Toolots NAX Series Technical manual

NAX-Series Horizontal Saw Band Machine Tool with Pillar

Operation Instruction

Max. Cutting Diameter: Unit: mm

Factory Serial No.:

2

Catalog

1、

ImportantNotes

……………………………………………1

2、

Main Application

……………………………………………3

3、

Normal Working Environment

………………………………3

4、

Main Models & Technique Parameters

…………………………3

5、

Mechanical Transmission System

………………………………3

6、

Key Structure of Machine Tool

…………………………………4

7、

Hydraulic System

………………………………………………6

8、

Electrical System

………………………………………………9

9、

Cooling System

………………………………………………12

10、

Lubricating System

………………………………………… 13

11、

Machine Tool Lifting & Installation

………………………… 13

12、

Debugging, Operation and Maintenance of the Machine Tool

… 15

13、

Common Fault Disposal of the Machine Tool

………………… 16

Safety Precautions

1、The Machine tool shall not be operated beyond the described application and working

scope.

2、Please read the operation instruction carefully before operation.

3

3、 The operator shall be professional trained to ensure safe working and avoid harm or

damage caused by false operation.

4、 The operation instruction shall be strictly followed to installate and operate the machine

tool. There should be enough space for operate and the space shall be cleaned without

obstacles to operator’s ensure safe operation and daily maintenance.

5、。 The operator should work as trained and required as the operation instruction, keeping

regular maintenance and repare to ensure safe operation conditions.

6、 Safety protection equipments must be put on the operator while working with machine

tools and should be regularly checked. It is forbidden to take the equipments off the

machine tool and prevention fence should be set if necessary.

7、All protection covers should be shut before machine tool operation while the adjustable

band saw protection covers should be near the working parts. During working, no

protective cover could be opened.

8、When removing and changing the saw blade, the machine tool should be confirmed to

have stopped working. Only then could the saw wheel protective cover be opened and the

support posted be checked to be firmly fastened. Protective gloves must be put on to avoid

puncture or hurt while changing the saw blade.

9、Highly attention that no part of the body should touch the working saw blade band or

get into the working area during the operation. It is also forbidden to take the jammed or

broken parts while the machine tool is working.

10、Gloves and loose clothes are not allowed during machine tool operation and

maintenance.

11、The parts should be checked to be firmly clamped before and during the whole sawing

working. The claming equipment should not be released until the saw bands stop working.

12、When the machine tool is working, the long and heavy parts should be firmly supported

during the cutting-in and cutting-out, preventing the fall of the cut parts and the turn-over

of the machine tool after the cutting task. Feeder and picking rack should be applied when

long materials are to be cut.

13、The power supply shall be completely cut off before the adjustment, maintenance,

repairing and cleaning of the machine tool, avoiding electric accidents.

14、The machine tool should be shut before transmission.

15、To adjust the guide arms spread, the machine tool must be shut. Then the fastening

hand wheel should be firmly fixed after the adjustment.

4

16、The power supply of the machine tool is 380V 50Hz AC Three Phase with the pressure

inflate value less than 10%. Extra power supply, grounding and leakage protection devices

should be set according to the rated capacity of the machine tool. Should there be possible

of pressure inflate and false operation, shared wiring with other equipments is not

permitted.

17、The power supply grounding must be reliable and perform well.

18、In circumstance of accident while operating the machine tool, please push the

emergency stop button.

19、The cooling liquid is harmful to human skins so that the operator should take good

protective measurements. It could not be released to the underground and must be dealt

according to environmental protection regulations. While processing, the operator could set

up protective panels to stop the cooling liquid from splashing around.

20、If the cutting chips are combustible materials, such as Magnesium and Titan, No open

flames if permitted, meanwhile, corresponding fire protection measures should be well

prepared.

21、No cutting is allowed with combustible powder composed materials such as the Carbon

Robs so as to prevent fire or exploitation.

2

、

Main Application

This machine tool is mainly applied in cutting all kinds of black metal and colored rod and

mould materials. When the processing data are put in, the cutting starts automatically. As

an ideal machine tool for piece batch cutting, it is blessed with high automatic operation

degree, simple operation, high cutting performance efficiency, less cutting false, better

geographic accuracy of the cutting piece, smaller noise etc.

3

、

Normal Working Environment

a、Over 0 Degree Centigrade surrounding environment temperature

b、Air relative humidity is no higher than 85% (media temperature should be 20+/-5

Degree Centigrade)

4

、

Machine Tool Models & Technique Parameters

Model

NAX1515

Max. Cutting Diameter

90° Φ400mm ■400*500

mm

45° Φ300mm ■:250*400

mm

Blade Speed

30.40.55.80

m/min

5

5

、

Mechanical Transmission System

The mechanical transmission system of the machine tool is shown in Picture 1.

Bearings of each part of the machine tool are listed on Table 5-1 and 5-2.

The main engine triggers the worm in the worm gear box via bands and then accomplishes

the transmission through the worm gear box to activate the active wheel. Then the passive

wheel is started by the active wheel via the saw band. The saw band accordingly works

with the active wheel to cut the parts.

Meanwhile, the hydraulic system forces the cylinder downwards, to the saw beam then falls

down to cut the parts. After the cutting, the hydraulic system forces the cylinder upwards

and the saw beam rises. At the same time, the main engine stops to prepare for the next

cycle.

Blade Size

1.3*41*5220

mm

Motor Output

4

kw

Hydraulic Pressure

0.75

kw

Coolant Pump

0.08

kw

Table height

630

mm

Machine Size(L*W*H)

2560*1600*1700

mm

Net Weight

2100

kg

Vice clamping

Hydraulic

Blade tensioning form

Maunal

Feeding cut adjust way

Hydraulic stepless

Feeding way

Manual

Hydraulic cooling way

Wind cooling

Voltage

380V 50HZ 3Phase

6

Main Structure of the Machine Tool

6.1 Deceleration Worm Gear Box Part

The part of the deceleration worm gear box lies beneath the frame. The linear speed of

the saw band is changed by the transmission band wheel which is triggered by the main

engine transmission band wheel.

6.2 Frame Part

The saw frame part is a welding combination of the iron plates, supporting the feeding

wheel, passive wheel and the transmission part of the saw band.

6.3 Machine Body

The machine body is a box-shaped welding part with a cooling water tank on the right

and a hydraulic oil tank on the left. There are four corresponding suspending loops in the

front and in the back of the body respectively, applied for lifting and moving. And there are

six tapped holes beneath for fastening the machine tool.

6.4 Working Table

The working table is equipped with the jaw and the hydraulic cylinder used for

clamping working parts. The working table supports the cutting parts to finish the cutting.

7、

Hydraulic System

7.1 Main Parameters for the Hydraulic System as below

:

Gear Oil Pump Pressure 6.3MP

Oil Pump Engine Power See Technique Parameters

Switching Valve Flow 10L/min

Overflow Valve Flow 10L/min

System Working Pressure 2.5-3.5MP

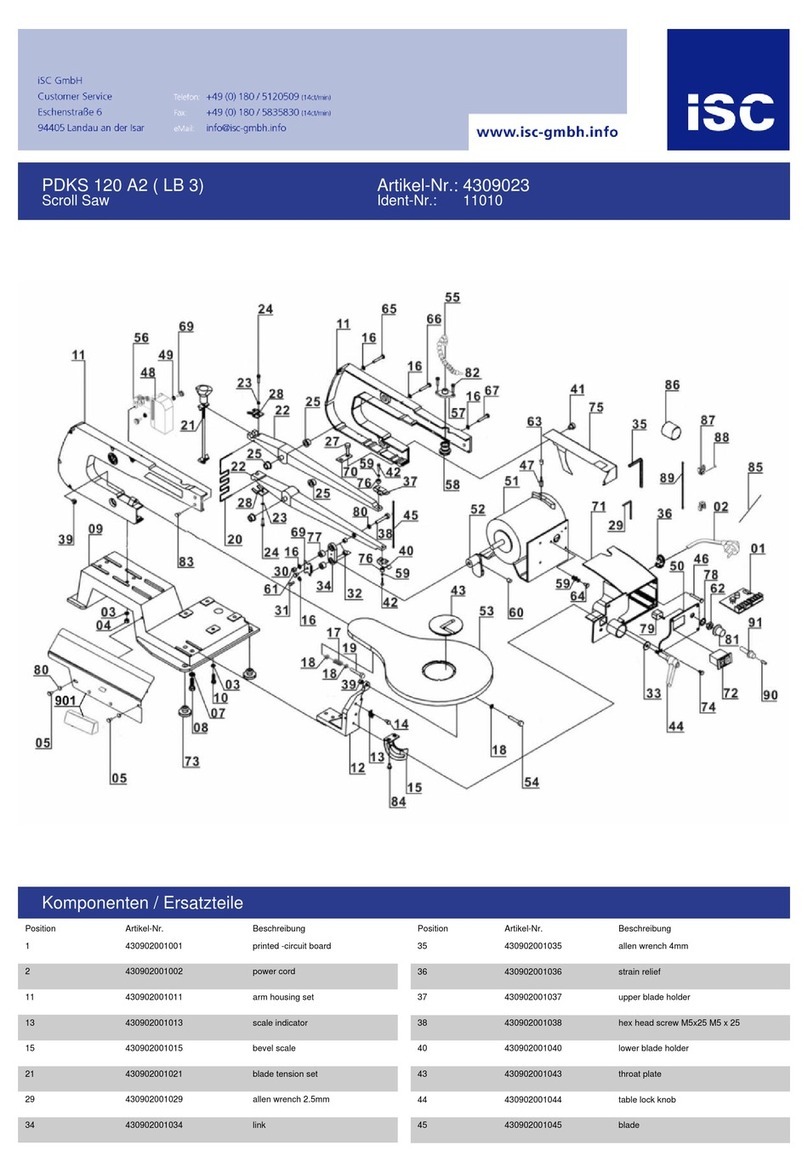

The Type, Name, Model and Quantity of the Hydraulic Unit

Unite Name

Model Type

Application Model

Quantity

Vane Pump

YB1-6

NAX151 and above

1

Gear Pump

CB-B4

NAX151 and above

1

Overflow Valve

YB-10B

NAX151 and above

1

Travel Valve

FKC-G02

NAX151 and above

1

Mag Valve

4WE6E

NAX151 and above

2

Mag Valve

3WE6B

NAX151 and above

1

Pressure Meter

Y60

NAX151 and above

1

7.3

Hydraulic Function Instruction

As shown in the following picture

:

7

夹 紧 油 缸

YA1 YA2

YA3

L

YA4 YA5

1、Release the Emergency Stop button, the oil pump starts working. Adjust the overflow

valve to push system pressure to required level.

2、Press the uplifting button. The upward mag valve and fast mag valve attract to each

other so that the saw frame rises.

3、Press the downward button and the downward mag valve and fast mag valve attract to

each other so that the saw frame falls.

4、vate, the downward valve closes. The saw nip would fall as to the speed set by the

throttle valve.

5、Press jaw clamping, the front jaw clamping mag valve closes and the jaw clamps

tightly.

6、Press jaw releasing, the front jaw releasing mag valve closes and the jaw releases.

7.4 Frequent Faults in Hydraulic System and Solutions

7.4.1 Abnormal Pressure Meter Display, Oil Foam

Causes: filter blocked; oil suction above the oil surface; high oil viscosity; air

leakage at the connection with the oil inlet pipe; wrong oil pump sealing; wrong overflow

valve performance.

Corresponding measures shall be taken according to different causes.

7.4.2 Insufficient Pressure or No Pressure

Causes: oil pump rightabout running; oil pump broken or worn; low oil viscosity.

Corresponding measures shall be taken according to different causes.

7.4.3 The Saw Frame Falls Down Automatically While in Neutral Position

Causes: inner leakage of the lifting mag valve; oil cylinder seal worn or broken

Replace mag valve or cylinder seal.

7.4.Abnormal Reaction to All Instruction

Cause: mag valve locked

8

Take off and clean corresponding mag valve

Keeping the oil clean could reduce accident and effectively prolong the service life of each

mag valve. The hydraulic oil tank shall be cleaned regularly and the oil shall be replaced.

8

、

Electric and Control System

8.1 Power Supply

The power supply for this machine tool is 380V 50Hz three-phase power.

Three sets of three-phase asynchronous motor for the main drive of the machine tool.

M1/Oil pump motor M1, M2/Sawband motor M2,

M3/Cooling water pump M3

All motor model specification and other electric unit could be found in catalog table 8-1.

线路板和变频器位于机床左前侧的电气箱内,操作面板在机床前侧。Circuit board

and frequency converter lie in the electric box at the left front of the machine tool. The

control panel is at the front of the machine tool.

Table 8-1 Electric Units List

Code

Name

Model

Spec.

Quantity

M1

Oil Pump Motor

YS7124

YT802-4

0.37KW(NAX1515)

0.75KW(and above)

1

1

M2

Key Motor

Y100M-4

Y112M-4

Y132M-6

Y132M2-6

3KW(4230)

4KW(4240)

4KW(4250/60)

5.5KW(4265)

1

1

1

1

M3

Water Pump

BD-12A

AYB-12

0.040KW(4230)

85W(4240 以上)

1

1

SQ

Travel Switch

YBLX-19/001

2

KM

Contactor

CJX1-12

36V

1

KM

Contactor

CJX1-22

36V

1

FR

Thermal Relay

JR36-20

3.2-5

1

FR

Thermal Relay

JR36-20

10-16

1

Breaker

PT14-20

3

QF

Breaker

DZ47-60

1

CT

Transformer

BK-200

1

KA

Middle Relay

JZC1-44

36V

2

Bridge Rectifier

KBPC35

1

9

SA/SB

Button

Φ22LAY-16

8

SB

Emergency Stop

Button

Φ22LAY16

1

HL

Working Light

JC-15

AC36V

1

Power LED

XDJ2

1

10

设

备

界

线

L1

L2

L3

F U1 (2 0 A)

油泵

M1

KM1

U

V

W

GB

立 柱 系 列 电器线路图(电磁阀 夹 紧 )

F R1

M2

主 机

M3

水泵

F R 2

KM2

U V W

KM1 YA5YA4

KM2

KM2

YA3

03 0

207

SB2

205

203

201

202

V

KA1 KA1

YA1 YA2

SB4

SB3

SB2

F U3 (2 A)

0

03

953 7

202201

SB

F R2F R1

F U4 (6 A)

F U2 (2 A)

SB1

11

SA1

HL1 HL

KA2SA4

29

27

25

23

21

KA2

SA3

19

17

SA2

15 SQ1

SQ2

KA2

KM2

KM2

KA1

KA1

KM1

13

01

1

CT

SB4 KA2 KA2

KA2

211

209 213

215

桥堆 工作灯 指示灯 油泵 钳紧 主机 上升 桥堆钳紧 钳松 下降 快降 上升

8.3

Electric Control Principle for Machine Tool

Electric control is as showed in picture.

1、Connect the power supply; turn on the power switch QF. The power LED shines. Turn

on the emergency stop button SB and the machine tool has been ready for operation.

2、。Press the oil pump activate button, KM1 contactor closes and the oil pump starts

working. Press the oil pump stop button, KM1 opens and then the oil pump stops.

3、。Press the jaw clamping button, the relay KA1 closes and the jaw clamps tightly. Press

jaw releasing button, the reply KA1 breaks and the jaw releases.

4、Press main engine activate button, contactor KM2 closes and then the main engine and

water pump starts operation. Meanwhile the contactor KM2’s open contact point closes

11

with mag iron YA3, then the saw frame falls downward as in required speed. Press main

engine stop button, relay KM2 opens and the main engine and water pump stop.

5、Press uplifting button, relay KA2 closes and the saw frame starts rising. Press fast fall

button, relay KA2 opens while SB4 button closes and the saw frame falls down.

Note: The emergency button is used only for emergency stop, so please always keep

it in good condition.

9

、

Cooling and Chip-Cleaning System

Within the cooling system of this machine tool, the cooling liquid is pumped up by the

water pump from the water tank to each water nozzle. The cooling liquid would then flow

back to the tank for cycling use. Emulsified liquid is generally used as the cooling liquid

and high performance cutting fluid would be best.

Attention should be paid to keeping the water clean and clear. The chips in the water

tank and the filter should be cleaned regularly. The dregs shall be washed away while

replacing the cooling liquid in the water tank.

Before each operation, please check if there is enough cooling liquid. Please add

necessary quantity of the cooling liquid during the operation. Cutting is not allowed

without cooling liquid.

10

、

Lubricating System

The worm gear box is a key part of the machine tool’s lubrication. The worm and wheel

within the box is lubricated with Gear Oil 18# which measures about 3 kilograms. The oil

should be fully replaced after one month test and after that the replace period is generally 3

to 6 month.

The slide on the linear track, the axles of the passive wheel and thread rod shall be

lubricated manually with butter drops, generally once a month.

As to the other parts, such as the guiding track of the machine tool, the lubrication should

be carried out before each shift operation.

11

、

Machine Tool Lifting and Installation

11.1Lifting and Installation

After the product box is opened, please first check if the machine tool is complete or

broken and then find out if all the parts and technique papers are there as listed in the

packing list. Should there be broken products or shortage of parts and else issues, please

carefully confirm the responsibility. If the problems lie within our responsibility scope,

please inform our factory or the sale departments.

。As to the lifting and installation details, please check the Diagram for Machine Tool

Lifting and Installation. While lifting, wood, rubber sheets should be inserted between

cable and machine tool to avoid scraping.

11.2 Machine Tool Adjustment

Armor plates should be put under the feet of the machine tool to adjust the horizontal

degree of the machine tool working table.

12

12

、

Machine Tool Debugging and Operation

12.1 Preparation Before Debugging

Connect power supply and check if the motor is running in the right direction. Add in

adequate cooling liquid in the cooling liquid tank. Put on the saw bank.

Check if the emergency stop button works well and is reliable.

12.2 Operation Procedure Demonstration

1、Turn on the breaker in the electric box and the power led shines.

2、Turn on the emergency stop button, check if the machine is working well

according to each movement. Then stretch the saw band tightly, release the jaw to make the

saw frame rise to proper position.

3、Put on the work part, adjust it to cutting position and then close the jaw clamping.

4、Adjust the upper and down travel switches to proper positions according to

diameter of the part.

5、Turn the speed valve to the min. position, turn on the main engine and water pump.

Then adjust the saw band to proper speed according to its materials and size. When the

cutting starts, adjust the valve to proper speed.

6

、

When the cutting task is done, the saw frame would collide with the travel switch

and then the main engine stops working. The saw frame fast rise until collide with the

upper limit travel switch; the saw frame stops rising to start a new round of cutting work.

12.3 Notice for Machine Tool Operation

1、The saw shall not be set in wrong ways that the blade should be set toward the

protection cover and tooth downward.

2、Once abnormal situation appears with the machine tool during the cutting, the

operator should immediately press the emergency stop button.

3、Choose the right cutting line speed. Generally, the saw line speed should not

exceed 50m/min. However, the saw speed should also be adjusted according to different

material hardness and stretching capacity.

4、Choosing proper feeding speed would greatly prolong the service life of saw band.

13、

Common Problems and Solutions

Mechanical Transmission Problems

No.

Problems

Causes

Solutions

13

1

The geometric

accuracy of the

cut part exceed

requirement

Loose jaw

Fasten the working part

Saw band and the working

table are off plumb

Adjust working table

Saw band worn or broken

Replace saw band

2

Smoking while

cutting

The cooling liquid could not

flow out fluently

Dredge the cooling

pipes

Fast feeding

Adjust the speed

Saw backbone not straight

Rubdown or replace

3

Blue or purple

iron chips

Too fast saw band speed

Change saw band

position and slow down

saw bank speed

4

Saw Break

Too fast feeding

Measures shall be taken

according to different

situations

Saw overstretched or less

stretched

Working part unfastened

5

Cutting

Vibration

Too fast saw band speed and

feeding

Adjust the speed

Saw backbone not straight

Repair or replace

6

Active Drive

System

Spinning

Saw Band

Touches Tooth

Loose drive belt

Stretch the belt

Too much stretching tension

of saw band

Adjust stretch tension

of saw band

Too fast feeding

Adjust the speed

Bad quality cooling liquid

Replace by good

quality cooling liquid

Improper tooth gap

Choose the right tooth

Working part unfastened

Fasten the working part

Too much feed

Decrease the feed

14

7

8

Short Saw Life

High line speed

Choose right speed

Too much feed

Decrease the feed

Poor saw quality

Replace saw band

1、

ions

No.

Problems

Causes

Solutions

1

Turn on the

general switch

but no power

supply

380V power not connected

Connect power supply

Switch broken

Replace

Emergency stop button not

reset

Turn on emergency stop

switch

2

Main engine

not activated

Fuse broken

Replace fuse

Thermal relay overloaded and

not reste

Exclude overload causes

3

Speed valve

could not stop

while cutting

Speed adjustment valve

blocked

Take off and clean

Inner leakage of rising & falling

mag valve

Replace mag valve

Inner leakage of oil cylinder

Replace oil cylinder seal

4

Abnormal

cutting

movements

Corresponding mag valve

blocked

Take off and clean mag

valve

Corresponding middle relay not

connected

Replace

15

5

Saw frame not

rise after work

part is cut

Lower limit travel switch not

connected

Adjust the switch

touch-block

Lower limit travel switch worn

and broken

Replace

Rising mag valve blocked

Take off and clean mag

valve

6

Saw frame

rising could not

stop after work

part is cut

Upper limit travel switch not

connected

switch touch-block

Upper limit travel switch worn

and broken

Replace

Rising mag valve blocked

Take off and clean the mag

valve

7

All meg valve

not move

Bridge rectifier worn and

broken

Replace

16

Fuse burnt

Replace

This manual suits for next models

1

Table of contents

Other Toolots Saw manuals