YOUR NEW CRAFTSMAN MITER BOX HAS

BEENADJUSTEDAND CHECKED AND ISREADY

FOR IMMEDIATE USE

OPERATION

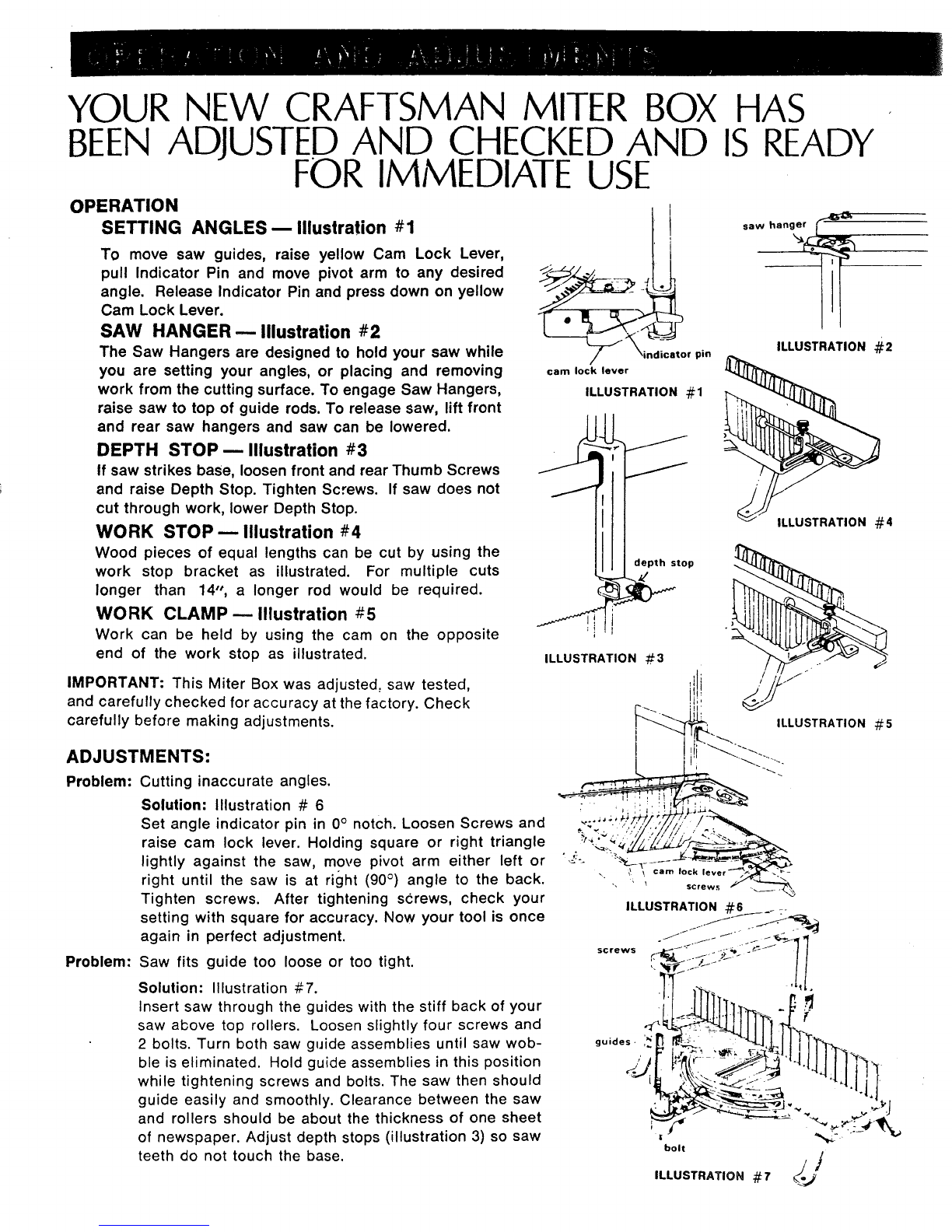

SETTING ANGLES-- Illustration #1

To move saw guides, raise yellow Cam Lock Lever,

pull Indicator Pin and move pivot arm to any desired

angle. Release Indicator Pin and press down on yellow

Cam Lock Lever.

SAW HANGER-- Illustration #2

The Saw Hangers are designed to hold your saw while

you are setting your angles, or placing and removing

work from the cutting surface. To engage Saw Hangers,

raise saw to top of guide rods. To release saw, lift front

and rear saw hangers and saw can be lowered.

DEPTH STOP-- Illustration #3

If saw strikes base, loosen front and rear Thumb Screws

and raise Depth Stop. Tighten Screws. If saw does not

cut through work, lower Depth Stop.

WORK STOP _Illustration #4

Wood pieces of equal lengths can be cut by using the

work stop bracket as illustrated. For multiple cuts

longer than 14-, alonger rod would be required.

WORK CLAMP mIllustration #5

Work can be held by using the cam on the opposite

end of the work stop as illustrated.

IMPORTANT: This Miter Box was adjusted, saw tested,

and carefully checked for accuracy at the factory. Check

carefully before making adjustments.

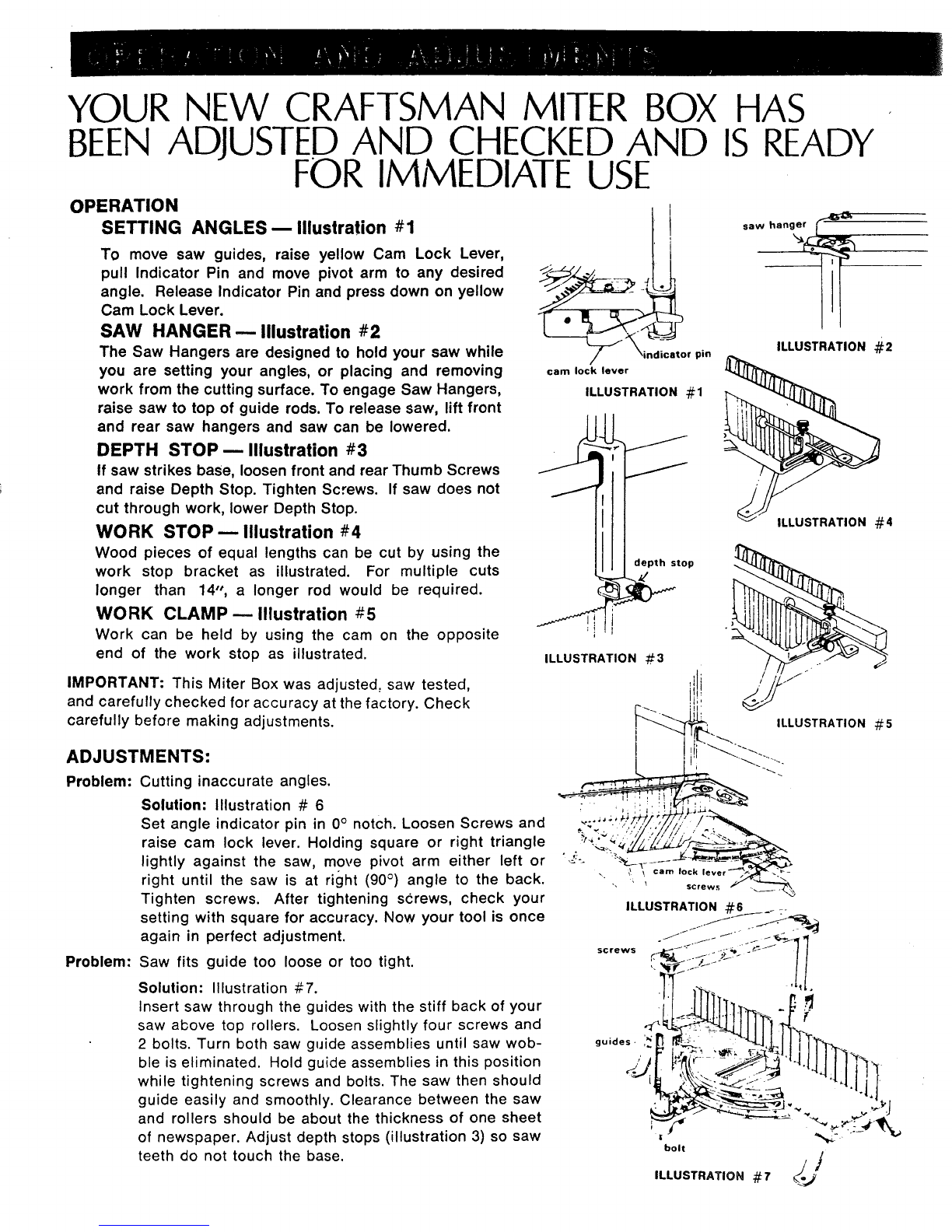

ADJUSTMENTS:

Problem: Cutting inaccurate angles.

saw hanger _1:_,_,

---'_"" pin ILLUSTRATION #2

cam lock lever

ILLUSTRATION #1

ILLUSTRATION .#4

depth stop

I

ILLUSTRATION #3

ILLUSTRATION .#5

Problem:

Solution: Illustration # 6

Set angle indicator pin in 0° notch. Loosen Screws and

raise cam lock lever. Holding square or right triangle

lightly against the saw, move pivot arm either left or

right until the saw is at right (90 °) angle to the back.

Tighten screws. After tightening screws, check your

setting with square for accuracy. Now your tool is once

again in perfect adjustment.

Saw fits guide too loose or too tight.

Solution: Illustration #7.

Insert saw through the guides with the stiff back of your

saw above top rollers. Loosen slightly four screws and

2 bolts. Turn both saw guide assemblies until saw wob-

ble is eliminated. Hold guide assemblies in this position

while tightening screws and bolts. The saw then should

guide easily and smoothly. Clearance between the saw

and rollers should be about the thickness of one sheet

of newspaper. Adjust depth stops (illustration 3) so saw

teeth do not touch the base.

. _ \ cam lock

guides - '_"

Ibolt

ILLUSTRATION #7