Toolots JLH-33 User manual

BAND SAW

JLH-33

NSTRUCTION MANUAL

`

Thank you for your choice of our products and it is our honor that you become our user.

Before you start to use your new machine please read the instruction manual carefully to

Enjoy safe using and a longer life service.

The complete instruction manual consists of the following parts.

□Safety Guidance

□Machine Overview

□Instruction Manual

Due to the continuous improvements,there will be difference between the product descriptions

In the manual and the actual details of the delivered machine.Please kindly understand and

The correct specification is subject to the delivered goods without further notice.

1、Safety Guidance

1

Please do not perform any installation、maintenance or adjustment of the machine without

reading

The Instruction Manual carefully and accepting complete training.

Please use the band sawing machine only after when you are familiar with the

characteristics of the machine,safety information and all related guidelines.

1.1 Unpacking\Lifting

⚫Wrongdoing in lifting may result in personal injury.

⚫Pay attention to the barycenter to avoid incline,otherwise dangers or death may occur.

⚫Do not move or stand under the machine when lifting.

⚫Take care of the box board and nails or other things to avoid to occurring dangers.

⚫Avoid to overturn the machine,otherwise dangers may occur.

1、Safety Guidance

2

1.2 Installation

⚫Improper level of the packing block under the machine could cause personal injury.

⚫Always have good grounding installation to ensure personal safety.

⚫Never operate the machine before adjusting process is completed.

⚫Do not clean the machine with gasoline and other flammable liquids.

⚫User must follow power parameter indicated in the instruction book in fear of damage

the machine.

⚫User must set the fuse in the power switch as pre-insurance unit.

1.3 Testing

⚫Must read guidance carefully and understood well before testing and prohibit improper

operation,otherwise occur dangers.

⚫Must fix workpiece on the working platform tightly, otherwise occur dangers.

⚫Never to operate machine without training.

⚫Must stop machine immediately when these is abnormal sound,and identify the reason and

rule out it.

⚫Operator must be in good health condition when operating the machine.

1.4 Operation

1、Safety Guidance

3

⚫Do not touch the blade、workpiece and chips when the machine is running.

⚫Do not check and/or repair the machine when the machine is running.

⚫Must fix the workpiece on the work platform tightly.

⚫Do not wear gloves when operating.

⚫Do not work in excess of the machine cutting conditions(Max.Torque.Max.Cutting

Resisance.Large Power).

⚫Prohibition of non-operator in the workplace.

⚫Do not move,install and measuring the workpiece if it is not in security state when the

machine stopped.

⚫Do not change the speed when the machine is running.

⚫Must to turn off the power switch when a sudden power failure,otherwise there are

dangers

when the machine running suddenly in which case the power supply suddenly again.

1.5 Maintenance

⚫Prohibition of disassembling and/or assembling on the impact of machine performance and

safety.

⚫Non-professional can not carry out related maintenance.

⚫Maintenance should be carried out under power off,otherwise occur dangers.

⚫Please read the chapter of maintenance in the Instruction Manual.

3、Installation and Adjustment

4

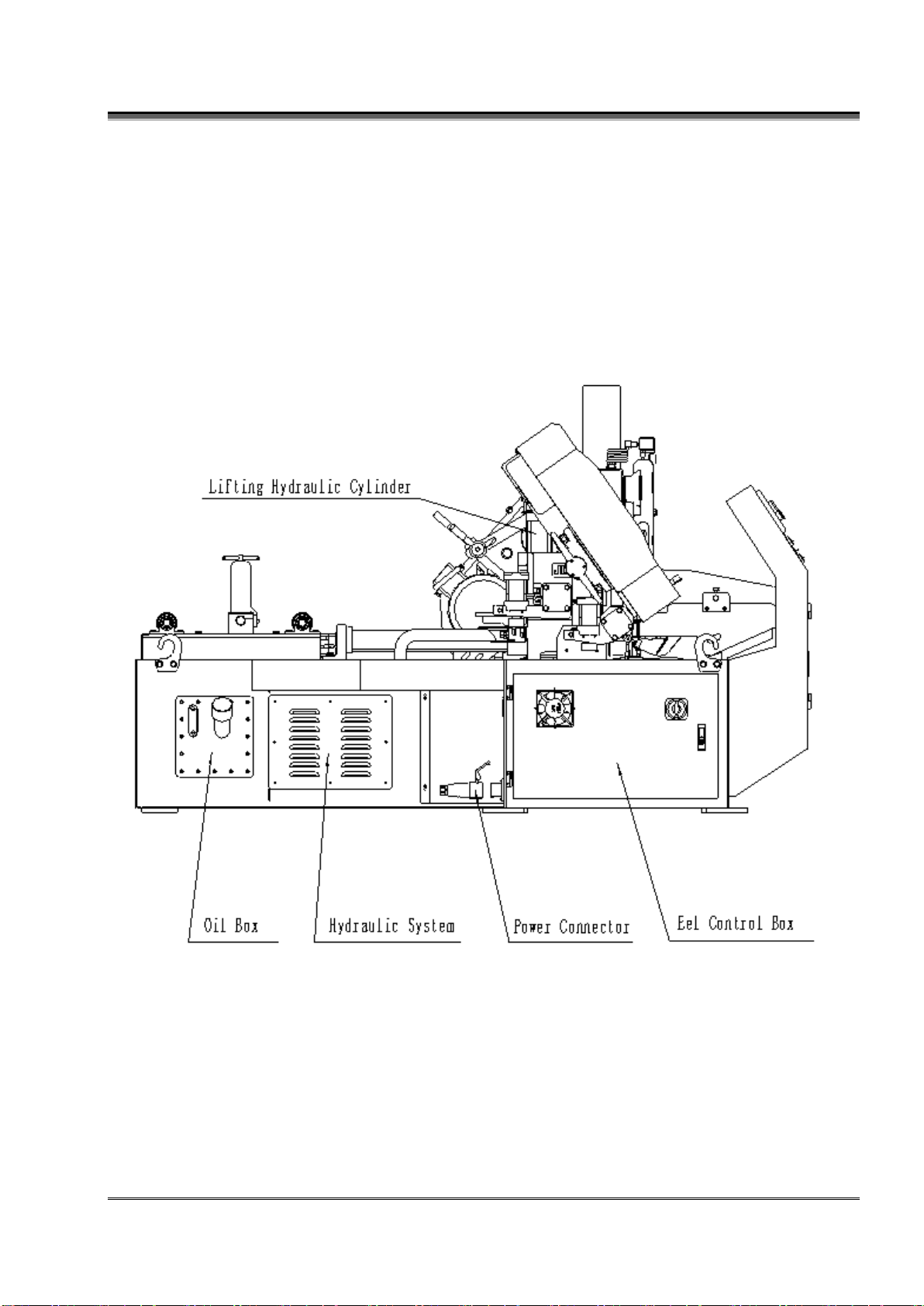

2.1 Front View

1Tungsten steel holder block

2Passive Wheel Cover

3Active Wheel Cover

4Fixed Guide Arm

5Guide Arm

6Belt Wheel Cover

7Activities Clamp

8Upper Clamp

3、Installation and Adjustment

5

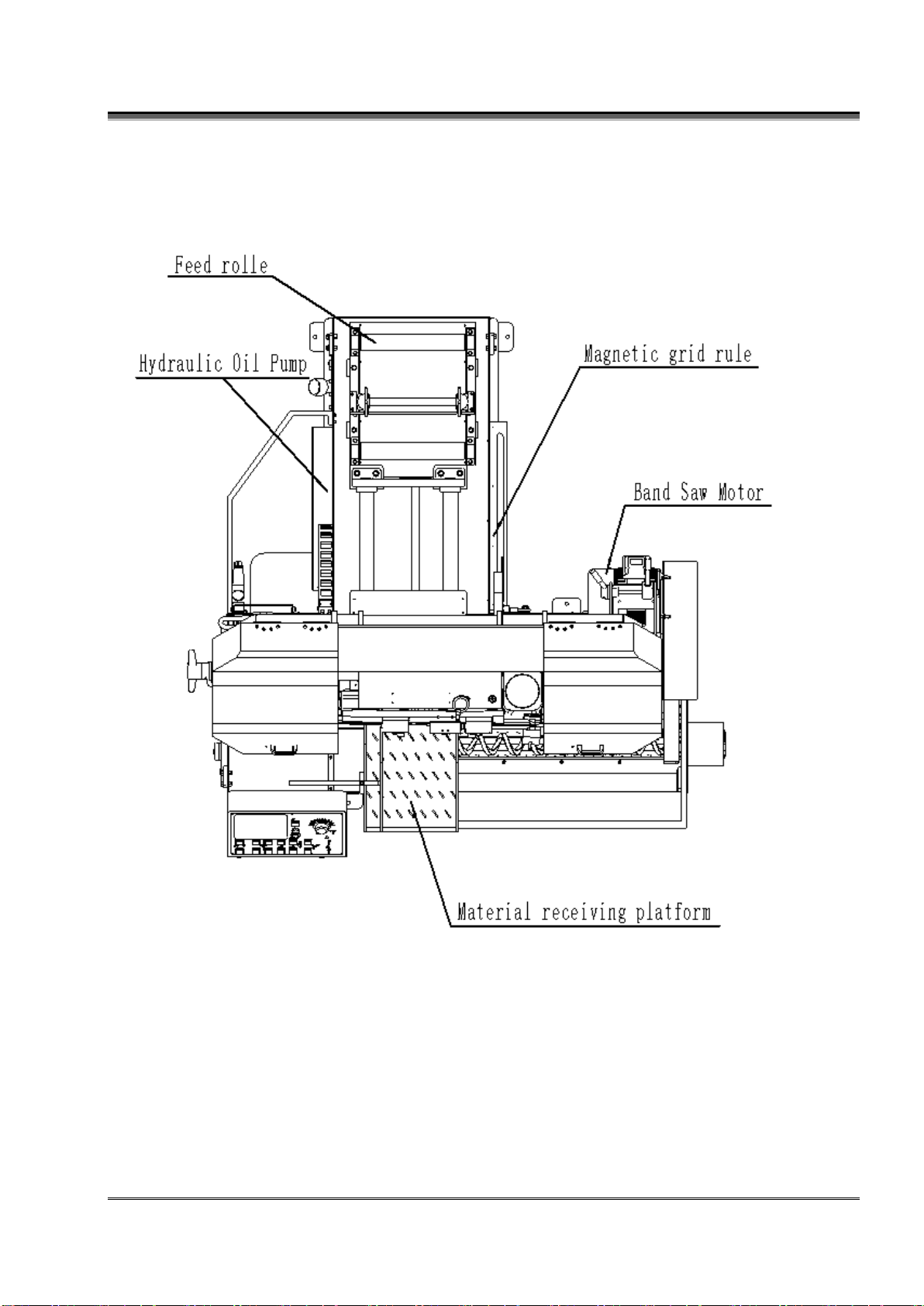

2.2 Left View

3、Installation and Adjustment

6

2.3 Up View

3、Installation and Adjustment

7

2.4 Specification

Model

B33

Single Capacity(in/mm)

Φ13 ▆13(W)ⅹ13(H)

Φ330 ▆300(W)ⅹ300(H)

bundle cutting (in/mm)

13(W)ⅹ4-3/4(H)

300(W)ⅹ120(H)

Single material Header Length(in/mm)

140(10mm 时)

5-1/2(25/64in,10mm 时)

Band Saw Speed (ft/min)

(m/min)

20~140

65~460

One Sending Length(in/mm)

500

19-5/8

Repeat positioning accuracy(mm)

±0.1

Band Saw Size(in/mm)

162(L)ⅹ1-1/2(W)ⅹ0.0042(T)

4115(L)ⅹ34(W)ⅹ1.1(T)

Band Saw Tension

hydraulic

(hp/kw)

Motor

Band Saw Motor

5/4

Hydraulic Motor

1/0.75

Cooling Motor

0.16/0.12

Tank Capacity

Hydraulic Oil(L)

72

Cutting liquid(L)

120

Weight(LB/KG)

3520

2.5Pressure Set and Data

Model

Pressure Category

B33

Pressure of Hydraulic(bar)

38±2

Band Saw Tension(100bar)

22±2

3、Installation and Adjustment

8

5T

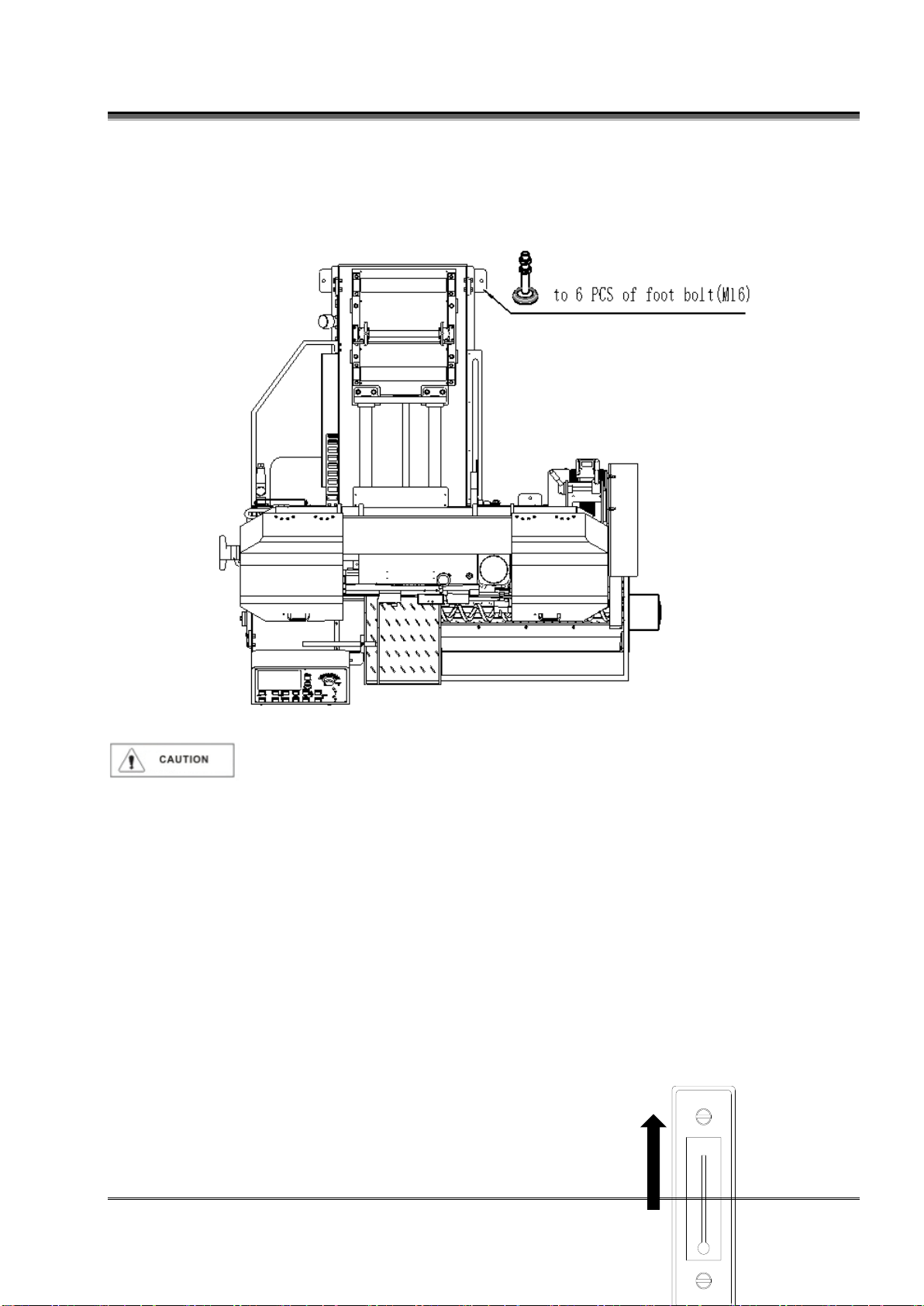

3.1 Transit and Lifting

3.1.1 Forklift handling

2000KG

1600G

3.1.2 Lifting

2000KG

⚫Sling must can bear twice weight of machine.Must focus lifting balance and around safe.

⚫Place the soft cushion between the machine and sling to protecting damage paint of

machine.

3、Installation and Adjustment

9

3.2 Cleaning

Paint anti-rust oil on the surface of the machine,must clean it with kerosene or other

Cleaning agent after placing the machine.

⚫No use gasoline or other corrosive cleaning agent to cleaning the machine,to preventing

fire.

3.3 Placing

There should be enough space to move workpiece.

;

When doing maintenance, make sure all the protection gate and/or the distributor will not

intervene when opened.

Fixer of machine to protect the saw frame and to facilitate the transport,so please

keep it carefully or use of moving machine.

3、Installation and Adjustment

10

3.4 Horizontal Adjustment

Adjust the level with the spirit level along the guide of work table according to the

Instruction manual after placing the machine,and then fix the foot bolt.

⚫When vertical movement of the spirit level,the permissible error must less than

0.1/1000.

⚫When lateral movement of the spirit level,the permissible error must less than

0.1/1000.

⚫It is very important for cutting precision to adjusting level of the machine.

⚫Please select and use the spirit level which the precision is 0.02mm/m.

3.5 Hydraulic Oil

Check the indicator of hydraulic oil as shown in figure.

3、Installation and Adjustment

11

OK

too little

3.6 Coolant Water

Has emptied the coolant water before leave factory,so please add

The coolant water and saponification liquid before using the machine.

⚫Need to cleaning the machine the end of daily work and/or no use for a long time to

protecting rusty the machine.

⚫It is possible to damage the water pump that the pump work without cooling water.

⚫In the winter,it is necessary to add warm water to thaw out frozen cooling water.

3、Installation and Adjustment

12

3.7 Power

60Hz 230V or 60Hz 460V 3P

⚫Electrical operation must complete by professional electrician.

⚫Power off all of relay.

⚫Wire must be fitted in with standard voltage parameters.

Trail running of machine

To rotate right and pull the power switch,the green indicator light means power on.

The saw frame will lift when to press the saw frame up button,otherwise it indicate

The wrong of power connection,please re-connecting power as follower.

①turn off the power switch

②power off all of relay

③transpose the power phase

④trail running of machine again

4、Instruction Manual

13

4.1 Operation Panel

1 2 3 4

`

5 6 7 9 14 13 16 17 18

8 10 12 11 15 19

symbol

Description

Function

1

HMI

machine control\data setting\condition

monitor,details refer to instruction

2

emergency button

press to emergency stop machine,loosen to reset

3

power indicator

light on indicate power on

4、Instruction Manual

14

4

feeding adjust valve

Turn left or right to adjust the feeding

speed,speed higher when value higher.

5

oil pump on-off

button

Press this button to start pump when pump is off,

press this button to stop pump when pump is on.

6

auto/manual transfer

switch

Turn right to manual work mode, turn left to auto

work mode.

7

Work start button

Press it saw wheel will work and work feeding when

in”manual mode”.press it machine will go

circulation work if has be back to original when in

“auto”mode.

8

Work stop button

Press it machine saw wheel will stop machine stop

work feeding when in “manual mode”, press it

machine will auto pause when in”auto mode”

9

saw frame up button

Press it saw wheel will stop working and frame rise

up when in “manual mode”, press it machine will go

back to original when in “auto mode”

10

saw frame down

button

Press it saw frame will go down rapidly, magnetic

valve on, loosen stop.

11

main vice clamp

button

Press this button, the magnetic valve on,keep

clamping.

12

main vice loosen

button

Press it main vice will loosen, magnetic valve on,

loosen stop.

13

material vice clamp

button

Press it material vice will clamp, magnetic valve

on, keep loosen.

14

material vice loosen

button

Press it material vice will loosen, magnetic valve

on, loosen stop.

15

feeding button

Press it roller will feeding material, magnetic

valve on, loosen stop.

16

material return button

Press it roller will return material, magnetic

valve on, loosen stop.

17

Feeding/return

material speed switch

行。Press it the light will on, buffer magnetic

valve off,feeding/return material switch to slow

running.

18

work light

Turn up to open, turn down to off.

19

water pump switch

Turn up to start water pump,turn down to switch off

water pump

4、Instruction Manual

15

4.2 Human-computer interface

4.2.1 Preface

This instruction is only about the human-computer interface operation instruction. Reading this manual should

be based on a certain understanding of the working principle, structure and related cutting process of the machine

tool, so before this should carefully read the random "machine tool manual", combined with the relevant chapters to

understand this description. This instruction has not done, please forgive more, if has not understood please

consult with the manufacturer service personnel .

4.2.2 开机画面 Boot screen

Boot into the manufacturer's promotional

screen, the lower left corner is the buttong

for English user. Click to enter the English

interface. In the lower right corner is the

button for Chinese users to enter the

Chinese interface.

4.2.3

4.2.3 Manual working screen

4、Instruction Manual

16

※To enable manual function, you must first switch the external button to manual shift, otherwise other buttons will

be invalid

The upper part of the screen is the functional area Shared by all interfaces. The following description is

applicable to the functional interface. It will not be repeated in the future.

Clock display: display time, date and other information. If there is any deviation from the local actual clock, the

clock information can be calibrated in the human-machine setting interface.

Current system status: it shows whether the current system is in manual mode 、auto mode、back original

mode, so that the operator can be clear at a glance.

Cutting mode:Display whether the current machining is constant speed cutting or variable

speed cutting.

Communication connection: it is used to indicate whether the communication connection between the human-

computer interface and the PLC is normal. The indicator light flashes when it is normal. Otherwise, the

communication connection line with PLC should be checked.

4、Instruction Manual

17

System status prompt bar: it indicates whether the current system is normal or abnormal.

Saw

blade linear speed: the machine tool is equipped with a saw wheel rotation induction device.

When the main machine is running, the system will detect the state of the high-speed signal

device.

For the operator to determine whether the speed of the saw blade meets the requirements

of the production cutting process.

Note: this function can only be used normally when the parameter "setting diameter of saw

wheel" is set in the "advanced parameters" interface.

Cutting speed:Display the current working speed value.

Current sawing force:Display the current sawing force.

Return position of material tongs:The machine is equipped a magnetic grid linear displacement

sensor,where the current position of the material table can be dynamically displayed in real time when the material

table moves back and forth.This function enables the operator to observe the dimension positioning of the material

rack at any time,and is conducive to the rapid troubleshooting of the feeding positioning fault of the machine.

This screen can complete the operation of machine all independent actions.

The work start is driven by motor, and other actions are all driven by hydraulic . Note that some actions has

their interlocks, limit protection and other functions, listed as follows:

1. Only when the main clamp solenoid valve works, "work start" can be self-locking operation, otherwise for inching

operation.

2.“work start", "main clamp clamping", "material clamp clamping", "rise" with self-locking function, other are inching.

4、Instruction Manual

18

3. "main clamp clamping t" and "main clamp loosen", "material clamp clamping" and "material clamp loosen", "fast down"

and "up", "feeding" and "return" are all interlocks.

4. When the work is started (cutting material), the "main clamp loosen" cannot be executed.

5. When the main clamp and the material clamp are both clamped, "feeding" and "returning"

cannot be executed.

6. When the saw frame reaches the lowest position, the lower limit switch action, the saw

frame will automatically turn into retractor.

7. When the frame reaches the upper limit switch position, the upper limit switch action, the

saw frame stops

Reset position: under manual mode, the

system allows the machine operator to manually reset the position of the current rack. Press "reset position" to

pop up the interface (as shown in the right picture), press "confirm" to reset, and press "close" to return.

Table of contents

Other Toolots Saw manuals