Toposens TS3 User manual

Toposens TS3 Datasheet

Operation Manual and Technical Specifications

Regulations

This device requires no regular maintenance. In the event that the

device becomes damaged or is inoperable, repair or service must be

handled by authorized, factory-trained technicians only. This device

should not be modified or operated without its housing.

Document Version

Rev

ision

Date

Changes

V 1.0

0

7/2020

Initial release

V 1.1

07/2020

Minor

corrections

PRELIMINARY PROTOTYPE

The Sensor is delivered as a development snapshot and is thus

considered a prototype. Future iterations of Toposens products are not

to be compared to this device!

1

No responsibility is assumed by Toposens for its use, nor for any

infringements of patents or other rights of third parties that may result

from its use.We reserve the right to alter our products without notice.

This also applies to products already on order provided that such

changes do not change the functionary of the product. Damage caused

by the prototype and/or software provided by Toposens GmbH are not

covered by Toposens GmbH. Handle and use at your own risk!

TS-3 Operation Manual and Technical Specifications 1

Regulations 1

Document Version 1

Disclaimer 1

Table of Contents 1

Specifications 2

Physical 2

Electrical 2

Acoustic Properties 2

Performance 2

Interface 2

Wiring Serial Connection 2

Operational Information 3

Technology 3

Theory of Operation 3

Interface 3

Data Frame 3

Commands and Acknowledgment Messages 3

Available “set”-Commands 3/4

Acknowledgement Messages 4

Special Case: Mode Command 4

Available “get”-Commands 4

Performance Characteristics Horizontal FOV 5

Performance Characteristics Vertical FOV 6

Known Issues 7

Primary Reflections 7

False Positives 7

Blind Spot Areas 7

Accuracy Issues 7

Refresh Rate Drops 7

Target Angle 7

Application Note 8

Arduino Connection 8

Arduino Library 8

EMC-Analysis 8

Contact 8

Disclaimer

Table of Contents

Preliminary Prototype | All right reserved | All Information without warranty

Physical

Specifications

Specification

Measurement

Size (LxWxH)

72 x 28 x 12 mm (2.8

×1.1 ×0.5 in.)

Weight

2

0g (0.70 oz.)

Operating temperature

0 to 60

°C (32 to 140°F)

Relative

humidity

5%

- 95% (not condensing)

Electrical

Parameter

Specification

Supply

Voltage (Vin)

Molex

-Microlock-Serial 3.3 VDC / USB 5.0 VDC

Power

Consumption

250 mA (

typical)

Performance

Parameter

Specification

Acoustic

Transmission Frequency

40 kHz

Operating Range

20 cm

- 500 cm*

Opening Angle

120

°

Distance

Resolution

±

30 mm

Distance

Accuracy

±

10% of distance measurement

Angular Resolution

3

°( = 40 angular steps over 120°)

Refresh Rate

20 Hz

typical

Latency

Approx

. 50 ms

* False positives present below 20 cm

Interface

Parameter

Specification

User Interface

USB

Serial Connection (UART)

USB

Mini

-USB-B-Port

Virtual COM

-Port UART-Bridge

[Silicon Labs CP210x OnBoard]

Serial Connection (UART)

Molex

Microlock Connector

576000 Baud

No Parity

8 Data / 1 Stop

-Bit

Logic

Level (@3.3Vdc)

Low: ~1.2 V | High: ~1.9 V

Wiring Serial Connection

Pin/Connector

Number

Function

Contact No. 1 Not Connected

Contact No. 2 TX Sensor Side

Contact No. 3 RX Sensor Side

Contact No. 4 Ground

Contact No. 5 Supply Voltage 3.3 VDC

Acoustic Properties

Parameter

Specification

Frequency 40 kHz ± 1kHz

Sound Pressure Level 120 dB SPL @ 30 cm

Mode of Operation Pulsed (20 pulses max, cyclic)

Ultrasonic transmission by industry standard.

2

Preliminary Prototype | All right reserved | All Information without warranty

Molex Part-No: 505567-0571

Technology

Operational Information

Toposens’3D Echolocation Sensor work by combining the time-of-flight

principle of conventional ultrasonic sensors with triangulation and

advanced signal processing algorithms.

At the beginning of each measurement cycle, the transducer on the

sensor sends out an ultrasonic pulse. This pulse is reflected by

surrounding objects and received by an array of microphones on the

sensor. Based on the time of flight of echoes arriving at the individual

microphones, the origins of the echoes are calculated as 3D

coordinates. These 3D coordinates are put out at the end of each

measurement cycle.

Theory of Operation

[1] the transducer (red) sends out an ultrasonic pulse, [2] the wave is

carried forward by the air molecules, [3] the wave is reflected by an

object, [4] a portion of the echo is directed back to the sensor, [5] the

echo is sequentially captured by the microphone array, arriving first at

(a) the left microphone, and then at (b) the right microphone, [6] a 3D

location of the echo’s origin (light red) is determined from the signal’s

time-of-flight and the delay between microphones receiving the echo.

Interface

The USB- and Serial Connection must not be used simulatiously –

This can damage the Sensor and connected Devices

The data stream for both output connections is identical. Both

connection modes support all configurations and modes.

Data Frame

The sensor outputs the measurements as a list of points in a human

readable ASCII format.

S000000P0000X00285Y-0184Z-0374V00050….E

Frame

Delimiter

Point

Delimiter

X [mm]

Y [mm]

Z [mm]

V [no Unit]

Frame

Terminator

S000000

P0000

X00285

Y-0184

Z-

0374

V00050

E

Each measurement data frame starts with S000000 and ends with E,

while individual points in a frame are separated by P0000. If noise is

detected during the measurement, the affected frames are flagged

with the frame delimiter S100000.

Data contained in each point: coordinates x, y & z in millimetres;

relative signal strength v in range 0 to 255.

Commands and Acknowledgment Messages

There are two types of commands, that can be sent to TS3: “Set"-and

“Get"-commands. “Set”-Commands change the sensor's settings and

trigger an acknowledgment message, which is returned by the sensor.

“Get”-Commands issue a request, which retrieves current settings and

information from the sensor.

•TS3 only receives a single command at a time

•Default values for parameters are applied at start up.

In case multiple commands are to be sent to TS3at once, it is necessary

to wait for the acknowledgment message for each respective command

before issuing the next command.

Available "set"-Commands

“Set”-commands change the sensor’s settings. When executed the

sensor answers with an acknowledgement.

Structure for each command: C <command> <value> \r

Length of string: C**********\r = 13 characters

Echo Rejection Threshold

Command

sReje

Effect

Sets

the minimum amplitude for echoes above

which

they

are considered valid detections. A low value

will

result

in a higher number of detections but also

a

higher

probability of false detections

Parameter

5

-digit unsigned integer representing the threshold

Applicable

Values

Default

= 1, min. = 0, max. = 20

Example

CsReje

00001\r for a threshold offset of 1

Noise Indicator Threshold

Command

sNois

Effect

Sets

a threshold which is applied to the

normalized

noise

level readings from the raw ADC

signals.

Detections

above this threshold are flagged as

"noisy"

Parameter

1

.4-digit unsigned float representing the threshold

Applicable

Values

Default

= 0.5, min. = 0.0000; max. = 0.9999.

Please

note

: only values between 0 and 0.9999

are

recommended

Example

CsNois

05000\r for a mark threshold of 0.5

Number of Pulses

Command

sPuls

Effect

Sets

number of ultrasonic pulses emitted by the

piezo

transducer

in every transmission cycle. Increasing

the

value

will allow the detection of objects that

are

further

away, decreasing it will increase the quality

of

detections

in close range

Parameter

5

-digit unsigned integer representing the number

of

pulses

to be sent out

Applicable

Values

Default

= 8, min. = 0, max. = 20

Example

CsPuls

00010\r for 10 pulses

Peak Detection Window

Command

sPeak

Effect

Sets

the kernel size (window width) that is applied

on

raw

ADC signals to detect valid echoes (peaks in

the

raw

ADC signal). A low value will allow for

better

separation

of multiple objects that are close to

each

other

. A high value will result in "smoother" and

more

stable

detections

Parameter

5

-digit unsigned integer representing the size of

the

the

object filter

Applicable

Values

Default

= 3, min. = 1, max. = 5

Example

CsPeak

00003\r for size of 3

3

Preliminary Prototype | All right reserved | All Information without warranty

Temperature

Command

sTemp

Effect

Sets

the temperature value used to calibrate

the

speed

-of-sound measurement.

Parameter

5

-digit signed integer representing temperature

value

as

a two-digit number with one decimal place.

Applicable

Values

Default

= value from internal temperature sensor,

to

use

internal value send command: CsTemp-1000\r,

for

external

values: min. = -40°, max. = 85°C.

Example

CsTemp

00220\r for temperature of 22°C

Acknowledgement Messages

Acknowledgment messages are sent once the associated command has

been processed. Structure for each acknowledgment message:

S <command number> C <repetition of command value> E

Length of string: S00000*C*****E = 14 characters.

Echo Rejection Threshold Acknowledgement

Message

S000001

C*****E

Associated Command

sReje

Example

Message

S000001C00001E acknowledges

that

echo

rejection threshold parameter has been

set

to

1by command CsReje00001\r

Noise Indicator Threshold Acknowledgement

Message

S000002

C*****E

Associated Command

sNois

Example

Message

S000002C05000E acknowledges

that

noise

indicator threshold parameter has been

set

to

0.5by command CsNois05000\r

Number of Pulses Acknowledgement

Message

S000003

C*****E

Associated Command

sPuls

Example

Message

S000003C00010E acknowledges

that

number

of pulses parameter has been set to 10

by

command

CsPuls00010\r

Peak Detection Window Acknowledgement

Message

S000004

C*****E

Associated Command

sPeak

Example

Message

S000004C00003E acknowledges

that

peak

detection window parameter has been set

to

3

by command CsPeak00003\r

Temperature Acknowledgement

Message

S000005

C*****E

Associated Command

sTemp

Example

Message

S000005C00220E acknowledges

that

temperature

parameter has been set to 22.0°C

by

commandCsTemp

00220\r

Special Case: Mode Command

This "set"-command allows to put the sensor into a specific scan mode.

There are two currently available:

•Mode 0: continuous scanning, the sensor scans its environment and

returns scan messages continuously. (No Ack)

•Mode 1: single scan, the command triggers the sensor to scan only

once and return the corresponding scan message. (No Ack)

Scan Mode

Command

sMode

Effect

Puts

the sensor into a specific scan mode.

Parameter

5

-digit unsigned integer representing the mode.

Applicable

Values

Default

=00000, optional = 00001.

Continuous

scan mode is default.

Example

CsMode

00001\r for 'single scan’ (=polling) mode.

Available "get"-Commands

Structure for each command: C <command> \r

Length of string: C*****\r = 8 characters

Firmware Version

Command

gVers

Effect

Returns

the firmware version uploaded on the TS3

Parameter

String

containing 5-digit value for Version.

Answer

CgVers

\r returns for example Version:00008

Parameter Configuration

Command

gConf

Effect

Returns

the current parameter configuration set in

the

sensors

firmware.

Parameter

String

containing 5-character values for Reje, Nois,

Puls,

Peak,

Temp.

Answer

CgConf

\r returns for example:

Reje:00001;Nois:05000;Puls:00010;Peak:00003;Temp:00220

4

Preliminary Prototype | All right reserved | All Information without warranty

Typical Performance Characteristics

Horizontal Field of View (FOV)

Horizontal Field of View Diagram

The pole is positioned in the field of view of the sensor. The

sensor data stream is analysed for reliable detections of the

pole ( pole visible in every output frame). Two different sensor

configurations* are documented.

Setup for Horizontal FOV-Measurement

Sensor Position

Height

70

cm (27.5 in.)

Orientation

Sensor

XY-plane parallel to ground

Target Pole

Height

100

cm (39.4 in.)

Diameter

Ø

75 mm ( 2.9 in.)

Sensor

Configuration* Area Color Number of Pulses Peak Window Echo Rejection

Configuration

2Dark gray 51 3

Configuration

3Light gray 71 2

* Both configurations can be found as “Suggested Configurations” in the Toposens-Visualizer

Blind Zone: This area is prone to false positives. Sensor outputs all detected points from 0 –500 cm (0-197 in.)

Configuration: Opening angle and max. detection distance dependent on configuration, target size and angle of reflection.

5

Preliminary Prototype | All right reserved | All Information without warranty

Max. Detection Distance: Echoes from large orthogonal surfaces (e.g. walls) can be detected at 500 cm ( 197 in.)

Typical Performance Characteristics

Vertical Field of View (FOV)

Vertical Field of View Diagram

The pole is positioned in the field of view of the sensor. The

sensor data stream is analysed for reliable detections of the

pole ( pole visible in every output frame). Two different sensor

configurations* are documented.

Setup for Vertical FOV-Measurement

Sensor Position

Height

70

cm (27.5 in.)

Orientation

Sensor

XZ-plane parallel to ground

Target Pole

Height

100

cm (39.4 in.)

Diameter

Ø

75 mm ( 2.9 in.)

Sensor

Configuration* Area Color Number of Pulses Peak Window Echo Rejection

Configuration

2Dark gray 51 3

Configuration

3Light gray 71 2

* Both configurations can be found as “Suggested Configurations” in the Toposens-Visualizer

Blind Zone: This area is prone to false positives. Sensor outputs all detected points from 0 –500 cm (0-197 in.)

Configuration: Opening angle and max. detection distance dependent on configuration, target size and angle of reflection.

5

Preliminary Prototype | All right reserved | All Information without warranty

Max. Detection Distance: Echoes from large orthogonal surfaces (e.g. walls) can be detected at 500 cm ( 197 in.)

Destructive interference can occur under certain circumstances. This

results in areas, not covered by the sensor. Those areas are of limited

spacial expansion of 10 –20 cm (3.9 –7.9 in.). Those blind spots occur in

a symmetrical pattern.

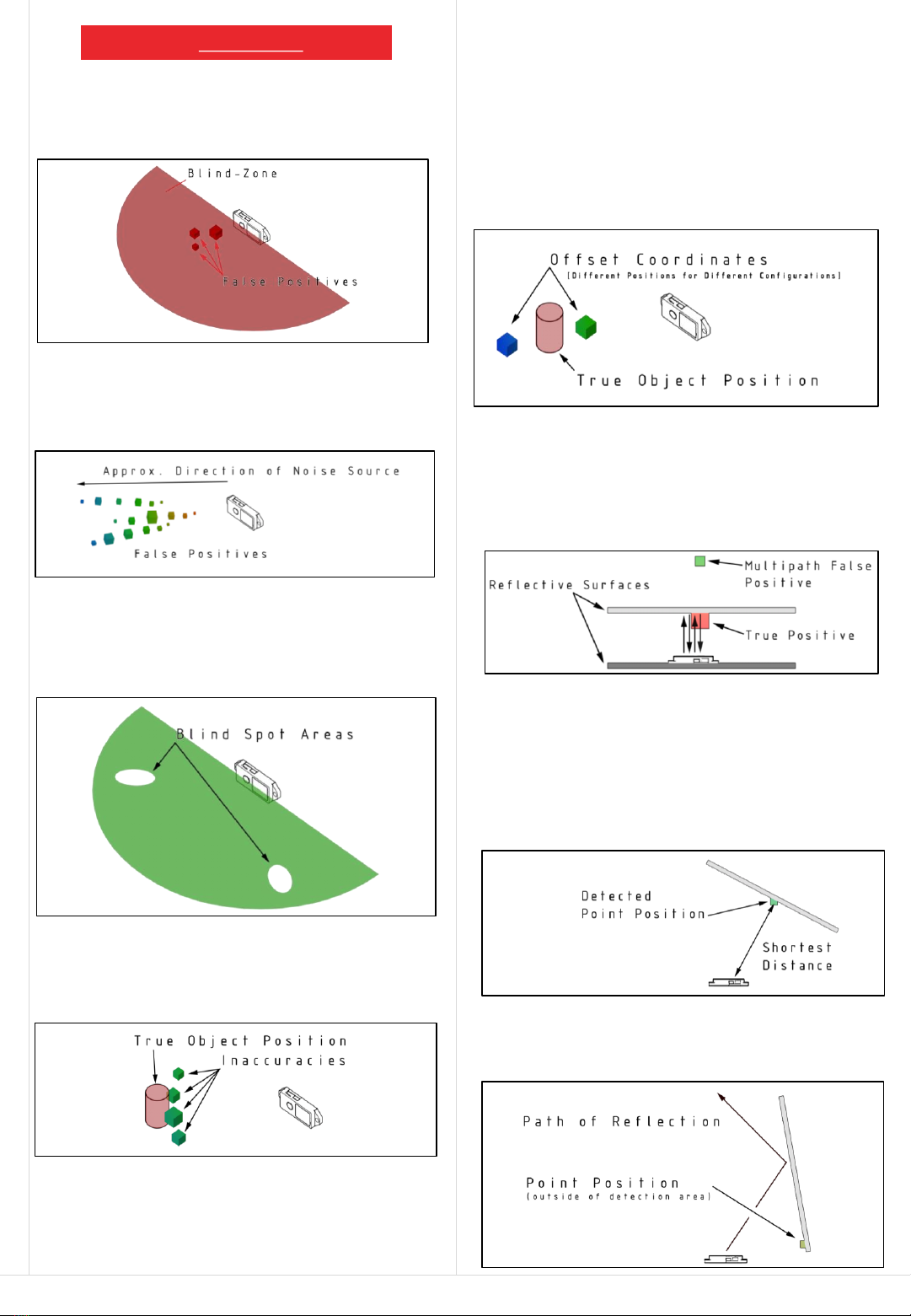

Known Issues

Primary Reflections

The sensor perceives the transmission pulse as reflections in close

proximity (0-20 cm / 0-7.8 in.). This effect can be mitigated by adjusting

the of the number of pulses and peak window size.

False Positives

Interfering echoes, environmental noise and other ultrasonic sources

are visible as false positives. Depending on the duration and amplitude,

noise points can occur at random positions.

Blind Spot Areas

The calculated position of an echo is dependent on the reflected signal

strength received by the sensor. Less energetic signals result in higher

positional variance up until the point of imperceptibility.

Accuracy Issues

These errors can be mitigated by adjusting the echo rejection threshold

to a higher value, with the disadvantage of a diminished detection

range and a smaller opening angle.

In the presence of continuous environmental noise, the system will

wait until noise contamination falls below an acceptable threshold

and trigger the next measurement. This will lead to missing frames

which in turn reduces the output refresh rate. Configurations with a

low echo rejection threshold are more prone to this behaviour.

Refresh Rate Drops

The reflective properties of the target object can influence the detected

echo position.

•Big planar objects (e.g. Walls) will reflect a single echo on the

surface of the object with the closest proximity to the sensor.

Target Angle

•Big planar objects (e.g. Walls) at certain angles will reflect most of

the acoustic energy away from the sensor. Possible detectable

positions can be located outside of the field of view of the sensor.

7

Preliminary Prototype | All right reserved | All Information without warranty

Calibration Issues

The calculated position of an echo is depending on the sensor

configuration. The pulse length as well as the selected peak detection

window size will add an offset to the actual coordinates.

Multipath Reflections

An echo, which is reflected multiple times between two surfaces e.g. in

close proximity with the sensor placed in between, will produce false

positives .

Arduino to Sensor Pin Connection

Sensor Connector Pin Arduino Pin

Contact No. 1: Not Used (GND) -

Contact No. 2: TX Sensor Side Pin 7: RX Arduino Side

Contact No. 3: RX Sensor Side Pin 8 : TX Arduino Side

Contact No. 4: Ground GND: Arduino Ground Connection

Contact No. 5: Voltage 3.3 V Vcc: Arduino 3.3V Connection

The Arduino library uses Serial1 to connect to the PC and Serial2 to

connect to the sensor. If two sensors are used, Serial3 of the Teensy 3.2

can be connected (Pin 9 for Arduino RX and Pin 10 for TX).

It should be noted that this setup requires polling mode for both

connected sensors to avoid interference.

Arduino Connection

The sensor can be connected to an embedded system via serial

connection. This example shows the connection to a Teensy 3.2 board.

This board was chosen due to the high baud rate necessary. The TS3

Sensor is not compatible with low speed MCUs like the Arduino UNO.

Application Note

Arduino Library

The sensor prototype is not certified under FCC/CE regulations. An EMC

measurement was conducted in a certified test institute to ensure

electromagnetic compliance.

Compliance is heavily dependent on the cable and MCU/PC used with

the TS3-Sensor.

For the following measurements, the USB-Connection was used in

combination with an USB-Power-Bank.

8

Preliminary Prototype | All right reserved

EMC-Analysis

The serial connection is not 5 V tolerant

Contact

Table of contents

Other Toposens Accessories manuals

Popular Accessories manuals by other brands

Sports Attack

Sports Attack JUNIOR HACK ATTACK instruction manual

Vernier

Vernier Go Direct Acceleration manual

Moog Videolarm

Moog Videolarm IPRS01 Installation and operation instructions

CARLO GAVAZZI

CARLO GAVAZZI PVS1V manual

Ghibli & Wirbel

Ghibli & Wirbel SANIPRO 20.12 AP Use and maintenance

Honeywell

Honeywell TC840MFE Installation and maintenance instructions