Model DI-32

General Instructions

As with all equipment, safety is to be a priority. The operator should understand the safety features and apply good

safety habits in transportation, adjustment, maintenance and operation of the machine. Practice and teach others

the safe operating procedures of this machine and help to prevent the possibility of accidents.

Safety Rules

1. For your own safety, read carefully the Instruction Manual before attempting to operate the machine.

2. If you are not thoroughly familiar and comfortable with the adjustment and operation of the machine, ask for

instruction from your supervisor or a fully qualified person. You may also contact Invicta USA.

3. Before the initial operation of the machine, remove all packaging, shipping grease and fully assemble the

machine. Pay special attention to the assembly of safety components.

4. Wear proper apparel while operating the machine. Never wear loose fitting clothing, gloves or ties. Always

remove rings or other jewelry before operating the machine. It is strongly suggested the operator wear

shoes with non-slip soles and also wear a protective hair net to prevent hair entanglement in moving parts.

5. Always wear personal safety equipment. Follow the safety regulations of your country and your company.

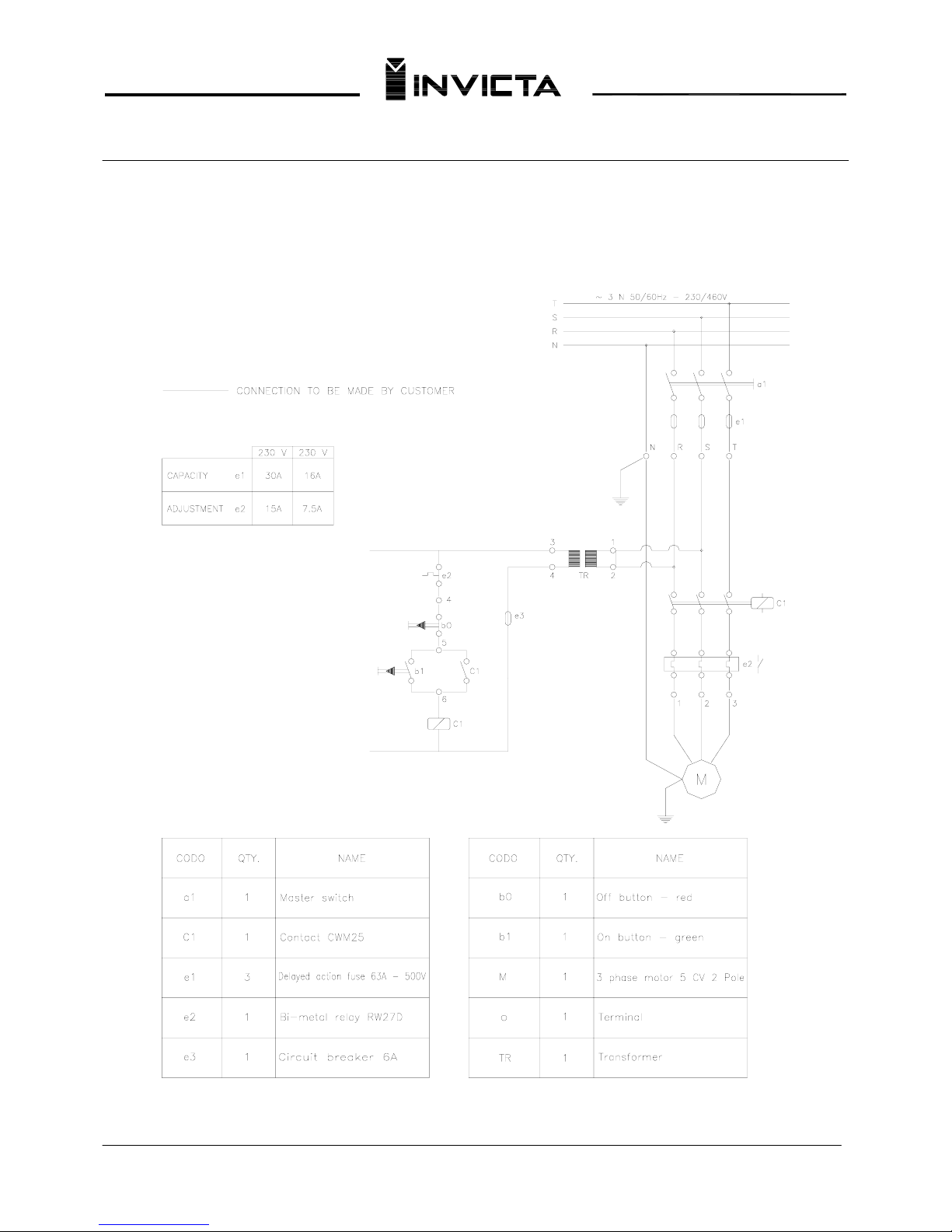

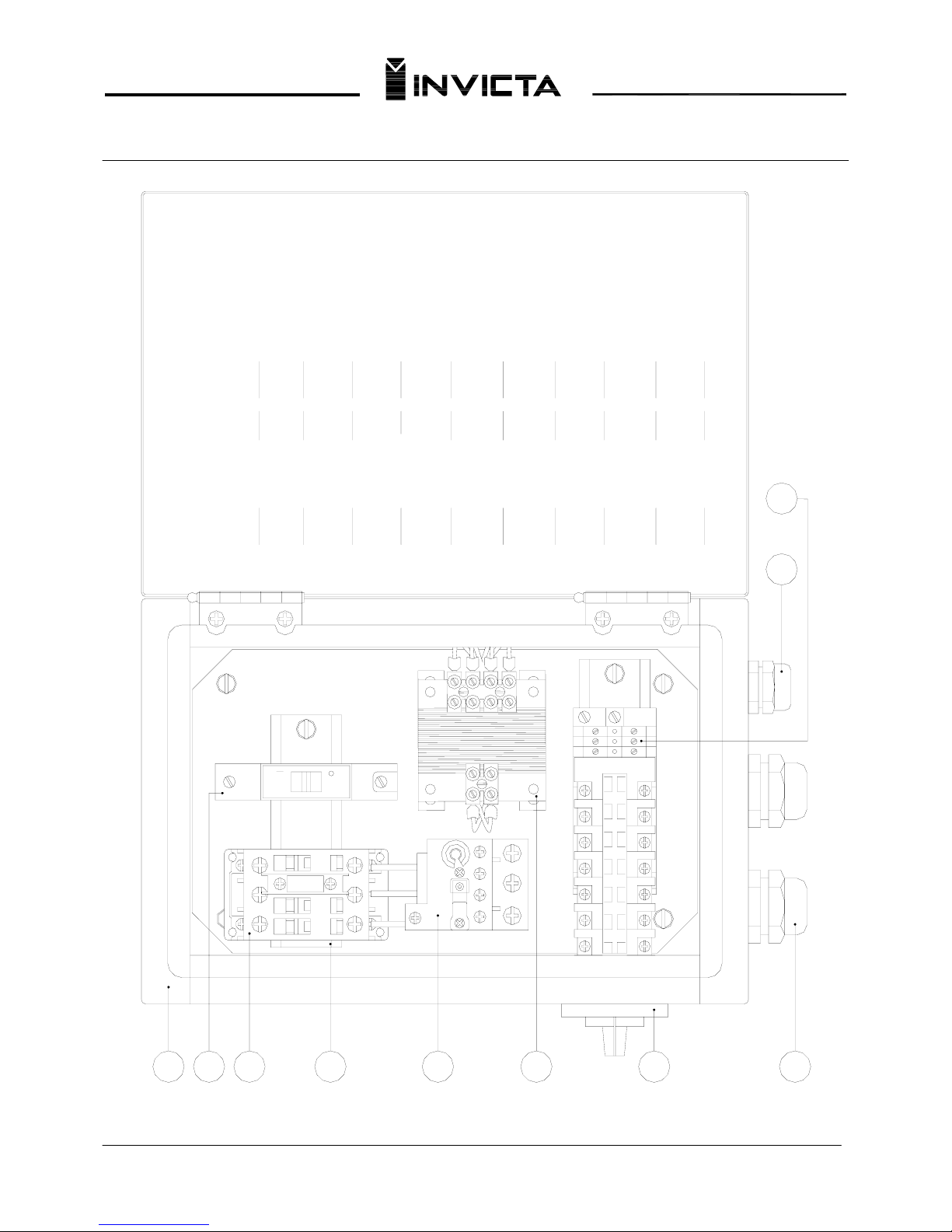

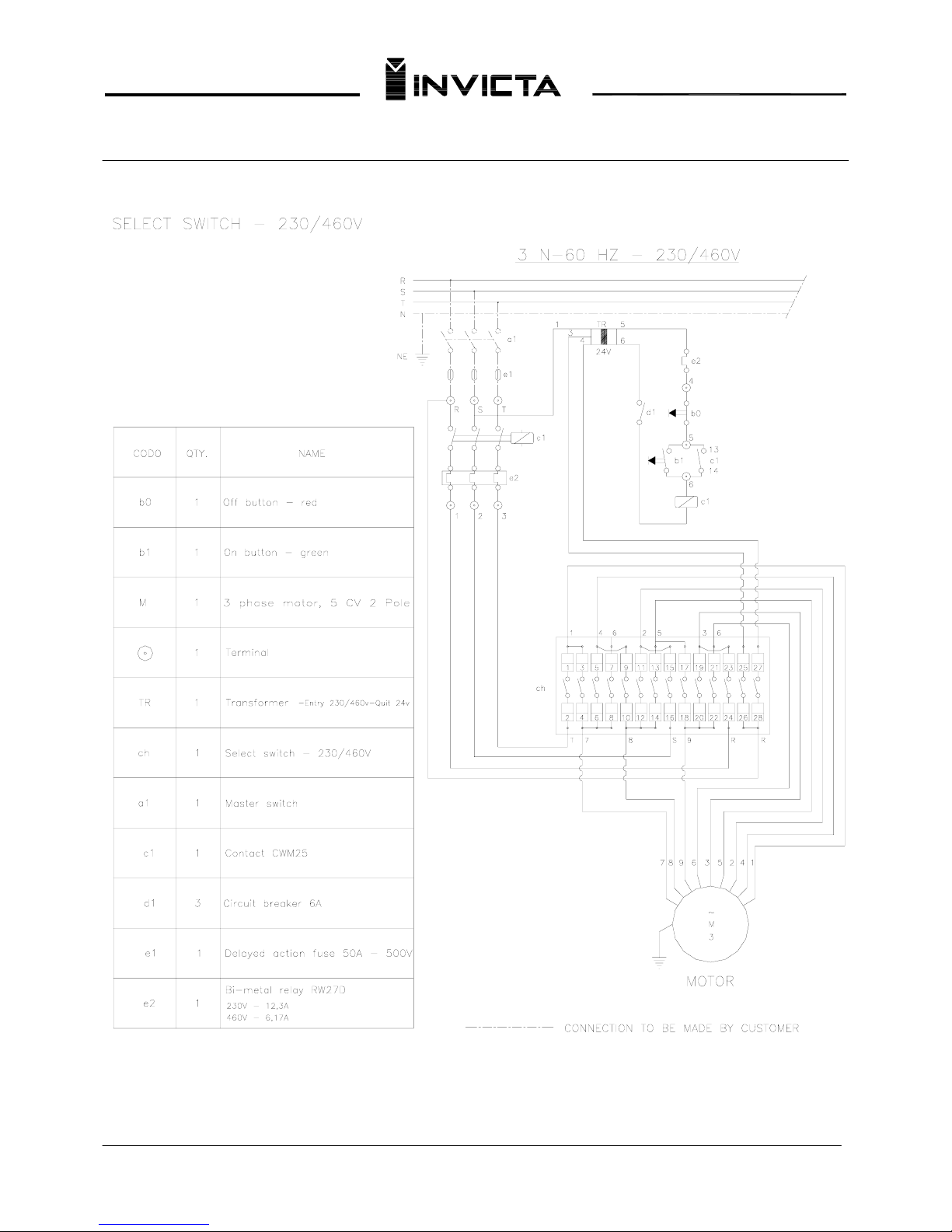

6. Have a certified person make all wiring connections to power source and properly ground the machine.

7. Always disconnect the machine from the power source and use lockout procedures before servicing,

changing cutting tools and during any cleaning of the machine.

8. Before starting the machine, be aware that the work area is clean and free of debris. Cluttered areas are

invitations for accidents to occur. .

9. Keep the safety guard(s) of the machine in place and in proper working condition. Never operate

machinery without safety equipment in place. Report any damage to your supervisor.

10. Keep children and visitors a safe distance from the working area.

11. Never leave the machine running while unattended. Turn off the power source during breaks. The machine

should come to a complete stop before walking away.

12. Do not operate the machine under the influence of drugs or alcohol. Consult your physician when taking

medications.

13. Do not force the machine beyond its limitations. It will produce a nicer and safer job and at the rate it was

designed to operate.

Additional Safety Rules for the Operation of Jointers

1) Avoid Kickbacks. “Kickback” can occur when the workpiece is forced back by the cutter during improper

operation. When “Kickback” occurs an injury can result. Some of the causes of Kickback are:

A- Dull and Improperly Adjusted Knives.

B- Knots, Nails or Imperfections in the workpiece.

C- Heavier Cuts than the machine was designed for.

D- Failure to use a pusher block when jointing or planing short, thin or narrow workpieces.

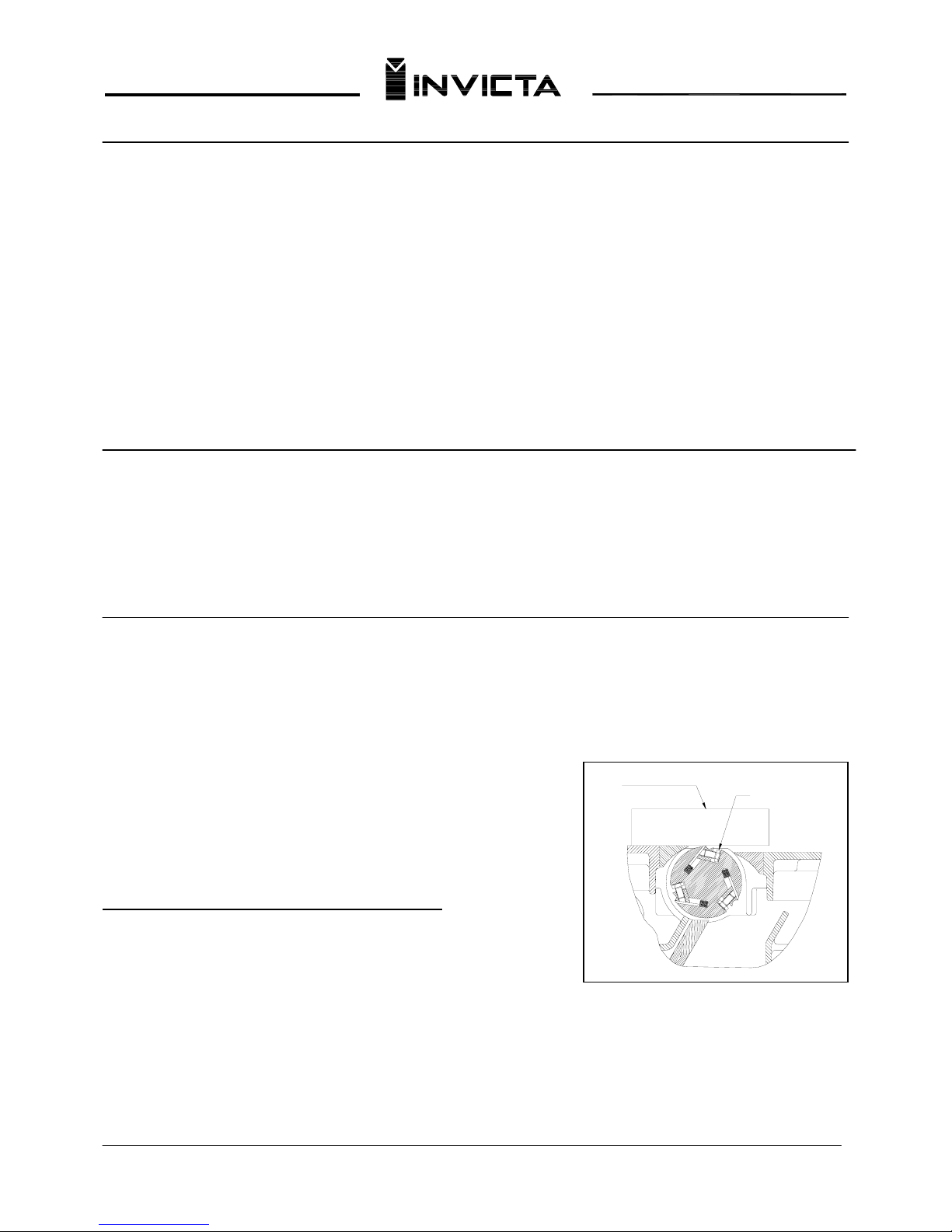

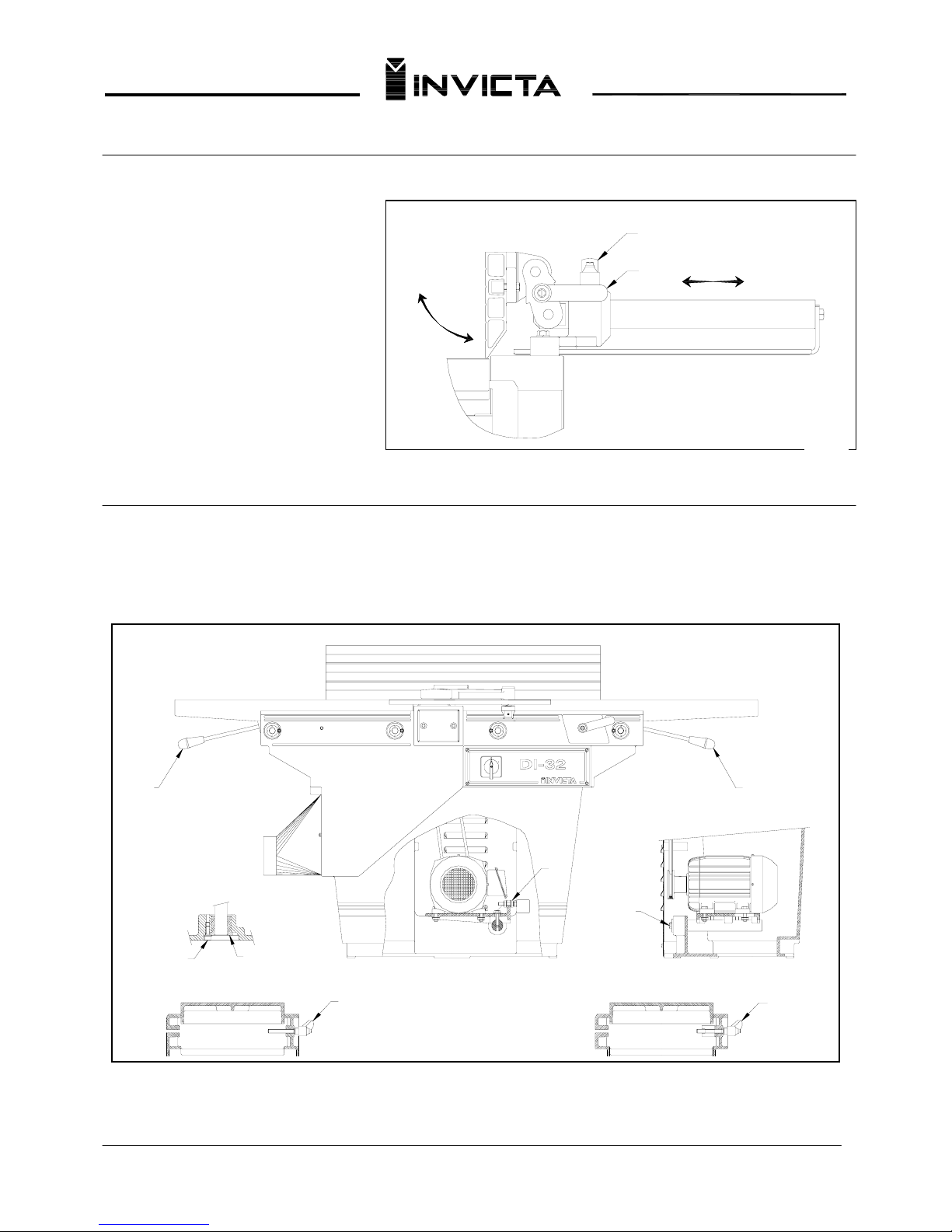

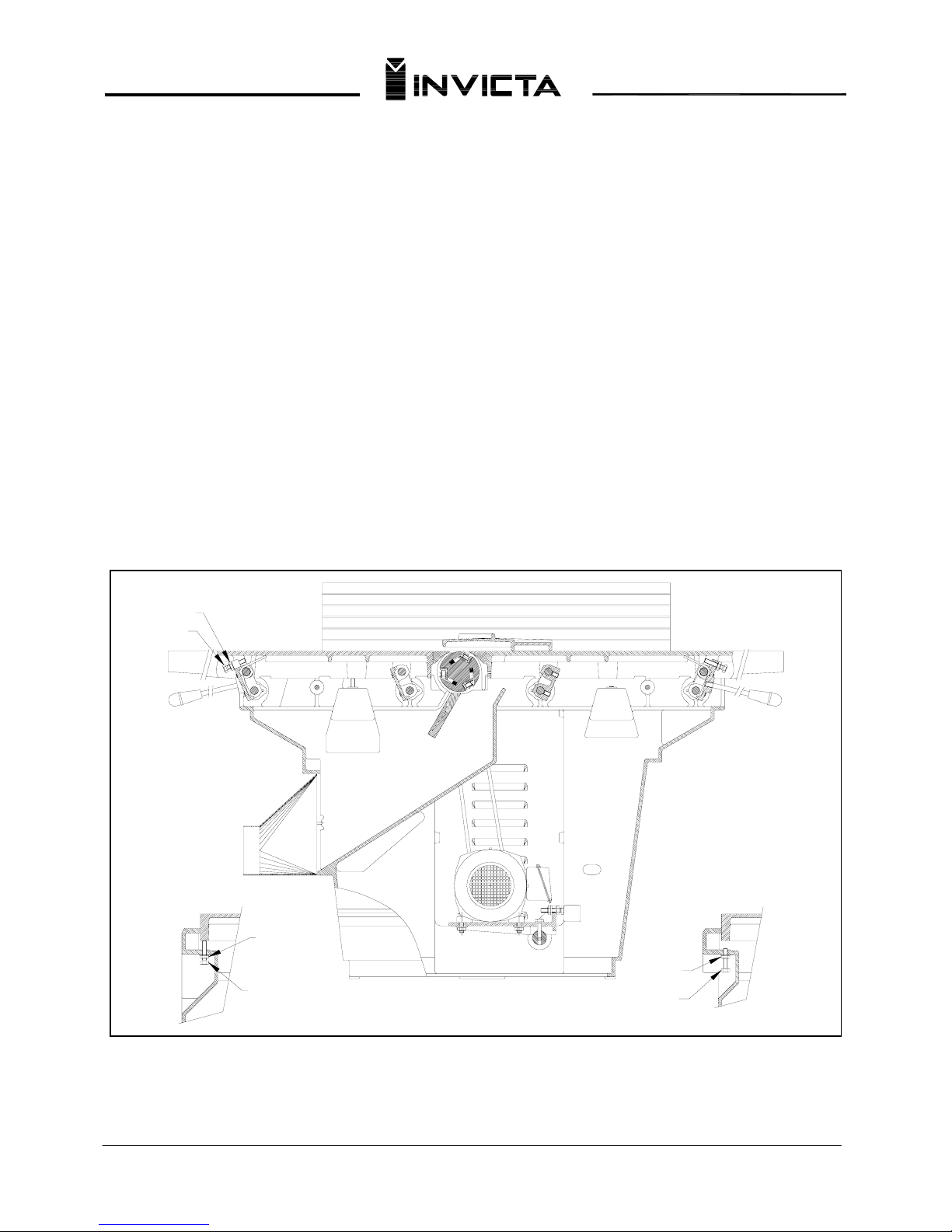

2) Always maintain the proper relationship of in-feed and out-feed table surfaces to the cutterhead.

3) Never start the work-piece into the cutterhead before allowing it to reach operation speed.

4) Keep the Knives sharp and free of rust and pitch

5) Never perform jointing or planing cuts deeper than l/8” (3 mm).

6) Support and control the workpiece properly all times during the operation.

7) Never reverse the direction of the workpiece after beginning operation. Kickback can occur.

8) Definitions of jointing and planing operations:

A- Jointing operations: The workpiece is positioned on the jointer with the narrow edge of work piece on the

in-feed table and the larger surface positioned against the fence. The workpiece is moved right to left from

the in-feed table across the cutterhead to the out-feed table.

B- Planing operations: Planing is a similar operation to the jointing operation except for the position of the

work piece. For planing, the larger flat surface of workpiece is placed on the infeed table of the jointer and

the narrow edge of the workpiece positioned against the fence.

01