Toolkraft MoterTools 829A S1 Use and care manual

SPRINGFIELD, MASS., U.S.A.

OPERATINGINSTRUCTIONSANDPARTSLIST

for

MODEL829A9"TILTINGARBORSAW

BEFOREATTEMPTINGTODOANYWORKWITHYOURSAW

READTHESEINSTRUCTIONSCAREFULLY

THISLISTWILLBEVALUABLETOYOUINORDERINGSERVICEPARTS

DONOTTHROWITAWAY

YOURTILTINGARBORSAWCANBETHEMOSTVERSATILETOOLINYOURWORKSHOP

WITHTHECOMPLETELINEOFTOOLKRAFTACCESSORIES

SHAPING& MOULDING

HEADSMC-5

XM-2156

WRENCH

DADOSETS DADOCUTS

Important:Theseinstructionswerewrittenfor

yourbenefit.Youmayneverbecompletelysatisfied

withtheoperationofyoursaw,unlessyouread

themthoroughly.

UNPACKINGANDINSTALLATION

YourToolkraftModel829TiltingArborCircularSawis

shippedcompletewithbuiltinmotor,readytooperateas

soonasyouhavefollowedthesimplestepsoutlinedinthis

manual.

1.Besuretoinspectallpackagingmaterialforpartsbefore

throwingitaway.

2.Thesawtablehasbeencoatedwitha protectivecoating

topreventrust.Thisshouldberemovedfromthetable

topandmiterslotstopreventstickingofyourworkpiece

ormiterbar.Usevarsolorkerosenetodissolvethecoating.

3.Yoursawshouldbemountedsecurelyona benchorstand

sothatthetableheightwillbeapproximately34"to38"

fromthefloor.EithertheToolkraftModelS1orS2Stand

maybeusedformountingthismachine.

Bothstandsaremadeofheavygagesteelandconformto

therigidspecificationssetbyToolkrafttoinsureyoua

lifetimeoftroublefreeservice.

SPECIFICATIONS

ModelS2Stand

Adjustableinheightfrom

24"to33¼".

Length— 21".

Width— 17¼".

With2 adjustablesteel

crossbars.

Color:MachineGray.

Shippingweight— 34lbs.

ModelS1Stand

Adjustableinheightfrom

24"to33¼".

Adjustableinlengthfrom

16½"to26⅛".

Width— 17¼"— with2

adjustablesteelcrossbars.

Color:MachineGray.

Shippingweight— 36lbs.

SeeaccessorypartslistunderStandsforprice.

POWERSUPPLYCONNECTIONS

ThemotorspecificationsofToolkraftModel829Motor-

1.Besuretheelectriccurrentinyourshopisofthesame

characteristicsasthatonthenameplateofyourmotor.

2.Measuretheapproximatedistancebetweenthepowerpanel

andtheoutletinyourshop.Checktoseethatthewiresize

ofthiscircuitislargeenoughtoconductsufficientcurrentto

yourmotor.Runningyourmachinewithlowerthan110

voltswillnotgiveyouthebenefitoffullpowerandcould

beinjurioustothemotor.

Thefollowingwiresizesarerecommendedfortroublefree

operation:

115VOLTLINESONLY

LengthofWireWireSizerequired(gage)

50ft.orless14

50to100ft.12

Ifitisnecessaryforyoutouseanextensioncordwith

yourmachine,makesureitisa 12gagecord.Thiswillpro-

videyouwithanadequatepowersupplyatthemachine.

3.Forcircuitprotectionusea 15ampereFustronorFustat

delayedactionfuse.Runningothermachinesorlightson

thissamecircuitcouldoverloadthecircuitandcauseyour

fusetoburnout.

STATICELECTRICITY

Attimesyoumightreceivea slightshockwhenyoutouch

yourmachine.Ifthishappensandyoufindthatallelectrical

connectionsattheswitchandmotorareintact,youcanbesure

thatitisonlya chargeofstaticelectricitybuiltupbyfriction

betweenmovingparts,suchasthepulley,beltandfriction

clutch.Thiscanbeeliminatedbygroundingyourmachine

toa waterorheatingpipe.

ASSEMBLYANDADJUSTMENTS

EveryToolkraftmachineisthoroughlytested,inspected

andalignedatthefactory.However,minoradjustmentsmight

benecessarybecauseroughhandlinginshipmentorunpacking

mayhavedisturbedthesettings.Checkyourmachinecare-

fullytobesureeverythingissquareandinline.

1.Mountthefenceguidebaronthefrontofthesawwith

theroundheadscrewsyoufindinthesmallbagtapedto

thisbar.Makesurethedistancefromthetopofthebar

tothetopofthetableisequalateachendoftable.

Loosenthescrewsandadjustifthisdistanceisnotequal

onbothsides.

2.Slidethefenceassemblyontotheguidebaruntilitisin

linewiththeoutsideedgeoftherighthandmiterbarslot

andlockitbypushingdownonthefencelocklever.Ifthe

fencedoesnotlockparalleltotheedgeofthisslot;lift

thefencelocklever,loosenthetwosocketheadcapscrews

(Index77onFig.1),squarethefencebyhand,tightenthe

screws,lockthefence,andrecheck.Ifthefencedoesnot

locktightly,youmayadjustitbyholdingthescrewinthe

rearofthefencewitha hexwrench,looseningthecheck

nutonecompleteturn,andtighteningthescrewoneturn

in,untilthechecknutlocks.Trythefencelockleveragain

andrepeatadjustmentifnecessary.

TOADJUSTMITERGAGE:

Checkthemitergagewitha squaretoseethatitindexes

exactlyat90°.Ifitdoesnot,youmaycorrectitbyloosening

themiterheadlockknob,turningthemiterheadbyhanduntil

itissquareandlockingitinpositionwiththemiterclampknob.

Nextloosenthe2 roundheadscrewsonthebottomofthe

guidebarabout½iturn,turnthepointerblockbyhanduntil

theballseatsitselfintothe90°indexinggrooveonthemiter

headcasting.Thenholditinplacebyhandwhileyoure-

tightenthe2 roundheadscrewsonthebottomofthebar.

Itwillthenindexcorrectlyeverytimeatany15°indexing

positiononthemiterhead.Loosenthepointerscrewandset

itinlinewiththe90°lineonthescale.

TOADJUSTBLADEPARALLELTOMITERSLOT:

Thesawblademustbeparalleltothefenceandmiter

slot.Tocheckthis,raisethebladeashighasitwillgo,mark

oneofthesawteethwitha crayonorpencil,turntheblade

untilthistoothislevelwiththetableatthefrontofthe

miterslot,andmeasurethedistancefromthistoothtotheedge

ofthelefthandmiterslotwitha steelscale.Nextturnthe

bladeuntilthesametoothislevelwiththetableattherear

ofthemiterslotandmeasurethedistancetothemiterslot.

Ifadjustmentisnecessaryloosenthe2 screwsholdingeach

trunnionguide(frontandrear)about½ turnandtapthe

trunnionguidestotheleftorrightwitha plastichammeruntil

thebladeisinlinewiththemiterslot.Besuretorecheckthe

alignmentafteryouhavetightenedthetrunnionguidescrews.

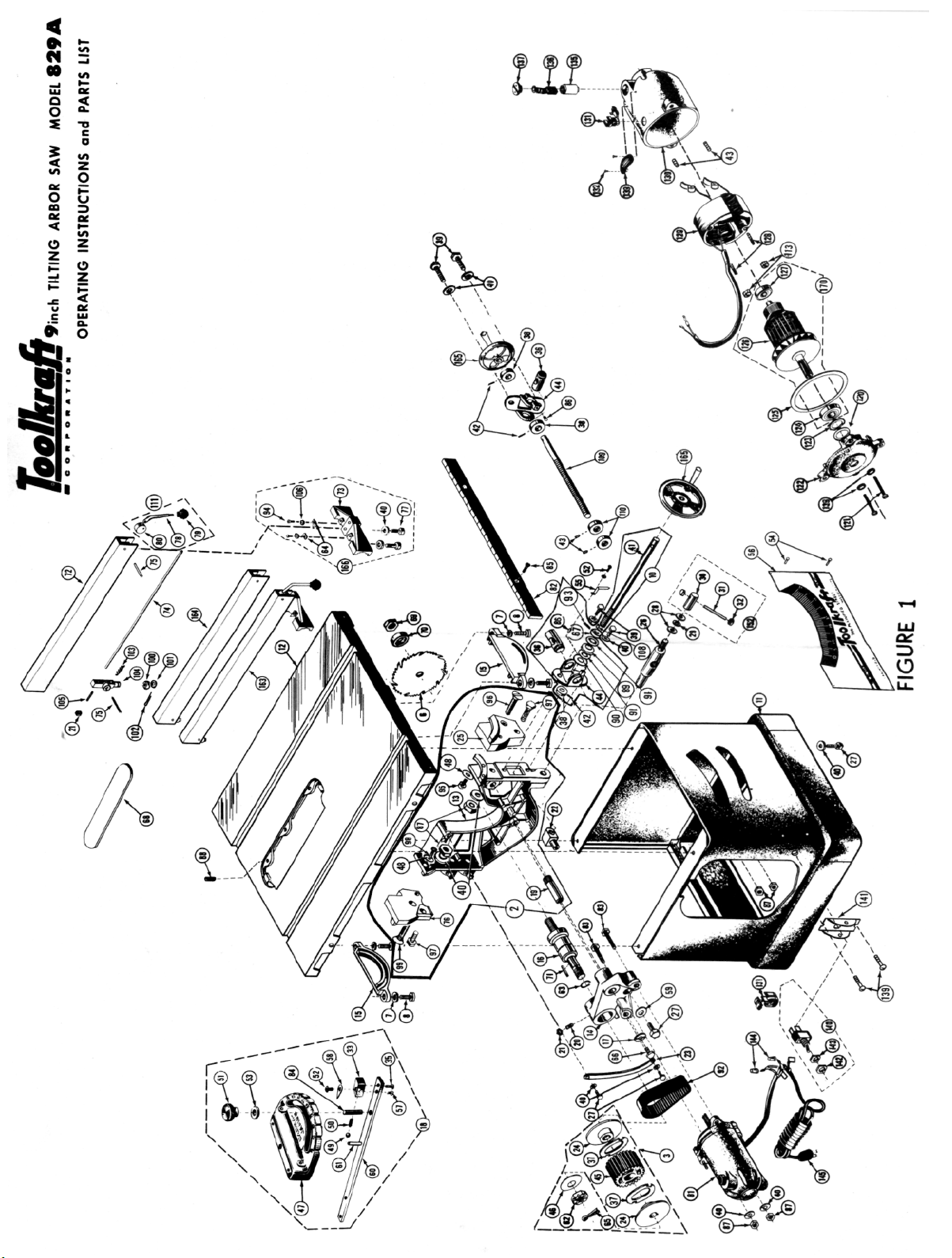

TOCHANGETHETIMINGBELT:SeeFigure1,Page4.

Removethe2 hexnuts(Index87)and2 washers(Index40),

thenslidethemotoroutandremovetheoldbelt.Puta new

beltoverthedrivenpulley(Index45),slipthemotorshaft

intothebeltandmountthemotorontheelevatingarm.Re-

placethewashersandnutsandpressthemotortowardthe

frontofthesawtomaintainbelttensionwhileyoutighten

thenutssecurely.CAUTION:Toomuchtensionwilldecrease

thebeltandbearinglife.Afterthenewbeltisinstalled

checkthedeflectionbypressingonthebeltinthecenter

betweenthedriveanddrivenpulleyswithyourfinger.There

shouldbeabout⅛"deflection.Repeattheadjustmentuntil

yougetthecorrecttension.

TOADJUSTCLUTCHASSEMBLY:Inordertoprotectthelife

ofthebeltandthemotorallToolkraft"MoterTool"tilting

arborsawsareequippedwitha speciallydesignedslipclutch.

Foryourconvenience,theclutchissetatthefactorytothe

propertorqueforcutting.Throughweartheclutchmaybe-

comelooseandsliptooeasily.Ifthishappens,followthe

adjustingstepsoutlinedbelow.(RefertoFigure1).

1.Raisethesawbladeapproximately1"abovethetableand

thenremovethetrapplate.Checkthenutwhichholds

thebladetoseethatitissecurelytightened.

—Page2—

2.Toadjusttheclutchitwillbenecessarytopreventtheblade

andarborfromturning.Thiscanbestbeaccomplishedby

placinga woodenwedgeacrosstheopeningofthetrap

slotandintooneofthelargegulletsinfrontoftheblade.

Nowusea pairofplierstoreachthroughtheopeningin

therearofthesawbaseandstraightenouttheendsofthe

cotterpinwhichholdsthecastellatednutinplace.Remove

thecotterpin(Index65)andusea wrenchtoturnthe

castlenut(Index62)clockwise1/12turn.Theninsertthe

cotterpinthroughtheholewhichislocated90°fromthe

onewhichthecotterpinwasfirstin.Iftheclutchstillslips

tooreadilyrepeattheaboveuntiltheclutchslipsonly

whenoverloaded.

3.Iftheclutchbecomescloggedwithsawdustanddoesnot

slipwhenthemotorisoverloaded,removethemotor,

takeoutthecotterpin,turnthecastellatednutoffthe

shaft,andthenpulltheentireclutchassemblyoffthe

arbor.Becarefulnottolosethedrivingkey(Index71).

Nowcleantheclutchpartsthoroughlyinkerosene.Place

thetwobronzewashersina panofNo.20SAEOiland

letthemsoakovernightifpossiblesothattheoilwill

penetratethemcompletely.

TOREASSEMBLECLUTCH:Firstchecktheretainingring

(Index63)toseethatitisproperlyseatedinthegroove

aroundthearbor.Replacethedrivingkey.Nowplaceone

steelwasheroneachsideofthepulleywiththeslotsover

thebossesinthepulley,andthenslipa bronzewasher(In-

dex24)intoeachsideofthepulleybore.Makesurethe

keywaysofthewasherslineupandslidetheentireassembly

ontothearborsothattheflangeofthepulleyistowardthe

outsideofarbor.Thespringwasher(Index46)issaucer

shaped.Placeitontheshaftsothatthetopofthesaucer

(outsidediameter)isagainstthebronzewasherandtighten

thecastlenutbyhand.CAUTION:Donotusea wrench

forthisinitialsetting.Usea pencilorcrayontoputa mark

ononeofthesixpointsonthecastlenutandthenputa

markonthebronzewasherdirectlyinlinewiththemarkon

thecastlenut.Nowusea wrenchtoturnthecastlenut½

turn(180°)ina clockwisedirection.Insertthecotterpin

throughoneoftheholesinthearborandbendtheendsof

itaroundtheoutsideoftheslotsinthecastlenut.Theclutch

shouldnowbesetatthepropertension.

Trythemachineandtightenthecastlenut1/12ofa turnat

atimeifthebladestillslipstooeasily.Dirtwillsometimes

buildupbetweenthewashersiftheyare beginningtowear

andcausethemtogallorpitunevenly.Whencleaningor

adjustingyourclutch,alwaysexaminethemovingpartsofthe

clutchassemblytoseeifreplacementsarerequired.Seethe

partslistforreplacementnumbersandprices.

TOCHANGEBLADES:

Removetheinsertplate,arbornutandouterwasher.

Beforereplacingthebladealwayscheckthefaceoftheinner

washer.Removeanydirtorsawdustdepositsfromthisface

sothatyourbladewillseatsquare.Alwaysrotatetheblade

severaltimesbyhandtomakesureitclearseverythingbefore

turningthepoweron.

TOADJUSTTILTSCREWSTOPS:

Tofacilitateyourcuttingsetups,stopcollarshavebeen

placedonthetiltingscrewsothatitwillstopwhentheblade

isatthe90°and45°positions.Ifyourtilthandwheelcontrol

doesnotstopwhenitisatthe45°and90°position,youshould

adjustthetiltingscrewstopcollars(IndexNo.110onFig1,

Page4).Todothis,placea squareagainstthetableandthe

blade,turntheelevatinghandleuntilthebladeisexactly90°

tothetableandtightenthetiltlockhandle(IndexNo.152on

Fig.1,Page4).Loosenthesetscrewontheouterstopcollar,

turnthiscollarinagainstthetiltlockstudandtightentheset

screw.Nowcheckthetiltpointerandsetitat0°ifitisnot

nowonthe0°line.Checkthe45°settingandadjustthe

innerstopcollarifnecessary.

TOADJUSTTENSIONOFELEVATINGSCREWHAND-

WHEEL:Iftheelevatingscrewhandleturnsfromthevibra-

tionofthemotorandchangestheheightsettingofthesaw

itwillbenecessaryforyoutoadjustthetension.Usea 3/32'

hexkeytotightenthe2 setscrews(Index10.8)intheelevating

screwfrontcollar(Index67)equallyoneachside.Thiswill

increasethetensionofthespringwashersandtakeupthe

wearbetweentheswivelpinandthecollarwashers.Trythe

handwheelagain.Ifitistootightloosenthesetscrews

evenly.Repeatuntilhandwheelnolongerslipsfromvibrations.

CONTROLS

Readthefollowingsectioncarefully.

Foryourownsafetyandsatisfaction,youmustbefamiliar

withthefunctionandfeelofallthecontrolsonyourmachine.

1.Thehandwheelinthefrontofthemachineisforraising

orloweringthebladefortheproperdepthofcut.Turn

itclockwisetoraisethebladeandcounterclockwiseto

lowertheblade.Thepropercuttingheightforthesaw

bladeshouldbejusthighenoughtocutthroughthe

workpiecewithoutleavinga burrontop.

2.Thehandwheelontherightsideofthemachineisfortilting

thebladetomakea bevelcut.Thebladewilltiltfrom0°

to45°.Turnthehandwheelclockwisetotilttoward45°

andcounterclockwisetoreturnto0°.

3.Thesmallhandlebelowthehandwheelinthefrontofthe

sawisthetiltlockhandle.Thisisusedtolocktheblade

intheproperbevelposition.Loosenthislocktomakeany

bladeanglechangewiththetiltscrew.

4.Themitergage(IndexNo.18,onFig1)isusedformiter

andcross-cuttingoperations.Itisgraduatedfrom90°

positionto30°positiontotherightandtotheleft.By

looseningtheknob(Index51)youmaypivotthemiter

headonthebartoanydesiredposition.Thereisa spring

loadedballwhichwillautomaticallylocateevery15°the

mostcommonlyusedanglepositions.Thebarismadeto

slideintheslotsoneithertherightorleftsideofthesaw

table.

5.Theripfence(Index163onFig1)isusedtoguidewood

fora rippingoperation.Thedistancefromthebladeto

thefencedeterminesthewidthoftheboardbeingripped.

Thisdistanceissetbyliftingthefencelockleverinfront,

movingthefencetothedesiredpositionbyhandand

lockingthefencebypushingdownonthefencelocklever.

Thepointers(index64)shouldbeadjustedinaccordance

withthethicknessofthebladeonyourmachinesothat

youcanquicklychangethewidthoftheripsettingbyusing

thegraduatedscaleontopofthefenceheadguidebar.

SAFETYPRECAUTIONS

1.Dressproperlyforwork.

Donothavelooseclothing,shirttail,shirtsleeves,neck-

ties,etc.,whichcouldbecomecaughtinpulleys,sawteeth

orknives.Weargoodshoeswhichwillprovidefirmfooting.

2.Keepyourworkareaasclearandneataspossible.

Clutteredsawtablesaredangerous.Clutteredfloorscan

causebadfalls.

3.Think— Keepyourmindonwhatyouaredoingwhile

youaredoingit.

4.Purchasetheapprovedbladeguardforyourmachine(see

AccessorySectionunderGuardandSplitter.)

5.Alwayspushnarrowstockpastthebladewitha pusher

stick.Havethisstickhandyatalltimes.

6.Nevermakea freehandcut.Usethemiterheadorrip

fenceforalloperations.Donotusebothforthesame

operation.

7.Examinethestockbeforecutting.Besureithasa straight

smoothsidetorunagainstthefence.Besureitdoesnot

containnails.Besureitwillnotbreakinthemiddle

whenripped.

8.Donotstanddirectlyinfrontofthesaw.Avoidstanding

inareawhereyoucouldbehitbykickbacks.Seethat

noonestandsinkickbackarea.

9.Whenyouarehandlingtheblade,removethepower

supplyplug.Theswitchcouldbeaccidentallypushedto

theonposition.

—-Page3—

PARTSLIST—TOOLKRAFT9"TILTINGARBORSAW—MODELNo.829A

(OrdersofLessThan$5.00AreSubjecttoa $1.00InvoiceCharge)

Index Part Units Price

No.No.NomeofPart Per. Assy. Each

Index Part Units Price

No.No.NameofPart Per. Assy. Each

289B-2TrunnionAssembly1 $25.00

3815A12-3FrictionClutchAssembly1 7.50

69-CB-50Blade— 9"Combination1 4.95

7XW-451LockWasher4 .25

8XS-69Screw4 .25

10829-10ElevatingScrewAssembly1 6.50

11829-11Base1 15.50

1289B-12Table1 32.85

1389B-13TrunnionFrame1 12.55

14825-14ElevatingArm1 5.25

1536-15TrunnionGuide2 1.25

16825-16ArborandBearingAssembly...1 11.00

17XW-457Washer1 .25

18825A-18MiterGageAssembly1 11.70

1936-17PivotPin1 .85

20XS-49Screw1 .25

21XN-220Nut2 .25

2236-16SwivelNut1 1.25

2389B-23GuidePlate1 .95

24825A-24Flange— FrictionClutch2 2.30

2589B-25FrontAdapter1 2.95

2636B12-26Stud— TiltLocking1 1.75

27XS-33Screw7 .25

28XW-482Washer2 .25

29XW-439Washer1 .25

3036-25Lock— Tilt1 .65

3136-66Handle— TiltLock1 .40

3236-66-1Cap— TiltLockHandle2 .30

33825A-33Block— MiterPointer1 1.10

35XS-169Screw1 .25

3636B12-36Pin— Swivel2 .95

37910A11-83Washer— ClutchFriction2 .25

3836-33Collar— Stop3 .35

39XS-32Screw4 .25

40XW-407Washer16.25

4136B11-41Screw— Elevating1 1.95

42XM-888Pin3 .25

43XS-173Screw4 .25

4436-81Bracket— TiltandElev.Screw. . 2 .70

45910A11-73Pulley—Arbor1 2.35

46825-46Washer— SpringType1 .50

47100-67MiterHead1 6.10

48XW-401Washer2 .25

49XB-783Ball1 .30

5085A-114MiterBallSpring1 .25

5136B12-51Knob— Miter1 .65

52XS-50Screw2 .25

53XW-420Washer1 .25

54XS-280Screw4 .25

5536B11 -55 Pointer— Tilt1 .50

5689B-56-3Plate— NameandIndex1 3.45

57XS-350Screw1 .25

58100-72Pointer—Miter1 .30

59XW-455Washer— Spring1 .25

60825A-60Bar— MiterGuide1 2.90

61XM-915Pin1 .25

62XN-385Nut1 .25

63XM-1241Ring1 .25

6450-91Pointer— FenceHead2 .25

65XM-868Pin1 .25

66XS-67Screw1 .25

67829-67Collar1 .60

6850-41Plate— Trap1 3.50

69XN-350Nut1 .25

7036-27Washer1 .45

71XM-1360Key— SlipClutch1 .25

7285A-102Fence1 13.25

7385A-107FenceHead1 5.50

7485A-105Rod— Fence1 1.00

—Page5—

75XM-933Pin— Fence2 $ .25

7689B-76Adapter— Rear1 2.95

77XS-200Screw2 .25

7885A-110Handle— Fence1 .65

79XM-826Knob— FenceHandle1 .35

8085A-109Cam—Fence1 1.50

81829A12-9Motor1 44.95

8285A-133Bar— FenceGuide— 22"long.1 6.25

83XS-198Screw2 .25

84XS-205Stud— MiterBar1 .25

85XS-20Screw2 .25

86XS-351Screw2 .25

87XN-213Nut6 .25

88XS-336Screw5 .25

89829-89SpringWasher— Friction— Elev.2 .25

90XW-577FiberWasher— Friction— Elev.. 1 .25

91XW-583Washer— Friction— Elev2 .25

92XM-1120Belt— Motor1 4.25

93XM-889RollPin— Elev.FrictionCollar. . 1 .25

94XS-300Screw2 .25

95XS-322Screw1 .25

96XS-348Screw1 .25

97XS-94Screw2 .25

98XS-331Screw1 .25

99XS-326Screw1 .25

10036B12-100Roll— RearFenceClamp1 .25

101XW-453Washer1 .25

102XM-1013CotterPin1 .25

10385A-143Spring1 .25

10436B12-76Clamp— RearFence1 1.35

105XS-203Screw1 .25

106XW-402Washer2 .25

108XS-18Screw2 .25

10989B-109Screw— Tilt1 3.50

11050-98Collar— Screw2 .45

11136B12-111CamandHandle1 2.75

113XN-200Nut2 .25

117XS-87Screw2 .25

120829A12-10-13Washer1 .25

121XS-362Screw2 .25

122829A12-9-2EndShield1 3.75

123XW-447Washer1 .25

124XB-653FrontMotorBearing1 5.00

125829-10-3BaffleRing1 .90

126829-10-11Armature1 18.95

127XB-651RearMotorBearing1 4.50

128829-10-12Stud2 .25

129829-10-5Field1 7.50

130829-10-6Housing1 10.00

131XM-1191Grommet2 .25

132XS-149Screw2 .25

133829-10-7Nameplate1 .25

135829-10-8BrushHolder2 1.40

136829-10-9BrushandSpring2 1.25

137829-10-10BrushCap2 .35

138XW-412Washer2 .25

139XS-260Screw2 .25

140XM-1605Switch1 2.25

141XM-1633SwitchGuard1 .45

142XN-347Nut—Switch1 .25

143XN-348Nut— Switch1 .25

144XM-1198Connector— SwitchandCord. 2 .25

145XM-1635CordandPlug1 2.00

15236-152TiltLockAssembly1 1.50

16385A-131FenceAssembly(Completewith

FenceHead)1 24.00

16485A-132FenceAssembly(LessFence

Head)1 20.00

16536-165Handwheel2 1.25

166• 36-166FenceHeadAssembly1 5.25

170829A12-10-14ArmatureFanandBearingAssy1 28.00

10.Readtheseinstructionsandconsultyourlocallibraryfor

morecompletebooksorarticleswrittenabouttheproper

useofcircularsaws.Yourmachinecanbedangerousif

nothandledproperly.Approachyourmachinewith

respectandconfidence,andnotwithfear.

LUBRICATION

Yoursawhasbeencarefullydesignedandbuilt.Itwill

giveyouyearsoftroublefreeservice,ifyougiveitproper

careandlubrication.

1.Arborballbearingsaregreasepackedatthefactoryand

neednofurtherlubricationforthelifeofyourmachine.

2.Usea greaseandgraphitelubricantonbothendsofthe

trunnionattheguides(Index15),ontheelevatingscrew

(Index41),thrustcollars(Index38and67),andtiltscrew

(Index109).

Thefollowingpartsshouldbeoiledfrequentlywitha good

gradeofS.A.E.20or30weightoil.

1.Elevatingswivelnut(Index22).

2.Swivelpins(Index36).

3.Pivotpin(Index19).

4.Tiltlockingstud(Index26).

5.Pivotpointsonthemitergageandripfence.

6.Allotherpointswherethereisfrictionbetweenmoving

parts.

Topreventthesawtablefromrusting,keepitcoveredwith

athincoatofoilwhenitisnotinuse.Wipeitoffbefore

usingthesaw.

HOWTOORDERREPAIRPARTS

Tohaveyourorderfilledpromptlyandcorrectly,please

furnishallthefollowinginformation:

1.Modelnumberandserialnumberofthemachine.

2.Number,name,anddescriptionofpart.

Youpaychargesfromshippingpointbasedonsizeand

totalweightoforder.

HELPFULHINTS

ToolkraftMoterTooltiltingarborsawsoperateat

about2000revolutionsperminutefasterthanmostcompa-

rablemachines.Theincreasedspeedgivesyoufast,accurate,

cleancuts.Forsmoothtroublefreeoperation,alwaysbuy

ToolkraftSawBladeswhichareofspecialdesigntooperate

attheincreasedcuttingspeed.Seeaccessorypartslist,page

7,forcompletelistofavailableblades.

Youmayfinditdifficulttohandlelargesheetsofplywood

orlongboardsbyyourself.Tryingtohandlethesewithout

theaidoftableextensionsandauxiliarysupportstandsof

sometypecouldcauseyoutospoilyourworkpieceortoslip

andcauseseriousorpainfulinjurytoyourself.Forsafety,

easeofhandling,andaccurateworking,werecommendthe

useofToolkraftHeavyCastIronGridTypeExtensions,

Number85A-200C,whichare9"wideand20"long.

Thesewillprovideyoursawwitha workingsurfacemorethan

twiceitspresentsize.Seeillustrationonfrontcover.See

accessorypartslist,page7,forprice.

Forthegreatesteaseinhandlinglargesheetsorripping

longboards,werecommendtheuseof1 ormoreToolkraft

ModelS-25WorkSupportStandsinadditiontothetable

extensions.Thisstandhasa 20"widearmcontaining10

steelbearingswhichrollinanydirection,a heavycastiron

base,anda telescopingheavysteeltubecolumnwhichcan

beadjustedtoanyheightfrom28" to52"high.Forillus-

trationandpriceseeaccessorypartslist,page7,under

"WorkSupportStand".

OPERATIONS

Therearea multitudeofdifferentcuttingoperationswhich

canbeperformedonyourcircularsaw.Carefulplanningof

yourworkwillenableyoutogroupsimilarcutssothatthey

canbeperformedwhilethesawissetupfora certainopera-

tion.Rememberthisoneveryjobyoudo.Itwillsaveyou

manyhoursofunnecessarywork.

RIPPING:Cuttingwoodparalleltothegrainisreferredto

asripping.Rippingcanbeperformedwitha combination

typeblade(ToolkraftNo.9-CB-50)ora ripblade(Tool-

kraftNo.9-RP-50).Forheavyorrepeatedrippingoper-

ationswerecommendusingtheripbladeformostsatisfactory

results.Followthestepsoutlinedbelowforripping.

1.Setandlocktheripfenceatthedesiredwidthfromthe

sawblade.

2.Raisethesawbladesothatitwilljustclearthewood.

3.Examinethework,itshouldhaveonestraightedgetoplace

againsttheguide.

4.Feedtheworkalongtheripfenceintothesawbladeata

steadyevenrate.

Usea pushersticktopushworkbetweenbladeandrip

fenceandholdtheworkagainstthefencewithyourother

hand.Pushthepieceallthewaythroughthesawandfence.

Neverleavea boardloosebetweena runningbladeand

thefence.

CROSSCUTTING:Cuttingdirectly90°acrossthegrainof

thewoodiscalledcrosscutting.Crosscuttingcanbedonewith

acombinationblade9-CB-50orcrosscutblade9-CC-50.

Acrosscutbladewouldbepreferableifyouplanonrepetitive

crosscutoperations.

Followthestepsoutlinedbelowforcrosscutting.

1.Measureandmarkthewoodtobecut.Miterextension

rodsEXT-MGseeaccessorypageforprice)areavail-

ableforsettinga fixedstoponthemiterhead.Thisstop

wouldenableyoutocutoffmanypiecestothesamelength

withoutmarkingeachboard.

2.Makesuretheboardhasonesmoothside.Placetheside

firmlyagainstthefaceofthemiterheadandpushthe

workthroughtheblade.

3.Themiterheadisusedinbackoftheworkpieceinmost

cutoffoperations.However,themiterheadmaybeplaced

onthefrontedgeofa boardwhichcompletelycoversthe

sawtable.

MITERSAWING:Mitercutsaresimplycrosscutsmadeat

anangleotherthan90°straightacrosstheboard.Usethe

samebladesasforcrosscutting.Setthemitergagetoyour

desiredangleofcut.Checkthisanglebymakingsometest

cutsonscrapmaterial.Placethestraightedgeofthematerial

againstthefaceofthemitergageandholditfirmlyinplace.

Aloosegripmaycauseittocreepandthecutwillnotbe

accurate.Forsawingwideorlongworkyoucanscrewor

boltanauxiliaryextensionboardtothefaceofyourmiter.To

insureaccuratecutsbesuretheboardisthesamethickness

onitsentirelength.Topreventchatteringorbinding,mount

itonthefaceofthemitersothatthebottomedgeis1/16"

to⅛ " abovethesawtablesurface.Cementa pieceofsand-

papergritsideoutagainstthefaceoftheboardtohelphold

theworkinposition.

DADOCUTTING:Therearethreemaintypesofcutswhich

canbemadewitha dadohead.

1.Dadocutting— A groovecutacrossthegrainofthewood.

Itisusuallymadeat90°angles,butmaybeatanyother

angle.Figure2 illustratesa rightangledadocut.Note

thata crossgraindadocutismadeinthesamemanneras

anordinarycrosscut.Usethemiterheadasa guideand

holdyourworkfirmlyinplace.Rememberthata dadois

removinga lotmorestockthananordinarybladeanditis

thereforenecessarytoslowdownaccordinglyonthefeed

ofthework.

2.Groovecutting— A channelcutintheboardinthesame

directionasthegrainiscalleda groove.Thiscutismade

ina mannersimilartorippinga board.Youshoulduse

theripfenceasa guideandfeedtheworkslowly.Be

surethefenceissquarewiththebladetopreventbinding.

Alwaysusea pusherstick.

—Page6—

ACCESSORIES

Index

No.

Part

No. Name of Part

Units Price

Per Assy. Each

BLADES— SANDINGDISCSANDARBORWRENCH

9-RP-509"Ripblade— ½ " hole.......1 4.95

9-CC-509"Crosscutblade— ½ " hole1 4.95

9-CB-509"Combinationblade— ½"

hole1 4.95

9-PW-509"plywoodhollow-ground

blade½"hole1 8.95

9-HG-509"Hollowgroundblade— ½"

hole1 11.50

9-CBT-509"Carbidetippedblade—½"

hole1 17.75

SND-88"Sandingdisc— ½"hole60

gritoneside,80gritother

side1 4.50

TCD-88"Tungstencarbideabrasive

discforcuttingorsanding

non-metallicmaterial— i.e.

Transonite,Masonite,Wall-

board,etc1 7.25

XM-2156Arborwrench— combination

boxandopenend¾"

opening1.80

DADOSANDDADOINSERTPLATE

D6-13-506"DadosetNo.3 - 13/16"

cut,½"hole1 19.50

D6-11-506"DadosetNo.2 - 11/16"

cut,½"hole1 18.75

D5-9-505"DadosetNo.2 - 9/16"

cut,½"hole1 11.75

DlP-9-10Dadoinsertplate1 2.75

SHAPINGANDMOLDINGHEADANDINSERTPLATE

SMC-5Shapingandmoldingcutter

head¾"holewith5/8"and

1½"bushing5"dia.x

11/32"widecompletewith

redplasticbox1 8.95

MIP-9-10Moldingcutterheadinsertplate1 2.75

GUARDANDSPLITTER

GR-9GuardandSplitterAssembly.. 1 7.95

50-70Guard(only)3.50

89B-207Splitter(only)1.80

89B-211 Splitterbracket(only)2.95

EXTENSIONSANDEXTENSIONPARTS

85A-200DSideextension9"x 20"less

guidebarandhardware...1 11.95

85A-200ASideextension9"x 20"with

9"L.H.guidebarand

hardware1 12.50

85A-200BSideextension9"x 20"with

9"R.H.guidebarand

hardware1 12.50

85A-200CSideextension(setof2)each

9"x 20"withL.H.andR.H.

guidebarsandhardware

(complete)1 24.95

Index Part Units Price

No. No.Name ofPart Per Assy. Each

85A-138Guidebar— leftside(9"long)1 1.55

85A-137Guidebar—rightside(9"long)1 1.55

MITEREXTENSIONROD

EXT-MGMiterextensionrodassembly1 2.25

SHAPINGANDMOLDINGCUTTERKNIVES

MK-3021"PlanerandJointerCutter

(setof3)4.50

MK-303TongueCutter(setof3)4.50

MK-304GrooveCutter(setof3)4.50

MK-350CabinetDoorLipCutter(set

of3)4.50

MK-351Combination¼"and½"

QuarterRoundCutter(set

of3)4.50

MK-352Three¼ " BeadCutter(setof3)4.50

MK-354CloverleafScreenMoldCutter

(setof3)4.50

MK-355BaseMoldCutter(setof3)...4.50

MK-201GlueJointCutter(setof3). . 4.50

MK-202"Ogee"WindowandDoor

StopCutter(setof3)4.50

MK-203¼"Fluteand½ " CoveCutter

(setof3)4.50

MK-20490°Flute,Ornamentaland

CombinationCutter(setof3)4.50

MK-205CurvedFluteand3/16"Quarter

RoundCutter(setof3)....4.50

MK-2061"FluteCutter(½"radius)(set

of3)4.50

MK-2075/16"QuarterRoundand

5/16"Cove(DropLeafTable

Cutter)(setof3)4.50

MK-2083/16"and⅜"QuarterRound

and¼"BeadCutter[set

of3)4.50

MK-209⅝"CoveCutter(setof3)...4.50

MK-210PanelCupboardDoorCutter

(setof3)4.50

POWERTOOLSTANDSANDSTANDACCESSORIES

No.S-1ToolkraftPowerToolStand. . 28.95

No.S-2ToolkraftPowerToolStand. . 24.95

XM-1649RubberFeet(setof4)forpower

toolstands2.95

XM-1650Casters(setof4)forpowertool

stands12.95

WORKSUPPORTSTANDMODELS-25

Worksupportstandheavycast

ironandsteelconstruction,

adjustableinheightfrom28"

to52"16.95

Designs,SpecificationsandPricesSubjecttoChange

WithoutNotice.

SERIALNUMBEROFMYMACHINE

DATEPURCHASED

PURCHASEDFROM

EXPIRATIONOFGUARANTEE

NOTES

829A-265

PrintedinU.S.A.1-63

—Page8—

QUALITY POWERTOOLS

BOX157BRIGHTWOODSTATION

TELEPHONE: REpublic7-3591

TOOLKRAFTPOWERTOOLGUARANTEE:

Seetheguaranteecardwhichwasenclosedwithyour

machineforcompletedetailsofToolkraft5 yearguarantee.

Toinsurepromptefficientguaranteeservice,filloutandreturn

yourguaranteecardassoonaspossible.

Foryourconvenience,factoryqualityrepairserviceisnow

availablethroughthenationwidefacilitiesofGeneralElectric

ApparatusServiceShopsandotherequallycapablein-

dependentserviceshops.Trainedpersonnelandgenuine

Toolkraftpartsassureyouhighqualityrepairservice.

Coasttocoastservicestationlocationsare listedbelow.

AUTHORIZEDSERVICESTATIONSFORTOOLKRAFTPRODUCTS

ALABAMA

BIRMINGHAMSERVICESHOP

7— 18thStreet,S.W.

Birmingham,Alabama

CALIFORNIA

LOSANGELESSERVICESHOP

6900StanfordAve.

LosAngeles1,Calif.

OAKLANDSERVICESHOP

3400WoodStreet

Oakland,Calif.

SACRAMENTOSERVICESHOP

99N.17thStreet

Sacramento,Calif.

SANFRANCISCOSERVICESHOP

1098HarrisonSt.

SanFrancisco3,Calif.

COLORADO

DENVERSERVICESHOP

3353LarimerSt.

Denver,Colo.

CONNECTICUT

SOUTHINGTONSERVICESHOP

370AtwaterSt.

Plantsville,Conn.

FLORIDA

JACKSONVILLESERVICESHOP

2020WestBeaverStreet

Jacksonville,Fla.

MIAMISERVICESHOP

1062East28thStreet

Hialeah,Florida

TAMPASERVICESHOP

19th& GrantSt.

Tampa1,Fla.

GEORGIA

(Atlanta)CHAMBLEESERVICESHOP

5035PeachtreeIndustrialBlvd.

Chamblee,Ga.

ILLINOIS

CHICAGOSERVICESHOP

4360W.47thStreet

Chicago32,III.

INDIANA

FT.WAYNESERVICESHOP

1731EdsallAve.

Ft.Wayne,Ind.

INDIANAPOLISSERVICESHOP

1740W.VermontSt.

Indianapolis22,Indiana

IOWA

BETTENDORFSERVICESHOP

1039StateSt.

Davenport,Iowa

KENTUCKY

LOUISVILLESERVICESHOP

3900CrittenDrive

Louisville,Ky.

LOUISIANA

NEWORLEANSSERVICESHOP

2815N.RobertsonSt.

NewOrleans,La.

MARYLAND

BALTIMORESERVICESHOP

920E.FortAve.

Baltimore30,Md.

MASSACHUSETTS

BOSTONSERVICESHOP

3960MysticValleyParkway

Medford55,Mass.

SPRINGFIELDSERVICESHOP

(Factory)

700PlainfieldSt.

Springfield,Mass.

MICHIGAN

DETROITSERVICESHOP

5950ThirdAve.

Detroit2,Mich.

MINNESOTA

MINNEAPOLISSERVICESHOP

2025— 49thAvenue,N.

Minneapolis12,Minn.

MISSOURI

KANSASCITYSERVICESHOP

3525GardnerAve.

KansasCity20,Mo.

ST.LOUISSERVICESHOP

1115EastRoad

St.Louis,Mo.

NEWJERSEY

NEWYORKSERVICESHOP

6001TonnelleAve.

NorthBergen,NewJersey

NEWYORK

ALBANYSERVICESHOP

1097CentralAve.

Albany,NewYork

BUFFALOSERVICESHOP

318UrbanStreet

Buffalo11,N.Y.

NEWYORKELECTRA-CRAFT

APPLIANCECO.

348W.42ndStreet

NewYork36,N.Y.

NORTHCAROLINA

CHARLOTTESERVICESHOP

2328ThriftRoad

Charlotte,NorthCarolina

OHIO

CINCINNATISERVICESHOP

444WestThirdSt.

Cincinnati2,Ohio

CLEVELANDSERVICESHOP

4966WoodlandAve.

Cleveland4,Ohio

COLUMBUSSERVICESHOP

2128EakinRd.

Columbus23,Ohio

TOLEDOSERVICESHOP

405DearbornSt.

Toledo4,Ohio

YOUNGSTOWNSERVICESHOP

272E.IndianolaAve.

Youngstown7,Ohio

OREGON

PORTLANDSERVICESHOP

2727N.W.29thAve.

Portland10,Oregon

PENNSYLVANIA

ALLENTOWNSERVICESHOP

668EastHighlandSt.

Allentown,Pa.

PHILADELPHIASERVICESHOP

1040E.ErieAve.

Philadelphia24,Pa.

HOMESTEADSERVICESHOP

ButtermilkHollowRd.

Homestead,Pa.

JOHNSTOWNSERVICESHOP

841OakSt.

Johnstown,Pa.

YORKSERVICESHOP

54N.HarrisonSt.

York,Pa.

TEXAS

CORPUSCHRISTISERVICESHOP

115WacoSt.

CorpusChristi,Texas

HOUSTONSERVICESHOP

5534HarveyWilsonDrive

Houston20,Texas

DALLASSERVICESHOP

3203ManorWay

Dallas,Texas

MIDLANDSERVICESHOP

3404BankheadHwy.

Midland,Texas

UTAH

SALTLAKECITYSERVICESHOP

301SouthSeventhWestSt.

SaltLakeCity4,Utah

VIRGINIA

RICHMONDSERVICESHOP

1403IngramAve.

Richmond24,Va.

ROANOKESERVICESHOP

115AlbermarleAve,S.E.

Roanoke7,Va.

WASHINGTON

SEATTLESERVICESHOP

3422FirstAve.South

Seattle4,Wash.

SPOKANESERVICESHOP

South115ShermanSt.

Spokane3,Washington

WESTVIRGINIA

CHARLESTONSERVICESHOP

306MacCorkleAve.

Charleston28,W.Va.

WISCONSIN

APPLETONSERVICESHOP

MidwayIndustrialArea

P.O.Box83

Appleton,Wisconsin

MILWAUKEESERVICESHOP

940W.St.PaulAve.

Milwaukee3,Wis.

OVERSEASSTATIONS

HAWAII

THEO.H.DAVIESLTD.

Honolulu,HawaiiU.S.A.

GUARANTEENO.11960

TOOLKRAFTCORPORATION

SPRINGFIELD,MASS.

This manual suits for next models

1

Table of contents

Other Toolkraft Saw manuals