14

IMPORTANT SAFETY INSTRUCTIONS AND WARNINGS – READ BEFORE USE

• Lithium Polymer batteries can be volatile. Whilst some of the instances listed below are rare, they can occur and it is

important for you to be aware of how to handle such situations. Failure to read and follow the below instructions may

result in fire, personal injury and damage to property if charged or used improperly.

• Top Gun Park Flite, its distributors or retailers assume no liability for failures to comply with these warnings and safety

guidelines.

• By using this battery, the buyer assumes all risks associated with lithium batteries. If you do not agree with these

conditions, return the battery immediately before use.

• The final use and preparation of the battery pack is ultimately beyond our control and those of our representatives and

retaillers. Your decision to use this product incorporates your agreement that you have read and understood the safety

precautions listed below and on each battery pack, and that you agree to accept full responsibility for any injury, loss or

damage resulting from all circumstances surrounding your use or misuse of this product.

GENERAL GUIDELINES AND WARNINGS

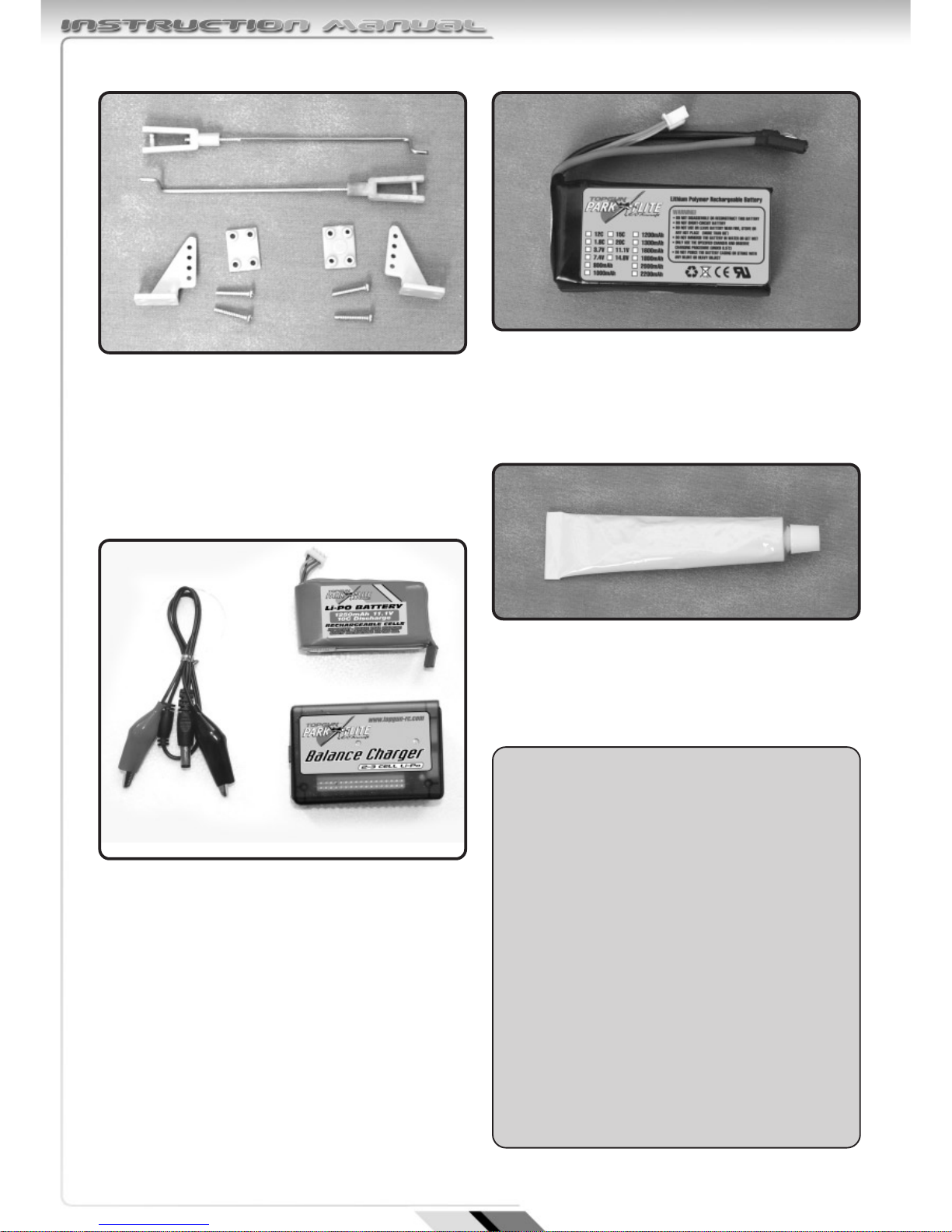

1) Only use the supplied specific Lithium Polymer charger. Do not use a NiMH or NiCd charger - Failure to do so may a cause fire, which

may result in personal injury and property damage.

2) Never charge batteries unattended. When charging LiPo batteries you should always remain in constant observation to monitor the

charging process and react to potential problems that may occur.

4) If at any time you witness a battery starting to balloon or swell up, discontinue charging process immediately, disconnect the battery

and observe it in a safe place for approximately 15 minutes. This may cause the battery to leak, and the reaction with air may cause the

chemicals to ignite, resulting in fire.

5) Since delayed chemical reaction can occur, it is best to observe the battery as a safety precaution. Battery observation should occur in a

safe area outside of any building or vehicle and away from any combustible material.

6) Wire lead shorts can cause fire! If you accidentally short the wires, the battery must be placed in a safe area for observation for

approximately 15 minutes. Additionally, if a short occurs and contact is made with metal (such as rings on your hand), severe injuries

may occur due to the conductibility of electric current.

7) A battery can still ignite even after 10 minutes.

8) In the event of a crash, you must remove battery for observation and place in a safe open area away from any combustible material for

approximately 15 minutes.

11) Never store or charge battery pack inside your car in extreme temperatures, since extreme temperature could ignite fire.

CHARGING PROCESS

1) Never charge batteries unattended.

2) Charge in an isolated area, away from any flammable materials and inside a closed tin or lipo charge sack. In the unlikely event that the

battery may fail and ignite, this procedure will ensure that a possible battery fire is contained and limiting any possible damage.

3) Let battery cool down to ambient temperature before charging.

DISCHARGE

Ensure that you adhere to the warning beeps on your transmitter and land the model accordingly. Do not fly until the battery is completely

discharged as damage will occur.

STORAGE & TRANSPORTATION

1) Store battery at room temperature between 40 and 80 degrees F for best results.

2) Do not expose battery pack to direct sunlight (heat) for extended periods.

3) When transporting or temporarily storing in a vehicle, temperature range should be greater than 20 degrees F but no more than 150

degrees F.

4) Storing battery at temperatures greater than 170 degrees F for extended periods of time (more than 2 hours) may cause damage to

battery and possible fire.

BATTERY LIFE

Batteries that lose 20% of their capacity must be removed from service and disposed of properly. Discharge the battery to 3V/Cell, making sure

output wires are insulated, then wrap battery in a bag for disposal.

PRODUCT WARRANTY

Product warranty is limited to original defects in material and workmanship. Warranty does not cover collateral damage. Due to the nature and

use of the battery there is no term warranty. Misuse, abuse, incorrect charging and other inappropriate use of this product are not covered

under warranty.