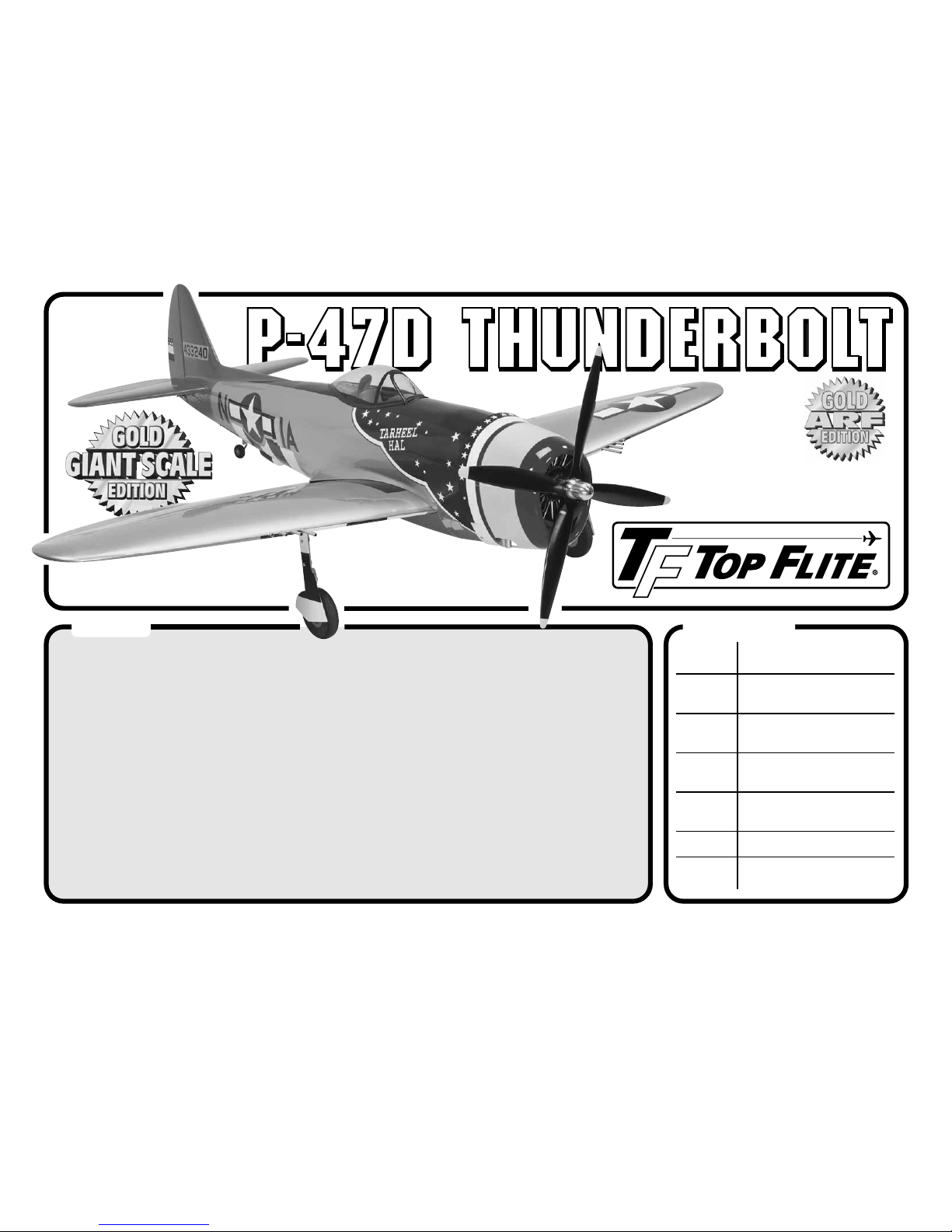

Top Flight Models P-47D Thunderbold User manual

READ THROUGH THIS MANUAL BEFORE STARTING CONSTRUCTION. IT CONTAINS IMPORTANT INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

Entire Contents © Copyright 2009 TOPA0703 MnlV1.0

WARRANTY

Top Flite Models guarantees this kit to be free from defects in both material and workmanship at the date of

purchase.This warranty does not cover any component parts damaged by use or modification. In no case

shall Top Flite’s liability exceed the original cost of the purchased kit. Further, Top Flite reserves the

right to change or modify this warranty without notice.

In that Top Flite has no control over the final assembly or material used for final assembly, no liability shall be

assumed nor accepted for any damage resulting from the use by the user of the final user-assembled prod-

uct. By the act of using the user-assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, the buyer is

advised to return this kit immediately in new and unused condition to the place of purchase.

To make a warranty claim send the

defective part or item to Hobby

Services at this address:

Include a letter stating your name, return shipping address, as much contact information as possible (daytime

telephone number, fax number, e-mail address), a detailed description of the problem and a photocopy of the

purchase receipt. Upon receipt of the package the problem will be evaluated as quickly as possible.

Hobby Services

3002 N. Apollo Dr.Suite 1

Champaign IL 61822 USA

SPECIFICATIONS

™

Wingspan

:85 in

[2160mm]

Wing

Area: 1329 sq in

[85.7 dm2]

Weight: 19.5 – 21.5 lb

[8842–9749 g]

Wing

Loading: 34–37 oz/sq ft

[104–113 g/dm2]

Length: 75 in

[1905mm]

Radio: 5-7 channel

Engine: 2.6–4.0 cu in

[43–65cc] spark ignition gas

Top Flite Models Champaign, IL

Telephone (217) 398-8970, Ext. 5

2

INTRODUCTION

The P-47D has been recognized as an excellent

modeling subject. The large wing and tail area and

long tail moment make an ideal flying airplane –

especially for a warbird! The Top Flite Giant P-47

Kit is a very successful model. Now, Top Flite has

developed the Giant P-47D ARF following the same

design as the kit.The Giant P-47D ARF will get you in

the air quickly with a great looking model, without the

sanding and covering required to build a kit.

Forthelatesttechnicalupdates or manualcorrections

to the Giant P-47D ARF visit the Top Flite web site

at www.top-flite.com. Open the “Airplanes” link, then

select the Giant P-47D ARF.If there is new technical

information or changes to this model a “tech notice”

box will appear in the upper left corner of the page.

AMA

If you are not already a member of the AMA, please

join! The AMA is the governing body of model

aviation and membership provides liability insurance

coverage, protects modelers’rights and interests and

is required to fly at most R/C sites.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Ph. (800) 435-9262 Or via the Internet at:

Fax (765) 741-0057 http://www.modelaircraft.org

IMPORTANT!!! Two of the most important things

you can do to preserve the radio controlled aircraft

hobby are to avoid flying near full-scale aircraft and

avoid flying near or over groups of people.

IMAA

The Top Flite Giant P-47D ARF is an excellent sport-

scale model and is eligible to fly in IMAA events.The

IMAA (International Miniature Aircraft Association) is

an organization that promotes non-competitive flying

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . 2

AMA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

IMAA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SCALE COMPETITION . . . . . . . . . . . . . . . . . . . . 3

SAFETY PRECAUTIONS. . . . . . . . . . . . . . . . . . . 3

DECISIONSYOU MUST MAKE. . . . . . . . . . . . . . 3

Engine Recommendations. . . . . . . . . . . . . . . 3

Radio Equipment . . . . . . . . . . . . . . . . . . . . . . 4

Retractable Landing Gear . . . . . . . . . . . . . . . 4

ADDITIONAL ITEMS REQUIRED . . . . . . . . . . . . 5

Required Hardware and Accessories . . . . . . 5

Adhesives and Building Supplies. . . . . . . . . . 5

Optional Supplies and Tools. . . . . . . . . . . . . . 5

IMPORTANT BUILDING NOTES . . . . . . . . . . . . . 5

KIT INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . 6

ORDERING REPLACEMENT PARTS . . . . . . . . . 6

COMMON ABBREVIATIONS. . . . . . . . . . . . . . . . 6

KIT CONTENTS. . . . . . . . . . . . . . . . . . . . . . . . . . 7

ASSEMBLE THE WINGS. . . . . . . . . . . . . . . . . . . 7

Hinge the Ailerons . . . . . . . . . . . . . . . . . . . . . 7

Mount the Aileron Servos. . . . . . . . . . . . . . . . 8

Mount the Retracts. . . . . . . . . . . . . . . . . . . . . 9

Install the Flap Servos . . . . . . . . . . . . . . . . . 11

Install the Aileron and Flap Pushrods . . . . . 11

Join the Wing . . . . . . . . . . . . . . . . . . . . . . . . 12

INSTALL THE FIXED MAIN LANDING GEAR . . 13

ASSEMBLE THE FUSELAGE . . . . . . . . . . . . . . 14

Install the Stabilizer . . . . . . . . . . . . . . . . . . . 14

Mount the FixedTail Gear . . . . . . . . . . . . . . 16

Mount the RetractableTail Gear. . . . . . . . . . 16

Install the Elevator and Rudder Servos . . . . 18

INSTALL THE ENGINE. . . . . . . . . . . . . . . . . . . . 19

ASSEMBLE AND INSTALL THE FUELTANK . . 21

INSTALL THE AIR RETRACT CONTROLS . . . . 22

INSTALL THE COWL . . . . . . . . . . . . . . . . . . . . . 23

APPLYTHE FINAL DETAILS . . . . . . . . . . . . . . . 26

FINISH THE WING. . . . . . . . . . . . . . . . . . . . . . . 28

Apply the Decals . . . . . . . . . . . . . . . . . . . . . 29

GET THE MODEL READY TO FLY . . . . . . . . . . 30

Install the Propeller . . . . . . . . . . . . . . . . . . . 30

Balance the Model Laterally. . . . . . . . . . . . . 30

Check the Control Directions. . . . . . . . . . . . 30

Set the Control Throws. . . . . . . . . . . . . . . . . 30

Balance the Model (C.G.). . . . . . . . . . . . . . . 31

CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

PREFLIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

IdentifyYour Model. . . . . . . . . . . . . . . . . . . . 33

Charge the Batteries . . . . . . . . . . . . . . . . . . 33

Ground Check and Range Check . . . . . . . . 33

ENGINE SAFETY PRECAUTIONS . . . . . . . . . . 33

AMA SAFETY CODE . . . . . . . . . . . . . . . . . . . . . 33

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Radio Control. . . . . . . . . . . . . . . . . . . . . . . . 34

IMAA SAFETY CODE . . . . . . . . . . . . . . . . . . . . 34

FLYING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Fuel Mixture Adjustments . . . . . . . . . . . . . . 35

Takeoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Flight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Landing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

GEAR DOOR DRILL GUIDE . . . . . . . . . . . . . . . 36

TABLE OF CONTENTS

2

l

e

T

a

il

G

ea

r

..........

16

n

d Rudder

S

ervo

s

. . . .

18

3

of giant-scale models. If you plan to attend an IMAA

event, obtain a copy of the IMAA Safety Code by

contacting the IMAA at the address or telephone

number below.

IMAA

205 S.Hilldale Road

Salina, KS 67401

Ph. (913) 823-5569Or via the Internet at:

www.fly-imaa.org/

imaa/sanction.html

SCALE COMPETITION

Though the Top Flite Giant P-47D is an ARF and

may not have the same level of detail as an “all-out”

scratch-built competition model, it is a scale model

nonetheless and is therefore eligible to compete in

the Fun Scale class in AMA competition (we receive

many favorable reports of Top Flite ARFs in scale

competition!).In Fun Scale, the“builder of the model”

rule does not apply.To receive the five points for scale

documentation, the only proof required that a full size

aircraft of this type in this paint/markings scheme

did exist is a single sheet such as a kit box cover

from a plastic model, a photo, or a profile painting,

etc. If the photo is in black and white, other written

documentation of color must be provided. Contact

the AMA for a rule book with full details.

If you would like photos of the full-size Tarheel Hal

P-47D for scale documentation, or if you would like

to study the photos to add more scale details, photo

packs are available from:

Bob’s Aircraft Documentation

3114Yukon Ave

Costa Mesa, CA 92626

Ph: (714) 979-8058 Or via the Internet at:

Fax: (714) 979-7279www.bobsairdoc.com

PROTECTYOUR MODEL,

YOURSELF & OTHERS…

FOLLOWTHESE IMPORTANT

SAFETY PRECAUTIONS

1. Your Giant P-47D ARF should not be considered

a toy, but rather a sophisticated, working model that

functions very much like a full-size airplane.Because

of its performance capabilities, the Giant P-47D

ARF, if not assembled and operated correctly, could

possibly cause injury to yourself or spectators and

damage to property.

2. You must assemble the model according to the

instructions. Do not alter or modify the model, as

doing so may result in an unsafe or unflyable model.

In a few cases the instructions may differ slightly from

the photos.In those instances the written instructions

should be considered as correct.

3. You must take time to build straight, true and

strong.

4. You must use an R/C radio system that is in

good condition, a correctly sized engine, and other

components as specified in this instruction manual.

All components must be correctly installed so that the

model operates correctly on the ground and in the air.

You must check the operation of the model and all

components before every flight.

5. If you are not an experienced pilot or have not

flown this type of model before, we recommend that

you get the assistance of an experienced pilot in your

R/C club for your first flights. If you’re not a member

of a club, your local hobby shop has information

about clubs in your area whose membership includes

experienced pilots.

6. While this kit has been flight tested to exceed

normal use, if the plane will be used for extremely

high stress flying, such as racing, or if an engine

larger than one in the recommended range is used,

themodelerisresponsiblefortakingstepstoreinforce

the high stress points and/or substituting hardware

more suitable for the increased stress.

7. WARNING: The cowl and landing gear covers

included in this kit are made of fiberglass, the fibers

of which may cause eye, skin and respiratory tract

irritation. Never blow into a part to remove fiberglass

dust, as the dust will blow back into your eyes.Always

wear safety goggles, a particle mask and rubber

gloves when grinding, drilling and sanding fiberglass

parts.Vacuum the parts andthe work areathoroughly

after working with fiberglass parts.

We, as the kit manufacturer, provide you with a top

quality, thoroughly tested kit and instructions, but

ultimately the quality and flyability of your finished

model depends on how you build it; therefore, we

cannot in any way guarantee the performance of

your completed model, and no representations

are expressed or implied as to the performance or

safety of your completed model.

REMEMBER: Take your time and follow the

instructions to end up with a well-built model that is

straight and true.

DECISIONSYOU MUST MAKE

This is a partial list of items required to finish the

Giant P-47D ARF that may require planning or

decision making before starting to build. Order

numbers are provided in parentheses.

ENGINE RECOMMENDATIONS

When considering engines for this model, refer to

the engine size recommendations on the cover of

the manual. Spark-ignition “gas” engines are most

popular with large-scale warbirds such as this. One

advantageofagasengineiseconomy– gasengines

tend to consume less fuel than a glow engine as

well. Additionally, gas engines deposit little exhaust

residue on the model. Among other engines, this

model was test flown with a Fuji-Imvac BT-43EI-2

engine. The Fuji-Imvac BT-43EI-2 provides more

than adequate power and flies the Giant P-47D ARF

in a scale-like manner.

4

NOTE: Instructions for mounting every possible

engine cannot be incorporated into this manual.

Modelers using another engine may refer to the

instructions as a guide for mounting their engine in a

similar way. If using the BT-43EI-2 engine an optional

muffler is recommended.

❏Bisson Inverted Muffler (BISG6543)

Per the IMAA Safety Code, magneto spark-ignition

engines must have a coil-grounding switch on the

aircraft to stop the engine and prevent accidental

starting, The switch must be operated manually

(without the use of the transmitter) and accessible by

thepilotandassistant.Ifusingaspark-ignitionengine,

refer to Install the Cowl on page 25 for details.

RADIO EQUIPMENT

Theradioequipmentandnumberofchannelsrequired

to fly the Top Flite Giant P-47D ARF depends on the

capabilities of your transmitter and how the servos

will be connected.

The Giant P-47D ARF requires a servo to operate the

air control valve if using retracts, a throttle servo, two

flap servos, two aileron servos, two elevator servos

and a rudder servo. Servos with a minimum of 50 oz-

in [3.9kg-cm] of torque are required for operating the

elevators, rudder, ailerons and flaps.We recommend

that metal geared servos also be used. Standard

servos may be used for the throttle and choke (the

servo operated choke is optional). A micro servo is

required to operate the retract air valve. An optional

servo operated kill switch may also be used (this is

in addition to the IMAA-required, manually operated

engine kill switch.A servo operated kill switch is only

really necessary for engines that do not reliably shut

off by closing the carburetor, but could also serve as

a backup.

Function Type RequiredQty.

Elevators 2 Futaba

S3305 (FUTM0045)

min. 50 oz-in torque

Rudder 1 Futaba

S3305 (FUTM0045)

min. 50 oz-in torque

Ailerons 2 Futaba

S3305 (FUTM0045)

min. 50 oz-in torque

Flaps 2 Futaba

S3305 (FUTM0045)

min. 50 oz-in torque

Tail

Steering 1Futaba

S3305 (FUTM0045)

min. 50 oz-in torque

Throttle 1 Futaba

S3004 (FUTM0027)

standard

Retract 1 Futaba

S3102 (FUTM0034)

micro

Optional

Choke Futaba

S3004 (FUTM0027)

standard

1

Total10–11

A receiver battery with a minimum of 1,000mAh is

recommended for flying the Giant P-47D ARF. The

battery voltage should be checked before every flight

to be certain it has enough “charge”.

In addition to the servos, the following items (or

similar items) are also required. The order numbers

shown in parentheses are for Futaba servos.

Items RequiredQty.

46"Y-harness for elevator, rudder/steering,

ailerons & flaps (FUTM4130)

46" Servo Extension for throttle, optional

choke, ailerons & flaps (HCAM2701)

312" [305mm] Servo Extension

for flaps & receiver switch (HCAM2711)

224" [610mm] Servo Extension

for ailerons (HCAM27021)

2Heavy Duty Switch Harness (FUTM4385)

1Ernst Charge Receptacle 124 (ERNM3001)

Note: The length and quantity of servo extensions

and Y-connectors may vary depending on the brand

of radio you are using and the radio installation.

RETRACTABLE LANDING GEAR

The Top Flite Giant P-47D ARF may be assembled

with either the included fixed landing gear or optional

retractable landing gear. If fixed landing gear is used

no other items will need to be purchased to install the

gear. If you wish to install retractable landing gear,

this model is designed for Robart pneumatic retracts.

Following is the complete list of items required to

install the Robart retracts:

Items RequiredQty.

1Robart #622P47

Top Flite Giant P-47

Pneumatic Retractable Main Landing Gear

(ROBQ1637)

1Robart #160LWC

RetractableTail Gear Assembly

(ROBQ2225)

1

Robart #157VRX

Large-Scale Deluxe Air Control Kit

– includes pressure tank, air line tubing,

variable-rate air valve, T-fittings

(ROBQ2305)

1Robart #169

10' [3048mm] Red & Purple Pressure Tubing

(ROBQ2369)

1

pkg. Robart #190

Air Line Quick Disconnects

(ROBQ2395)

Note: An air pump will also be required to pressurize

the air tank. The Robart hand pump could be used,

but is not practical because of the large capacity

of the air tank in this model. A small, 12V electric

pump is recommended and can be purchased at an

automotive or hardware store.

5

ADDITIONAL ITEMS REQUIRED

REQUIRED HARDWARE AND

ACCESSORIES

In addition to the items listed in the “Decisions You

Must Make” section, following is the list of hardware

and accessories required to finish the Top Flite

Giant P-47D ARF. Order numbers are provided in

parentheses.

❏(2) Dubro #813 1/8" Fuel Line Barb (DUBQ0670)

❏(1) Dubro #554 X-large Tygon Fuel Line

(DUBQ0427)

❏(1) R/C foam rubber (1/4" [6mm] (HCAQ1000) or

1/2" [13mm] (HCAQ1050)

❏Optional Black paint for the plywood radial

engine frame

❏Propeller and spare propellers suitable for your

engine.

❏Painted Pilot (GPMA2807)

ADHESIVES AND BUILDING SUPPLIES

This is the list of Adhesives and Building Supplies

that are required to finish the Giant P-47D ARF.

❏1/2 oz. [15g] Thin Pro™CA (GPMR6001)

❏1/2 oz. [15g] Medium Pro CA+ (GPMR6007)

❏Pro 30-minute epoxy (GPMR6047)

❏Pro 6-minute epoxy (GPMR6045)

❏Threadlocker thread locking cement

(GPMR6060)

❏Mixing sticks (50, GPMR8055)

❏Mixing cups (GPMR8056)

❏Epoxy brushes (6, GPMR8060)

❏Denatured alcohol (for epoxy clean up)

❏R/C-56 canopy glue (JOZR5007)

❏Milled fiberglass (GPMR6165)

❏Masking tape (TOPR8018)

❏Plan protector (GPMR6167) or wax paper

❏Drill bits: 1/16" [1.6mm], 5/64" [2mm], 3/32"

[2.4mm], 7/64" [2.8mm], 1/8" [3.2mm], 3/16"

[4.8mm], 1/4" [6.4mm]

❏Small metal file

❏Stick-on segmented lead weights (GPMQ4485)

❏Silver solder w/flux (STAR2000)

❏Hobby Heat™micro torch (HCAR0755)#1 Hobby

knife (HCAR0105)

❏#11 blades (5-pack, HCAR0211)

❏#11 blades (100-pack, HCAR0311)

❏Sanding tools and sandpaper assortment (see

Easy-Touch™Bar Sander section)

❏Curved-tip canopy scissors for trimming plastic

parts (HCAR0667)

Covering tools

❏Top Flite MonoKote®sealing iron (TOPR2100)

❏Top Flite Hot Sock™iron cover (TOPR2175)

❏Top Flite MonoKote trim seal iron (TOPR2200)

❏Top Flite MonoKote heat gun (TOPR2000)

OPTIONAL SUPPLIES ANDTOOLS

Hereisa list ofoptionaltoolsmentionedinthe manual

that will help you build the Giant P-47D ARF.

❏2 oz. [57g] spray CA activator (GPMR6035)

❏CA applicator tips (HCAR3780)

❏CA debonder (GPMR6039)

❏Builder’s Triangle Set (HCAR0480)

❏Scale Warbird Template (TOPQ2187)

❏36" metal ruler (HCAR0475)

❏Hobbico®High Precision Diagonal Cutter 5"

(HCAR0630)

❏Pliers with wire cutter (HCAR0625)

❏Robart Super Stand II (ROBP1402)

❏Switch & Charge Jack Mounting Set

(GPMM1000)

❏Panel Line Pen (TOPQ2510)

❏Rotary tool such as Dremel

❏Rotary tool reinforced cut-off wheel (GPMR8200)

❏Servo horn drill (HCAR0698)

❏AccuThrow™Deflection Gauge (GPMR2405)

❏CG Machine™ (GPMR2400)

❏Laser incidence meter (GPMR4020)

❏36" bar for incidence meter (GPMR4021)

❏Precision Magnetic Prop Balancer (TOPQ5700)

IMPORTANT BUILDING NOTES

●Anytime a sheet metal screw is installed in wood,

first install the screw, remove the screw and apply a

couple of drops of thin CA in the hole to harden the

threads.After the CA has cured, reinstall the screw.

●Photos and sketches are placed before the

step they refer to. Frequently you can study photos in

following steps to get another view of the same parts.

●The Giant P-47D ARF is factory-covered with Top

Flite MonoKote film. Should repairs ever be required,

MonoKote can be patched with additional MonoKote

purchased separately. MonoKote is packaged in six-

foot rolls, but some hobby shops also sell it by the

foot. If only a small piece of MonoKote is needed for

a minor patch, perhaps a fellow modeler would give

you some.MonoKote is applied with a model airplane

coveringiron,butinanemergencyaregularironcould

be used. A roll of MonoKote includes full instructions

for application. Following are the colors used on this

model and order numbers for six foot rolls.

Aluminum (TOPQ0205)

Orange (TOPQ0202)

White (TOPQ0204)

Black (TOPQ0208)

Sapphire Blue (TOPQ0226)

Missile Red (TOPQ0201)

6

●The stabilizer and wing incidences and engine

thrust angles have been factory-built into this

model. However, some technically-minded modelers

may wish to check these measurements anyway.

To view this information visit the web site at www.

greatplanes.com and click on “Technical Data.” Due

to manufacturing tolerances which will have little

or no effect on the way your model will fly, please

expect slight deviations between your model and the

published values.

KIT INSPECTION

Before starting to build, take an inventory of this kit

to make sure it is complete, and inspect the parts

to make sure they are of acceptable quality. If any

parts are missing or are not of acceptable quality, or if

you need assistance with assembly, contact Product

Support. When reporting defective or missing parts,

use the part names exactly as they are written in the

Kit Contents list.

Top Flite Product Support

3002 N Apollo Drive, Suite 1

Champaign, IL 61822

Ph: (217) 398-8970, ext. 5

Fax: (217) 398-7721

E-mail: airsupport@top-flite.com

ORDERING

REPLACEMENT PARTS

ReplacementpartsfortheTopFliteGiantP-47DARFare

availableusingtheordernumbersinthe Replacement

Parts List that follows. The fastest, most economical

service can be provided by your hobby dealer or mail-

order company. Not all parts are available separately

(an aileron cannot be purchased separately, but is only

available with the wing kit).Replacement parts are not

available from Product Support, but can be purchased

from hobby shops or mail order/Internet order firms.

Hardware items (screws, nuts, bolts) are also available

from these outlets.

To locate a hobby dealer, visit www.top-flite.com

and click on “Where to Buy”. Follow the instructions

provided on the page to locate a U.S., Canadian or

International dealer.

Parts may also be ordered directly from Hobby

Services by calling (217) 398-0007, or via facsimile

at (217) 398-7721, but full retail prices and shipping

and handling charges will apply. Illinois and Nevada

residents will also be charged sales tax. If ordering

via fax, include a Visa or MasterCard number and

expiration date for payment.

Mail parts orders Hobby Services

and payments by 3002 N Apollo Drive, Suite 1

personal check to: Champaign IL 61822

Be certain to specify the order number exactly as

listed in the Replacement Parts List. Payment by

credit card or personal check only;no C.O.D.

If additional assistance is required for any reason

contactProductSupportbye-mailatproductsupport@

top-flite.com, or by telephone at (217) 398-8970.

Order

Number Description

REPLACEMENT PARTS LIST

How to

purchase

Instruction manual

Missing pieces

Full-size plans

FuselageTOPA1810

Wing SetTOPA1811

Stab/ElevatorsTOPA1812

RudderTOPA1813

CowlTOPA1814

CanopyTOPA1815

Landing Gear Wires

TOPA1816

Contact

Product

Support

Not available

Contact

your

hobby

supplier

to

purchase

these

items

Order

Number Description How to

purchase

Gear CoversTOPA1817

Dummy EngineTOPA1818

Tailwheel Assy.TOPA1819

Spinner HubTOPA1820

DecalsTOPA1821

Stab TubesTOPA1822

Contact

your

hobby

supplier

to

purchase

these

items

COMMON ABBREVIATIONS

Stab = Horizontal Stabilizer

Fin = Vertical Stabilizer

LE = Leading Edge

TE = Trailing Edge

" = Inches

mm = Millimeters

SHCS = Socket Head Cap Screw

mAh = Milliamp Hours (refers to the

usable capacity of a battery)

To convert inches to millimeters, multiply inches

by 25.4 (25.4mm = 1")

7

ASSEMBLETHEWINGS

HINGETHE AILERONS

Start with the left wing so the assembly matches the

photos the first time through.

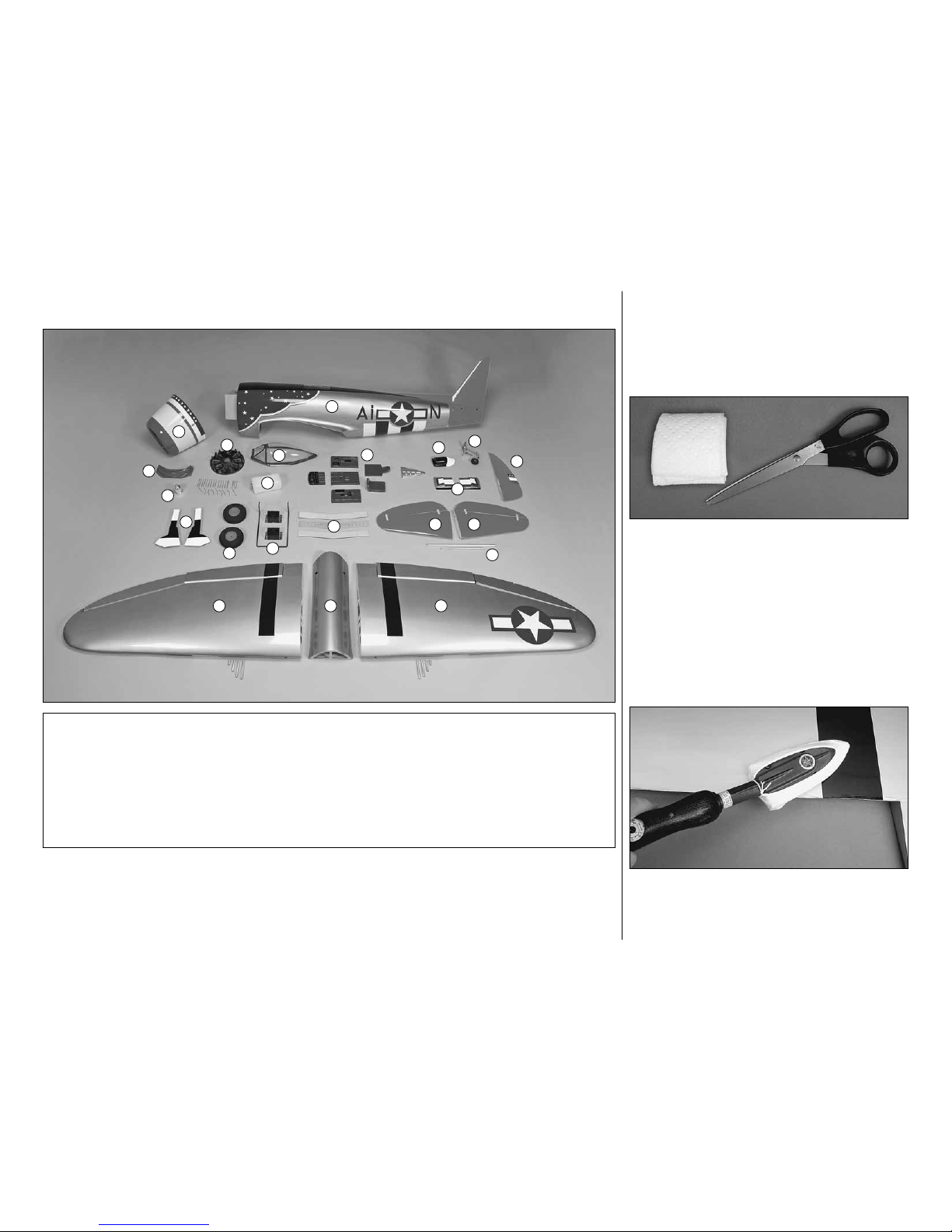

❏1. Lay a few paper towels on top of each other

and cut them into small squares.These paper towel

squares will come in handy for wiping away excess

epoxy throughout the assembly process (and will

save you from wasting whole paper towels).

❏❏2. Separate the aileron and flap from the wing

by carefully peeling off the masking tape holding

them together. Use a paper towel square dampened

with naphtha lighter fluid or similar solvent to remove

any glue left behind from the tape.

❏❏3. If necessary, use a covering iron with a

covering sock to go over the wing, flap and aileron

to remove any wrinkles. The best method to remove

the wrinkles is to glide the iron over the covering until

KIT CONTENTS

1 - Fuselage

2 - Left wing

3 - Right wing

4 - Belly pan

5 - Left Stabilizer

6 - Right Stabilizer

7 - Stabilizer Joiner Tubes

8 - Rudder

9- Fixed Tail Gear

10 - Innercooler Exhausts

11 - Turbo Charger Exhaust

12 - Cockpit Parts

13 - Wing Joiner Parts

14 - Fixed Main Gear

15 - Wheels

16 - Landing Gear Doors

17 - Fuel Tank

18 - Canopy

19- Dummy Engine

20 - Spinner Nut

21 - Cooler Intake

22 - Cowl

1

6

2

4

9

10

11

12

13

14

16

15

17

18

19

20

21

8

7

3

5

22

8

the wrinkles disappear, then go over the area again,

pushing down on the iron to bond the covering to the

wood. If the wrinkles don’t disappear, the balsa in

that area might be flexing inward.If this is happening,

don’tpress down.Simply lettheheatof theironshrink

the covering. If the wrinkles momentarily disappear,

then immediately reappear, the iron may be too hot,

thus causing air bubbles. Lower the temperature of

the iron or use a sharp #11 blade to puncture several

holes in the covering, then reheat. The suggested

iron temperature is around 360 degrees F.

The P-47 had many attributes that led to its

reputation. One of the most important was its

durability in combat. Oftentimes the P-47 would

bring pilots home with missing cylinders, blown-off

wingtips and largeportionsoftail surfaces missing.

The P-47’s internal systems were also durable and

well protected.

MOUNTTHE AILERON SERVOS

❏❏1. Use a sharp hobby knife to trim the opening

from over the left aileron servo hatch and the eight

screw holes.

❏❏2. Install a servo arm on the aileron servo.

Position the aileron servo on the aileron servo hatch

cover as shown with the servo arm centered in the

opening.Set the two 5/16" x 5/8" x 13/16" [7.9x 15.8

x 20.6mm] hardwood blocks in the embossed servo

block locations, checking that they are correct. If not,

mark the new location.

❏❏3. Use 6-minute epoxy to glue the two blocks

to the bottom of the servo hatch over the embossed

servo block locations. Thoroughly coat the end of

the blocks and allow them to set for a few seconds

while the blocks absorb the epoxy. Then, recoat the

blocks. Use clamps to hold the blocks to the servo

hatch tray.

❏❏4. Once the epoxy has cured, remove the

clamps.Place a1/16"[1.6mm]spacer,suchas a piece

of cardstock or a piece of paper folded several times,

under the servo and between each mounting block.

After the servo is installed the spacer will be removed,

providing adequate spacing for vibration isolation.

❏❏5. Drill 1/16" [1.6mm] holes through the blocks

for the servo mounting screws. Mount the servo to

the blocks with the screws that came with the servo.

Remove the servo mounting screws and apply a

couple of drops of thin CA in each hole to harden the

threads. Allow the CA to fully harden.Then, reinstall

the servos and remove the spacer.

❏❏6. Drill 1/16" [1.6mm] holes through the blocks

at the two hole locations on the top of the aileron

servo hatch. Install two #2 x 3/8" [9.5mm] flat head

sheet metal screws to secure the servo mounting

blocks to the aileron servo hatch. Use thin CA to

harden the screw threads

❏❏7.Connect a 24" [610mm] servo extension wire

to the aileron servo. Cut a piece of heat shrink tubing

9

in half and slide it over the servo connections. Shrink

the tubing by applying heat to the tubing.

❏❏8. Use the string in the wing to pull the aileron

wire through the wing.

❏❏9. Place the aileron servo hatch with the servo

in the wing. Be certain that the hatch is positioned

correctly as shown. Secure the hatches using six #2

x 3/8" [9.5mm] flat head sheet metal screws.Use thin

CA to harden the screw threads.

❏10. Go back to step 1 and install the right aileron

servo following the same procedure.

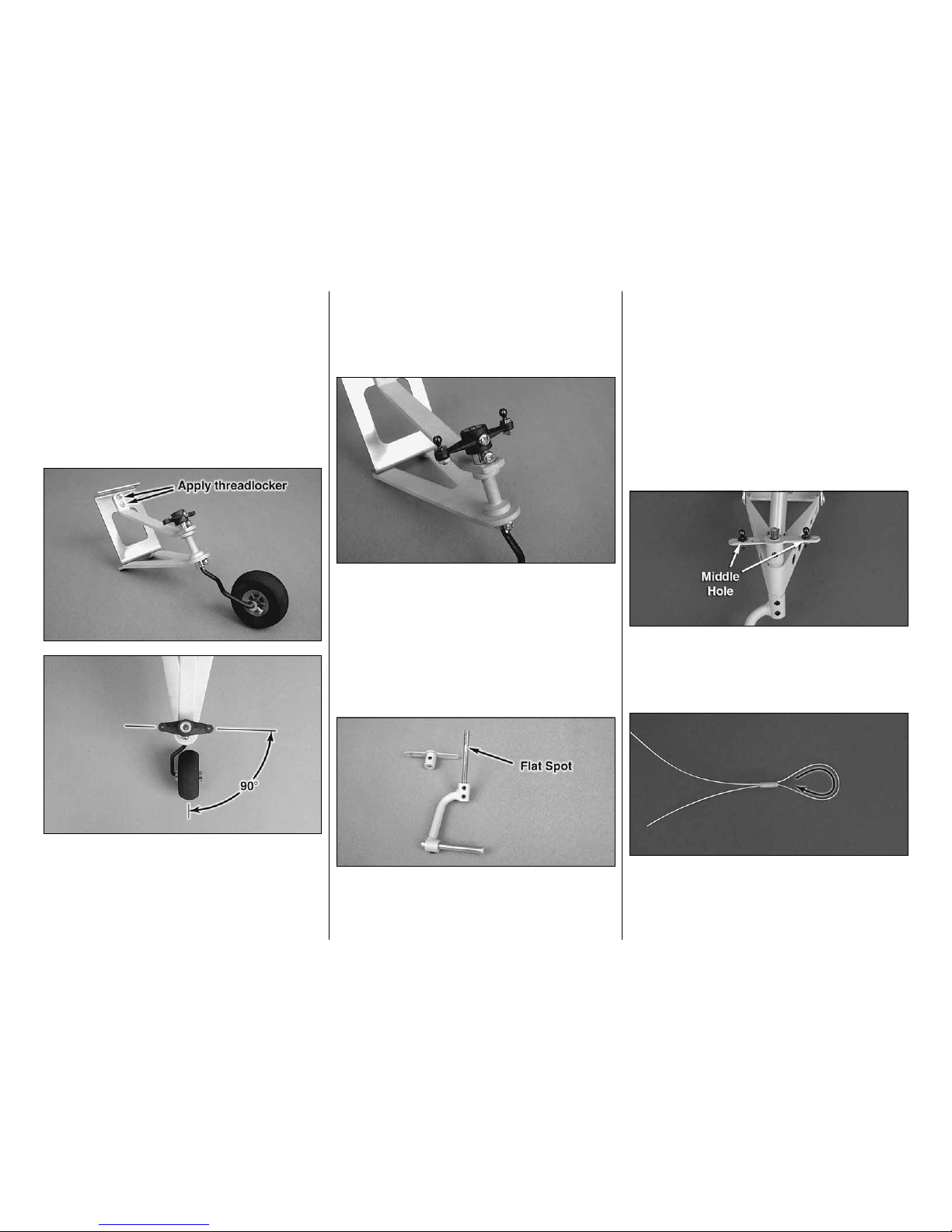

MOUNTTHE RETRACTS

Note: The fixed main landing gear will not be

installed until after the two wing halves have been

joined.If usingthefixedmainlanding gear, proceed

to “Install the Flap Servos” on page 13.

Install the left retract first.

❏❏1. Use a hex wrench to loosen the strut

mounting bolt and remove the strut. Slide two

aluminum landing gear door mounts onto the strut

and reinstall the strut in the strut mount.

❏❏2.Trim the axle that is included with the Robart

retracts to 1-1/2" [38mm] long. File a flat spot at the

end of the axle. Insert the axle through the included

5" [127mm] wheel and into the retract.Apply a drop of

threadlocker to the 10-32 x 3/16" [4.8mm] set screw,

included with the retract, and tighten the set screw

onto the flat of the axle. Make sure that the wheel

rotates freely.

❏❏3.Test fit the retract unit with the wheel into the

wing. Position the retract so the wheel is centered in

the wheel well. Adjust the strut position in the retract

body as necessary to achieve the correct spacing

all the way around the wheel.You may need to sand

the top of the opening in the rib slightly to allow the

retract to fit.Remove as little wood as possible.

10

❏❏4. Extend the retract. View the wheel from

directly above. Adjust the strut so that the wheel

is parallel to the root of the wing. Lock the strut in

position by applying a drop of threadlocker to the

threads and securely tightening the bolt at the top of

the strut.

❏❏5. Double check that the wheel will fully retract

into the wing. Extend the retract to make sure it does

not interfere with any part of the wing and that the

retract is operating smoothly.

❏❏6.Holdtheretractinthewing.Usingthemounting

holes as a guide, drill 7/64" [2.8mm] pilot holes into the

retract rails.Caution: Do not inadvertently drill into the

air cylinder when you get to the middle hole. Mount

the retracts with five #6 x 3/4" [19.1mm] sheet metal

screws, one in each corner and one in the middle as

shown.Use one #6 x 1/2" [12.7mm] sheet metal screw

in the hole over the air cylinder.

❏❏7.Remove the six screws and retract and apply

a couple of drops of thin CA in the holes.

❏❏8. Cut the covering from the holes in the top of

the wing for the servo wires and the airline tubing.

❏❏9. Cut a 21" [533mm] piece of red air line

tubing and a 23" [584mm] piece of purple air line

tubing from the tubing included with the Robart Air

Control Kit (not included). Connect the red line to

the front of the air cylinder and the purple to the

back of the air cylinder.

❏❏10. Connect the two pieces of air line tubing to

the string in the retract bay. Guide the airline tubing

through the front of the retract bay, through the flap

bay and out the hole in the top of the wing. Also pull

the aileron servo lead out the hole. Tape the airline

andaileron servoleadtothe topofthewing.Remount

the retract in the wing.

❏❏11. Use a sharp hobby knife to remove the

covering from over the five mounting holes in the

plywood retract cover. Set the retract cover over the

retract and drill a 1/16" [1.6mm] pilot hole using the

holes in the cover as a guide.

❏❏12.Mount the retract cover to the wing with five

#2 x 3/8" [9.5mm] flat head sheet metal screws.

❏❏13.Cut two of the landing gear door drill guides

from the back of the manual. Place the drill guides

in the rectangle recesses of the landing gear door.

Place the landing gear door on a piece of scrap wood

and drill a 1/8" [3.2mm] hole through the door at the

marked hole location.

11

❏❏14. Adjust the position of the two landing gear

door mounts so that they align with the flats on the

landing gear door when the door is positioned in the

landing gear opening.

❏❏15. Install a #4 flat washer on 4-40 x 3/8"

[9.5mm] machine screw. Insert the machine screw

through one of the holes in the gear door and

thread it into the landing gear door mount.Note that

it tightens against the landing gear strut before it

tightens against the gear door. Install the second

machine screw to hold the gear door in position.

Check to make sure that the gear door is flush with

the bottom of the wing. 1.5mm thick rectangular

plywood spacers have been included to space the

gear doors out if needed. Both screws will need to

be shortened, a little at a time, so that they tighten

against both the landing gear strut and the gear

door. Be sure to use threadlocker on the screws.

❏16. Return to step 1 and mount the right retract in

the right wing.

The P-47 was manufactured by Republic Aircraft

Corporation, which at one time was named

Seversky Aircraft Corporation, started by two fellow

Russians, Alexander De Seversky and Alexander

Kartveli.

INSTALLTHE FLAP SERVOS

❏❏1. Install the flap servos following the same

procedure used to install the aileron servos.Note that

the flap servos face the same direction.

❏❏2.Connect a 12" [305mm] servo extension wire

to the flap servo. Secure the extension to the servo

with a piece of heat shrink or electrical tape.

❏❏3. Route the flap servo leads to the root of the

wing and out the hole in the top of the wing.

INSTALLTHE AILERON AND

FLAP PUSHRODS

Do the left aileron first.

❏❏1. Slide a silicone clevis retainer over a 4-40

threaded metal clevis.Thread a 4-40 nut followed by

the 4-40 metal clevis, threaded 12 turns onto a 4-40

x 12" [305mm] metal pushrod.Attach the clevis to the

aileron servo arm 5/8" [15.9mm] from the center of

the arm.

❏❏2. Position the control horn so that it is inline

with the pushrod and over the plywood mounting

plate. The pushrod holes in the control horn should

be aligned with the hinge line of the aileron. On the

aileron, mark the four mounting holes. Remove the

control horn and drill a 5/64" [2mm] pilot hole at each

mark. Do not drill completely through the aileron.

Attach the control horn using four #4 x 1/2" [12.7mm]

sheet metal screws. Use thin CA to harden the holes.

❏❏3. Install the metal solder clevis in the second

hole from the end of the control horn. Center the

aileron servo and aileron. Mark the pushrod where it

meets the solder clevis. Remove the pushrod and the

solder clevis and cut the pushrod 1/4" [6.4mm] past

the mark.Solder the solder clevis to the pushrod using

the techniques described in the following HotTip.

12

HOW TO SOLDER

1. Use denatured alcohol or other solvent to

thoroughly clean the pushrod. Roughen the end of

the pushrod with coarse sandpaper where it is to

be soldered.

2. Apply a few drops of soldering flux to the end of

the pushrod, then use a soldering iron or a torch

to heat it. “Tin” the heated area with silver solder

by applying the solder to the end.The heat of the

pushrod should melt the solder – not the flame

of the torch or soldering iron – thus allowing the

solder to flow.The end of the wire should be coated

with solder all the way around.

3. Place the clevis on the end of the pushrod. Add

another drop of flux, then heat and add solder.

The same as before, the heat of the parts being

soldered should melt the solder, thus allowing

it to flow. Allow the joint to cool naturally without

disturbing. Avoid excess blobs, but make certain

the joint is thoroughly soldered.The solder should

be shiny, not rough. If necessary, reheat the joint

and allow to cool.

4. Immediately after the solder has solidified, but

while it is still hot, use a cloth to quickly wipe off

the flux before it hardens.Important: After the joint

cools, coat the joint with oil to prevent rust. Note:

Do not use the acid flux that comes with silver

solder for electrical soldering.

This is what a properly soldered clevis looks

like – shiny solder with good flow, no blobs and

flux removed.

❏❏4.Slide a silicone clevis retainer over the solder

clevis.Reinstall the aileron pushrod with the threaded

clevis attached to the control horn.

❏❏5. Assemble and connect the flap pushrods

following the same procedure. We installed the

pushrod in the outer hole of the control horn and the

hole 3/8" [9.5mm] from the center of the servo arm.

Note: With the flap fully retracted “up”, the servo arm

is centered on the servo.

❏6. Return to step 1 and install the aileron and flap

pushrods on the right wing.

The Thunderbolt was a massive airplane, the

biggest and heaviest single engine, single-place

fighter ever built. The engine, the Pratt & Whitney

18 cylinder twin-row radial, developed 2,000 H.P.

and was the most powerful engine at the time.

However, in turn, it needed a highly efficient

duct system for its super-charger. The designer,

Alexander Kartvile, designed the duct system first,

then built the fuselage around it.

JOINTHE WING

Note: Keep the retracts (if installed) in the retracted

(up) position so they do not extend and retract as you

handle the wing.

❏1. Clean the aluminum wing joiner with denatured

alcohol to remove any possible contaminant.

❏2. Gather everything required for gluing the

wing joiner and wing together including 30-minute

epoxy, mixing sticks, epoxy brush, clamps, #64

rubberbands, 12" [305mm] long dowel or wire,

denatured alcohol and small paper towel squares.

Mix up a 1/2" oz. [14.7cc] of 30-minute epoxy. Apply

a generous amount of epoxy to one side of each of

the plywood wing joiners. Sandwich the aluminum

wing joiner between the two plywood wing joiners.

Hold the joiner together with clamps. Use a paper

towel dampened with denatured alcohol to wipe off

any excess epoxy around the edges.

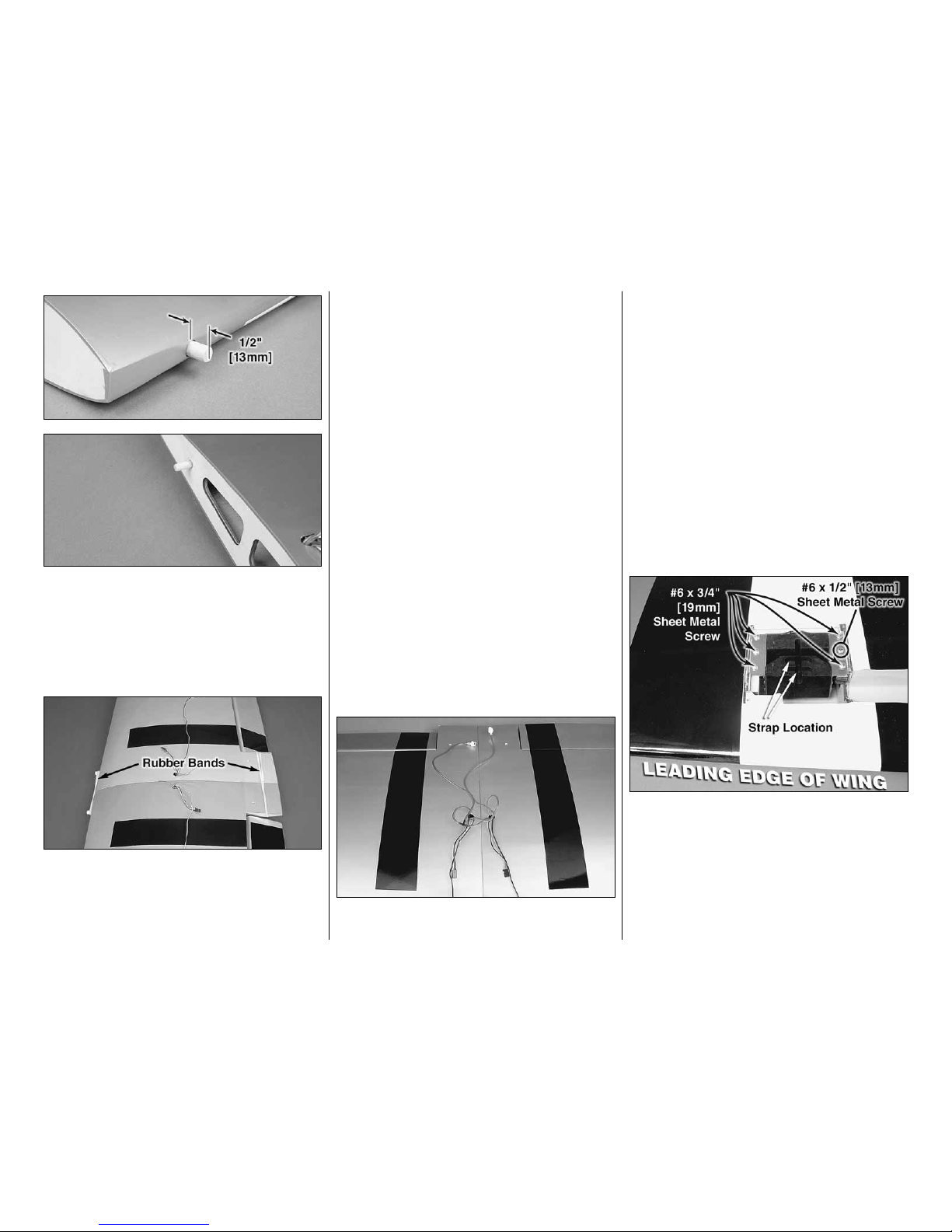

13

❏3. Use 6-minute epoxy to glue the two 3/8"

[9.5mm] diameter forward wing dowels in the

leading edge of the wing. The wing dowels should

protrude approximately 1/2" [12.7mm] from the

wing. Also glue the 1/4" [6.4mm] aft root rib guide

dowel in the left wing half. Clean off any excess

epoxy before it cures.

❏4. Once the epoxy has cured, remove the clamps

from the wing joiner and sand off any excess epoxy

you may have missed.Test fit the wing joiner in each

wing half making sure that both wings halves fit

together at the root without any gap.Trial fit clamping

the wing together with rubberbands around the wing

dowels and the trailing edge.

❏5.Removetherubberbandsandseparatethewing

halves. Remove the wing joiner. Mix 2 oz. [59.1cc] of

30-minute epoxy. Working quickly, pour a generous

amount into the joiner pocket of one wing half. Use

your wire or dowel to thoroughly distribute the epoxy,

coating all surfaces inside the joiner pocket. Coat

the root rib and one half of the wing joiner that goes

into the wing. Insert the joiner in the wing. Proceed

immediately to the next step.

❏6.Coat the joiner pocket in the other wing half and

the other end of the wing joiner. Join the wing halves

together.Then, stand the wing on end with one of the

wing tips resting on the floor. Use a piece of R/C foam

or something similar to cushion and stabilize the wing

so it won’t slide around.

❏7. With the wing resting on end, use paper towel

squares to wipe off any excess epoxy as it squeezes

out. Wrap the rubberbands around the wing dowels

and the aft end of the wing. Add several strips of

masking tape to tightly hold the wings together as

you continue to wipe off excess epoxy as it squeezes

out. Be certain the leading and trailing edges of the

wing accurately align. Do not disturb the wing until

the epoxy has fully cured.

Perform this step only if you have installed retracts.

❏8. Join the matching air lines from each wing half

with a couple of T-fittings that came with the Robart

air control kit. Cut two 10" [254mm] pieces of air line

(also from the control kit) and fit each line to the

T-fittings.Connectonequick-connectorwithanO-ring

to one of the air lines and one of the quick connectors

without an O-ring to the other line. This will prevent

improper connection to the quick-connectors on the

air valve when mounting the wing to the fuselage.

INSTALLTHE FIXED MAIN

LANDING GEAR

If you have installed the retractable landing gear

proceed to ASSEMBLETHE FUSELAGE.

❏1. Place both fixed landing gear mounts on the

landing gear plates.The mounts are the same, but

the part with the straps goes towards the leading

edgeof thewing.Using the holesin the mountsasa

guide, drill six 7/64" [2.8mm] holes into the landing

gear plates. Attach the landing gear mounts to the

landing gear plates with five #6 x 3/4" [19.1mm]

sheet metal screws and one #6 x 1/2" [12.7mm]

sheet metal screw.

14

❏2. Mount each main landing gear wire in the

landing gear mount with two metal straps and four #4

x 1/2" [12.7mm] sheet metal screws.

❏3. Mount the wheels to the landing gear with

a wheel collar on both sides of both wheels. Use

a small drop of threadlocker on all the 3 x 5mm

machine screws.Make sure the machine screw in the

outer wheel collar tightens against the flat spot on the

landing gear wire.

❏4.Use a sharp hobby knife to remove the covering

from over the five mounting holes in the plywood

retract cover. Set the retract cover over the retract

and drill a 1/16" [1.6mm] pilot hole using the holes in

the cover as a guide.

❏5. Mount the retract cover to the wing with five #2

x 3/8" [9.5mm] flat head sheet metal screws.

Various prototypes and incarnations of the P-47

began to materialize at Republic Aircraft around

1940. One of the first designs recognizable as a

P-47 was the XP-44 Rocket. One of the engine

performance features carried over from Seversky

was the gear-driven supercharger and later a

turbo-supercharger.

ASSEMBLETHE FUSELAGE

INSTALLTHE STABILIZER

❏1. Test fit the two aluminum stabilizer tubes in the

fuselage and slide the stabilizers on the tubes. The

shorter tube goes in the front hole. If the aluminum

tubes are too tight to slide through the holes, take

a sharp hobby knife and gently scrape the inside of

the holes. During the manufacturing process a small

amount of resin or filler may be left behind in the hole.

❏2. Once you are satisfied with the fit of the

stabilizer halves, remove the stabilizer halves and

the joiner tubes. Use medium grit sandpaper to

roughen up the aluminum tubes.Clean the tubes with

denatured alcohol and insert both tubes back into the

fuselage until the end exits on the opposite side by

approximately 1" [25.4mm].

❏3. Gather everything required for gluing the

stabilizer halves to the fuselage, including 30-minute

15

epoxy, mixing sticks, epoxy brush, 12" [305mm] long

dowel or wire, masking tape, denatured alcohol and

small paper towel squares. Mix up 3/4 oz.[22.1cc] of

30-minute epoxy. Apply a generous amount of epoxy

to the long side of the aluminum joiner tubes. Pull

the tubes through the fuselage so that they are close

to centered. Pour a small amount of epoxy into both

holesof oneofthe stabilizer halves and usingadowel

or wire, coat the inside of the holes. Apply epoxy to

the root rib of the stabilizer and the fuselage. Insert

the end of the aluminum tubes with epoxy on them

into the stabilizer and press the stabilizer against

the fuselage. Wipe off any excess epoxy that may

have squeezed out before it runs down the fuselage.

Quickly repeat the process on the other side. Wipe

off any excess epoxy with a dampened paper towel

and denatured alcohol. Use pieces of masking tape

to hold the stabilizer tight against the fuselage until

the epoxy cures.

❏❏4. Without using any glue, install five hinges

into the rudder. Note that the pivot point of each

hinge must align with the center of the leading edge.

To achieve this alignment, the hinges will be fairly

deep in the rudder.Also note that the hinges must be

perpendicular to the leading edge.

❏❏5. Again without glue, test fit the rudder to

the fin. Move it left and right a few times to align the

hinges. The rudder doesn’t have to move very far,

only 2" [50.8mm] left and 2" [50.8mm] right measured

at the widest part of the rudder at the trailing edge.If

there is too much resistance, or if you are not able to

move the rudder left and right 2" [50.8mm], widen the

gap slightly between the rudder and the fin.

❏❏6. Remove the rudder and all the hinges. Add

a small drop of oil to the pivot point on the hinges.

This will prevent the epoxy from adhering to the pivot

point.Makesure oildoesnot get onthegluing surface

of the hinge. If it does, clean the oil off with a paper

towel square dampened with denatured alcohol.

❏❏7. Mix up approximately 1/4 oz. [7.4cc] of

30-minute epoxy. Use a toothpick to thoroughly apply

the epoxy in the holes in the fin and rudder. Use the

toothpick to get the epoxy out of the opening of the

holes in the rudder and fin so it doesn’t get into the

hinge pin. Wipe away any excess epoxy around the

outside of the holes with a couple of the small paper

towel squares dampened with denatured alcohol.

❏❏8.Use the toothpick to apply epoxy to the ends

of the rudder hinges that go into the fin. Insert each

hinge into the fin and wipe away any excess epoxy

that squeezes out of the hole.

❏❏9. Apply epoxy to the other end of the hinges.

Join the rudder to the fin, pushing the hinges only

about 3/4 of the way into the rudder.Use a toothpick

to wipe away any epoxy that squeezes out. Then, fit

the rudder the rest of the way in.

16

❏❏10. Move the rudder left and right a few times

to align the hinges and make certain that the rudder

deflects left and right enough. Use a small piece of

maskingtape tohold the tipof therudder inalignment

with the tip of the fin. Allow the epoxy to fully cure.

MOUNTTHE FIXEDTAIL GEAR

If you are installing the retractable tail gear, skip

to “MOUNT THE RETRACTABLE TAIL GEAR” on

this page.

❏1.Slide a 3.5mm wheel collar on the tail gear wire.

Insert the tail gear wire in the tail gear mount. Install

a second wheel collar followed by the steering arm

on the tail gear wire. Apply a drop of threadlocker on

three 3x6mm machine screws. Secure the two wheel

collars and the steering arm to the tail gear wire with

the three 3x6mm machine screws.Adjust the location

of the steering arm so that it is flush with the top of

the tail gear wire and perpendicular to the tail wheel.

Also, remove the two nuts from the top of the tail gear,

apply threadlocker and reinstall the nuts.

❏2. Enlarge the holes in the steering arm with a

5/64" [2mm] drill bit. Mount a 2-56 ball link ball to

each arm with a 2-56 nut and a drop of threadlocker.

❏3.Skip to step 5 in “Mount the RetractableTail

Gear” and follow the steps for installing the pull-

pull cable.

MOUNTTHE RETRACTABLETAIL GEAR

❏1. Remove the steering arm from the Robart

#160LWC retractable tail gear assembly (not

included). File a flat spot near the top of the shaft

for the set screw in the steering arm to lock onto.

Mount the steering arm to the shaft with a drop of

threadlocker and the set screw.

❏2. File another flat spot near the bottom of the

shaft for one of the set screws in the strut. Tighten

both set screws with a drop of threadlocker on each.

Be certain the steering arm and the axle in the strut

remain parallel with each other. Make adjustments to

the flat spots if necessary.

❏3. Enlarge the hole through the 1-3/4" [44mm] tail

wheel with a #9[5mm] drill.Cut the axle included with

the Robart retractable tail gear to the correct length,

then file a flat spot on it and mount it to the strut.

❏4. Enlarge the middle hole in both sides of the

steering arm with a 3/32" [2.4mm] drill. Insert a 2-56

ball link ball in the hole.Secure each ball with a 2-56

nut and a drop of threadlocker.

❏5. Use wire cutters to cut the supplied braided

cable into two equal lengths. Slide a small copper

tube (called a swage) over one end of the cables,

then guide the end of the cable back through.

17

❏6. Wrap the cable back around the swage and

back through the swage.

❏7. Use pliers to pull the cable from the first loop to

reduce the size of the second loop.

❏8.Now pull on the long end of the cable to reduce

the size of the first loop. Slip the loop over one of the

ball link balls on the steering arm. Tighten the loop

until it is small enough to remain secure on the ball,

yet may still be pried off. Squeeze the swage with

pliers. Connect the other cable to the other ball link

ball the same way.

❏9. Retractable tail gear only: Connect 40"

[1016mm] of purple air line to the forward air fitting and

40" [1016mm] of red air line to the aft fitting on the air

cylinder. There is not enough air line leftover from the

main gear, so additional line will have to be purchased

separately (Robart #169Pressure Tubing).

❏10. Place the tail gear in the fuselage while

simultaneously guiding the pull/pull cable through the

whiteplasticguidetubes.Ifinstallingtheretractabletail

gear, also guide the air lines through the fuselage.

❏11.Removethecoveringfromoverthetwotailgear

mounting holes in the bottom of the fuselage.Drill four

3/32" [2.4mm] holes through the rails for mounting the

tail gear. If your drill bit is not long enough to reach the

rail nearest the top of the fuselage, use medium CA

to temporarily glue a 3/32" [2.4mm] drill bit in a 1/8"

[3.2mm] brass tube.After drilling the holes, the drill bit

can be removed from the tube by heating the tube.

❏12.Mount the tail gear in the fuselage with four #6

x 1/2" [12.7mm] sheet metal screws.

After the British policy of giving names to aircraft

had caught on in the U.S., the XP-47B was dubbed

“Thunderbolt” by C. Hart Miller, Republic’s Director

of Military Contracts. Republic officially approved

the name.

18

INSTALLTHE ELEVATOR & RUDDER SERVOS

❏1. Insert the three 4-40 x 48" [1220mm] metal

pushrods in the three outer pushrod tubes shown in

the photo.

❏2.Threada4-40nut,threaded clevisandasilicone

clevis retainer, 12 turns, onto both elevator pushrods

and the rudder pushrod.

❏3. Mount the control horns to the elevators and

the rudder. Follow the same procedure used for the

ailerons, by drilling 3/32" [2.4mm] holes and using

#4 x 1/2" [12.7mm] sheet metal screws. Attach the

elevator clevis in the third hole from base of the

control horn. Install the rudder clevis in the second

hole from the base of the control horn. Don’t forget

to harden the holes with thin CA after first installing,

then removing the screws.

❏4. Place two elevator, one rudder and one tail

wheel steering servo in the servo tray as shown.

Make three one-arm servo arms and one two-arm

servo arm from the servo arms that came with your

servos.Position the servo arms as shown.

❏5. Install solder clevises on the elevator servo

arms in the hole 7/16" [11.1mm] from the center of

the servo arm. Install a solder clevis on the rudder

servo arm in the hole 1/2" [12.7mm] from the center

of the servo arm. Following the same procedure that

was done for the aileron and flap pushrods, mark

the elevator and rudder pushrods where they are to

be cut for the solder clevises. One at a time, remove

the threaded metal clevis from the control horn end,

remove the pushrod from the fuselage, cut it to the

correct length and solder a metal solder clevis on the

end.Reinstall the pushrod from the front and connect

the solder clevis to the servo arms. Reinstall the

threaded metal clevis and 4-40 nut. Don’t forget to

use a silicone clevis retainer on all the clevises.

❏6. Thread a 4-40 nut and a 4-40 metal clevis, 12

turns, on to each of the 4-40 rigging couplers. Slide

a silicone clevis retainer over each clevis. Install the

cleviseson thetailwheel steering servoarm in theholes

7/16" [11.1mm] from the center of the servo arm.

19

❏7. Center the servo arm and the tailwheel gear.

Install a swage on each cable, securing it following

the same procedure used on the tail gear. Use a

pliers to crimp the swage tightly on the cable.

❏8. Mount the receiver on/off switch and charge

receptacle in a strategic location where it won’t

interfere with anything inside the fuselage and

where it will not get coated with engine exhaust

outside the fuselage.

❏9. Overlap by 1" [25.4mm] a 6" [152mm] long

piece of hook and a 6" [152mm] long piece of loop

material. Route the hook and loop material through

the two slots in the left forward fuselage side. Wrap

your receiver battery in R/C foam rubber and secure

it to the side of the fuselage with the hook and loop

material. Connect the receiver battery to the receiver

switch. Use the included heat shrink material to

secure the connectors. Make sure the receiver

battery is secure.

❏10. Mount the receiver on the other side of the

fuselage using hook and loop material. Connect the

receiver switch and the servos to the receiver. Route

the receiver antenna through the remaining pushrod

tube.Attach a strain relief on the antenna.

Early production Thunderbolts were not without

teething pains typical of any new aircraft. Takeoff

runs were long (nearly a half-mile to clear a fifty

foot obstacle) and there were several electrical and

hydraulic glitches, not to mention the unfamiliarity

of a totally new design.One fighter group damaged

or wrecked half of the P-47s received.

INSTALLTHE ENGINE

The following engine mounting instructions shows

the installation of the Fuji-Imvac BT-43EI-2 gas

engine.The installation of other brands of engines

will be similar and the following instructions can be

used as a guide.

❏1. The Giant P-47 ARF firewall has two sets of

engine mounting bolt patterns embossed on it. The

“X”is for the Fuji-Imvac BT-43EI-2 gas engine and the

“+” is for the DA-50 gas engine. If you are installing

an engine with a different mounting bolt pattern the

firewall also has crosshairs embossed on it to help

locate the correct mounting location.

❏2. Drill a 1/4" [6.4mm] hole through the firewall at

each location marked with an“X”.Install the M5 blind

nuts in the holes from the back of the firewall. Mount

20

the engine to the firewall using four M5 x 30mm long

andfourM5flatwashers.Applyadropofthreadlocker

to each bolt before installing. For reference, the

distance from the front of the firewall to the front of

the drive washer is 6-3/4" [171.4mm].With the Fuji-

Imvac BT-43EI-2 one of the 1/8" [3.2mm] plywood

engine spacers was required between the engine

and the firewall.

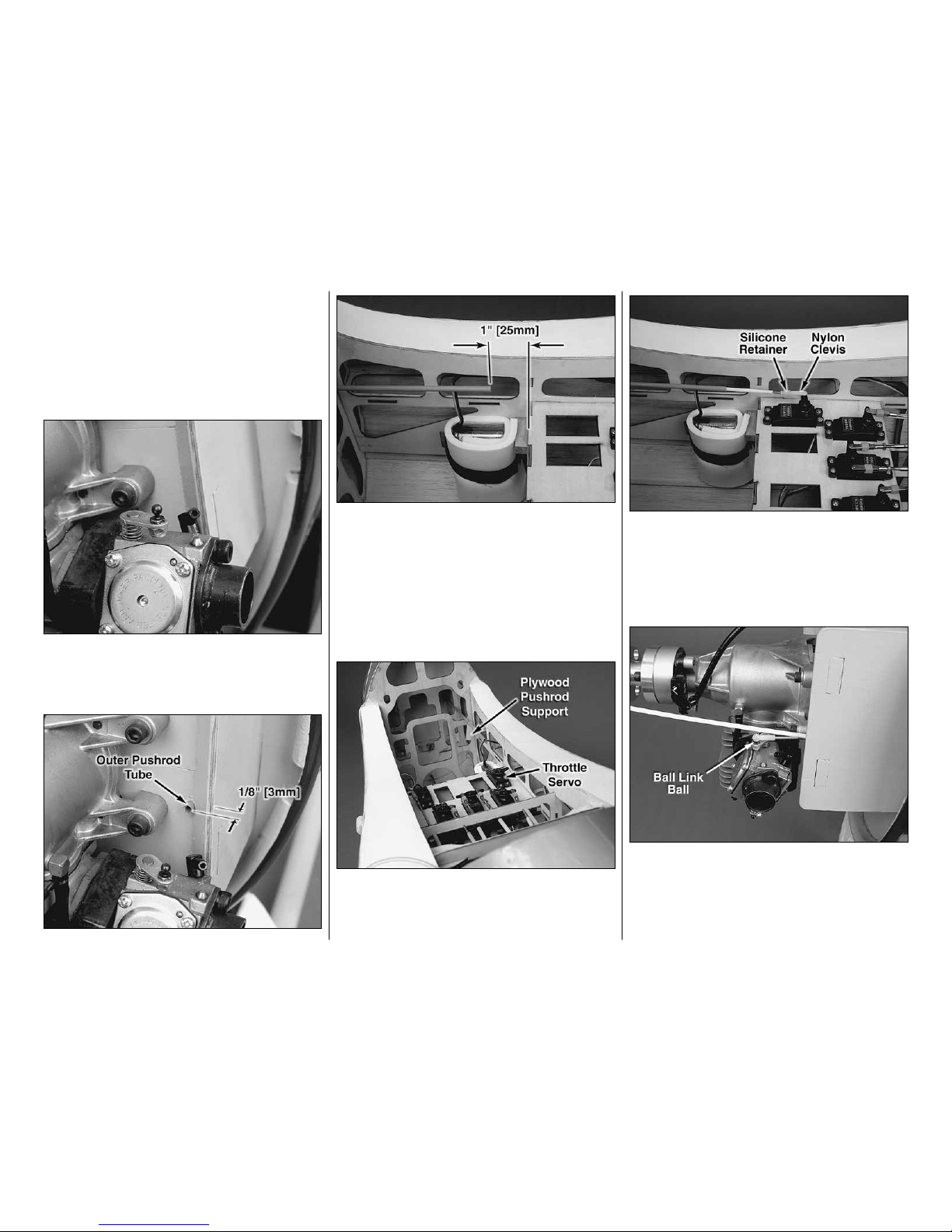

❏3. Install a 2-56 ball link ball on the throttle arm of

the carburetor. Secure the ball link ball with a 2-56

lock nut.

❏4. Drill a 3/16" [4.8mm] hole inline with the ball

link ball.Use medium sandpaper to roughen the gray

outer pushrod tube. Clean the tube with denatured

alcohol and insert the tube into the previously drilled

hole in the firewall. Route the tube through the front

formersofthefuselageuntilitprotrudesapproximately

1/8" [3mm] from the firewall. Use thin CA to glue the

tube to the firewall. Trim the tube approximately 1"

[25.4mm] in front of the servo tray.

❏5. Mount the throttle servo in the servo tray and

slide a plywood pushrod support onto the outer

pushrod tube.

❏6. Thread a 2-56 x 1" [25.4mm] threaded rod

approximately 3/8" [9.5mm] into the end of the white

inner pushrod tube. Thread a nylon clevis 14 turns

onto the end of the threaded rod. Slide a silicone

clevis retainer over the clevis. Attach the clevis to the

throttle servo arm.

❏7. Thread the nylon ball link socket 14 turns

onto the second 2-56 x 1" [25.4mm] threaded rod.

Attach the ball link socket to the ball link ball on the

throttle arm.

Table of contents

Other Top Flight Models Toy manuals

Popular Toy manuals by other brands

Fisher-Price

Fisher-Price Think & Learn FXW98 manual

Henseleit Helicopters

Henseleit Helicopters Three-Dee-Fun TDR-II user manual

MD Helicopters

MD Helicopters MILVIZ MD530F Rotorcraft flight manual

Kyosho

Kyosho RC SURFER instruction manual

Firelands

Firelands Eddie Rickenbacker's SPAD S.XIII Ultra-Micro... quick start guide

Eduard

Eduard B-26 Marauder interior Assembly instructions