ToolMaster Industrial ATS-255 User manual

1

www.machineryhouse.com.au

www.machineryhouse.co.nz

Industrial Series

AiR METAL SHEARS

INSTRUCTION MANUAL

Order Code: A085

www.machineryhouse.com.au www.machineryhouse.co.nz

ATS-255

2

www.machineryhouse.com.au

www.machineryhouse.co.nz

1. Read and understand this entire manual before

attempting assembly or operation.

2. Read and understand all warnings posted on

the tool and in this manual. Failure to comply

with all of these warnings may cause serious

injury.

3. Replace warning labels if they become

obscured or removed.

4. Do not use this tool for other than its intended

use. If used for other purposes, Toolmaster

disclaims any real or implied warranty and

holds itself harmless from any injury that may

result from that use.

5. Always wear approved safety glasses or face

shield while using this tool. (Everyday eye

glasses only have impact resistant lenses; they

are not safety glasses.)

6. Wear ear protectors (plugs or muffs) if the

noise exceeds safe levels.

7. Wear gloves and protective clothing if

operationproducessparksoryingparticles.

Glovesshouldbetight-tting,withoutfrayed

ngersorhangingthreads.Keephandsand

body away from the working area of tool.

8. Do not operate an air tool continually at full

throttle without a work load on the tool.

9. The air tool must be properly lubricated

before operating.

10. Never start a percussion type air tool (chipper,

breaker, buster, etc.) without securing the

tooling in the retainer and placing the tip

against the work surface.

11. Do not operate air tool without its guards in

place. Do not modify the tool.

12. Do not operate this tool while tired or under the

inuenceofdrugs,alcohol,oranymedication.

13. Adopt a comfortable posture with proper

balance,and maintain secure footing at all

times.Non-slipfootwearoranti-skidoorstrips

are recommended.

14.Donotwearlooseclothingorjewellery.Conne

long hair.

15. Excessive air pressure and too much free

rotation may decrease life of the tool and may

cause a hazardous situation.

16. Check air hoses for wear, and keep them away

from heat and sharp edges. Repair or replace

damaged air hose immediately. Do not carry

tool by the air hose.

17. Air hose may cause tripping hazards; keep hose

awayfromtrafcareas.

18.Donotusethistoolnearammableobjects,or

in potentially explosive environments. Do not

use near live electrical wires.

19. Do not use power tools in damp or wet location,

orexposethemtorain.Keepworkareawell

lighted.

20. Do not leave a connected tool unattended.

When not in use, disconnect tool from air

source.

21. Shut off air supply and discharge any residual

pressure from tool before removing hose,

making adjustments, changing accessories, or

storing tool.

22.Makesuretoolisswitchedoff,andyournger

off the trigger, before connecting to air supply.

Remove adjusting keys before operating.

24.Keepvisitorsasafedistancefromthework

area.Keepchildrenaway.

Safety Air Tool Warnings

3

www.machineryhouse.com.au

www.machineryhouse.co.nz

Warning: Some dust, fumes and gases created by power sanding, sawing, grinding,

drilling, welding and other construction activities contain chemicals that may cause cancer and birth

defects or other reproductive harm. Some examples of these chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically treated timber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as dust masks that are specically designed to lter out microscopic particles.

Technical Specications

Safety Specic For Air Metal Shear

1. ATS-255 shear is designed for cutting sheet

material, such as steel, aluminium and plastics.

If you are not familiar with the proper and safe

operation of a pneumatic shear, do not use

until proper training and knowledge have been

obtained.

2. Secure the workpiece with clamps or in a vise.

Keepbothhandsontooltopreventlossof

control.

3. Keephandsawayfromthereciprocating

blades.

4. Replace blades if they become damaged or

dull.

4. Do not lubricate the tool with combustible

liquids, such as kerosene, diesel or jet fuel.

5. Do not dispose of this tool with normal

household waste. Never dispose of the air tool

intore.

6. Use only recommended accessories; improper

accessories may be hazardous.

7. Maintaintoolswithcare.Keepairtoolclean

and oiled for best and safest performance

Capacity (Mild Steel) 1.2mm

Capacity (Aluminium) 1.6mm

Length 255mm

Strokes per Minute 2500

Swivel Head 360 deg.

Motor Type Air Rotor

Air Consumption 4.5 CFM (127 L/min)

Sound Pressure 85.5dBA

Maximum Air Pressure 90 PSI

Recommended Air Hose 10mm

Inlet 1/4” BSPT

Weight 1.1kg

4

www.machineryhouse.com.au

www.machineryhouse.co.nz

Any missing parts or damage should be reported immediately to your Toolmaster distributor. Do not use

a damaged tool. Read this instruction manual thoroughly for operation, maintenance and safety

Instructions. The diagram below is the ideal setup position. The lubricator is optional and if not used, then

a few drops of Pneumatic Tool Oil need to be added to the airline connection before operation. Add a few

more drops after each hour of continual use.

WARNING: Operating the tool at pressures over the rated capacity may cause severe

damage and/or personal injury. Do not exceed 90 PSI while operating the tool. Do not

use an accessory rated at a lower maximum pressure than the tool.

C

ompressor

A

ir

H

ose

F

ilter

r

egulAtor

l

ubriCAtor

A

ir

H

ose

C

oupler

& F

itting

t

ool

Fig. 1

Setup

The recommended air system is shown in Fig.1.

1. Useproperairhosesize(refertotoolspecications).Thehoseshouldbejustlongenoughto

serve the working area. Excessive hose length will cause pressure drop.

WARNING! Ensure that the air supply is clean and does not exceed 90psi. Too high an air

pressure and/or unclean air will shorten the life of the air tool due to accelerated wear,

and may cause damage and/or personal injury.

2. Drain the compressor air tank daily. Water in the air line will damage the air tool.

3. Cleanthecompressorairinletlterscreenweekly.

4. Line pressure should be increased to compensate for unusually long air hoses (over 8 meters).

Theminimumhoseboreshouldbe10mmandttingsmusthavethesameinsidedimensions.

5. Keephosesawayfromheat,oilandsharpedges.Checkhosesforwear,andmakecertainthatall

connections are secure.

IMPORTANT: The leader hose is optional, but connecting a quick-change coupling directly to the

tool is not recommended, as vibration may cause the connection to fail. For the best result, add a

leader hose and install any quick-change couplings further down the line.

Air Supply

l

eAder

H

ose

5

www.machineryhouse.com.au

www.machineryhouse.co.nz

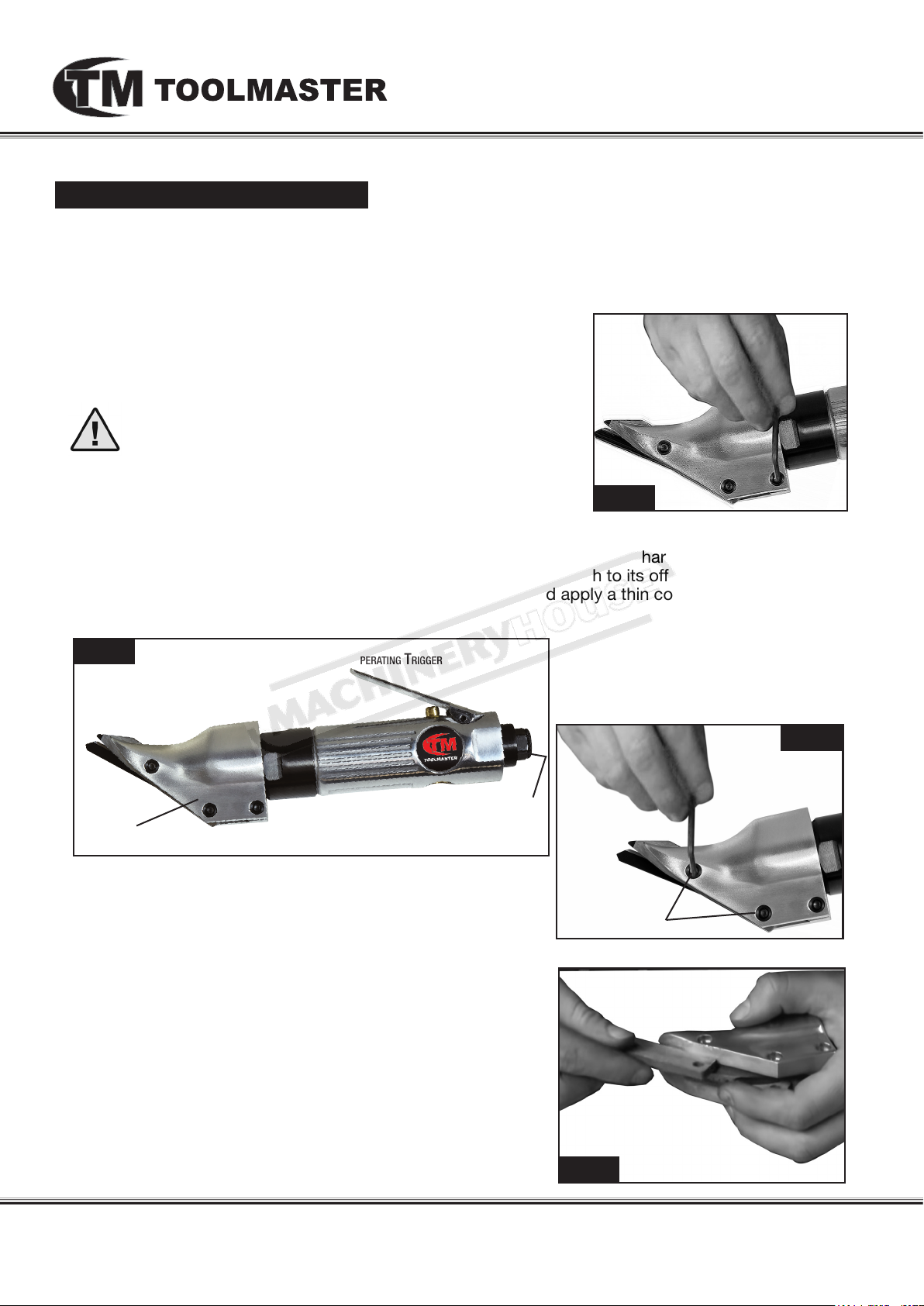

Operating Instructions

1. Remove protective cap from air inlet (Fig. 1). If an in-line oiler is not being used, add 4 or 5 drops of

air tool oil (not included) into the air inlet.

2. Blow out air line to remove any dirt or moisture, then connect air supply hose to tool. Set air

pressure to 90 psi.

3. Place cutting blades against workpiece, and both hands on tool.

4. To swivel head, loosen (do not remove) the three socket

head screws with a hex wrench, just enough to allow head to

swivel. (Fig. 2)

5. Rotate head to desired angle, and retighten the three screws.

CAUTION! TO PREVENT INJURY FROM TOOL OR

ACCESSORY FAILURE:

Do not exceed the tool’s maximum air pressure rating.

If the tool still does not have sufcient force a maximum

pressure and sufcient airow, then a larger tool may be

required.

6. To prevent accidents, turn off the tool, detach the air supply, safely discharge any residual air

pressure in the tool, and release the throttle and/or turn the switch to its off position after use.

Clean external surfaces of the tool with clean, dry cloth, and apply a thin coat of tool oil, then store

the tool indoors out of children’s reach.

Fig. 2

Fig. 3 operAting trigger

Air inlet

Cutter HeAd

CHANGING THE BLADES.

From time to time the blades may need to be sharpened or

replaced. See the procedure below

1. DISCONNECT THE TOOL FROM THE AIR LINE

2. Loosen the three socket head screws that are in the head.

3. Remove the front two screws but do not remove the cutter

head from the tool. (Fig. 4)

4. Remove the old blades making sure that you remember

where each part is placed.

5. Replace the sharpened or new blades making sure they

are returned as they were removed. (Fig. 5)

Front two sCrews

Fig. 4

Fig. 5

Replacement Blades. Order Code A0862

6

www.machineryhouse.com.au

www.machineryhouse.co.nz

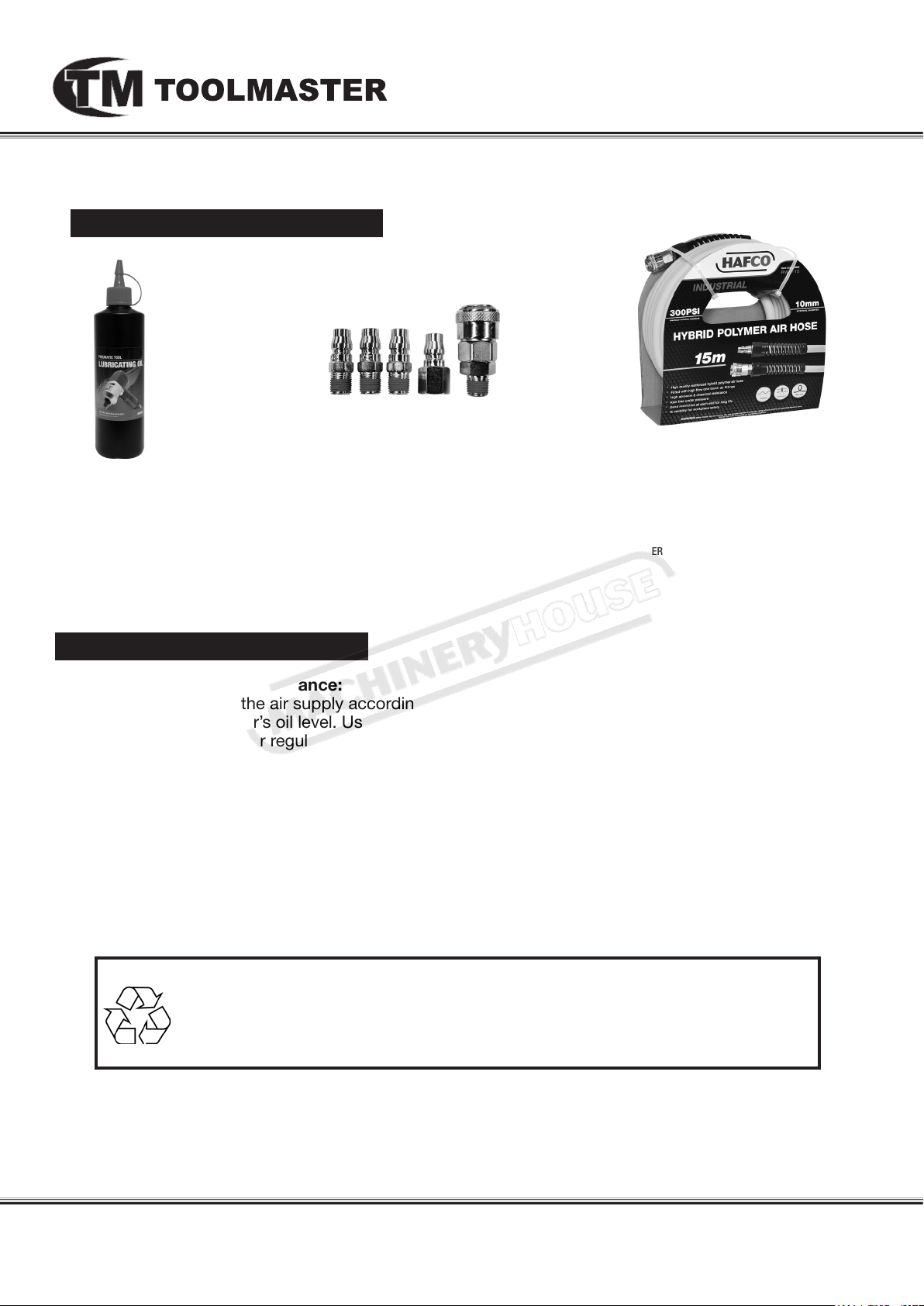

1. Daily - Air Supply Maintenance:

Every day, maintain the air supply according to the component manufacturers’ instructions.

Maintain the lubricator’s oil level. Use Pneumatic Tool Oil (Order Code A037)

Drainthemoisturelterregularly.

Performing routine air supply maintenance will allow the tool to operate more safely and will also

reduce wear on the tool.

2. Quarterly (every 3 months) – Tool Disassembly, Cleaning, and Inspection:

Havetheinternalmechanismcleaned,inspected,andlubricatedbyaqualiedtechnician.

For a full service contact your local Toolmaster service agent.

When not in use, disconnect from air supply, clean nibbler and store in a safe and dry place.

Environmental Protection.

Recycle unwanted materials instead of disposing of them as waste.

All tools, accessories and packaging should be sorted, taken to a recycle centre

and disposed of in a manner which is compatible with the environment.

Maintenance

Optional Accessories

pneumAtiC tool oil 500ml

order Code A037

rwK-15 - industriAl polymer Air Hose

15 metre xØ9.5mm id Hose

order Code H008

rwK-30 - industriAl polymer Air Hose

30 metre xØ9.5mm id Hose

order Code H009

5 pieCe pACK - HigH-Flow Air Fittings

1/4” bspt

order Code F935

7

www.machineryhouse.com.au

www.machineryhouse.co.nz

Symptoms Possible Cause Possible Solution

Decreased output.

1.Notenoughairpressureand/orairow.

2. Obstructed throttle.

3. Incorrect lubrication or not enough

Lubrication.

4. Blocked air inlet screen (if equipped).

5. Air leaking from loose housing.

6. Mechanism contaminated.

1. Check for loose connections and make sure

thatairsupplyisprovidingenoughairow

(CFM) at required pressure (PSI) to the tool’s air

inlet. Do not exceed maximum air pressure.

2. Clean around throttle to ensure free movement.

3. Lubricate using air tool oil and grease according

to directions.

4. Clean air inlet screen of buildup.

5. Make sure housing is properly assembled and

tight.

6.Havequaliedtechniciancleanandlubricate

mechanism.Installin-linelterinairsupplyas

stated in Setup: Air Supply.

Housing heats

during use

1. Incorrect lubrication or not enough

lubrication.

2. Worn parts.

1. Lubricate using air tool oil and grease according

to directions.

2.Havequaliedtechnicianinspectinternal

mechanism and replace parts as needed.

Severe air leakage

(Slight air leakage

is normal,

especially on older

tools.

1. Cross-threaded housing components.

2. Loose housing.

3. Damaged valve or housing.

4. Dirty, worn or damaged valve.

1. Check for incorrect alignment and uneven gaps.

If cross-threaded, disassemble and replace

damaged parts before use

2. Tighten housing assembly. If housing cannot

tighten properly, internal parts may be

misaligned

3. Replace damaged components.

4. Clean or replace valve assembly.

Review the troubleshooting and procedures in this section if a problem develops with your Air Tool.

If you are still unable to resolve the problem, then contact your local Toolmaster distributer.

INDUSTRIAL AIR TOOLS

Troubleshooting

This manual suits for next models

1

Table of contents

Popular Power Tools manuals by other brands

Toparc

Toparc 052925 Translation of the original instructions

Hitachi Koki

Hitachi Koki H45FRV instruction manual

DeWalt

DeWalt DCMAS5713X1 Original instructions

Universal Tool

Universal Tool UT8726 operating instructions

Black & Decker

Black & Decker BDPE400 manual

Cleco

Cleco Cleco 110PTHD instruction manual