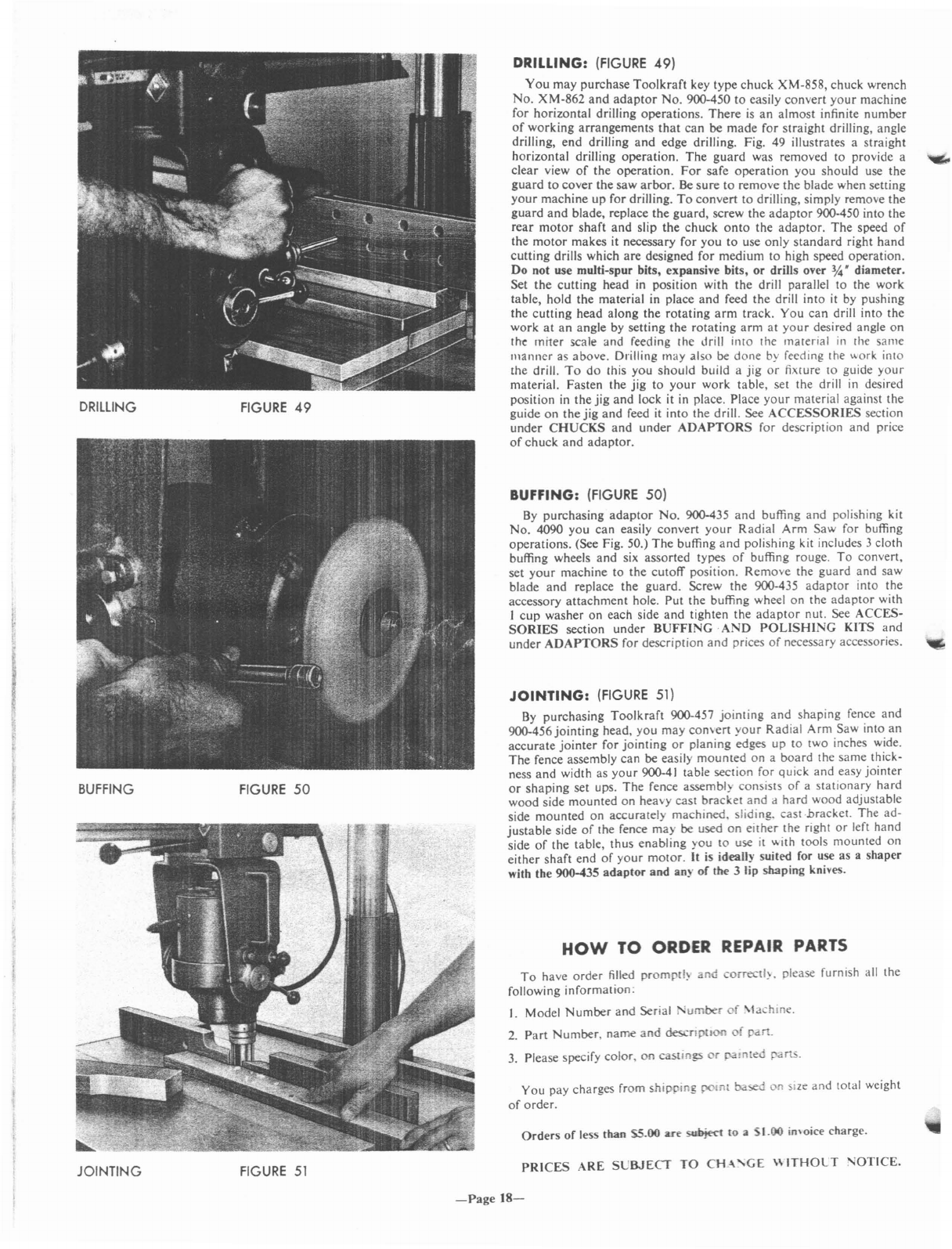

Always include the information below when ordering

parts:

1.

The

Part

Number

in this list

(not

the Index Number).

2.

The

Part

Name

in this list.

3.

The Model

Number

and

Serial

Number

of

your machine.

4.

The color

of

painted parts.

THIS

LIST

WILL

BE

VALUABLE

TO YOU

IN

ORDERING

SERVICE

PARTS

OR ACCESSORIES-DO

NOT

THROW IT AWAY

TOOLKRAFT CORPORATION,

700

PLAINFIELD

STREET,

SPRINGFIELD,

MASSACHUSETTS

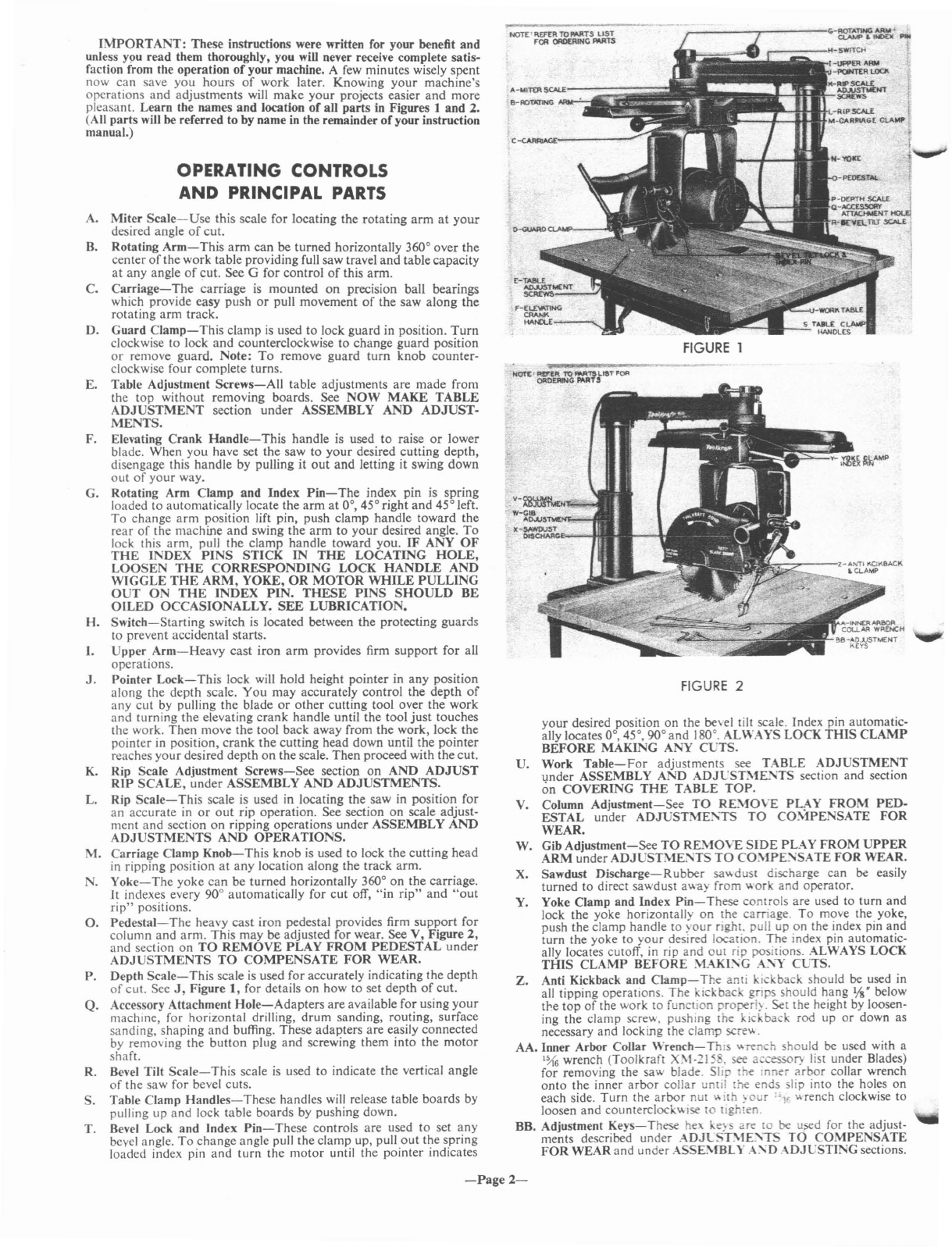

your

desired position

on

the

be\el

tilt scale. Index pin automatic-

ally locates

0°,45°,90°

and

180°. ALWAYS

LOCK

THIS

CLAMP

BEFORE

MAKING

ANY

CCTS.

U.

Work

Table-For

adjustments see TABLE

ADJUSTMENT

under

ASSEMBLY AND ADJCST:\1E.....

TS

section

and

section

on

COVERING

THE

TABLE

TOP.

V. Column

Adjustment-See

TO

RE:\10VE

PLAY

FROM

PED-

ESTAL

under

ADJUSTME:\TS

TO

CO"-1PENSATE

FOR

WEAR.

W. Gib

Adjustment-See

TO

RE:\10VE

SIDE

PLAY

FROM

UPPER

ARM

under ADJUST"-iE:'\TS

TO

CO:\fPE:\SA

TE

FOR

WEAR.

X. Sawdust

Discharge-Rubber

sa",duSI discharge

can

be easily

turned

to

direct sawdust away from work and operator.

Y. Yoke Clamp

and

Index

Pin-These

controls are used to turn

and

lock the yoke horizontally

on

the carriage.

To

move the. yoke,

push the clamp handle

to

your

right, pull up on the index pm a':ld

turn

the yoke to

your

desired location. The index pin automatic-

ally locates cutoff, in rip

and

out

rip positions. ALWAYS LOCK

THIS

CLAMP

BEfORE

:\1AKI:\G A

...

"1'

CLTS.

Z.

Anti Kickback and

CIamp-

The anii kickback should be used in

all tipping operations. The kickbac. grips should hang

Vs"

below

the

top

of

the work

to

function

properi~.

Set the height by loosen-

ing the clamp screw, pushing the kickback rod up

or

down as

necessary

and

locking Ihe clamp scre"'.

AA. Inner Arbor Collar

Wrem:h-

Tnl;

wrench should be used with a

1~6

wrench (Toolkraft

X\I-215

.see accessory list under Blades)

for removing the saw blade. Sli the Inner

arbor

collar wrench

onto

the inner

arbor

collar until

the

ends slip into the holes

on

each side.

Turn

the

arbor

nut

'ilh

~o

r

"1;

"'rench clockwise

to

loosen

and

counterclock"'lsc

to

lighten.

BB. Adjustment

Keys-These

hex

ke~

sare

to

be

u.><:d

for the adjust-

ments described under

.-\DJCST\lE:\iS

TO

COMPENSATE

FOR

WEAR and under ASSE..'\fBLY.-\:\D

:\DJCSTING

sections.

FIGURE

2

"'-=--'''"''41''

~~--_H-SWfTCH

1

-tJIPfER

ARM

"-rOM"tR

LOCJ\

K-~~Nl

SCREWS

I

L-A,IP5CAl.E t

M-CARRtAGE

CLAW

i'

r-------,...------

..

-~"'f~

.....

!

FIGURE

1

C-eARRI.'o<>E:-----

NOT£'

REF£R TOMRT.s

LIST

fOIl

ORDERING

""'1S

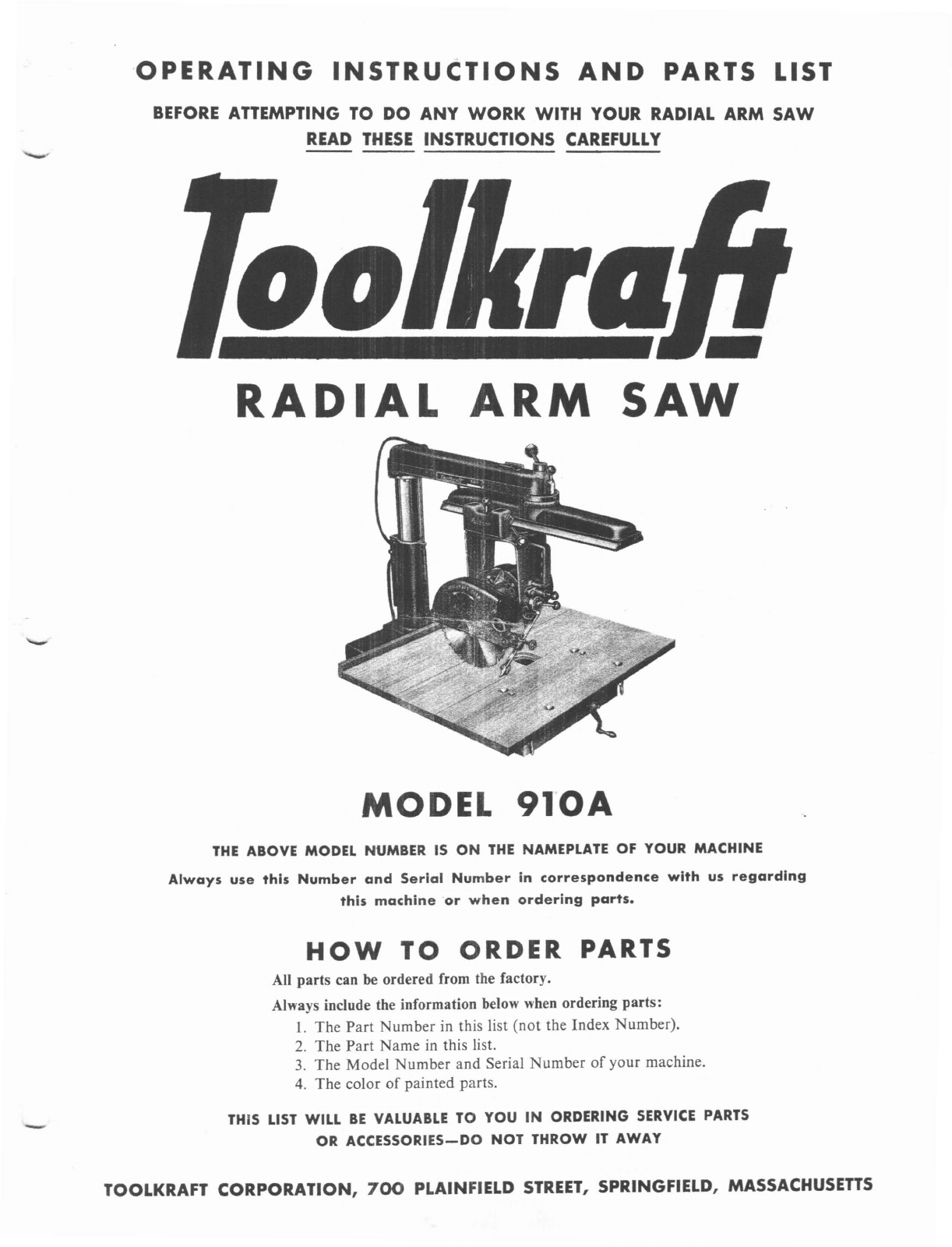

OPERATING CONTROLS

AND PRINCIPAL

PARTS

IMPORTANT:

These instructions were written for your benefit

and

unless

Y9U

read them thoroughly, you will never receive complete satis-

faction from the operation

of

your machine. Afew minutes wisely spent

now

can

save

you

hours

of

work later. Knowing

your

machine's

operations

and

adjustments will

make

your

projects easier

and

more

pleasant. Learn the names

and

location

of

all

parts

in Figures 1

and

2.

(All

parts

will be referred to by name in the remainder

of

your instruction

manual.)

A.

Miter

Scale-Use

this scale for locating the

rotating

arm

at

your

desired angle

of

cut.

B.

Rotating

Arm-This

arm

can

be

turned

horizontally 360° over

the

center

of

the work table providing full saw travel

and

tablecapacity

at

any angle

of

cut.

See Gfor

control

of

this

arm.

C.

Carriage-

The

carriage is

mounted

on

precision ball bearings

which provide easy push

or

pull movement

of

the saw along

the

rotating

arm

track.

D.

Guard

Clamp-This

clamp

is

used

to

lock guard in position.

Turn

clockwise

to

lock

and

counterclockwise

to

change

guard

position

or

remove guard. Note:

To

remove

guard

turn

knob

counter-

clockwise

four

complete turns.

E. Table Adjustment

Screws-All

table adjustments are

made

from

the

top

without removing boards. See

NOW

MAKE

TABLE

ADJUSTMENT

section

under

ASSEMBLY

AND

ADJUST-

MENTS.

F. Elevating

Crank

Handle-This

handle is used

to

raise

or

lower

blade. When

you

have set

the

saw

to

your

desired cutting depth,

disengage this

handle

by pulling

it

out

and

letting

it

swing

down

out

of

your

way.

G. Rotating Arm Clamp

and

Index

Pin-The

index pin is spring

loaded

to

automatically locate the

arm

at

0°, 45° right

and

45° left.

To

change

arm

position lift pin, push clamp handle toward

the

rear

of

the machine

and

swing

the

arm

to

your

desired angle.

To

lock this

arm,

pull

the

clamp

handle

toward you.

IF

ANY

OF

THE

INDEX

PINS

STICK

IN

THE

LOCATING

HOLE,

LOOSEN

THE

CORRESPONDING

LOCK

HANDLE

AND

WIGGLE

THE

ARM,

YOKE,

OR

MOTOR

WHILE

PULLING

OUT

ON

THE

INDEX

PIN.

THESE

PINS

SHOULD

BE

OILED

OCCASIONALLY.

SEE

LUBRICATION.

H.

Switch-Starting

switch is located between

the

protecting

guards

to prevent accidental starts.

I.

Upper

Arm-Heavy

cast

iron

arm

provides firm

support

for

all

operations.

J.

Pointer

Lock-This

lock will hold height pointer in

any

position

along the depth scale.

You

may

accurately

control

the

depth

of

any

cut

by pulling the blade

or

other

cutting tool over the work

and

turning the elevating

crank

handle until

the

tool

just

touches

the work.

Then

move

the

tool back away from

the

work, lock

the

pointer in position,

crank

the

cutting head down until the

pointer

reaches

your

desired depth

on

the scale.

Then

proceed with the cut.

K. Rip Scale Adjustment

Screws-See

section

on

AND

ADJUST

RIP

SCALE,

under

ASSEMBLY

AND

ADJUSTMENTS.

L. Rip

Scale-This

scale is used in locating the saw in position for

an

accurate

in

or

out

rip operation. See section

on

scale adjust-

ment

and

section

on

ripping operations

under

ASSEMBLY

AND

ADJUSTMENTS

AND

OPERATIONS.

M.

Carriage Clamp

Knob-This

knob

is

used to lock

the

cutting

head

in ripping position

at

any

location along the track arm.

N.

Yoke-The

yoke

can

be turned horizontally 360°

on

the

carriage.

It

indexes every 90° automatically for

cut

off,

"in

rip"

and

"out

rip"

positions.

O.

Pedestal-The

heavy

cast

iron

pedestal provides firm

support

for

column

and

arm.

This may be adjusted for wear. See V, Figure

2,

and

section

on

TO

REMOVE

PLAY

FROM

PEDESTAL

under

ADJUSTMENTS

TO

COMPENSATE

FOR

WEAR.

P. Depth

Scale-This

scale

is

used for accurately indicating

the

depth

of

cut. See

J,

Figure

1,

for details

on

how to set depth

of

cut.

Q.

Accessory Attachment

Hole-Adapters

are

available for using

your

machine for horizontal drilling,

drum

sanding, routing, surface

sanding,'shaping

and

buffing. These adal?ters

are

easily connected

by removing the

button

plug

and

screwing them

mto

the

motor

shaft.

R. Bevel Tilt

Scale-This

scale

is

used

to

indicate the vertical angle

of

the saw for bevel cuts.

S. Table Clamp

Handles-These

handles will release table

boards

by

pulling up

and

lock table boards by pushing down.

T. Bevel Lock and Index

Pin-These

controls are used

to

set

any

bevel angle.

To

change angle pull

the

clamp up, pull

out

the spring

loaded index pin

and

turn

the

motor

until the pOinter indIcates

-Page

2-

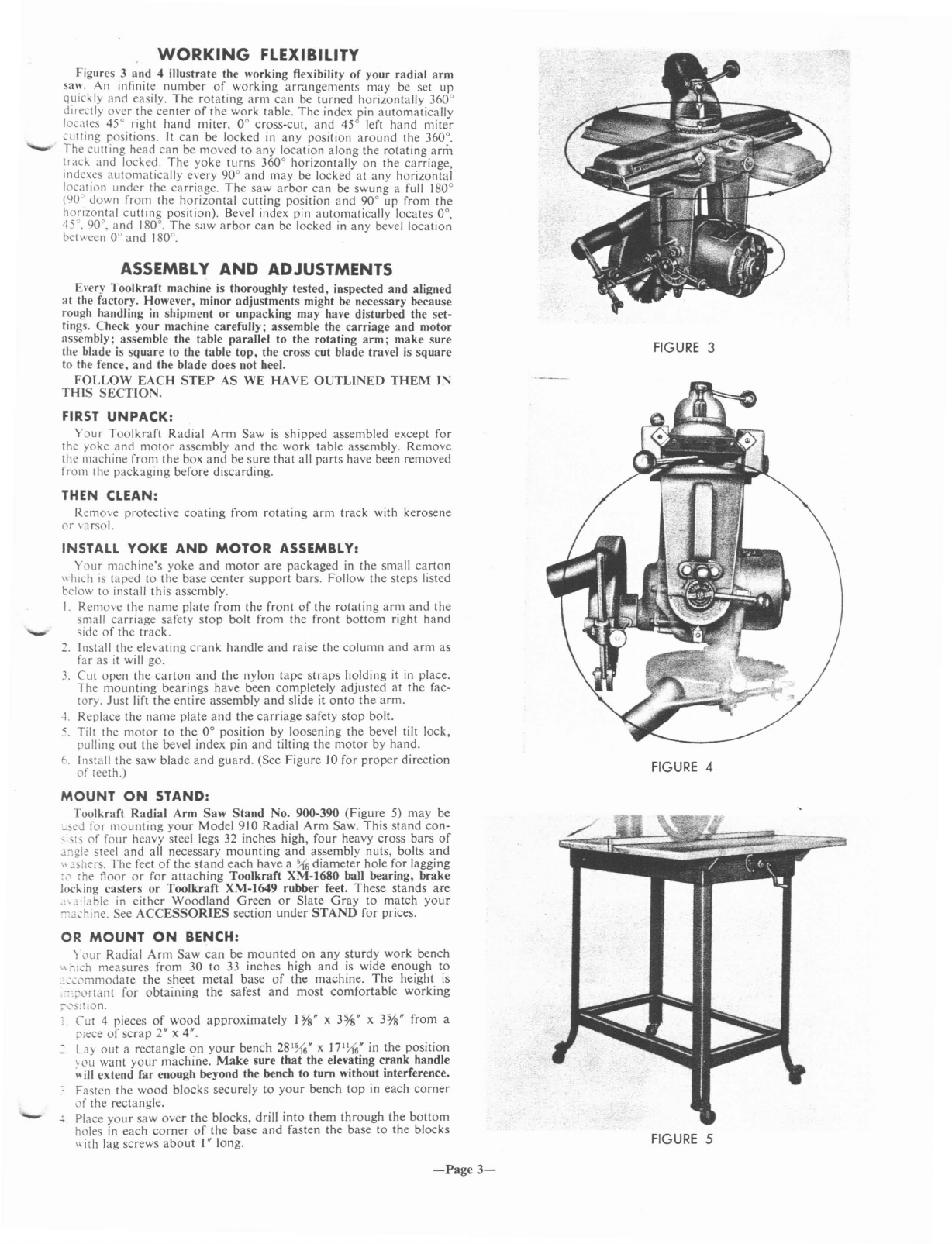

WORKING

FLEXIBILITY

Figures 3

and

4

illustrate

the working flexibility

of

your

radial

arm

saw. An infinite

number

of

working

arrangements

may

be set

up

quickly

and

easily.

The

rotating

arm

can

be

turned

horizontally

360°

directly

ovcr

the

center

of

the

work

table.

The

index pin

automatically

locates 45° right

hand

miter.

0°

cross-cut.

and

45° left

hand

miter

culting

positions.

It

can

be

locked

in

any

position

around

the

360°.

The

cUlting head

can

be

moved

to

any

location

along

the

rotating

ann

track

and

locked.

The

yoke

turns

360°

horizontally

on

the

carriage.

indc\cs

automatically

every

90°

and

may

be locked

at

any

horizontal

location

under

the

carriage.

The

saw

arbor

can

be

swung

afull 180°

(90'

down

from

the

horizontal

cutting

position

and

90°

up

from

the

horizontal

cutting

position). Bevel index pin

automatically

locates 0°.

45 .90°.

and

180°.

The

saw

arbor

can

be locked in

any

bevel

location

bet\\een

0°

and

180°.

ASSEMBLY

AND

ADJUSTMENTS

Every

Toolkraft

machine is thoroughly

tested,

inspected

and

aligned

at

the factory. However,

minor

adjustments

might be necessary because

rough handling

in

shipment

or

unpacking

may have disturbed the set-

tings. Check

your

machine

carefully;

assemble the

carriage

and

motor

assembly; assemble the

table

parallel

to

the

rotating

arm;

make

sure

the blade is

square

to the

table

top,

the

cross

cut

blade travel is

square

to the fence,

and

the

blade

does

not heel.

FOLLOW

EACH

STEP

AS

WE

HAVE

OUTLINED

THEM

IN

THIS

SECTION.

FIRST

UNPACK:

Your

Toolkraft

Radial

Arm

Saw

is

shipped

assembled

except

for

the yoke

and

motor

assembly

and

the

work

table

assembly.

Remove

the

machine

from

the

box

and

be

sure

that

all

parts

have been

removed

from

the

packaging

before

discarding.

THEN

CLEAN:

Remove

protective

coating

from

rotating

arm

track

with

kerosene

or

\arsol.

INSTALL

YOKE

AND

MOTOR

ASSEMBLY:

Your

machine's

yoke

and

motor

are

packaged

in

the

small

carton

which

is

taped

to

the

base

center

support

bars.

Follow

the

steps

listed

below

to

install

this

assembly.

I.

Remove

the

name

plate

from

the

front

of

the

rotating

arm

and

the

small

carriage

safety

stop

bolt

from

the

front

bottom

right

hand

side

of

the

track.

~

Install

the

elevating

crank

handle

and

raise

the

column

and

arm

as

far

as

it will

go.

3.

Cut

open

the

carton

and

the

nylon

tape

straps

holding

it in place.

The

mounting

bearings

have

been

completely

adjusted

at

the

fac-

tory.

Just

lift

the

entire

assembly

and

slide it

onto

the

arm.

of.

Replace

the

name

plate

and

the

carriage

safety

stop

bolt.

5.

Tilt

the

motor

to

the

0°

position

by

loosening

the

bevel tilt lock.

pulling

out

the

bevel

index

pin

and

tilting

the

motor

by

hand.

6.

Install

the

saw

blade

and

guard.

(See

Figure

10

for

proper

direction

of

teeth.)

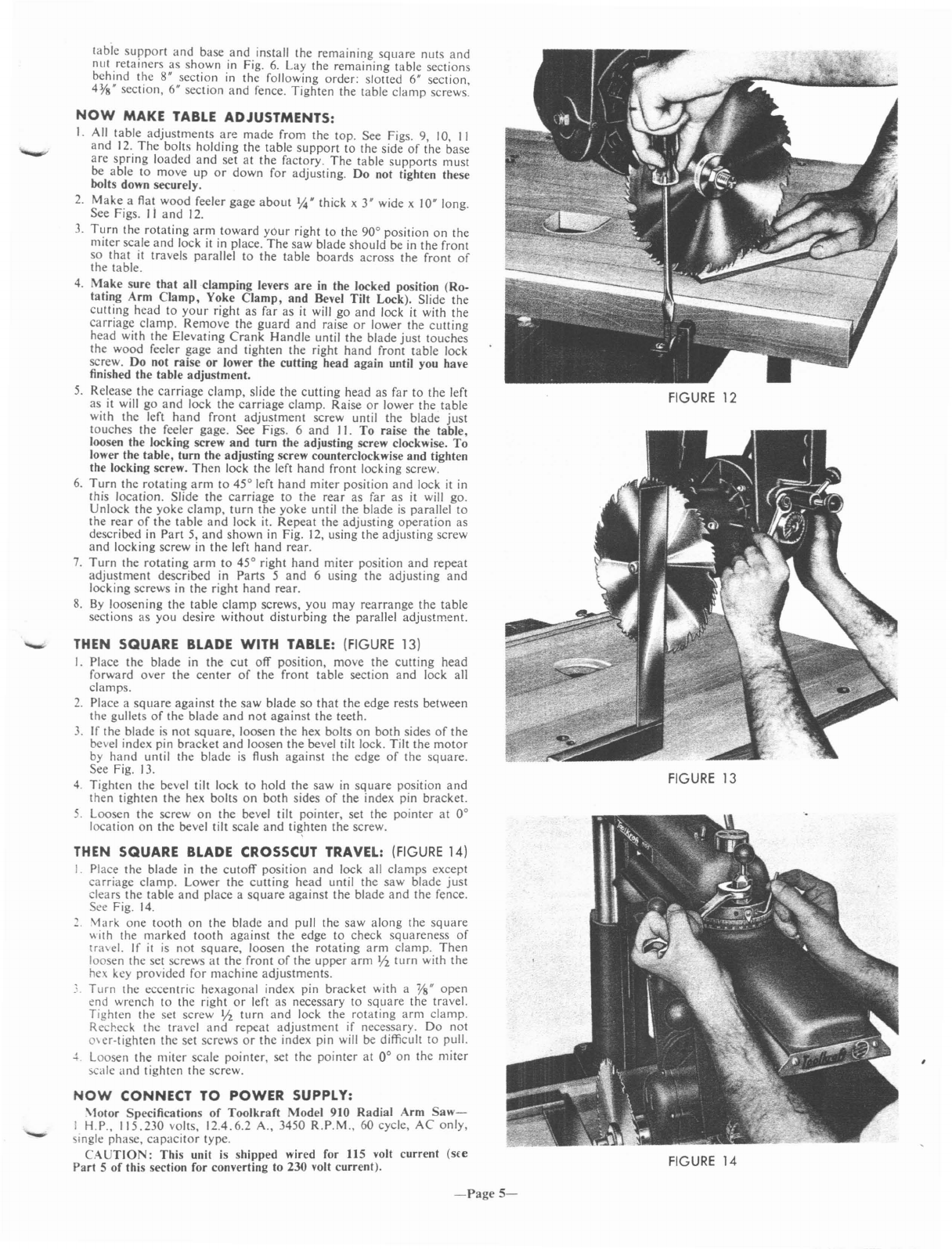

MOUNT

ON

STAND:

Toolkraft

Radial

Arm

Saw

Stand

No. 900-390

(Figure

5)

may

be

_sed for

mounting

your

Model

910

Radial

Arm

Saw.

This

stand

con-

S,SIS

of

four

heavy

steel legs 32

inches

high,

four

heavy

cross

bars

of

Ji1gk steel

and

all

necessary

mounting

and

assembly

nuts,

bolts

and

\\

rhers.

The

feet

of

the

stand

each

have

a

~6

diameter

hole

for lagging

'c'

[he floor

or

for

attaching

Toolkraft

XM-1680

ball bearing,

brake

locking

casters

or

Toolkraft

XM-1649

rubber

feet.

These

stands

are

.'\Jdable

in

either

Woodland

Green

or

Slate

Gray

to

match

your

,,:'achll1e. See

ACCESSORIES

section

under

STAND

for

prices.

OR

MOUNT

ON

BENCH:

)

our

Radial

Arm

Saw

can

be

mounted

on

any

sturdy

work

bench

\\

~Ich

measures

from

30

to

33 inches high

and

is

wide

enough

to

_,:.:,'mmodate

the

sheet

metal

base

of

the

machine.

The

height is

--;:,ortant for

obtaining

the

safest

and

most

comfortable

working

:'

........

s!tion.

Cut

4pieces

of

wood

approximately

I

Ys"

x

3Ys"

x3Ys'

from

a

"iece

of

scrap

2" x4".

•

Layout

a

rectangle

on

your

bench

281~6"

x17')16' in

the

position

\

au

want

your

machine.

Make

sure

that

the elevating

crank

handle

~

ill

extend

far

enough beyond

the

bench

to

turn

without interference.

Fasten

the

wood

blocks

securely

to

your

bench

top

in

each

corner

of

the

rectangle.

-

!.

Place

your

saw

over

the

blocks,

drill

into

them

through

the

bottom

holes in

each

corner

of

the

base

and

fasten

the

base

to

the

blocks

\\

ith lag screws

about

I"

long.

-Page

3-

FIGURE

3

FIGURE 4

FIGURE

5

FIGURE

6

FIGURE

7

ADJUSTING

SCREW

;{zoxI

HE

ADLE

SS

SET

SCREW

SECTION

ON

BE

FIGURE

8

NEXT,

ASSEMBLE

TABLE:

I.

Because

of

wood's

natural

tendency to

absorb

moisture,

your

table

boards

may

have become slightly warped

during

or

after

shipment.

Crank

the

saw

up far

enough

to slip table

boards

into position.

Lay the

boards

out

on

the table

support

with the fence

in

position

at the rear.

Empty

out

the cloth

bag

containing

the table adjusting

and

fastening screws

onto

atable

and

pick

out

:2

round

head screws

'"

long

and

2flat washers. Slip the I"

round

head screws with flat

washer

through

each

of

the

front

holes

in

the table

support

to hold

the table in place

and

tighten the table clamps. If

the

table

clamps

are

too

tight

or

too

loose, they

can

be adjusted by

changing

the

location

of

the

nuts

which set the clamping screws in position.

Check

with a

straight

edge for high spots

or

gaps

on

the table

surface.

Check

the length

of

the fence for straightness. Any section

of

the table which

is

not flat

should

be sanded

or

planed.

Sanding

can

be

done

with

Toolkraft

Rotary

Sander

No. 4004 and 900-440

Adaptor.

Planing

may

be

done

with Toolkraft

Rotary

Planer

No.

4060 and 900-440

Adaptor.

See

ACCESSORIES

section for price.

See

OPERATION

section for illustrations.

2.

After

checking

your

boards, loosen the table clamps and remove

all

boards

from the table

supports.

See Figs. 6

and

8for detail

of

adjustment

and

locking screw assembly.

From

the table adjusting

and

fastening screws, pick

out

4headless screws

I"

long (these are

your

adjustment

screws), 4

square

nuts

and

4sheet metal

nut

re-

tainers. Insert

the

nut into

the

sheet metal nut retainer, slide the

nuts

and

nut retainers between

the

table

support

and

sheet metal

base

at

the second

and

fourth

holes in from

the

front

on

each side

so

that

the

hole in the table

support

lines up with the hole in the

nut

retainer

and

nut.

Turn

the headless adjusting screws

through

the

holes in

the

table

support

angle

and

nut retainer into the

square

nut until

approximately

l/S"

of

the

screw

is

through

the

bottom

of

the

nut.

3.

Place the 8" wide table section

in

position

on

the front

of

the

table

support

angle

so

that

the holes line up

and

the previously

installed front

adjusting

5crews

come

through

the small holes.

The

counterbored

side

should

be facing up. See Fig.

9.

Put

one

of

the

FIGURE

9

four

Aat

washers into each

of

the

four

counterbored

holes. Slip the

two I" long round head screws into the two front holes

and

fasten

securely with lock washers

and

ht:x

nuts. See Fig.

6.

Slip the two

I

~"

long

round

head screws into the third hole from the front

on

each side.

Take

the two

square

nuts

and

two nut retainers and

fasten to the

I~"

round

head screws as shown

in

Figs. 6and

7.

Slip the two \1,4" long

round

head screws

through

rear holes

in

the

FIGURE

10

FIGURE

11

-Page

4-

tabie

support

and

base

and

install the

remaining

square

nuts

and

nut

retainers

as

shown

in Fig.

6.

Lay

the

remaining

table

sections

behind

the

S"

section

in

the following

order:

slotted

6" section,

4%"

section,

6"

section

and

fence.

Tighten

the

table

clamp

screws.

__

THEN SQUARE

BLADE

WITH

TABLE:

(FIGURE

13)

I.

Place

the

blade

in

the

cut

off

position,

move

the

cutting

head

forward

over

the

center

of

the

front

table

section

and

lock all

clamps.

2.

Place a

square

against

the

saw

blade

so

that

the

edge

rests between

the gullets

of

the

blade

and

not

against

the

teeth.

3.

If

the

blade

is

not

square,

loosen

the

hex bolts

on

both

sides

of

the

bevel index pin

bracket

and

loosen

the

bevel tilt lock. Tilt

the

motor

by

hand

until the

blade

is

flush

against

the

edge

of

the

square.

See Fig. 13.

4.

Tighten

the

bevel tilt lock

to

hold

the

saw

in

square

position

and

then

tighten

the

hex

bolts

on

both

sides

of

the

index pin

bracket.

5.

Loosen

the

screw

on

the

bevel tilt

pointer,

set

the

pointer

at

0°

location

on

the

bevel tilt scale

and

tighten

the

screw.

FIGURE

12

FIGURE

14

FIGURE

13

THEN SQUARE

BLADE

CROSSCUT TRAVEL:

(FIGURE

14)

I.

Place

the

blade

in

the

cutoff

position

and

lock all

clamps

except

carriage

clamp.

Lower

the

cutting

head

until

the

saw

blade

just

clears

the

table

and

place

a

square

against

the

blade

and

the

fence.

See Fig.

14.

2.

Mark

one

tooth

on

the

blade

and

pull

the

saw

along

the

square

"ith

the

marked

tooth

against

the

edge

to

check

squareness

of

tra\el.

If

it

is

not

square,

loosen

the

rotating

arm

clamp.

Then

loosen

the

set screws

at

the

front

of

the

upper

arm

Y2

turn

with

the

hex key

provided

for

machine

adjustments

.

..

Turn

the

eccentric

hexagonal

index pin

bracket

with a

Ys"

open

end

wrench

to

the

right

or

left

as

necessary to

square

the

travel.

Tighten

the set

screw

Y2

turn

and

lock

the

rotating

arm

clamp.

Recheck

the

travel

and

repeat

adjustment

if necessary.

Do

not

o\er-tighten

the

set screws

or

the

index pin will be difficult

to

pull.

J.

Loosen

the

miter

scale

pointer,

set

the

pointer

at

0°

on

the

miter

scale

and

tighten

the

screw.

NOW

CONNECT

TO

POWER SUPPLY:

\totor

Specifications

of

Toolkrafl

Model

910

Radial

Arm

Saw-

IH.P.,

115.230

volts,

12.4.6.2

A., 3450

R.P.M.,

60 cycle,

AC

only,

single

phase,

capacitor

type.

CAUTION:

This

unit is

shipped

wired for 115 voll

current

(s£e

Part

5

of

this section for converting to 230 voll

current).

NOW

MAKE

TABLE

ADJUSTMENTS:

1.

All

table

adjustments

are

made

from

the

top.

See Figs. 9, 10, II

and

12.

The

bolts

holding

the

table

support

to

the side

of

the

base

are

spring

loaded

and

set

at

the

factory.

The

table

supports

must

be

able

to

move

up

or

down

for

adjusting.

Do

not tighten these

bolts down securely.

2.

Make

aflat

wood

feeler

gage

about

'4" thick x3" wide x10" long.

See Figs.

II

and

12.

3.

Turn

the

rotating

arm

toward

yOur right

to

the

90°

position

on

the

miter

scale

and

lock it in place.

The

saw

blade

should

be in

the

front

so

that

it

travels

parallel

to

the

table

boards

across

the

front

of

the

table.

4.

Make

sure

that

all

clamping

levers

are

in the locked position

(Ro-

tating

Arm

Clamp,

Yoke

Clamp,

and

Bevel

Tilt

Lock). Slide

the

cutting

head

to

your

right

as

far

as

it will

go

and

lock

it

with

the

carriage

clamp.

Remove

the

guard

and

raise

or

lower

the

cutting

head

with

the

Elevating

Crank

Handle

until

the

blade

just

touches

the

wood

feeler

gage

and

tighten

the

right

hand

front

table

lock

screw.

Do

not

raise

or

lower the

cutting

head

again

until you have

finished the

table

adjustment.

5.

Release

the

carriage

clamp,

slide

the

cutting

head

as

far

to

the

left

as

it will

go

and

lock

the

carriage

clamp.

Raise

or

lower

the

table

with

the

left

hand

front

adjustment

screw until

the

blade

just

touches

the

feeler gage. See Figs. 6

and

)

1.

To

raise

the

table,

loosen the locking screw

and

turn

the

adjusting screw clockwise.

To

lower the

table,

turn

the

adjusting

screw counterclockwise

and

tighten

the locking screw.

Then

lock

the

left

hand

front

locking screw.

6.

Turn

the

rotating

arm

to

45°

left

hand

miter

position

and

lock

it

in

this

location.

Slide

the

carriage

to

the

rear

as

far

as

it

will

go.

Unlock

the

yoke

clamp,

turn

the

yoke

until

the

blade

is

parallel

to

the

rear

of

the

table

and

lock it.

Repeat

the

adjusting

operation

as

described in

Part

5,

and

shown

in

Fig. 12, using

the

adjusting

screw

and

locking

screw in

the

left

hand

rear.

7.

Turn

the

rotating

arm

to

45°

right

hand

miter

position

and

repeat

adjustment

described

in

Parts

5

and

6using

the

adjusting

and

locking

screws in

the

right

hand

rear.

S.

By

loosening

the

table

clamp

screws,

you

may

rearrange

the

table

sections

as

you

desire

without

disturbing

the

parallel

adjustment.

-

-Page

5-

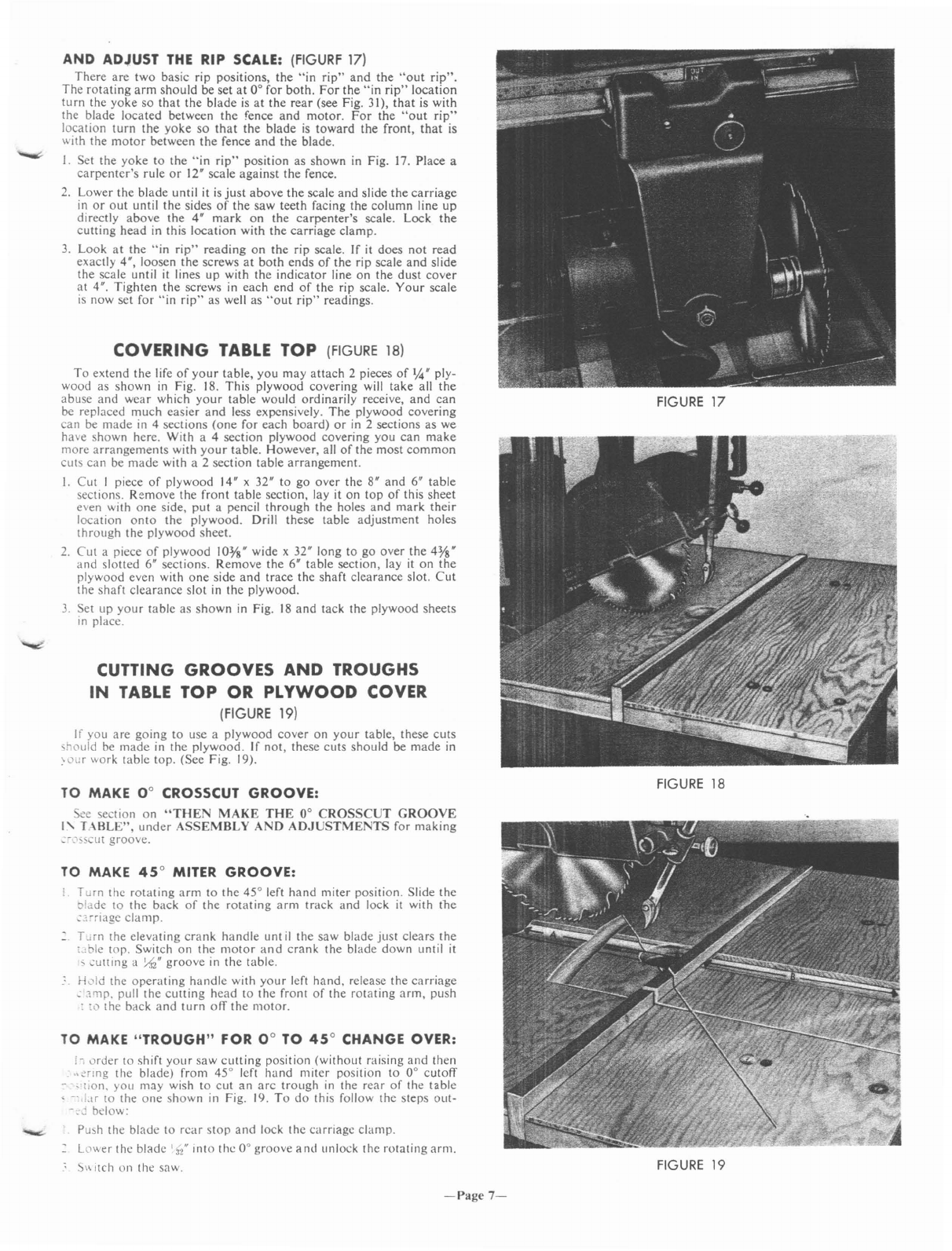

AND ADJUST

THE

RIP

SCALE:

(FIGURF 17)

There

are

two

basic

rip

positions,

the

"in

rip"

and

the

"out

rip".

The

rotating

arm

should

be

set

at

0°

for

both.

For

the

"in

rip"

location

turn

the

yoke

so

that

the

blade

is

at

the

rear

(see

Fig.

31),

that

is

with

the

blade

located

between

the

fence

and

motor.

For

the

"out

rip"

location

turn

the

yoke

so

that

the

blade

is

toward

the

front,

that

is

with

the

motor

between

the

fence

and

the

blade.

1.

Set

the

yoke

to

the

"in

rip"

position

as

shown

in

Fig.

17.

Place

a

carpentcr's

rule

or

12'

scale

against

the

fence.

2.

Lower

the

blade

until

it

is

just

above

the

scale

and

slide

the

carriage

in

or

out

until

the

sides

of

the

saw

teeth

facing

the

column

line

up

directly

above

the

4'

mark

on

the

carpenter's

scale.

Lock

the

cutting

head

in

this

location

with

the

carriage

clamp.

3.

Look

at

the

"in

rip"

reading

on

the

rip

scale.

If

it

does

not

read

exactly

4',

loosen

the

screws

at

both

ends

of

the

rip

scale

and

slide

the

scale

until

it lines

up

with

the

indicator

line

on

the

dust

cover

at

4".

Tighten

the

screws

in

each

end

of

the

rip

scale.

Your

scale

is

now

set

for

"in

rip"

as

well as

"out

rip"

readings.

COVERING

TABLE

TOP (FIGURE 18)

To

extend

the

life

of

your

table,

you

may

attach

2pieces

of

1,4'

ply-

wood

as

shown

in Fig.

18.

This

plywood

covering

will

take

all

the

abuse

and

wear

which

your

table

would

ordinarily

receive,

and

can

be

replaced

much

easier

and

less

expensively.

The

plywood

covering

can

be

made

in 4

sections

(one

for

each

board)

or

in 2

sections

as

we

have

shown

here.

With

a 4

section

plywood

covering

you

can

make

more

arrangements

with

your

table.

However,

all

of

the

most

common

cuts

can

be

made

with

a2

section

table

arrangement.

1.

Cut

I

piece

of

plywood

14" x32"

to

go

over

the

8"

and

6"

table

sections.

Remove

the

front

table

section,

lay

it

on

top

of

this

sheet

even with

one

side,

put

apencil

through

the

holes

and

mark

their

location

onto

the

plywood.

Drill

these

table

adjustment

holes

through

the

plywood

sheet.

2.

Cut

a

piece

of

plywood

I0Ys'

wide

x

32"

long

to

go

over

the

4Ys'

and

slotted

6"

sections.

Remove

the

6'

table

section,

lay it

on

the

plywood

even

with

one

side

and

trace

the

shaft

clearance

slot.

Cut

the

shaft

clearance

slot

in

the

plywood.

3.

Set

up

your

table

as

shown

in Fig.

18

and

tack

the

plywood

sheets

in place.

CUTTING GROOVES AND TROUGHS

IN

TABLE

TOP OR PLYWOOD COVER

(FIGURE 19)

If

you

are

going

to

use

a

plywood

cover

on

your

table,

these

cuts

sMuld

be

made

in

the

plywood.

If

not,

these

cuts

should

be

made

in

\

0ur

work

table

top.

(See

Fig.

19).

TO MAKE

0°

CROSSCUT

GROOVE:

S<:e

section

on

"THEN

MAKE

THE

0°

CROSSCUT

GROOVE

I'

T.

.\BLE",

under

ASSEMBLY

A D

ADJUSTMENTS

for

making

:-

.'>scut

groove.

TO

MAKE

45°

MITER

GROOVE:

Turn

the

rotating

arm

to

the

45° left

hand

miter

position.

Slide

the

~Iade

to

the

back

of

the

rotating

arm

track

and

lock

it with

the

:."riage

clamp.

- T.lrn

the

clevating

crank

handle

unt

il

the

saw

blade

just

clears

the

,,,ble

lOp.

Switch

on

the

motor

and

crank

the

blade

down

until it

"..:uttlllg a

;,{z"

groove

in

the

table

.

..

Hvld

the

operating

handle

with

your

left

hand,

release

the

carriage

;

~rnp.

pull

the

cutting

head

to

the

front

of

the

rotating

arm,

push

:

:0

the

back

and

turn

off

the

motor.

TO MAKE

"TROUGH"

FOR

0°

TO

45°

CHANGE OVER:

I-

vrder

lO

shift

your

saw

cutting

position

(without

raising

and

then

.'~r1ng

the

blade)

from

45°

Icft

hand

miter

position

to

0°

cutoff

• -

lion.

you

may

wish

to

cut

an

arc

trough

in

the

rear

of

the

table

,

..

I,lr

to

the

one

shown

in Fig. 19.

To

do

this

follow

the

steps

out-

-d

below:

Push

the

blade

to

rcar

stop

and

lock

thc

carriage

clamp.

-

Lo"er

the

blade

'{/

into

the

0°

groove

a

nd

unlock

the

rotating

arm.

S"

itch

on

the

saw.

FIGURE

17

FIGURE

18

FIGURE

19

-Page

7-

FIGURE

20

FIGURE

21

4. Lift

the

rotating

arm

index

pin

and

swing

the

blade

to

the

right

slowly

until

the

rotating

arm

index

pin

automatically

locates

the

45°

miter

position.

5.

Shift

the

saw

back

to

the

0°

groove,

lower

the

blade

another

~'<2H

and

repeat

the

operation.

TO MAKE

"TROUGH"

FOR

RIPPING:

I.

The

rotating

arm

should

be

in

the

0°

cutoff

position

and

the

yoke

in

the

"in

rip"

position.

See

Fig. 19,

Section

A.

2.

Place

the

fence

in

back

behind

all

table

sections

and

lock

it

in

place.

3.

The

blade

should

be

even

with

the

inside

edge

of

the

fence

and

the

carriage

clamp

locked.

4.

Start

the

motor

and

lower

the

blade

until

it

is

cutting

aI

:r/

deep

trough

into

the

table.

5.

Hold

the

operating

handle

with

your

left

hand.

release

the

carriage

clamp

with

your

right.

pull

the

blade

to

the

front

stop

on

the

roo

tating

arm.

push

it

back

to

the

fence

and

lock

carriage

clamp.

Lower

the

blade

another

'~12'.

release

carriage

clamp

and

pull

the

blade

to

the

front

stop,

push

it

back

and

switch

motor

off.

O.

Raise

the

blade

even

with

the

table

lOp.

Turn

the

yoke

to

the

"out

rip"

position

and

continue

the

rip

trough

cut

to

the

front

of

the

table

following

the

s'!me

procedure

as

used

to

make

the

"in

rip"

trough.

See

Section

Bin Fig. 19.

ADJUSTMENTS

TO

COMPENSATE

FOR

WEAR

TO ADJUST

THE

CLUTCH

ASSEMBLY: (FIGURE 20)

In

order

to

safeguard

the

motor

and

belt

of

your

machine,

we

have

equipped

it

with

a

specially

designed

clutch

assembly.

This

clutch

has

been

set

at

the

factory

at

the

proper

tension

to

assure

correct

cutting

performance.

Continuous

overloading

or

intermittent

overloading

over

a

long

period

of

time

may

cause

wear

to

the

slip

clutch

parts

and

make

it

slip

too

readily.

To

reset

the

clutch

make

the

following

adjustments:

1.

Remove

the

saw

guard,

the

saw

blade,

the

arbor

bracket

and

the

belt.

(See

Fig.

20).

2.

Remove

the

cotter

pin,

hold

the

motor

shaft

with

a

screw

driver,

(this

shaft

is

crossdrilled

with

4

locating

holes),

turn

the

nut

clock-

wise

1/12

revolution

and

insert

the

cotter

pin

through

the

shaft

hole

which

is

:ocated

90°

from

the

hole

from

which

you

removed

the

pin.

Spread

the

ends

of

the

pin

so

it will

not

slip

out.

3.

Slip

the

belt

over

the

large

pulley

carefully

so

that

the

teeth

on

the

belt

are

engaged

with

those

on

the

pulley.

Slip

the

small

pulley

and

arbor

bracket

into

position.

Be

sure

that

the

teeth

of

the

small

pulley

are

engaged

with

those

on

the

belt.

4.

You

will

notice

that

there

are

4

oversize

clearance

holes

for

mount-

ing

the

arbor

bracket

to

the

motor

bracket.

These

holes

are

for

adjusting

the

arbor

bracket

to

the

proper

location

to

maintain

belt

tension.

Insert

the

4

fastening

serews

through

the

arbor

bracket

into

the

motor

bracket

and

tighten

them

by

hand.

Press

down

gently

with

one

hand

on

the

arbor

bracket,

hold

it in

this

position

to

maintain

a

slight

belt

tension

and

tighten

the

4

screws

securely.

CAUTION:

Do not force the arbor bracket down, gentle pressure

from your hand

will

hold the belt

at

the proper tension.

5.

Mount

the

blade

and

guard

and

try

a

sample

cut.

If

the

blade

still

slips

too

readily,

repeat

the

above

adjustment

until

the

blade

slips

only

when

overloaded.

IF

CLUTCH

DOES

NOT

SLIP:

If

your

saw

blade

will

not

slip

under

extreme

overload

or

abuse,

it

has

probably

become

clogged

with

sawdust

or

other

foreign

material

and

needs

to

be

cleaned.

1.

Before

removing

the

clutch

assembly.

scratch

a

mark

on

one

of

the

corners

of

the

castle

nut

and

another

mark

directly

in line

with

it

on

the

outer

bronze

washer.

2.

Remove

the

cotter

pin

and

castle

nut

and

slip

the

clutch

assembly

off

the

shaft.

Slip

the

Woodruff

Key

out

of

the

slot

in

the

motor

shaft.

3.

Clean

all

the

parts

thoroughly

in

kerosene.

Let

the

bronze

washers

soak

overnight

in a

pan

of

S.A.E.

No.

JO

Oil.

TO

REASSEMBLE

THE

CLUTCH:

1.

Slip

the

Woodruff

Key

into

the

slot

on

the

motor

shaft

and

slide

the

inner

bronze

washer

onto

the

shaft

against

the

spacer

sleeve.

2.

Place

asteel

washer

on

each

side

of

the

pulley

\\ ith

the

pins

extend-

ing

into

anyone

of

the

4

slots

around

the

pulley. Slip the

outer

bronze

washer

into

the

flange

side

of

the

pulley".

3.

Slide

the

above

four

parts

onto

the

motor

shaft

and

over

the

inner

bronze

washer.

Place

the

spring

"asher

on

the

motor

shaft

against

the

outer

bronze

washer

and

turn

the

castle

nut

onto

the

motor

shaft

by

hand.

Hold

the

shaft

with

a

scre\\

dri\

er

and

tighten

the

castle

nut

with

a

wrench

until

the

mark

on

the

nut

lines

up

with

the

one

on

the

outer

bronze

washer.

Insert

the

cotter

pin,

reassemble

the

drive

and

make

a

test

cut.

TO REMOVE

THE

PLAY BETWEEN

THE

UPPER

ARM

AND

ROTATING ARM: (FIGURES

21

and

22)

If

the

rotating

arm

sags

"hen

the

cutting

head

is

mo\ed

to

the

ends

of

the

arm,

the

arm

pi\

at

stud

connecting

the

upper

and

lower

arms

should

be

adjusted

to

take

up

the

"ear.

To

adjust

folio"

each

step

as

outlined

below:

I.

See

Figure

21.

Remo\e

the

rotate>r

arm

clamp

nut

and

loosen

the

screws

on

either

side

of

the

bo~

on

the

front

of

the

upper

arm.

2.

Loosen

the

set

sere\\

in

the

inner

te

Slon

r.

t

just

enough

so

that

the

tension

nut

will

not

be

laded

In

pla-.:e

l'f1

te

threads

of

the

stud.

See

Figure

21.

3.

See

Figure

22.

Hold

the

arm

pi\ot

5!UJ

\

",;

"large S,'re"

driver

to

keep

it

from

turning

and

tighten

t e

Jnner

tenslI:,n

nut

by turn1l1g

it

clockwise

with

a

"I~'

open

enC

"re,.:;;

1.;;<

Arbor

l'ut

Wrench

XM-2158

for

this

adjustment

If

\0"

ra\

,wr'hased

it

as

one

of

your

Radial

Arm

Sa\\

H,Xl'SSOf!C"> I,

-Page

8-

FIGURE

22

4.

Retighten

the

set screws, replace

the

rotator

arm

clamp

nut,

try

sliding the

arm

back

and

forth

to

check for sagging

and

try

turning

the

ann

to

the 45° left

and

right

miter

positions to see if it

turns

easily.

5.

Repeat

adjustment

if

machine

still sags

or

loosen tension

nut

if it

will

not

turn

freely.

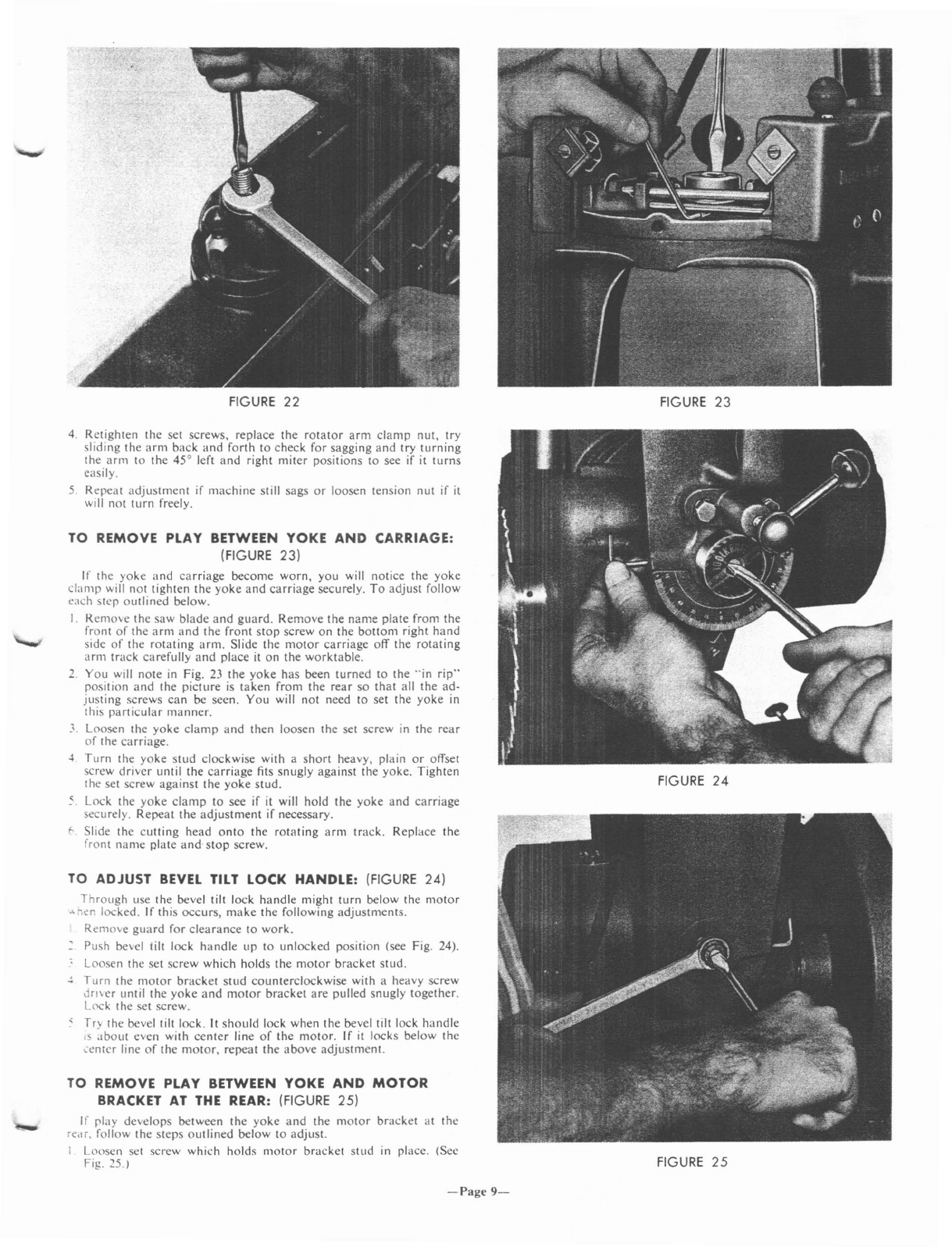

TO REMOVE PLAY BETWEEN YOKE

AND

CARRIAGE:

(FIGURE 23)

If the

yoke

and

carriage

become

worn,

you will notice the

yoke

clamp

will not tighten the

yoke

and

carriage

securely.

To

adjust

follow

each step

outlined

below.

I.

Remove

the

saw

blade

and

guard.

Remove

the

name

plate

from

the

front

of

the

arm

and

the

front

stop

screw

on

the

bottom

right

hand

side

of

the

rotating

arm.

Slide the

motor

carriage

off

the

rotating

arm

track

carefully

and

place it

on

the

worktable.

2.

You

will

note

in

Fig.

23

the

yoke

has

been

turned

to

the

"in

rip"

position

and

the

picture

is

taken

from

the

rear

so

that

all

the

ad-

justing

screws

can

be seen.

You

will not need

to

set the

yoke

in

this

particular

manner.

3.

Loosen the

yoke

clamp

and

then

loosen the set screw

in

the

rear

of

the

carriage.

~.

Turn

the

yoke

stud

clockwise with a

short

heavy, plain

or

offset

screw

driver

until

the

carriage

fits

snugly

against

the

yoke.

Tighten

the set screw

against

the

yoke

stud.

<Lock the

yoke

clamp

to

see if it will hold the

yoke

and

carriage

securely.

Repeat

the

adjustment

if necessary.

f..

Slide the

cutting

head

onto

the

rotating

arm

track.

Replace

the

front

name

plate and,

stop

screw.

TO ADJUST

BEVEL

TILT LOCK HANDLE: (FIGURE 24)

Through

use

the

bevel tilt lock

handle

might

turn

below

the

motor

A

-en

locked. If this

occurs,

make

the following

adjustments.

Remove

guard

for

clearance

to

work.

Push bevel tilt lock

handle

up

to

unlocked

position (see Fig. 24).

Loosen the

set

screw

which

holds

the

motor

bracket

stud

.

.:

Turn

the mOlOr

bracket

stud

counterclockwise

with aheavy screw

Jmcr

until

the

yoke

and

motor

bracket

are

pulled snugly

together.

Lcx:k

the set screw.

Try the bevel tilt lock.

It

should

lock when

the

bevel tilt lock

handle

,s

about

even with

center

line

of

the

motor.

If

it

locks below

the

,enter

line

of

the

motor,

repeat

the

above

adjustment.

TO REMOVE PLAY BETWEEN YOKE

AND

MOTOR

BRACKET AT

THE

REAR: (FIGURE 25)

If

play

develops

between

the

yoke

and

the

motor

bracket

at

the

rear, follow the

steps

outlined

below

to

adjust.

ILoosen set screw which

holds

motor

bracket

stud

in

place. (See

Fig. 25.)

FIGURE

23

FIGURE

24

FIGURE

25

-Page

9-

FIGURE

26

FIGURE

27

FIGURE

28

2.

Hold

the

motor

bracket

stud

with

a

heavy

screw

driver

and

turn

the

nut

clockwise

with

a

wrench

until

the

motor

bracket

and

yoke

fit

snugly

but

not

tight

against

each

other.

3.

Release

bevel

tilt

lock

and

try

tilting

the

motor

several

times.

If

further

adjustment

is

necessary

repeat

the

above

instructions.

Turn

nut

counterclockwise

to

loosen.

TO

REMOVE PLAY

FROM

PEDESTAL: (FIGURE 26)

To

remove

any

play

which

may

develop

between

the

pedestal

and

the

column

follow

the

steps

outlined

below.

I.

If

the

column

is

loose

in

the

pedestal;

loosen

the

locking

bolt.

turn

the

adjusting

screw

sleeve

about

1/12

revolution

counterclockwise,

(see

Fig.

26),

hold

it in

position

with

one

wrench

and

lock

it

in

this

position

by

turning

the

locking

bolt

clockwise

with

another

wrench.

CAUTION:

Never

turn

the

adjusting

sleeve all

the

way into

the

pedestal

in a

clockwise

direction.

This

could

cause

the

pedestal

to

spring

out

of

shape

or

crack.

You

probably

will

never

have

to

turn

the

adjusting

sleeve in

or

out

more

than

'/.s

of

a

revolution

to

adjust.

2.

Try

raising

and

lowering

the

blade

with

the

elevating

crank

handle.

If

it is

too

loose

repeat

above

adjustment.

If

it

is

too

tight,

loosen

the

locking

bolt,

turn

the

adjusting

sleeve in a

clockwise

direction

and

retighten

the

locking

bolt.

Try

raising

and

lowering

the

blade

again

and

make

any

further

adjustment

that

is

necessary.

TO REMOVE SIDE PLAY

FROM

THE

UPPER ARM:

(FIGURE

27)

After

your

saw

has

been

in use

for

some

time

you

may

notice

that

the

arm

(even

though

locked

in

position)

can

be

shifted

from side

to

side

when

the

blade

is

at

the

front

end

of

the

rotating

arm.

Follow

the

steps

outlined

below

to

correct

this

condition.

I.

On

each

side

of

the

pedestal

at

the

back

you

will

note

2

headless

set

screws

with

check

nuts.

(See

Fig. 27).

You

must

take

up

the

wear

evenly

on

both

sides

of

the

pedestal

by

adjusting

the

brass

gibs

from

each

side.

First,

hold

the

screws

on

the

right

side

with

a

screw

driver

and

loosen

the

check

nuts.

2.

Now

tighten

the

screws

securely

and

count

the

number

of

clock-

wise

turns,

then

back

the

two

screws

out

exactly

'/2

the

number

of

turns

it

took

to

tighten

them.

Hold

each

screw

in this

location

with

a

screw

driver

and

tighten

the

check

nut.

3.

Next,

loosen

the

upper

and

lower

check

nuts

on

the

left

side

with a

wrench

and

tighten

the

set

screws.

Lock

them

securely

in

position

with

the

check

nuts.

4.

Try

the

arm

to

see

if

the

side

motion

has

been

eliminated.

Try

to

raise

the

blade

with

the

elevating

crank

handle.

Repeat

the

adjust-

ment

if

all

side

play

is

not

eliminated.

If

the

gib

pressure

is

too

great

on

the

column

key

and

causes

a

bind

"hen

raising

or

lowering

the

cutting

head,

back

off

the

set

screws

slightly

on

one

side

until

the

bind

is

eliminated

and

lock

check

nuts.

5.

This

adjustment

might

have

disturbed

the

setting

of

the

rotating

arm.

Check

as

described

under

THE1'\

SQLJARE

BLADE

CROSS-

CUT

TRAVEL

and

make

any

necessary

adjlolstments.

TO ADJUST

THE

CARRIAGE

BALL

BEARINGS:

(FIGURE

28)

The

carriage

is

mounted

on

the

rotating

arm

track

with 4ball

bear-

ings

and

2

roller

bearings.

Two

ball

bearings

are

mounted

in afixed

position

on

each

side

of

the

carriage

and

roll

along

the

45°

track.

Two

roller

bearings

are

mounted

in afixed

position

on

the

bOllom

of

the

rotating

arm.

The

two

bearings

on

the

left side

are

permanent,

but

the

two

ball

bearings

mounted

on

the

right

hand

SIde

of

the

track

are

adjustable.

If

play

develops

bet"een

the

track

and

the

bearings.

follow

the

steps

outlined

below

to

adjust.

I.

(See Fig. 28.)

Remove

the

carriage

damr

knob.

2.

Remove

the

right

hand

dust

cover

b\

taking

(\ut

the

two screws.

J.

Loosen

the

set

sere'"

on

the

carriage

SIde

rlate

b~

turning

It

counter-

clockwise

<l

few

turns.

4.

Tighten

the

front

hex

bolt

and

the

rear

he'

boll

aprroxill1ately

the

same

number

of

turns

to

move

the

Sltle

rlate

In

e\enly.

Keep

trying

the

travel

on

the

track

as

~()U

3J)U>t

l<'

mdke

surc

the

bearings

aren't

binding

on

the

track.

5.

After

you

have

the

he>.

bolts

tlghlen"J

>t' th,l

the

carriage

moves

smoothly

and

some"

hat

snuglY al(\ng

the

track.

tIghten the

socket

set

scrcw

securel~

.

-Page

10-

RIGHT HAND MITERING

FIGURE

30

FIGURE

29

FIGURE

31

CROSSCUTIING

RIPPING

7

0.

It

is

important that the bearings be

in

line from front to back on

the track ·arm.

To

check this, apply some light grease to the tracks

of

the rotating arm. Wipe the grease down to athin film. Then pull

the carriage to the front stop

of

the track and push it back to observe

the tracks left

in

the grease. There should be only one mark, the

width

of

the bearing face. If the bearings are

not

moving in the

same line, you must make further adjustments. If the front bearings

are higher than the rear, tighten the rear hex screw. If the front

bearing

is

lower, you' must tighten the front hex bolt. This adjust-

ment

is

important

in

keeping your saw

SQuare

for ripping operations.

The

felt

track wipers on each side

of

the right

and

left hand dust

covers

will

wear and should be adjusted occasionally so

that

sawdust

won't pile up on the track

and

cause abind

in

the crosscut travel.

I.

Loosen the screws

in

the metal backing plates.

2.

Slide each felt wiper down until it fits snugly against the track

and

tighten the screws.

TO

ADJUST

FELT

TRACK

WIPERS:

OPERATIONS

CROSSCUTTING:

(FIGURE

29)

The rotating

arm

must be positioned

at

0° on the miter scale.

The

motor position should read 0° on the bevel tilt scale and the yoke

should be positioned to the left

of

the rotating arm

in

the cutoff po-

sition. Place the wood on the work table against the fence.

The

blade

should be behind the fence and should be lowered into the crosscut

groove

in

the table. Make sure all clamps except the carriage clamp

are

in

the lock position. Hold the operating handle with one hand

and turn the saw on with the other. Hold the work against the fence,

pull the blade through the work, push the blade back to the rear

of

the fence and turn saw off. (See Fig. 29.)

For

best crosscut results, use IO-CC-58 Crosscut Blade with the

Model 910A Radial

Arm

Saw. See

ACCESSORIES

section under

BLADES for prices.

RIGHT

AND

LEFT

HAND

MITERING:

(FIGURE

30)

(See Fig. 20.)

The

rotating

arm

should be positioned to

your

desired

miter angle as indicated on the miter scale.

The

most common miter

cuts are 45° right hand

and

45° left hand.

The

miter index pin will

locate these positions automatically. Push the blade to the rear

of

the

fence and lower it into the 45° miter groove. Hold the work against

the fence, pull the blade through the work and push the blade back.

For best results use the same blade as for crosscutting.

Radial Arm Saws

do

not

require frequent oiling. Oil merely tends

.0

collect dust and clog up the mechanism. Oil the 3index pins

and

moving surfaces

about

once per month with S.A.E. No. 20 Oil to

minimize the wear. Squirt a

few

drops through the slot

in

the rear

of

the pedestal on the thrust bearing

and

on the elevating screw

about

once per month. Never oil the Rotating Arm Track. This track should

be cleaned occasionally with lacquer thinner

or

carbon

tetrachloride

to remove any dirt

or

grease.

LUBRICATION

RIPPING:

(FIGURE

31)

Your machine

will

rip to the center

of

a581

11."

wide board. You can

rip boards up to

18"

wide with the saw in the

"in

rip"

position

and

boards from

12"

to 29" wide with the saw

in

the

"out

rip"

position.

To set the machine to the

"in

rip"

position, (see Fig. 31), turn the

rotating arm to 0° position, turn the yoke to

your

left until it auto-

matically indexes

in

the position with the blade parallel to the fence,

between the fence and the motor. When using the

"in

rip"

position,

lock the carriage on the rotating

arm

track

at

the desired width

of

the board to be ripped. Lower the blade into the rip trough, feed the

material through from the right hand side as shown

in

Fig. 31. Never

rip from the anti-kickback side

of

the guard. Always tilt the guard so

that the ripping end just clears the work, lower the anti-kickback arm

until the grips hang

Ys"

below the work. Never rip without using the

guard and anti-kickback grips.

To Set the Machine to the

"Out

Rip"

Position, turn the yoklt to

your right until

it

indexes parallel to the fence with the motor between

the fence and the blade.

The

"out

rip"

cutting operation

is

performed

In

the same

manner

as the

"in

rip"

but since cutting head

is

turned

180°

the work

is

fed

from the left instead

of

from the right.

The

"out

rip"

position

is

normally used only for ripping wider than

18",

Long

work should

be

supported, as it comes through the blade and over the

opposite end

of

the table to prevent it from kicking up into the blade.

-Page

11-

I

@ /

@@J@

"\

:1:

I/

-jtf-

\~~

",

--

r(/

',A'

,

,

/

-Page

12-

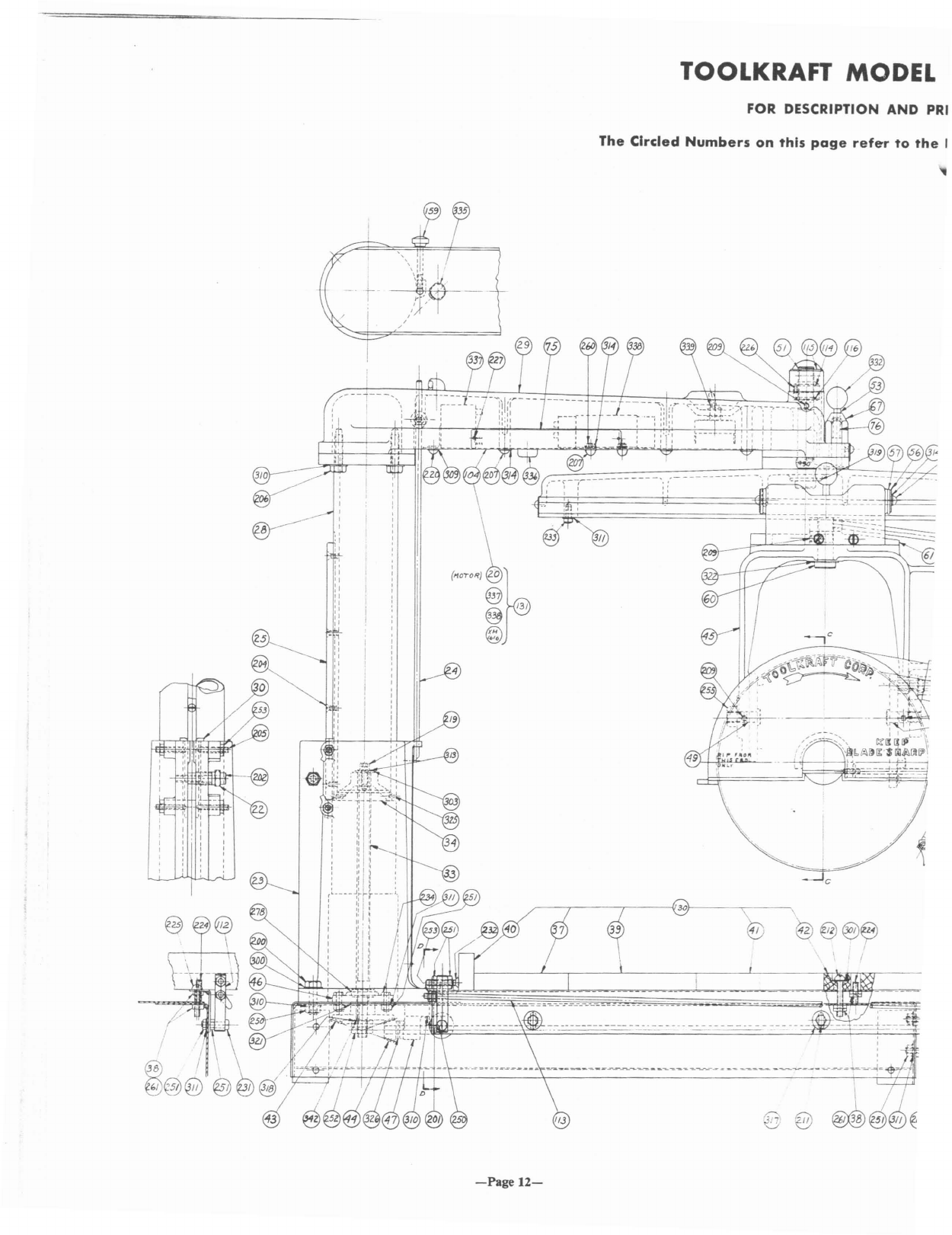

TOOLKRAFT MODEL

FOR DESCRIPTION

AND

PRI

The

Circled

Numbers

on

this

page

refer

to

the

I

<;:.:-::::-,

..

~~~

i

\~b£i<~Ii:$cli~~I}l\

•

I..

..'

J

(I

__

----I

..!.

_

'}----"'-~--\

~

@§@~

I

,!

,-----~

-H+-iH-'--Y-'

~

---.-tt

-

----..

---------------

-----~~_.

--

----

--------~---~~-~~

//3

ARADIAL ARM

SAW

F

PARTS

SEE

THE

PARTS

LIST

rs

in

the

Index

Number

Column

of

the

Parts

List.

~

._--

:':.---®

-'-

j-

/3

7

/3

.32

-Page

13-

~

/

TOOLKRAFT MODEL

910A

RADIAL ARM

SAW

FOR DESCRIPTION AND PRICES OF

PARTS

SEE

THE

PARTS

LIST

The

Circled

Numbers

on

this

page

refer

to

the

Nu_mb~rs

In

the

Index

Number

Column

of

the

Parts

List.

3

-5

~

__

"'....L _

c

3

2.

~

-++~--H"-d).----r1P=-===-~~~

'.

L

-I

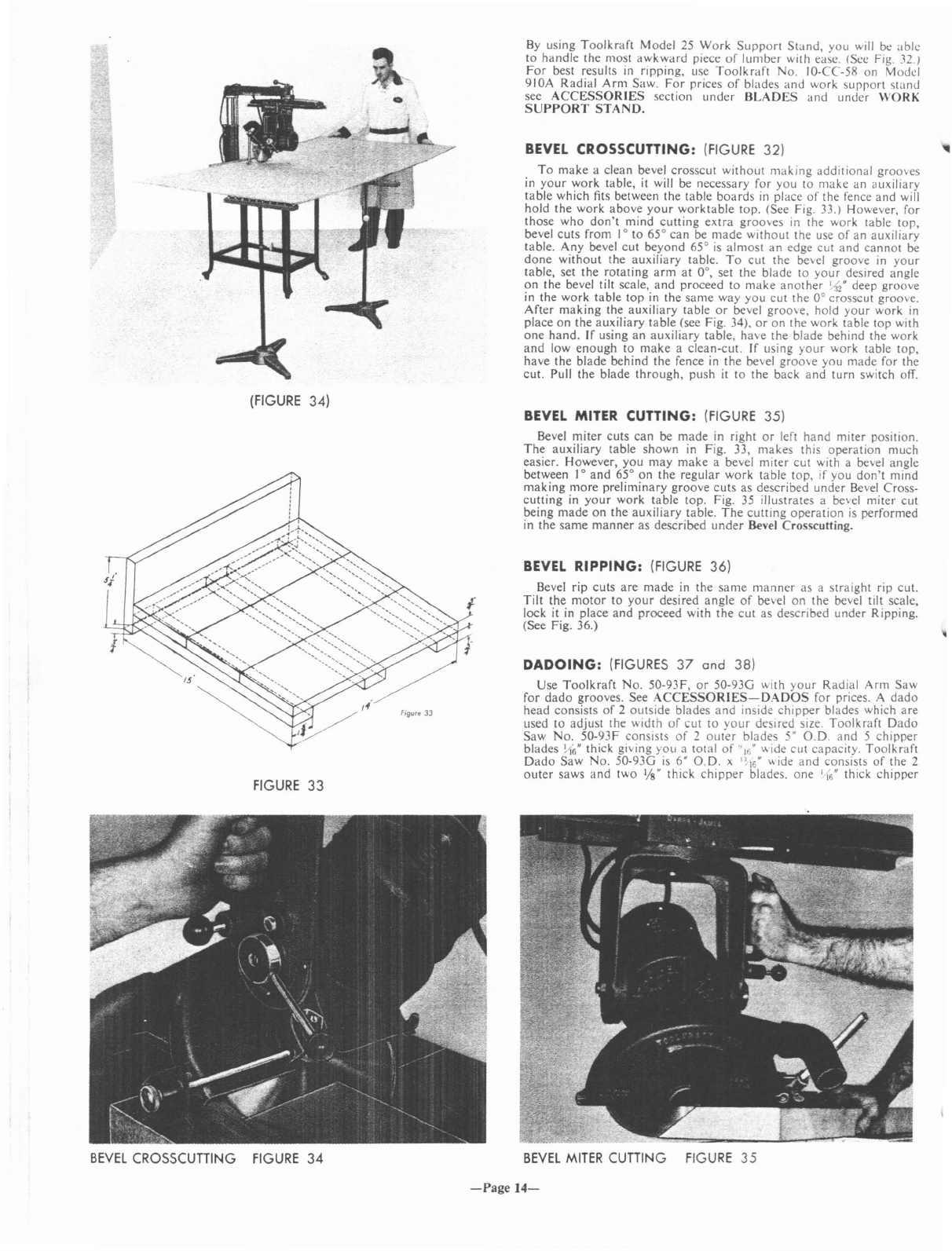

By

using

Toolkraft

Model

25

Work

Support

Stand,

you

will be

able

to

handle

the most

awkward

piece

of

lumber

with easc. (Sec Fig. 32.)

For

best results

in

ripping,

usc

Toolkraft

No.

IO-CC-58 on Model

910A

Radial

Arm

Saw.

For

prices

of

blades

and

work

support

stand

see

ACCESSORIES

section

under

BLADES

and

under

WORK

SUPPORT

STAND.

BEVEL

CROSSCUTTING:

(FIGURE

32)

To

make

aclean bevel

crosscut

without

making

additional

grooves

in

your

work

table,

it

will be necessary for

you

to

make

an

auxiliary

table

which fits between

the