TOP DC FC 125 User manual

www.topacdc.com Amazon Store Facebook

MODEL: FC 125

MIG WELDER

OPERATOR'S MANUAL

CONTENTS

Please save these instructions. This manual contains important safety and operating

instructions. Read all instructions and follow them with each use of this product.

1-4

SPECIFICATIONS 4

4-5

OPERATING INSTRUCTIONS 5-7

…………...……………………………….…………….…………….

………...……………………………….……………….……………….

……...……………………………….………….……

MAINTENANCE AND SERVICE 7-9

…………………………….…………….…………….

9

TROUBLE SHOOTING .……………………………….……………….……………….

…………...……………………………….………….……

SAFETY INFORMATIONVITAL

1. General Safety Rules

2. Specific Safety Rules

SET-UPINITIAL

1. Work Piece And Work Area Setting Up

2. General Operating Instructions

1. Cleaning, Maintenance and Lubrication

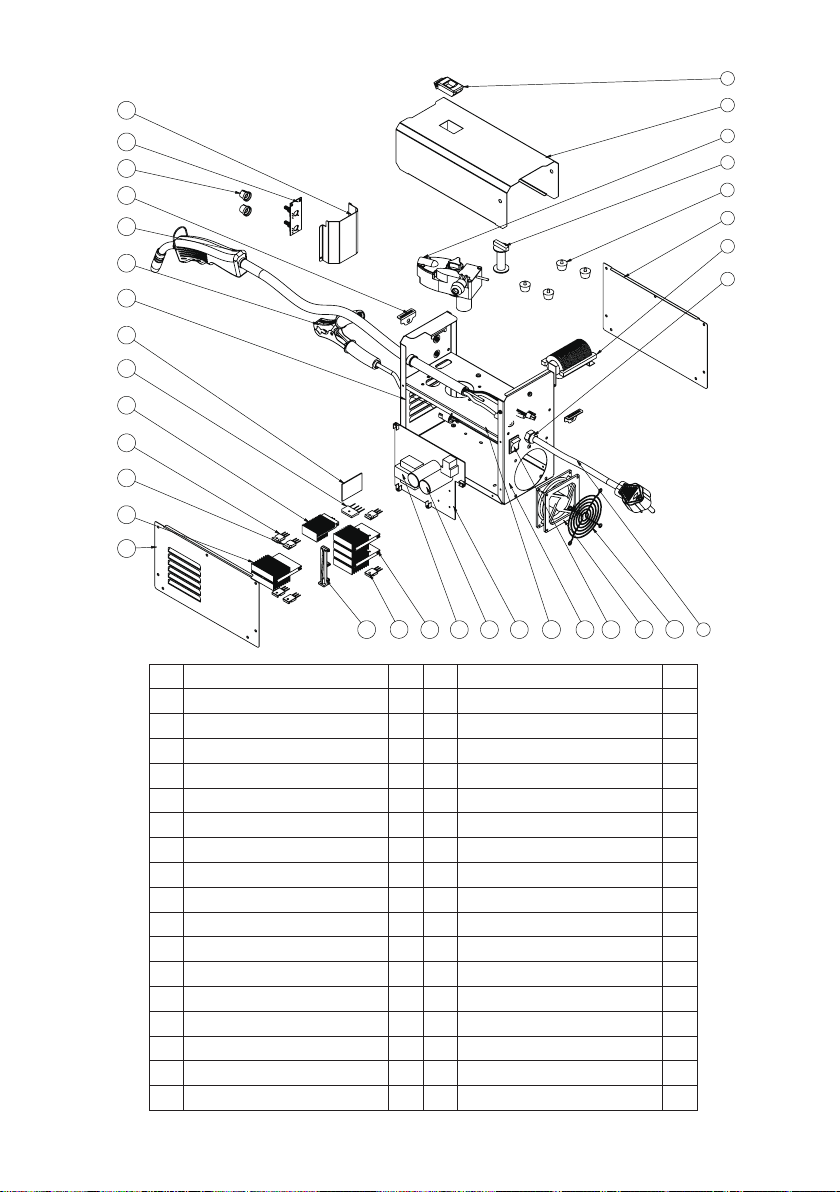

2. Parts List and Assembly Diagram

1

VITAL SAFETY INFORMATION

1. General Safety Rules

1) Work Area Safety

a. Take a suitable work area, must be clean and well bright. Cluttered or dark areas

could cause accidents.

b. Do not operate machines in explosive atmospheres, such as the presence of

flammable liquids, gases or dust. Welding sparks may ignite the dust or fumes.

c. Keep children and bystanders away while operating a machine. Distractions can

make you lose all the control.

2) Electrical Safety

a. Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

b. Do not expose machines to rain or wet conditions. Water entering a machine will

increase the risk of electric shock.

c. Do not abuse the Power Cord. Never use the Cord for pulling or unplugging the

machine. Keep Cord away from heat, oil, sharp edges or moving parts. Damaged or

entangled Cords increase the risk of electric shock.

d. When operating a machine outdoors, use an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

3) Personal Safety

a. Stay alert, watch what you are doing and use common sense when operating a

machine. Do not use a machine while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while operating machines may result in

serious personal injury.

b. Use safety equipment. Always wear eye protection. Safety equipment such as arc

shaded, impact safety full face shield, dust mask or respirator, heavy-duty work gloves,

non-skid safety shoes, or hearing protection used for appropriate conditions will reduce

personal injuries. Do not wear loose fitting things, like rings, scarves, etc., which is high

risk of being trapped or burnt.

c. Avoid accidental starting. Ensure the Power Switch is in the off-position before

plugging in. Plugging in machines that have the Switch on invites accidents.

d. Do not overreach. Keep proper footing and balance at all time. This enables better

control of the machine in unexpected situations.

4) Machine Use and Care

a. Use the correct machine for your application. The correct machine will do the job

better and safer at the rate for which it was designed.

b. Do not use the machine if the Power Switch does not turn it on and off. Any

machine that cannot be controlled with the Switch is dangerous and must be repaired.

c. Disconnect the Power Cord from the power source before making any adjustments,

changing accessories, or storing machines. Such preventive safety measures reduce

the risk of starting the machine accidentally.

d. Store idle machines out of the reach of children and do not allow persons unfamiliar

with the machine or these instructions to operate the machine. Machines are

dangerous in the hands of untrained users.

e. Maintain machines. Check for misalignment or binding of moving parts, breakage of

parts and any other condition that may affect the machine’s operation. If damaged,

have the machine repaired before use. Many accidents are caused by poorly

maintained machines.

2

f. Use the machine and accessories in accordance with these instructions and in the

manner intended for the particular type of machine, taking into account the working

conditions and the work to be performed. Use of the machine for operations different

from those intended could result in a hazardous situation.

5) Service

Have your machine serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the machine is maintained.

2. Specific Safety Rules

1) Maintain labels and nameplates on the Inverter Machine. These carry important

safety information.

2) Avoid electric shock. Do not permit electrically live parts, cables, or electrodes to

contact skin, clothing, or gloves. Wear protective clothing. This unit draws enough

current to cause serious injury or death. Do not use the Machine unless you are

insulated from the ground and the work piece.

3) Avoid body damage. Arc rays and infrared radiation can injure eyes and burn skin.

Wear eye and body protection. Do not allow viewing by visitors without proper eye

and body protection. Use a Face Shield with arc shaded filter plate.

4) Move flammable and explosive materail at least 10 meters from the welding arc to

prevent sparks or molten metal from starting a fire. Keep a type ABC fire

extinguisher within easy reach. Thoroughly clean the object being welded of any

paint, grease, or other foreign material.

5) Avoid unintentional starting. Prepare to begin work before turning on the Inverter

Machine.

6) Do not leave the Machine unattended when it is plugged into an electrical outlet.

Turn off the machine, and unplug it from its electrical outlet before leaving.

7) Use clamps or other practical ways to secure and support the work piece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to

loss of control.

8) This product is not a toy. Keep it out of reach of children.

9) People with pacemakers should consult their physician(s) before using.

Electromagnetic fields in close proximity to heart pacemaker could cause

pacemaker interference or pacemaker failure. In addition, people with pacemakers

should:

• Avoid operating alone.

• Do not use with Power Switch locked on.

• Properly maintain and inspect to avoid electrical shock.

• Any Power Cord must be properly grounded. Ground Fault Circuit Interrupter (GFCI)

should also be implemented – it prevents sustained electrical shock.

10) Prevent eye injury and burns. Wearing and using personal safet y clothing and safety

devices reduce the risk for injury.

• Wear safety impact eye goggles underneath welding eye protection featuring at least

a Number 10 shade lens rating.

• Leather leggings, fire resistant shoes or boots should be worn when using this

product. Do not wear pants with cuffs, shirts with open pockets, or any clothing that can

catch and hold molten metal or sparks.

• Keep clothing free of grease, oil, solvents, or any flammable substances. Wear dry,

insulating gloves and protective clothing.

• Wear an approved head covering to protect the head and neck. Use aprons,

cape, sleeves, shoulder covers, and bibs designed and approved for welding and

welding procedures.

• When welding overhead or in confined spaces, wear flame resistant ear plugs or ear

muffs to keep sparks out of ears.

11) Prevent accidental fires. Remove any combustible material from the work area.

•When possible, move the work to a location well away from combustible materials. If

relocation is not possible, protect the combustibles with a cover made of fire resistant

material.

• Remove or make safe all combustible materials for a radius of 10 meters around the

work area. Use a fire resistant material to cover or block all open doorways, windows,

cracks, and other openings.

• Enclose the work area with portable fire resistant screens. Protect combustible walls,

ceilings, floors, etc., from sparks and heat with fire resistant covers.

•If working on a metal wall, ceiling, etc., prevent ignition of combustibles on the other

side by moving the combustibles to a safe location. If relocation of combustibles is not

possible, designate someone to serve as a fire watch, equipped with a fire

extinguisher, during the welding process and for at least one half hour after the welding

is completed.

• Do not weld or cut on materials having a combustible coating or combustible internal

structure, as in walls or ceilings, without an approved method for eliminating the

hazard.

• Do not dispose of hot slag in containers holding combustible materials. Keep a fire

extinguisher nearby and know how to use it.

• After welding, make a thorough examination for evidence of fire. Be aware that

easily-visible smoke or flame may not be present for some time after the fire has

started. Do not weld or cut in atmospheres containing dangerously reactive or

flammable gases, vapors, liquids, and dust. Provide adequate ventilation in work areas

to prevent accumulation of flammable gases, vapors, and dust. Do not apply heat to a

container that has held an unknown substance or a combustible material whose

contents, when heated, can produce flammable or explosive vapors. Clean and purge

containers before applying heat. Vent closed containers, including castings, before

preheating, or welding.

12) Do not touch live electrical parts. Wear dry, insulating gloves. Do not touch

electrode or conductor tong with bare hand. Do not wear wet or damaged gloves.

13) Protect yourself from electric shock. Do not use outdoors. Insulate yourself from the

work piece and ground. Use nonflammable, dry insulating material if possible, or

use dry rubber mats, dry wood or plywood, or other dry insulating material big

enough to cover your full area of contact with the work or ground.

14) Ensure that the unit is placed on a stable location before use. If this unit falls while

plugged in, severe injury, electric shock, or fire may result.

15) Never remove the grounding prong or modify the Power Cord Plug in any way. Do

not use adapter plugs with this product.

3

16) Avoid overexposure to fumes and gases. Always keep your head out of the fumes.

Do not breathe the fumes. Use enough ventilation or exhaust, or both, to keep

fumes and gases from your breathing zone and general area.

17) Live torch when Trigger is pressed. Keep Torch away from people and flammables

before touching Trigger.

18) Turn off, unplug, and discharge electrode to ground before perform-ing any

inspection, maintenance, or cleaning.

19) Use only compressed air at between 0.4 and 0.5 MPA. Never use oxygen, carbon

dioxide, combustible gases or any bottled gas as an air source for the Machine.

Such gases are capable of explosion and serious injury to people.

20) The warnings, precautions, and instructions discussed in this instruction manual

cannot cover all possible conditions and situations that may occur. It must be

understood by the operator that common sense and caution are factors which

cannot be built into this product, but must be supplied by the operator.

SPECIFICATIONS

INITIAL SETTING UP INSTRUCTION

4

Input Voltage 120VAC / 60HZ

Current Input 23.5A

Output Range 30-125A

Rated Duty Cycle 30%@90A

Maximum OCV 45.5 V

Wire Speed 0-120 IPM

Welding Wire Capacity 0.030/ 0.035” Flux Cored

Wire Spool Capacity 2 LB Spool

Read the entire Important Safety Information section at the beginning of this manual

including all text under subheadings therein before set up or use of this product.

To prevent serious injury from accidental operation:

Turn the Power Switch of the machine to its “OFF” position and unplug it from its electrical

outlet before assembling or making any adjustments to the machine.

Note: For additional information regarding the parts listed in the following pages,

refer to the Assembly Diagram near the end of this manual.

1. Assembly

1) Unpack and make sure all the items in good condition. When you receive the

parcel, check it carefully from the packing list to make sure no damage due to

shipping. If there is any damage happened, inform the carrier immediately to

claim before installing. Complete the information and damage details in the

order’s returns and refund of the Amazon order in that case. Care the safety to

avoid damaging the machine when using bars, hammers, etc.

OPERATING INSTRUCTIONS

2) Make sure the machine is transported securely. If the machine must be moved,

always disconnect the power cable from the electrical outlet. And do not touch

live electrical parts.

CONTROLS & INDICATORS

Power indicator

Voltage knob

Wire speed knob

Overload Indicator

1. Power Indicator turns on when Power Switch is ON.

2. Overload Indicator turns on when the machine working time exceeds rated duty cycle.

3. Voltage Knob and Scale: Turn the knob to adjust output voltage.

4. Wire Feed Speed Knob and Scale: Turn the knob to adjust wire feed speed.

5

Read the entire Important Safety Information section at the beginning of this manual

including all text under subheadings therein before set up or use of this product.

To prevent serious injury from accidental operation:

Turn the Power Switch to “OFF” or “0” position before performing any inspection,

maintenance, or cleaning procedures.

1 Work Piece and Work Area Setting Up

Prevent eye injury and burns. Wearing personal protective

equipment to reduce the risk of injury.

1) Designate a work area that is clean and well-lit. The work area must not allow

access by children or pets to prevent injury and distraction.

2) Route the Power Cord along a safe route to reach the work area without creating a

tripping hazard or exposing the Power Cord to possible damage. The Power Cord must

reach the work area with enough extra length to allow free movement while working.

3) There must not be hazardous objects, such as utility lines or foreign objects, nearby

that will present a hazard while working.

4) A barrier, such as a welding curtain or welding shroud should be put up to protect

others in the work area and limit the spray of sparks.

6

2 General Operating Instructions

Protective gear must be worn when using the machine.

Arc shaded, eye protection, a full face shield, heavy-duty work gloves, a welding

apron, respirator, and heavy -duty work clothes without pockets should be worn

when using this product. Do not look at the ignited arc without eye protection.

Light from the arc can cause permanent damage to the eyes. Light from the arc

can burn the skin. Do not breathe arc fumes.

1) BEFORE EACH USE, inspect the general condition of the Machine. Check for

•loose hardware,

•damaged cord/electrical wiring,

•cooling fan operation,

•cracked or broken parts

•any other condition that may affect the safe operation.

IMPORTANT: The duty cycle defines the number of minutes, within a 10 minute period,

during which a given Machine can safely produce a particular current.

• This Machine is equipped with an internal thermal protection system to help prevent

damage to the unit. When the unit overheats; it automatically shuts down, then returns

to service when it cools down.

2) Clean the weld surfaces thoroughly with a wire brush or angle grinder; there must

be no rust, paint, oil, or other materials on the weld surfaces, only bare metal.

3) Use clamps (not included) to hold the workpieces in position so that you can

concentrate on proper welding technique. The distance (if any) between the two

workpieces must be controlled properly to allow the weld to hold both sides securely

while allowing the weld to penetrate fully into the joint. The edges of thicker

workpieces may need to be chamfered (or beveled) to allow proper weld

penetration.

4) Clamp Ground Cable to bare metal on the workpiece near the weld area, or to metal

work bench where the workpiece is clamped.

5) Turn the Power Switch to the OFF position, then plug the Power Cord into a

properly grounded, GFCI protected 120 VAC receptacle that matches the plug.

6) Turn on the machine.

7) Settings - Refer to Setting chart attached on the machine.

8) Trigger the torch and start to weld. The end of the MIG Gun should be tilted so that

wire is angled anywhere in-between straight on and 15° in the direction you are

welding.

WARNING! TO PREVENT SERIOUS INJURY, point torch away from your body

when triggering the torch.

Note: If the Machine working time reaches to the maximum working time according to

the duty cycle, the thermal protector will activate and the “Overload Indicator” will

illuminate. The Machine will automatically shut down until it cools, then you may resume

welding again.

9) When welding is complete, set the MIG Gun down on a heat-proof, electrically

nonconductive surface.

10) A weld from flux-cored wire will be covered by slag. Use a chipping hammer to

knock this off. Be careful not to damage the weld or base material.

11) Turn the Power Switch OFF after fan stops rotating. Allow Welder to cool down,

then unplug the Power Cord.

12) Remove Ground Clamp from workpiece or table.

13) Respool wire by clipping wire, removing gas nozzle/contact tip on MIG gun,

releasing Idler Arm on Wire Feed mechanism, and rotating the Wire Spool

counterclockwise. Be sure to securely hold wire as it is being respooled because the

end of wire has a tendency to quickly unravel once it clears the wire feeder.

14) Clean the machine and then store the unit indoors out of children’s reach.

MAINTENANCE AND SERVICE

Procedures not specifically explained in this manual must be performed only

by a qualified technician.

To prevent serious injury from accidental operation:

Turn the Power Switch of the Machine to its “OFF” position and unplug the machine

from its electrical outlet before performing any inspection, maintenance, or cleaning

procedures.

To prevent serious injury from machine failure

Do not use damaged equipment. If abnormal noise or vibration occurs, have the

problem corrected before further use.

1 Cleaning, Maintenance, and Lubrication

1) BEFORE EACH USE, inspect the general condition of the Machine. Check for

loose screws, cracked or broken parts, damaged electrical wiring, and any other

condition that may affect its safe operation.

2) After Use, clean external surfaces of the machine with clean cloth.

3) Periodically, using compressed air, blow out all dust and debris from the interior.

4) If the unit repeatedly shuts down from thermal overload, stop all use.

Have the Machine inspected and repaired by a qualified service technician.

5) Store the Machine and accessories in a clean and dry location out of reach of

children.

WARNING! If any part of this Machine is damaged, it must be replaced only

by a qualified service technician.

A Parts list and assembly diagram are provided as following just for

reference. Contact the distributer or the seller to get the spare parts for

maintenance and have the damaged parts be replaced by a qualified

technician only.

7

Parts List and Assembly Diagram

1 Lock catch 1

NO. Part Name QTY

2 Top Cover 1

3 Wire feeder 1

4 Axis 1

5 Foot pad 4

6 Left cover 1

7 Output choke 1

8 Line card 1

9 Power cable 1

10 Fan cover 1

11 DC fan 1

12 Switch 1

13 Bottom cover 1

14 Bracket 1

15 Main PCB 1

NO. Part Name QTY

16 Capacitance 2

17 Transformer 1

31 Braces ring 2

32 Knob 2

33 Panel PCB 1

34 Panel shield 1

18 IGBT heat sink 2

19 IGBT 2

20 Support 1

21 Right cover 1

22 Rectifier heat sink 1

23 Fast recovery diode 3

24 Triode 1

25 Rectifiers heat sink 1

26 Bridge rectifiers 1

27 Control PCB 1

28 Front panel 1

29 Ground clamp assembly 1

30 Welding torch 1

8

1

2

4

6

7

3

8

9

11 10

32

33

30

29

31

27

26

24

25

23

22

21

20 18

19 151617 12

34

1314

28

5

Service

Thank you for purchasing our mig welder. Your purchase includes our free 1-year

limited warranty. If you have any questions or issues about your product, Welcome to

contact us at

topacdc01@gmail.com

Please have your order number available when asking for support.

TROUBLE SHOOTING

Be certain to shut off the welder, disconnect if from power, and discharge the flux gun to

ground before adjusting, cleaning, or repairing the unit

Possible Cause Likely Solutions

When switched

on, power indicator

lights but welder

does not function

1) Tripped thermal protection

device

2) Faulty or improperly

connected trigger.

3) Machine is in low- or over -

voltage protection

1) If the alarm indicator is illuminated without an error

code, welder has overheated and shut down. Stop

and wait with the power switch ON for the welder to

cool. Reduce duty cycle to help reduce wear on the

welder.

2) Ensure the gun connection is properly seated on the

machine.

3) If the alarm light is illuminated, check input voltage

and ensure it falls within the specified range. If input

voltage is correct, turn the welder off and back on.

Power ON indicator

does not light when

switched on

1) Unit is not connected to outlet

properly

2) Outlet is unpowered

3) Circuit supplies insufficient

input voltage or amperage

4) Plug does not have correct

rating.

5) Input power cord is not seated

properly

1) Verify the voltage at the outlet and the connection to

the outlet.

2) Check circuit breaker, if any is tripped, determine and

remedy cause before resetting.

3) Verify that the circuit is designed to supply the

required input voltage and amperage as detailed.

4) Make sure installed plug is correct rating.

5) Ensure the input power cord is fully secured.

Wire feeds,

but arc does

not ignite

1) Improper ground connection

2) Improperly sized contact tip

3) Excessively worn contact tip

4) Dirty contact tip.

1) Make sure that the workpiece is contacted properly by

the ground clamp and that the workpiece is properly

cleaned near the ground clamp and the welding

location.

2) Verify that contact tip is the proper size of the welding

wire. If needed, replace contact tip with proper size

and type.

3) Check that the hole in the tip is not deformed or

enlarged. If needed, replace contact tip with proper

size and type

4) Properly clean contact tip.

Porosity in

the weld metal

1) Dirty workpiece

2) Gun is being used too far

away from workpiece

3) Dirty welding wire is

introducing contamination

into the weld

1) Clean workpiece down to bare metal.

2) Check contact tip to work distance for the proper

procedure.

3) Make sure that welding wire is clean and free of rust

and residues.

Problem

9

Table of contents