Toolots 912 Series User manual

1

METAL CUTTING BAND

SAW MACHINE

MODEL 912 SERIES

INSTRUCTION MANUAL

2

3

WARNING: FALURE TO FOLLOW THESE RULES

MAY RESULT IN SERIOUS PERSONAL INJURY

As with all machinery there are certain hazards involved with operation and

use of the machine. Using the machine with respect and caution will

considerably lessen the possibility of personal injury. However, if normal

safely precautions are overlooked or ignored, personal injury to the

operator may result.

This machine was designed for certain applications only. We strongly

recommends that this machine NOT be modified and/or used for any

application other than for which it was designed. If you have any questions

relative to its application DO NOT use the machine until you contact with

us and we have advised you.

You machine might not come with a power socket or plug. Before using

this machine, please do ask your local dealer to install the socket or

plug on the power cable end.

SAFETY RULES FOR ALL TOOLS

A. USER:

(1). WEAR PROPER APPAREL. No loose clothing, gloves, rings,

bracelets, or ether jewelry to get caught in moving parts.

(2). AWAYS WEAR EYE PROTECTION. Refer to ANSLZ87.1 standard

for appropriate recommendations.

Also use face dust mask if cutting operation is dusty.

(3). DON”T OVERREACH. Keep proper footing and balance at all times.

(4). NEVER STAND ON TOOL. Serious injury could occur if the tool is

tipped or if the cutting tool is accidentally contacted.

(5). NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

POWER OFF. Don’t leave tool until it comes to a complete stop.

4

(6). DRUGS, ALCOHOL, MENICATION. Do not operate tool while

under the influence of drug, alcohol or any medication.

(7). MAKE SURE TOOL IS DISCONNECTED FROM POWER

SUPPLY. While motor is being mounted, connected or reconnected.

(8). ALWAYS keep hands and fingers away from the blade.

(9). STOP the machine before removing chips.

(10). SHUT-OFF power and clean the BAND SAW and work area before

leaving the machine.

B. USE OF MACHINE:

(1). REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of

checking to see that keys and adjusting wrenches are removed from tool

before turning it “on”.

(2). DON’T FORCE TOOL. It will do the job better and be safer at the

rate for which it was designed.

(3). USE RIGHT TOOL. Don’t force tool or attachment to do a job for

which it was not designed.

(4). SECURE WORK. Use clamps or a vise to hold work when practical.

It’s safer than using your hand frees both hands to operate tool.

(5). MAINTAIN TOOLS IN TOP CONDITION. Keep tools sharp and

clean for best and safest performance. Follow instructions for lubricating

and changing accessories.

(6). USE RECOMMENDED ACCESSORIES. Consult the owner’s

manual for recommended accessories. The use of improper accessories may

cause hazards.

(7). AVOID ACCIDENTAL STARTING. Make sure switch is in “OFF”

position before plugging in power cord.

(8). DIRECTIONOF FEED. Feed work into a blade or cutter against the

5

direction of rotation of the blade or cutter only.

(9). ADJUST AND POSRTION the blade guide arm before starting the

cut.

(10). KEEP BLADE GUIDE ARM TIGHT, A loose blade guide arm will

affect sawing accuracy.

(11). MAKE SURE blade speed is set correctly for material being cut.

(12). CHECK for proper blade size and type.

(13). STOP the machine before putting material in the vise.

(14). ALWAYS have stock firmly clamped in vise before starting cut.

(15). GROUNDALL TOOLS. If tool is equipped with three-prong plug, it

should be plugged into a three-hole electrical receptacle. If an adapter is

used to accommodate atwoprong receptacle, the adapter lug must be

attached to a known ground. Never removed the third prong.

C.ADJUSTMENT:

MAKE all adjustments with the power off. In order to obtain the machine

precision and correct ways of adjustment while assembling, the user should

read detailed instruction in this manual.

D.WORKING ENVIRONMENT:

(1). KEEP WORK AREA CLEAN. Cluttered areas and benches invite

accidents.

(2). DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power

tools in damp or wet locations, or expose them to rain. Keep work area

well-lighted.

(3). KEEP CHILEREN AND VISITIORS AWAY. All children and

visitors should be kept a safe distance from work area.

(4). DON’T install & use this machine in explosive, dangerous

6

environment.

E. MAINTENANCE

(1). DISCONNECT machine from power source when making repairs.

(2). CHECK DAMAGED PARTS. Before further use of the tool, a guard

par that is damaged should be carefully checked to ensure that it will

operate properly and perform its intended function check for alignment of

moving parts, binding of moving parts, breakage of parts, mounting, and

any other conditions that may affect its operation. A guard or other part that

is damaged should be properly repaired or replaced.

(3). DISCONNECT TOOLS before servicing and when changing

accessories such as blades, bits,cutters,etc.

(4). MAKE SURE that blade tension and blade tacking are properly

adjusted.

(5). RE-CHECK blade tension after initial cut with a new blade.

(6). TO RPOLONG BLADE LIFE ALWAYS release blade tension at the

end of each work day.

(7). CHECK COOLANT DAILY . Low coolant level can cause

foaming and high blade temperatures. Dirty or week coolant can clog pump,

cause crooked. Cast low cutting rate and permanent blade failure. Dirty

coolant can cause the growth of bacteria with ensuing skin irritation.

(8). WHEN CUTTING MAGNESIUM NEVER use soluble oils or

emulsions (oil-water mix) as water will greatly intensify any accidental

magnesium chip fire. See your industrial coolant supplier for specific

coolant recommendations when cutting magnesium.

(9). TO PRNMT corrosion of machined surfaces where a soluble on is

used as coolant, pay particular attention on wiping dry the surfaces where

fluid accumulates and dose not evaporate quickly, such as between the

7

machine bed and vise.

F. SPECTIFIED USAGE:

This machine is used only fir general cutting within the range of cutting

capacity.

G. NOISE

A weighted sound pressure level: 80 dB

H. SAFETY DEVICE:

By the time the saw arm cover is opened, the interlock switch will function

to stop the machine, do not remove this switch from machine for any

reason, and check its function frequently.

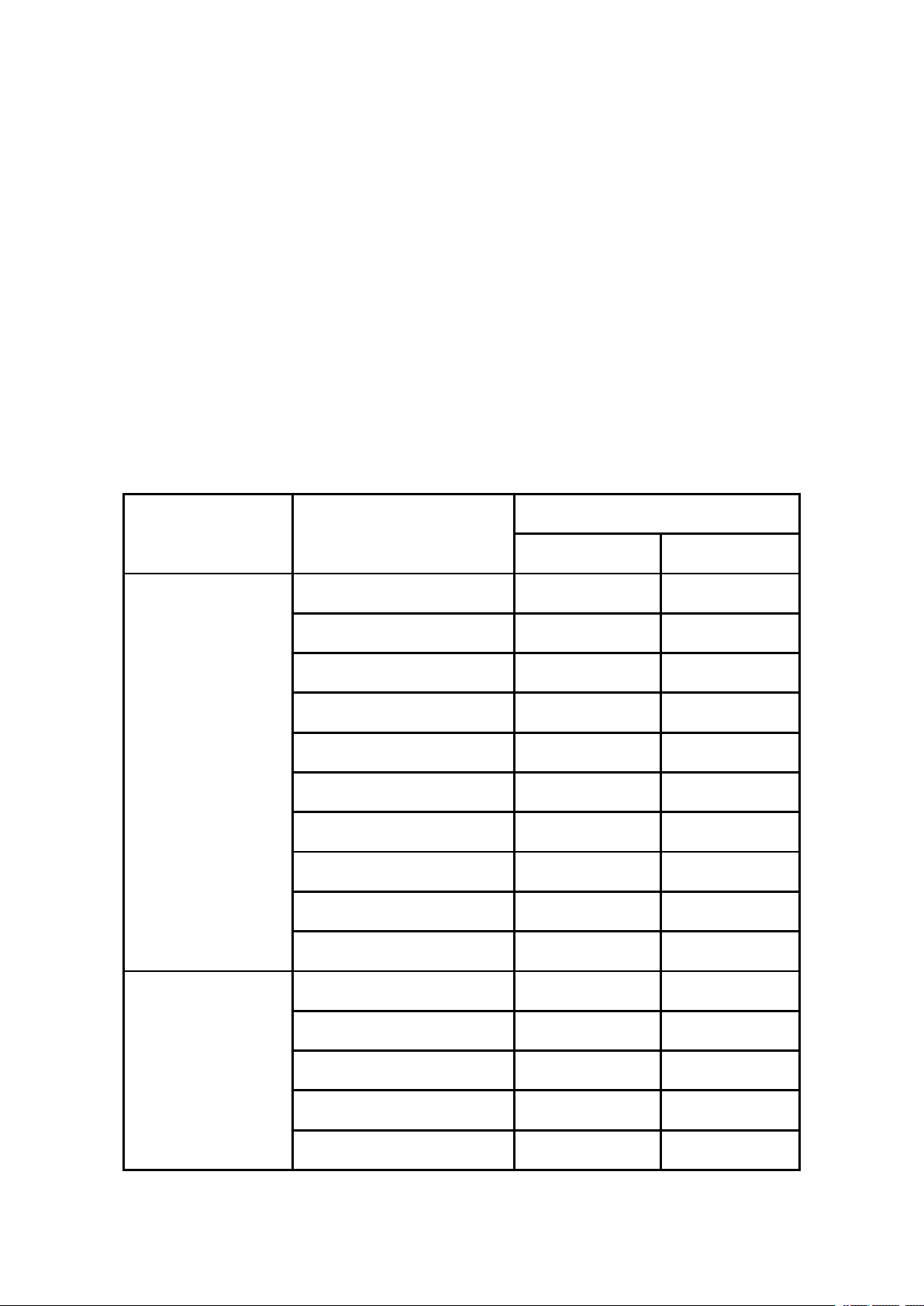

1. SPECIFICATION

MOTOR

Saw Blade Speed

(MPM)

912B

60HZ

32 60 88 115

Saw Blade Speed

(FPM)

912B

60HZ

105 196 288 377

Blade Size

27X0.9X2655mm/1”X0.035”X104.5”

Dimension LxWxH(mm)

1380X460X1050(B)

N.W/G.W(kgs)

155/180(G..DR.GDR) 140/165(B)

Working Capacity

0°

O(mm)

230(9”)

□(mm)

178X305X(7”X12”)(G.B)

±45°

O(mm)

150(6”)(G.B)

□(mm)

127X150(5”X6”)(G.B)

Packing

Measurement(mm)LXWXH

1420X530X1100(B)

Overall height (w/o stand)

1600mm(63”)

Noise

80dB MAX

8

2. TRANSPORTATION OF MACHINE:

Unpacking

1. Transportation to desired location before unpacking, please use

lifting jack. (Fig. B)

2. Transportation after unpacking, please use heavy duty fiber belt to

lift p the machine.

ALLWAYS KEEP PROPER FOOTING &BALANCE WHILE

MOVING THIS MACHINE.

As this machine weight 155kg. It is recommended that the machine shall be

transported, with help of lifting jack.

Transportation Recommendation:

(1). Tighten all locks before

operation.

(2). Always Keep proper footing &

balance while moving this 155kgs

machine, and only use heavy duty

fiber to lift the machine as Fig. A

(3). TURN OFF the power before wiring, &be sure machine in proper

grounding, overload & circuit breaker is recommended for safety wiring.

(4). CHECK carefully if the saw blade is dunning in counter-clockwise

direction in not, reverse the wiring per circuit diagram the repeat the

running test.

9

(5). KEEP machine always out from sun, dust, wet, raining area.

6. MINIMUM ROOM SPACE FOR MACHINE OPERATION

7. MAKE PROPER TOOTH SELECTION

For maximum cutting efficiency and lowest cost pre cut, it is important to

select the blade with the right number of teeth per inch (TPI) for the

material being cut. The material size and shape dictate tooth selection.

TOOTH SELECTION

You need to consider

1. The width of the cut. That is the distance in the cut that each tooth must

travel from the point it enters the worpiece until it leaves the workpiece.

2. The shape of the workpiece.

●Squares, Rectangles, Flats (Symbol :■)

10

Locate the width of cut on the chart. (Inches on the outer circle and

millimeters on the inner circle.) Select the tooth pitch on the ring

marker with the square shape which aligns with the width of cut.

EXAMPLE: 6” (150mm) square, use a 2/3 Vari-Tooth.

●Round Solids (Symbol :■)

Locate the diameter of your workpiece on the chart. Select the tooth

pitch on the ring marked with the ring marked with the round shape

which aligns with the size of stock you are cutting.

EXAMPLE: 4” (100mm) round, use a 3/4 Vari-Tooth.

● Tubing, Pipe, Structural (Symbol: O H^)

Determine the average width of cut by dividing the area of the

workpiece by the distance the saw blade must travel to finish the cut.

Locate the average width of cut on the chart. Select the tooth Ditch on

the ring marked with the tubing and structural shape which aligns with

the average width you are cutting.

EXAMPLE: 4” (100mm) outside diameter, 3”(75mm) inside diameter

tubing. 4” (100mm) OD = 12.5 sq.In. (79c ㎡)

3” (75mm) I D =7.0 sq.In. (44c ㎡)

Area = 5.5 sq.In. (35c ㎡)

5.5 sq.In. (35c ㎡)/4” (100mm) distance =1.38(35mm) average width

1.38” (35mm), use a 4/6 Vari- Tooth

NOTE: The band speed and cutting rate recommendations presented on

this chart are approximations and are to be used as a starting point for

most applications. For exact sawing parameters’ consult your saw blade

supplier.

8. BI-METAL SPEEDS AND FEEDS

11

These figures are a guide to cutting 4”(100mm) material (with a 314

Vari-tooth when using a cutting fluid.

Increase Band Speed:

15% When cutting 1/4” (6.4mm) material (10/14 Vari-Tooth)

12% When cutting 3/4” (19mm) material ( 6/10 Vari-Tooth )

10% When cutting 1-1/4” (32mm) material ( 5/8 Vari-Tooth )

5% When cutting 2-1/2” (64mm) material ( 4/6 Vari-Tooth )

Decrease Band Speed:

12% When cutting 8” (200mm) material ( 2/3 Vari-Tooth )

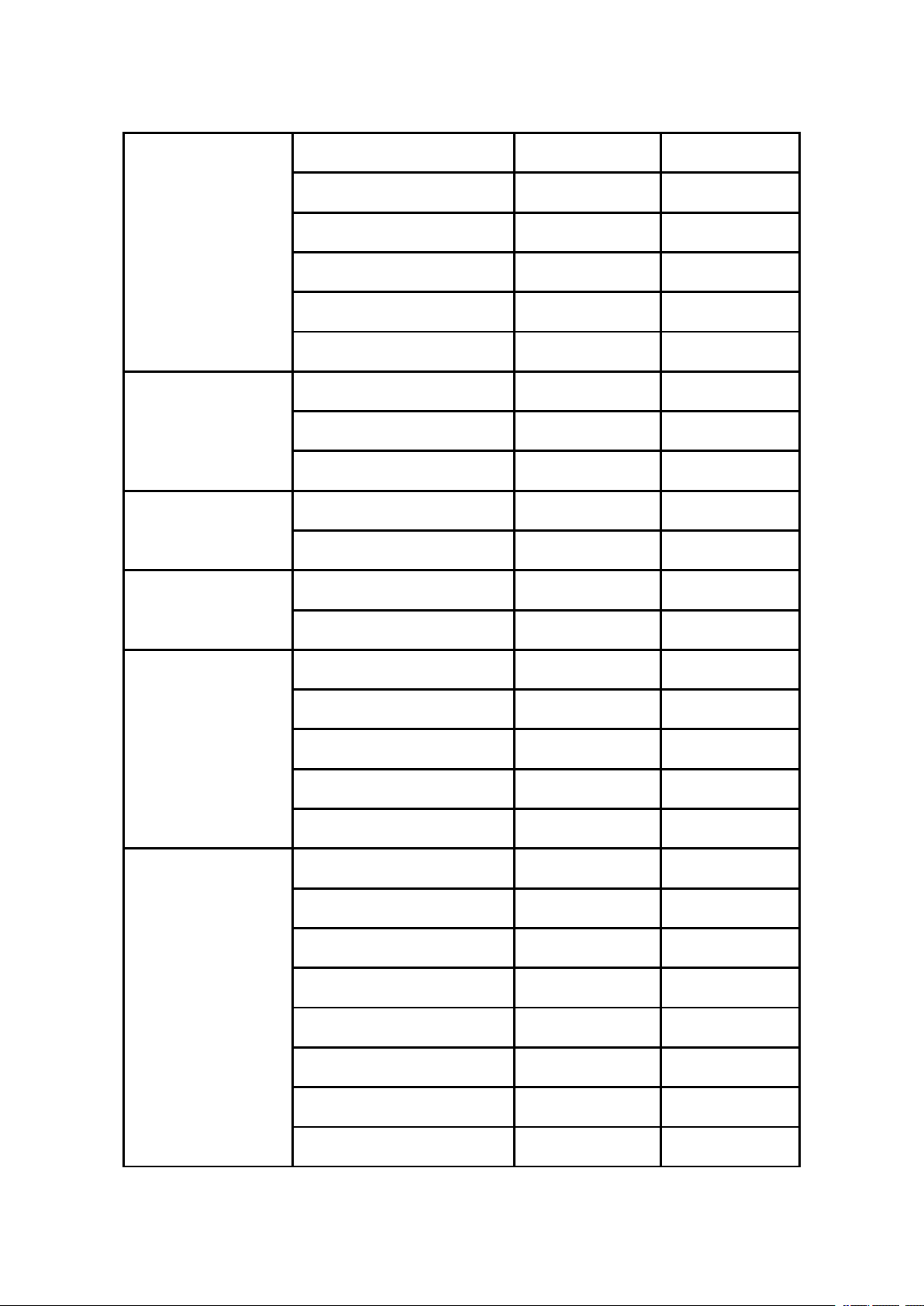

MATERIAL

ALLOY ASTM NO

BAND SPEED

FT./MIN

M/MIN

Copper

Alloy

173,932

314

96

330,365

284

87

623,624

264

81

230,260,272

244

74

280,264,632,655

244

74

101,102,110,122,172

234

71

1751,182,220,510

234

71

625,706,715,934

234

71

630

229

70

811

214

65

Carbon

Steel

1117

339

103

1137

289

88

1141,1144

279

85

1141HI STRESS

279

85

1030

329

100

12

1008,1015,1020,1025

319

97

1035

309

94

1018,1021,1022

299

91

1026,1513

299

91

A36 (SHAPES),1040

269

82

1042,1541

249

76

Carbon

Steel

1044,1045

219

67

1060

199

61

1095

184

56

Ni-Ci-Mo

Alloy Steel

8615,86120,8622

239

73

4340,E4340,8630

219

67

Ni-Ci-Mo

Alloy Steel

8640

199

61

E9310

174

53

Tool Steel

A-6

199

61

A-2

179

55

A-10

159

49

D-2

90

27

H-11,H-12,H-13

189

58

Stainless

Steel

420

189

58

430

149

46

410,502

140

43

414

115

35

431

95

29

440C

80

24

304,324

120

36

304L

115

35

13

347

110

33

316,316L

100

30

416

189

58

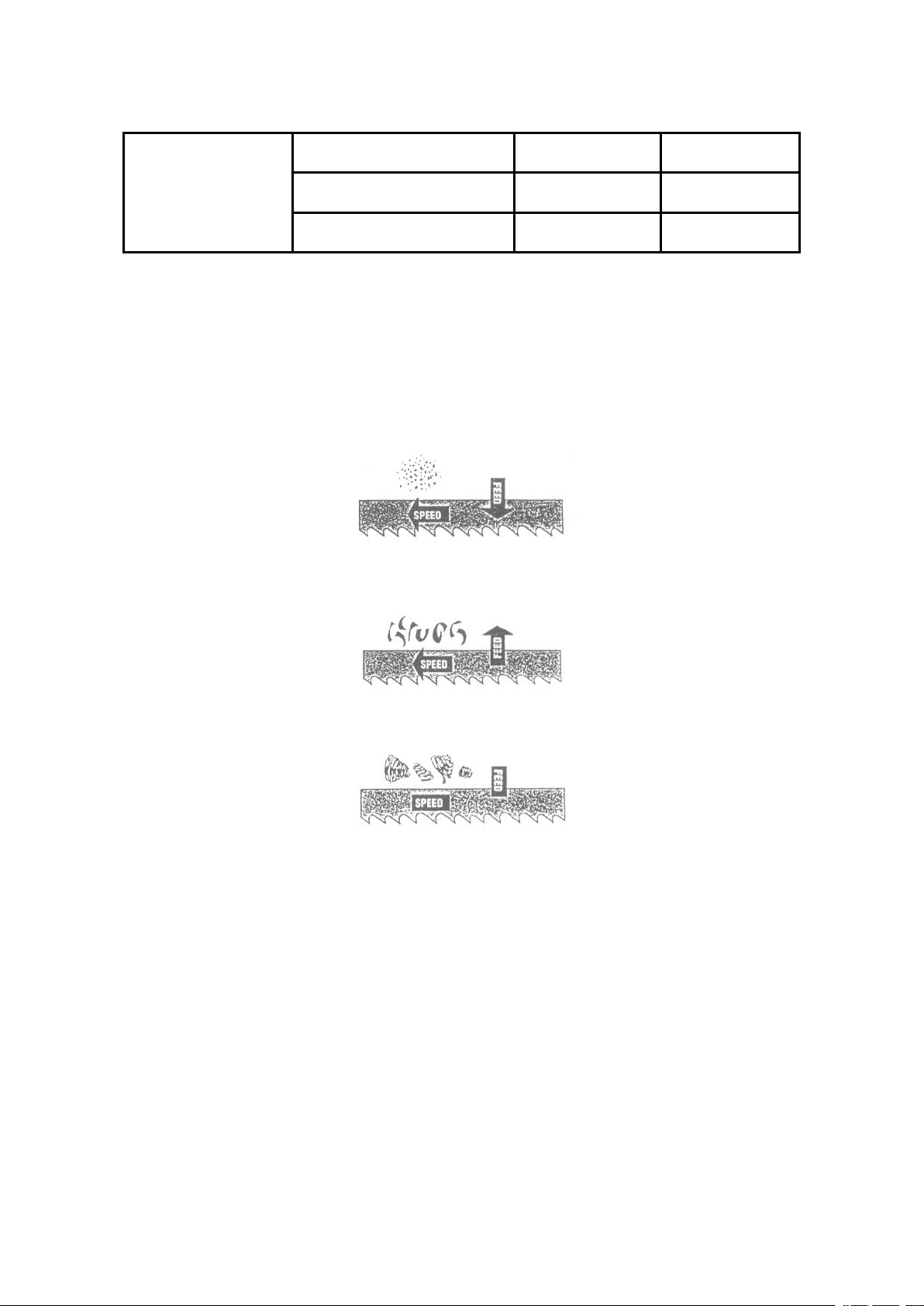

TELLTALE CHIPS

Chips are the best indicator of correct feed force. Monitor chip

information and adjust feed accordingly.

Thin or powdered chips-increase feed rate or reduce band speed.

Burned heavy chips-reduce feed rate and/or band speed.

Curly silvery and warm chips-optimum feed rate band speed.

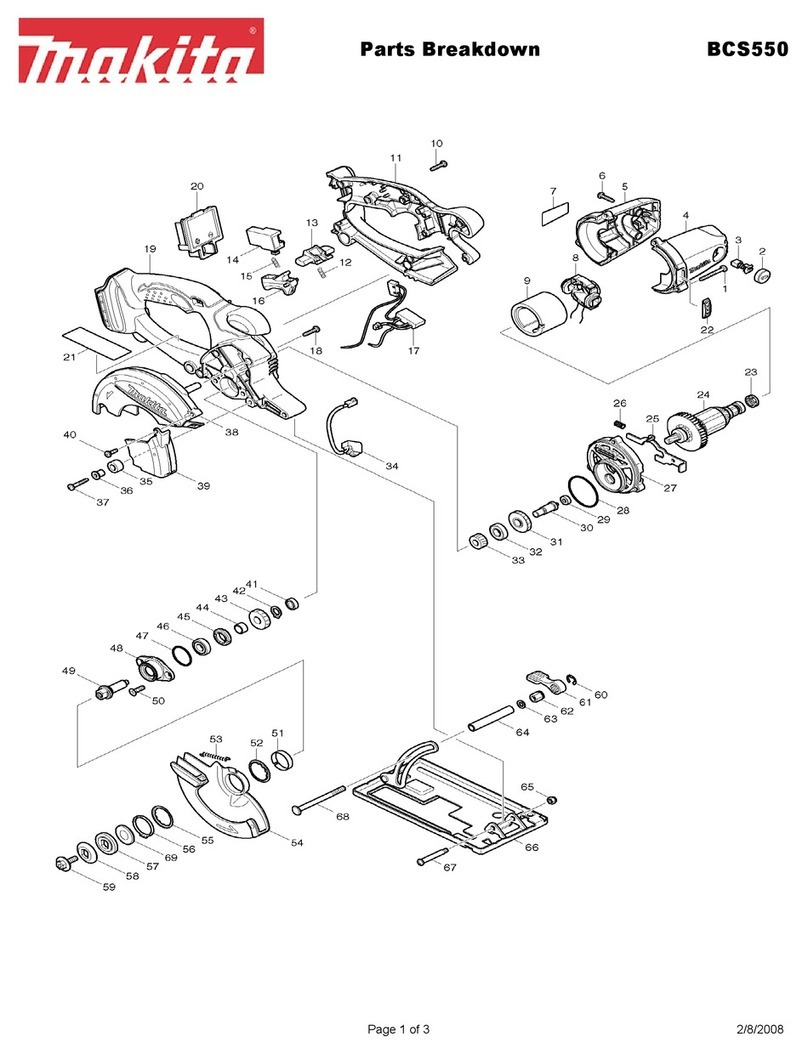

9. ASSEMBLY

A 1 HP, motor, split phase or capacitor-start it recommended for best

economical performance. Counterclockwise rotation is required. Note that

rotation can be reversed by following directions given on terminal

nameplate.

(1). Assembly the motor Mounting plate to the head using the long bolt

Note that the flat side of the plate faces up.

(2). Assemble the guard plate to the head using the screw and Lock Washer

and the Carriage Bolt Washer and Wing Nut are used to secure the motor

14

mounting plate to the Guard plate through the slotted hole in the Guard

plate. These components also serve to position and lock the motor in place

for proper speed/ belt adjustment.

(3). Place the spacer over the long Bolt and secure it wit the nut.

(4). Secure the Motor to the Motor Mounting plate with the four bolts and

nuts. Note that the motor shaft is placed through the large opening in the

Guard plate and must be parallel with the drive Shaft.

(5). Assemble the Motor Pulley, the smaller of the two provided, to the

motor shaft Note, the larger diameter must be closest to the motor. Do not

tighten the set screw.

(6). Assemble the Driven Pulley, the larger of the two provided, to the

protruding drive Shaft Note the small diameter must be closest to the

bearing. Do not tighten the set screw.

(7). Place the belt into one of the pulley grooves and the other end into the

respective grooves of he second pulley.

(8). Line up the belt and both pulleys such that the belt is running parallel

in the pulley grooves.

(9). Tighten the set screws of both pulleys in this position.

(10). Place the belt into proper pulley combination for proper blade speed.

See material cutting chart.

(11). Adjust the position of the Motor to obtain approximately 1/2”

depression in the belt when applying pressure with you thumb.

(12). Tighten the head screw Holding the Motor Mounting plate to the

Guard plate.

(13). Connect the Electrical Harness to the motor terminal box. The motor

should be protected with a time delay fuse or circuit breaker with rated

amperage slightly greater than the full load amperage of the motor.

10. OPERATION

15

WORK SET UP

(1). Raise the saw head to the highest position.

(2). Open vise to accept the Piece to be cut by rotating the wheel at the

end the base.

(3). Place workpiece on saw bed. If the piece is long, support the end.

(4). Clamp workpieced securely in vise.

WORK STOP ADJUSTMENT

(1). Loosen the thumb screw holding the work stop casing to the shaf.

(2). Adjust the work stop casing to the desired length position.

(3). Rotate the work stop to as close to the bottom of the cut as

possible.

(4). Tighten thumbscrew.

(5). DO NOT ALLOW the blade to rest on the work while the motor is

shut off.

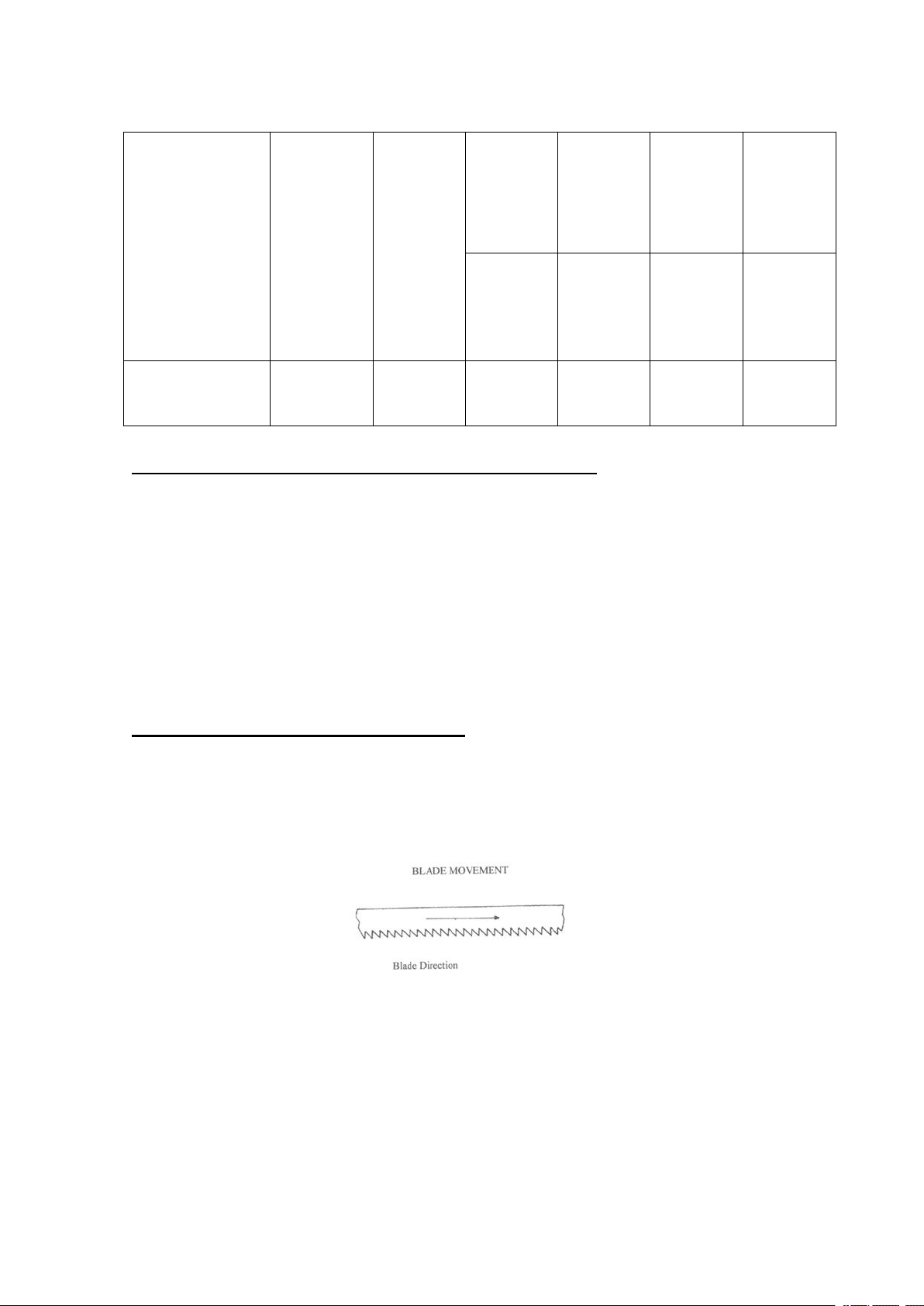

BLADE SPEEDS

When using your Band saw always change the blade speed to best suit

the material being cut the material Cutting Shirt givers suggested

settings for several materials.

Material

Speed F.P.M

Belt Groove Used

912(G.GDR)

912 (B.DR)

60Hz

50Hz

60Hz

50Hz

Motor

pulley

Saw

Pulley

Tool,Stainless

Alloy Steels

Bearing Bronze

125

104

105

85

small

largest

16

Medium to High

Carbon Steels

Hard Brass or

Bronze

Low to Medium

Carbon Steel

Soft Brass

255

212

196

164

Medium

Large

288

240

Large

Medium

Aluminum

Plastic

380

316

377

12

Largest

Small

MANUAL OF GEAR TYPE SPEED CHANGING

(1) Select the proper cutting speed according to the material of work-pieces

and blade select chart.

(2) Turn the speed-changing handle directly for the necessary speed.

(3) Changing speed during cutting is prohibited.

(4) But changing speed when machine is stopped and sunning (before

cutting)

BALDE DIRECTION OF TRAVEL

Be sure the Made is assembled to the pulley such that the vertical edge

engages the work piece first.

BLADE MOVEMENT

17

STARTING SAW

Switch button function description

CAUIION : NEVER OPERATE SAW WITHOUT BLADE GUARDS IN

PLACE.

Be sure the blade is not in contact with the work when the motor is started.

Start the motor, allow the saw to come to full speed, and then begin the cut

by letting the head down slowly onto the work. DO NOT DROP OR

FORCE. Let the weight of the saw head provide the cutting fore. The saw

automatically shuts off at the end of the cut.

BLADE SELECTION

A 8-tooth per inch, general-use blade is furnished with metal Cutting Band

Saw. Additional blades in 4, 6, 8, and 10 tooth sizes are available. The

choice of lade pitch is governed by the thinness of the work to be cut: the

thinner the workpiece, the more teeth advised. A minimum of three (3)

teeth should angage to workpiece at all times for proper cutting. If the teeth

of the Blade are so far apart that they straddle the work, severe damage to

the workpiece and to the Made can result.

CHANGING BLADE

Raise saw head to the highest position and open the blade guards. Loosen

A (Emergency Push Button)

B (Start Button)

C (Stop Button)

D (Coolant Selection Switch)

18

tension screw knob sufficiently to allow the saw blade to slip off the wheels.

Install the new blade with teeth slanting toward the motor as follows:

(1). Place the blade in between each of the guide bearings.

(2). Slip the blade around the motor pulley (bottom) with the left hand

and hold in position.

(3). Hold the blade taut against the motor pulley by pulling the blade

upward with the right hand which is placed at the top of the Made.

(4). Remove left hand from bottom pulley and place is at the top aide of

the Made to continue the application on the upward pull on the blade

(5). Remove right hand from blade and adjust the position of the top

pulley to permit left hand to slip the blade around the pulley using

the thumb, index and little finger as guides.

(6). Adjust the blade tension knob clockwise until it is just right enough

so no blade slippage occurs. Do not tighten excessively.

(7). Replace the blade guards.

(8). Place 2-3 drops of oil on the blade.

TRU-LOCK VISE SYSTEM INSTRUCTIONS

(1). The position of the vise when tightened.

(2). The position of the vise when loosened. (Half opened).

(3). The position of the vise when loosened.(Completely opened).

To operate, proceed as follows:

1) Rise the arm 2”above the workpiece, close the cylinder valve to

19

maintain the arm 2”above the workpiece.

2) Put you workpiece on the table. Move the vise handle (a) upwards to

an angle of 45 degree (a-half opened) to loosen the vise. Move the

vise jaw bracket against the workpiece by turning the rectangular

handle (b). Push down on the vise handle (a) to lock the workpiece in

position.

3) To loosen the workpiece from the vise, hold the workpiece and lift the

vise handle (a) to a 90 degree position (completely opened). Remove

workpiece.

QUICK VISE ADJUSTMENT FOR ANGLE CUT (912B. 912G)

(1). Loosen the A. B. C. D. Screw.

(2). Adjust rear vise to the threaded hole position. (E)

(3). Set the scale to the desired angle.

(4). Adjust he front vise (F) to parallel the rear vise (E)

(5). Tighten the A. B. C. D. Screw.

QUICK VISE ADJUSTMENT FOR ANGLE CUT (912DR. 912GDR)

(1). Pull out plastic knob (A). Turn and lock the plastic knob.

(2). Loosen grip (B) .Then rotate the Body Frame for the desired angle.

Be aware the blade position is higher than the Vise Table by

pulling up the Body Frame when count-clockwise rotation for

angle cutting and for clockwise rotation for angle cutting higher

the Body Frame and keep the blade position higher than the vise.

Then pull forward the vise Jaw Bracket (Front) to a proper

20

location.

(3). Fasten the grip (B) when the cutting angle is reached.

(4). There is angle set-screw for ±45° rotation.

11. BLADE GUIDE BEARING ADJUSTMENT

ATTENTION: This is the most important adjustment on your saw. It is

impossible to get satisfactory work from your saw if the blade guides are

not properly adjusted. The blade guide bearing on your metal. Cutting Band

Saw are adjusted and power tested with several test cuts before leaving the

factory to insure proper setting. The need for adjustment should rarely

occur straight, and if the situation is not corrected it will cause serious

blade damage. Because guide adjustment is a critical factor in the

performance of your saw, it is always best to try a new blade to see if this

will correct poor cutting before beginning to adjust. If a blade becomes dull

on one side sooner than the other, for example, it will begin cutting crooked.

A blade change will correct this problem the guide adjustment will not. If a

new blade does not correct the problem, check the blade guides for proper

spacing.

NOTE: There should be from 000(just touching) 001 clearance between the

blade and guide bearings to obtain this clearance adjust as follows:

1. The inner guide bearing is fixed and cannot be adjusted.

2. The outer guide bearing is mounted to an eccentric bushing and can

be adjusted.

3. Loosen the nut while holding to an eccentric bushing and can be

This manual suits for next models

4

Table of contents

Other Toolots Saw manuals