Torit Donaldson WSO 20 User manual

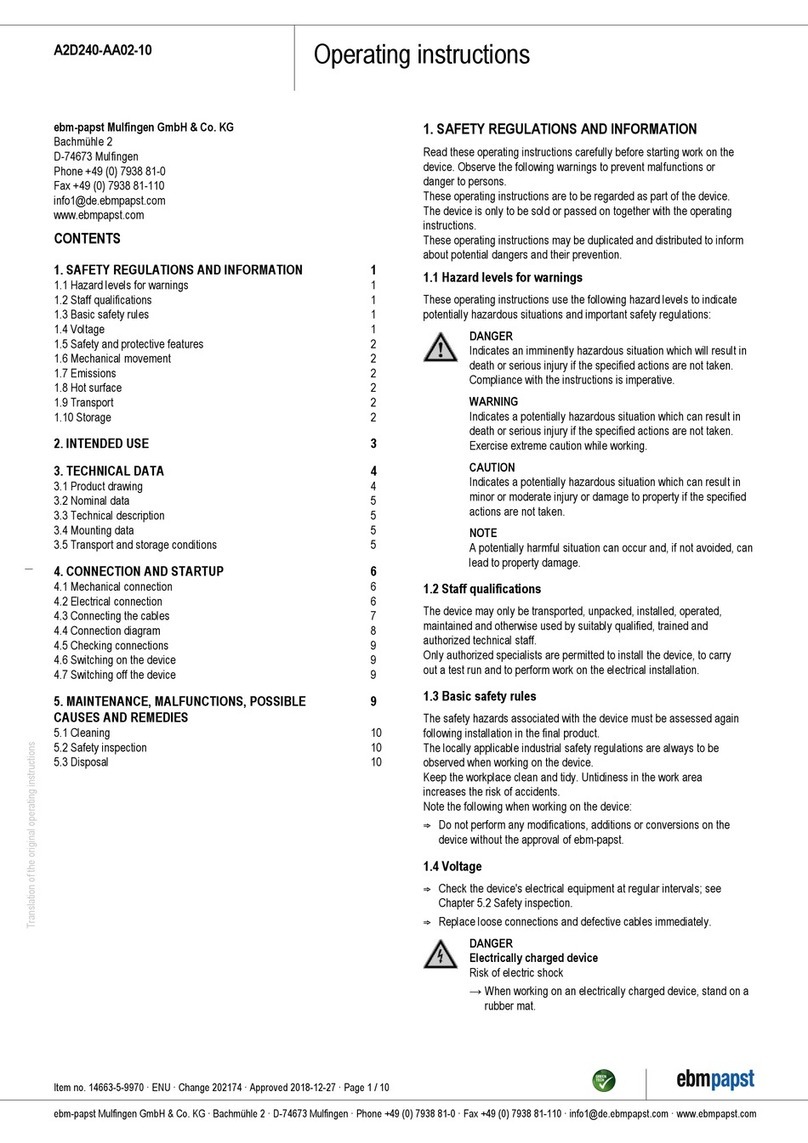

WSO 25-1 WSO 25-2

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

This manual is property of the owner. Leave with the unit when set-up and start-up are complete. Donaldson Company reserves the right to

change design and specifications without prior notice.

Illustrations are for reference only as actual product may vary.

WSO Mist Collector

WSO 20, 25-1, 25-2 and 25-3

Installation and Operation Manual

Installation, Operation, and Service Information

IOM AD3616801 (ENG)

Revision 4

English

Master Language

i

Donaldson Company, Inc.

Model Number _____________________________ Serial Number ______________________________

Ship Date _________________________________ Installation Date _____________________________

Customer Name _______________________________________________________________________

Address _____________________________________________________________________________

____________________________________________________________________________________

Filter Type ____________________________________________________________________________

Accessories __________________________________________________________________________

Other________________________________________________________________________________

Data Sheet

This manual has been supplied to assist with the installation, operation and maintenance for the collector

purchased. Please read the manual before installing, operating, or performing maintenance on the collector

as it contains specific precautions for worker safety. It is the owner’s responsibility to ensure that this

manual is available for use by installers, operators and maintenance personnel that will be working with this

collector. This manual is the property of the owner and should be left with the collector when installation has

been completed. DO NOT operate this collector until you have read and understood the instruction warnings

located in this manual.

For additional copies of this manual, contact Donaldson Torit.

The Safety Alert Symbol indicates a hazardous situation which, if not avoided could result in death or

serious injury. Obey all safety messages following this symbol to avoid possible injury or death.The

possible hazards are explained in the associated text messages.

The Notice symbol indicates a potential situation or practice which is not expected to result in

personal injury, but which if not avoided may result in damage to equipment.

IMPORTANT NOTES

WSO Mist Collector, WSO 20, 25-1, 25-2, and 25-3

ii

Magnehelic®and Minihelic®are registered trademarks of Dwyer Instruments, Inc.

Contents

IMPORTANT NOTES .................................................................i

Safety Communication............................................................1

Description................................................................................3

Purpose and Intended Use ....................................................3

Rating and Specification Information...................................4

Operation...................................................................................5

Inspection on Arrival...............................................................6

Installation Codes and Procedures ......................................6

Installation.................................................................................6

Foundations or Support Framing .......................................7

Collector Location................................................................7

Site Selection .......................................................................7

Ceiling-Mounted Collectors (WSO 20 and 25-1)..............7

Rigging Instructions.................................................................8

Hoisting Information ............................................................8

Standard Equipment................................................................9

Provisional Anchor Bolt Recommendations....................9

Typical Floor Mount Installation ........................................9

Ceiling Mount (WSO 20 and 25-1)...................................11

P-Trap Installation..............................................................12

Inlet Collar Installation ......................................................12

Electrical Wiring.................................................................13

Preliminary Start-Up Check .................................................14

Motor Starter Control Box ................................................14

Maintenance Information.....................................................15

Operational Checklist ........................................................15

Filter Removal and Installation.........................................15

First Stage Filter Cleaning and Installation ................15

Primary Filter Installation ..............................................16

Final Filter Installation (WSO 20 and 25-1)..................17

Final Filter Installation (WSO 25-2 and 25-3) ..............17

P-Trap Service ....................................................................18

P-Trap with Y-Strainer, Screen Cleaning and Removal18

Drain Collection Container................................................19

Optional Equipment................................................................20

Fan Blower ..........................................................................20

Factory-Installed HEPA/95% DOP Filter..........................20

Field Installation Afterfilter (WSO 20 and 25-1).............20

Magnehelic®or Minihelic® Installation.........................21

Remote-Mount Magnehelic Installation ........................21

Damper and Silencer, TBI.................................................23

Sprinkler...............................................................................24

Troubleshooting......................................................................25

Service Notes.........................................................................27

1

Donaldson Company, Inc.

Improper operation of dust collectors and/or dust control systems may contribute to conditions in a work

area or facility which could result in severe personal injury, and product or property damage. All dust

collection equipment should be used only for its intended purpose and should be properly selected and sized

for its intended use.

Process owners have important responsibilities relating to identifying and addressing potential hazards

in their processes. When the potential for handling combustible dust exists within a process the process

owner should include combustion hazards in their risk management activities and should comply with

applicable codes and standards related to combustible dust.

Electrical installation must be performed by a qualified electrician.

This equipment is not designed to support site ducts, piping, or electrical services. All ducts, piping, or

electrical services must be adequately supported to prevent injury and/or property damage.

Site selection must account for wind, seismic zone, and other load conditions.

Equipment may reach peak sound pressure levels above 80 dB (A). Noise levels should be considered when

selecting collector location.

Combustible Dust Hazards

Among other considerations, the current NFPA standards require owners whose processes involve

potentially combustible materials to have a current Dust Hazard Analysis, which can serve as the foundation

for their process hazard mitigation strategy. Mitigation may include but is not limited to:

Prevention of all ignition sources from entering any dust collection equipment.

Selection and implementation of fire and explosion mitigation, suppression, and isolation strategies

appropriate for the risks in their process.

Development and use of work practices to maintain safe operating conditions, and to ensure combustible

dust does not accumulate within their plant.

Donaldson recommends process owners consult experts in combustion risks to ensure these responsibilities

are met. Some processes may involve materials or processes which have inherent fire and explosion

hazards. The process owner retains responsibility to comply with applicable codes and standards and

to manage the risks associated with the process or materials. Donaldson is neither an expert nor a

certified consultant in fire, spark, or explosion detection, suppression, or control. Donaldson does not

provide engineering consulting services related to process or dust hazard analyses, or code and standard

compliance.

Donaldson may provide referrals to consultants and/or suppliers of equipment or services related to the

detection and/or mitigation of sparks, fires and/or explosions, but Donaldson does not assume responsibility

for any such referrals, nor does Donaldson assume any liability for the fitness of a mitigation strategy or

product for a particular installation or application. The process owner’s final selection of dust collection

and risk mitigation strategies should be based on the outcome of a Dust Hazard / Process Hazard Analysis

performed by the process owner. Although early engagement of a dust collector supplier can provide helpful

insights on the availability and features of various products, process owners should consult with combustible

dust experts and/or process safety experts before making actual product and mitigation strategy selections.

Safety Communication

WSO Mist Collector, WSO 20, 25-1, 25-2, and 25-3

2

Donaldson recommends all industrial air filtration system designs be reviewed and approved by an expert

consultant responsible for the integrity of the system design and compliance with applicable codes and

standards. It is the process owner’s responsibility to understand risks in their process and mitigate those

risks in accordance with all applicable laws, regulations and standards, including those published by the

NFPA. Donaldson also recommends proper maintenance and housekeeping procedures and work practices

be evaluated, developed, and followed to maintain any industrial air filtration products in safe operating

condition.

Many factors beyond the control of Donaldson can affect the use and performance of Donaldson products

in a particular application, including the conditions under which the product is used. Since these factors are

uniquely within the user’s knowledge and control, it is essential the user evaluate the Donaldson products to

determine whether the product is fit for the particular purpose and suitable for the user’s application.

3

Donaldson Company, Inc.

Designed for versatility, the WSO (Water, Smoke, and Oil)

mist collector is specifically engineered for water-based,

smoke, and oil-based mist applications. WSO mist

collector, Models WSO 20, 25-1, 25-2, and 25-3 collect

airborne mist such as oil, water-soluble, semi-synthetic

and synthetic coolant from machining operations. Two

stages of filtration, plus an optional HEPA or 95% DOP

filter, provide a cleaner, healthier work environment as

well as a more cost effective means of mist collection.

With maximum airflow capacities up to 2,000 cfm for

WSO 20 and 25-1 and 5,500 cfm for WSO 25-2 and 25-3,

the WSO is a strategic component to meeting industrial

and government air-quality standards. The high

efficiency filter cartridges allow air and coolants to be

recycled.

Designed to increase the versatility of the collector,

a variety of filter media specifically designed for mist

collection is a standard offering on the product line. The

WSO 20 contains a 20 inch tall primary filter and the

WSO 25-1, 25-2, and 25-3 contain a 25 inch tall primary

filter uniquely designed for either water-based coolants,

straight oils, or thermally-generated smoky applications.

Standard options include drain collection containers,

P-Traps, and afterfilters.

WSO models 20 and 25-1 include the blower and motor.

WSO models 25-2 and 25-3 are available with or without

a blower and motor.

Airborne mist is small droplets of metalworking fluids

suspended in the air. Metalworking fluids include

straight oils, water-soluble coolants, semi-synthetic and

synthetic coolants. These fluids perform a variety of

functions such as lubricating or cooling the part or the

tool, flushing chips away from the part, and suppressing

dust and smoke.

Mist is created two ways: mechanical action or thermal

effects. Mechanical action involves coolant used for

light lubrication and generally creates mist greater than

one micron in size. Thermal effects occur when heat

vaporizes the coolant, the vapor cools and recondenses

into a mist. Thermal effects create mist from 0.01 to 1

micron in size. Other contaminants, such as dust from

the part or the tool or smoke from the vaporization

of the oil or coolant are also generated when using

metalworking fluids.

The WSO mist collector is not designed to handle water

mist alone. There should be some type of oil content

to allow coalescing or water vapor will simply pass

through the filters. The extremes of very heavy oil and

light, thin oil should be avoided. Very heavy oil, similar

to tar consistency, will not drain while very light, thin oil,

similar to paint thinner consistency, may evaporate.

Description Purpose and Intended Use

Misuse or modification may result in severe

personal injury and/or property damage.

Do not misuse or modify.

WSO Mist Collector, WSO 20, 25-1, 25-2, and 25-3

4

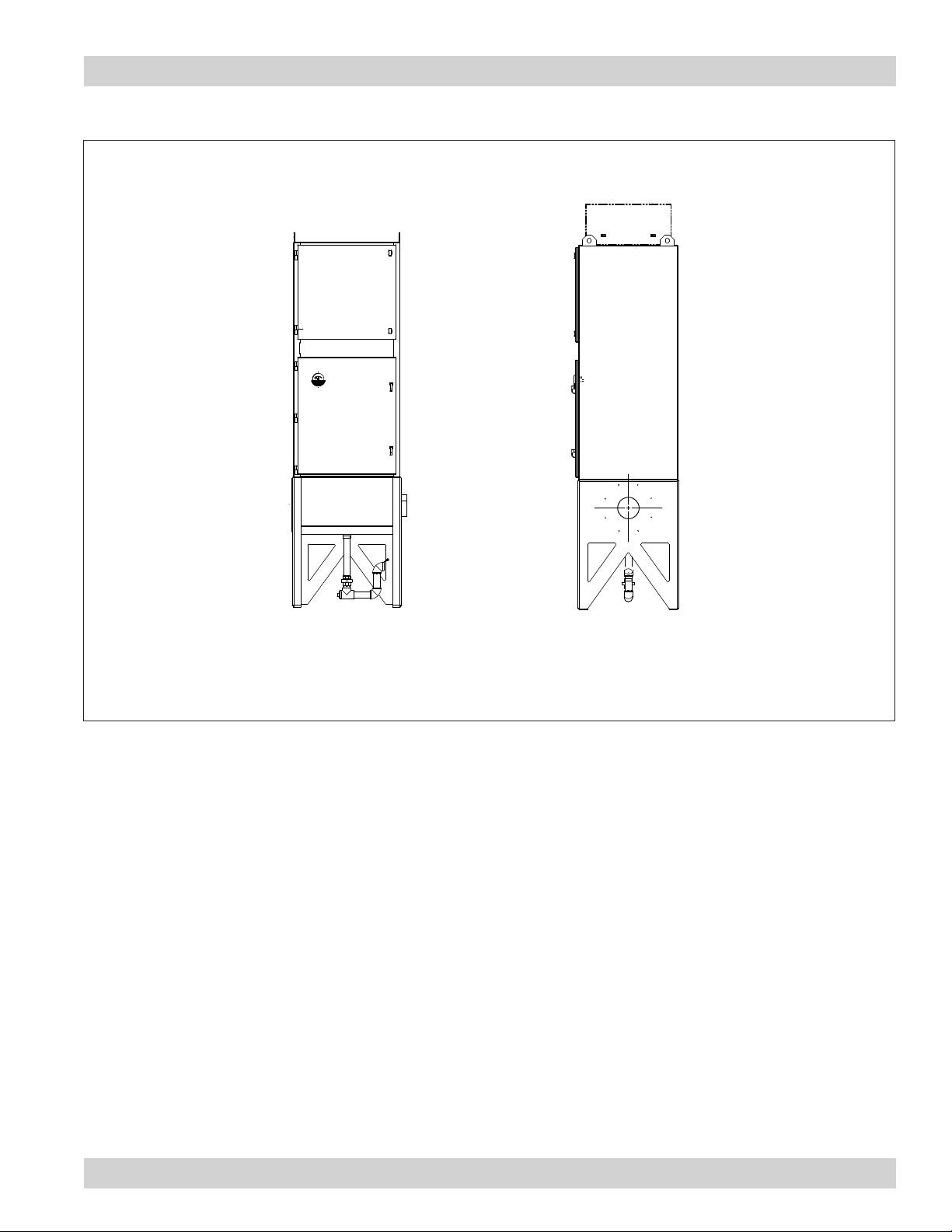

Front

WSO 25-1

Typical Side View

WSO 25-1

Rating and Specification Information

Collectors are rated for the following loads as calculated per relevant sections of the IBC 2006 code*:

Seismic Spectral Acceleration, Ss.......................................................1.5 g

Seismic Spectral Acceleration, S1.......................................................0.6 g

Installed Unit Base Elevation..............................................................Grade

Occupancy Category..................................................................................1.0

Housing rating, inches water gauge ..................................................... - 20

Power and controls ............. 208-Volt, 230/460-Volt, 575-Volt, 3 Ph, 60 Hz

*If collector was supplied with a Record Drawing, the specifications on the drawing will supersede the standard

specifications above.

5

Donaldson Company, Inc.

primary filter cartridge

clean-air outlet

coalesced

large droplets

first-stage filter

dirty-air inlet

clean-air plenum

blower and motor

p-trap (drain)

optional afterfilter

Collector Operation, WSO 25-1 shown

During normal operation, contaminated air enters the

collector through one or both dirty-air inlets located

on each side, toward the bottom of the collector. The

incoming air slows and turns upward, causing large

mist droplets and particles to fall out of the air stream

and into the hopper. The air passes through a reusable

first-stage filter designed to collect and coalesce large

droplets and particles.

The primary stage of filtration is the pleated filter

cartridge specifically designed to collect, coalesce, and

drain fine mist. As the mist coalesce, the droplets are big

enough to run down the cartridge and drain back into

the collector. The droplets will drain on both the inside

and outside of the cartridge. Liquid that collects on the

inside of the cartridge drains through the bottom portion

of the porous media and into the hopper. Clean, mist-free

air exits the cartridge and discharges through the top of

the collector.

Operation

WSO Mist Collector, WSO 20, 25-1, 25-2, and 25-3

6

Inspection on Arrival

1. Inspect collector upon delivery.

2. Report any damage to the delivery carrier.

3. Request a written inspection report from the Claims

Inspector to substantiate any damage claim.

4. File claims with the delivery carrier.

5. Compare collector received with description of

product ordered.

6. Report incomplete shipments to the delivery carrier

and your Donaldson Torit representative.

7. Remove crates and shipping straps. Remove loose

components and accessory packages before lifting

collector from truck.

8. Check for hardware that may have loosened during

shipping.

9. Use caution removing temporary covers.

Installation Codes and Procedures

Codes may regulate recirculating filtered air

in your facility. Consult with the appropriate

authorities having jurisdiction to ensure

compliance with all national and local codes

regarding recirculating filtered air.

Safe and efficient operation of the collector depends on

proper installation.

Authorities with jurisdiction should be consulted

before installing to verify local codes and installation

procedures. In the absence of such codes, install

collector according to the National Electric Code,

NFPA No. 70-latest edition and NFPA 91 (NFPA 654 if

combustible dust is present).

A qualified installation and service agent must complete

installation and service of this equipment.

All shipping materials, including shipping covers, must

be removed from the collector prior to or during collector

installation.

Failure to remove shipping

materials from the collector

will compromise collector

performance.

Inspect collector to ensure all hardware is properly

installed and tight prior to operating collector.

Installation

Use proper equipment and adopt all safety

precautions needed for servicing equipment.

Electrical service or maintenance work must

be performed by a qualified electrician and

comply with all applicable national and local

codes.

Turn power off and lock out electrical

power sources before performing service or

maintenance work.

Do not install in classified hazardous

atmospheres without an enclosure rated for

the application.

Site selection must account for wind, seismic

zone, and other load conditions when

selecting the location for collectors.

Codes may regulate acceptable locations for

installing dust collectors. Consult with the

appropriate authorities having jurisdiction to

ensure compliance with all national and local

codes regarding mist collector installation.

Collectors must be anchored in a manner

consistent with local code requirements.

Anchors must be sufficient to support dead,

live, seismic, and other anticipated loads.

Consult a qualified engineer for final selection

of anchorage.

7

Donaldson Company, Inc.

Ceiling-Mounted Collectors (WSO 20 and

25-1)

Lifting lugs on the unpowered collector (25-2 or

25-3) are not intended for ceiling suspension.

Collector is floor-mount only. Failure to comply

may result in personal injury and/or property

damage.

Ensure weight of oil-laden collector plus

weight of required materials and equipment

will be adequately supported. Failure to comply

may result in personal injury and/or property

damage.

WSO 20 and 25-1 can be suspended or hung from

overhead supports. The supports must be adequate

to carry the live load of the collector and installation

performed to reduce sway or vibration to the collector.

The dry collector weight is shown on the specification

control drawing shipped with the collector.

The live load will include the weight of all ancillary

hardware attached to the mist collector, as well as the

weight of the mist-laden, wet filters. Consult the coolant

MSDS for the specific gravity of the coolant to estimate

the weight of the mist-laden, wet filters.

Provide clearance from heat sources and interference

with utilities when selecting the location for suspended

collectors.

Collector Location

Donaldson Torit equipment is not designed to

support site installed ducts, interconnecting

piping, or electrical services. All ducts, piping,

or electrical services must be adequately

supported to prevent severe personal injury

and/or property damage.

When hazardous conditions or materials are

present, consult with local authorities for the

proper location of the collector.

Mist collection equipment may reach peak

sound pressure levels above 80 dB (A). Noise

levels should be considered when selecting

collector location.

Locate the collector to ensure easy access to electrical

connections, to simplify mist collection container

handling and routine maintenance, and to ensure the

straightest inlet and outlet ducts.

Site Selection

This collector can be located on a foundation or

structural framing.

Provide clearance from heat sources and avoid any

interference with utilities when selecting the location.

Foundations or Support Framing

Prepare the foundation or support framing in the

selected location. Foundation or support framing must

comply with local code requirements and may require

engineering.

Foundation and support framing must be capable of

supporting dead, live, wind, seismic and other applicable

loads. Consult a qualified engineer for final selection of

foundation or support framing.

WSO Mist Collector, WSO 20, 25-1, 25-2, and 25-3

8

Rigging Instructions

Suggested Tools & Equipment

Clevis Pins and Clamps Lifting Slings

Crane or Forklift Pipe Sealant

Drift Pins Pipe Wrenches

Drill and Drill Bits Screwdrivers

End Wrenches Socket Wrenches

Adjustable Wrench Spreader Bars

Torque Wrench (inch/lbs, 9/16-in Socket)

Hoisting Information

Failure to lift the collector correctly can result

in severe personal injury and/or property

damage.

Use appropriate lifting equipment and adopt

all safety precautions needed for moving and

handling the equipment.

A crane or forklift is recommended for

unloading, assembly, and installation of the

collector.

Location must be clear of all obstructions, such

as utility lines or roof overhang.

Use all lifting points provided.

Use clevis connectors, not hooks, on lifting slings.

Use spreader bars to prevent damage to collector’s

casing.

Check the Specification Control drawing for weight and

dimensions of the collector and components to ensure

adequate crane capacity.

Allow only qualified crane or forklift operators to lift the

equipment.

Refer to applicable OSHA regulations and local codes

when using cranes, forklifts, and other lifting equipment.

Lift collector and accessories separately and assemble

after collector is in place.

Use drift pins to align holes in section flanges during

assembly.

9

Donaldson Company, Inc.

Standard Equipment

The collector has a high center-of-gravity and

may overturn if not secured properly.

Secure the collector to the lifting device.

Use care when moving the collector.

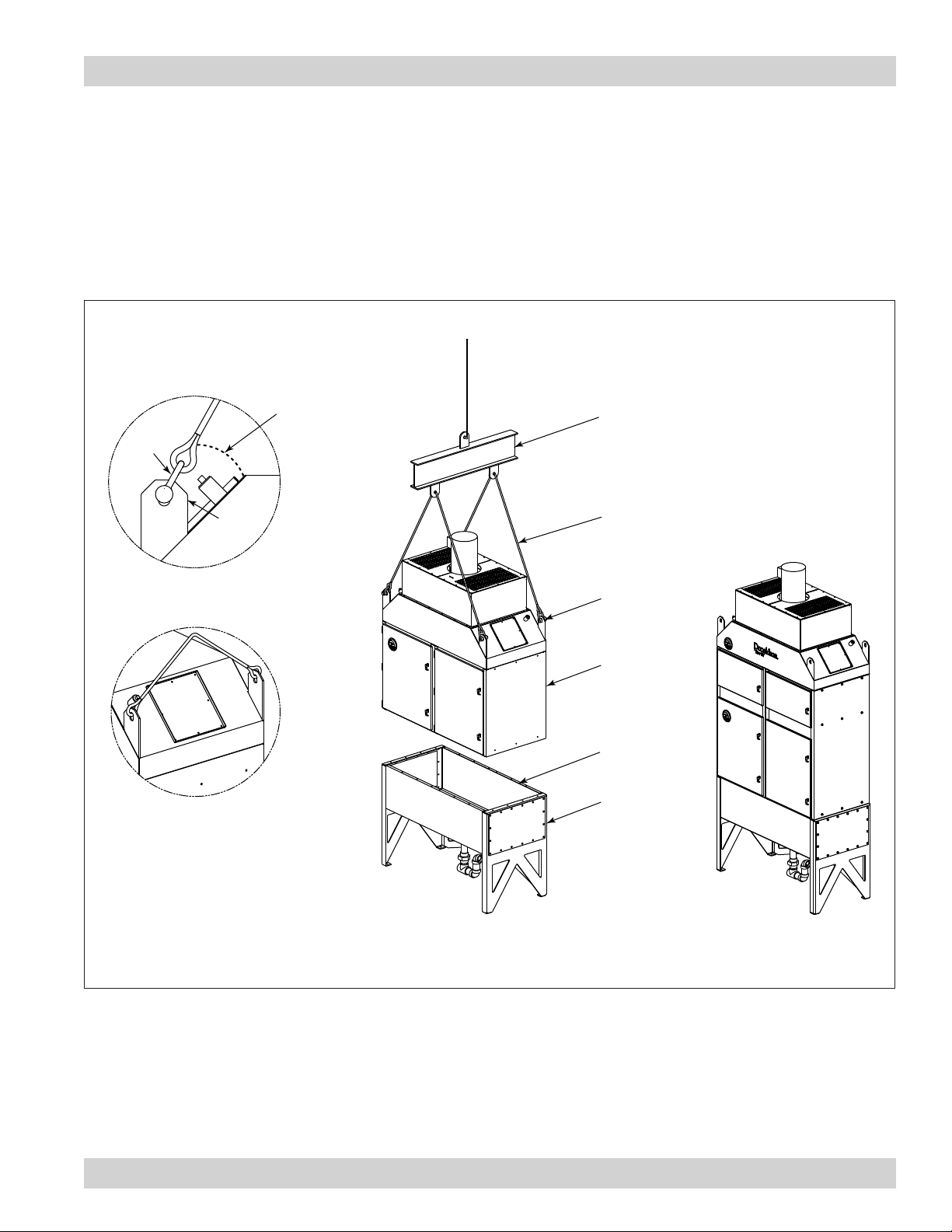

The WSO mist collector is shipped in two sections, an

inlet plenum with legs and a filter cabinet section with

a blower and motor (for powered WSO 20 and 25-1

models) or without a blower and motor (for unpowered

WSO 25-2 and 25-3 models).

2. Using a crane or forklift, raise the inlet plenum to the

required height.

Note: When using a crane, use clevis pins and a

sling attached to four lifting lugs.

3. For the WSO 20, attach legs to the outside of the

collector’s stub legs with supplied fasteners. Do not

tighten hardware at this time.

4. Lower the inlet plenum with legs to the anchor bolts.

5. Level inlet plenum and secure all hardware.

6. Apply supplied sealant to the top flange of the inlet

plenum.

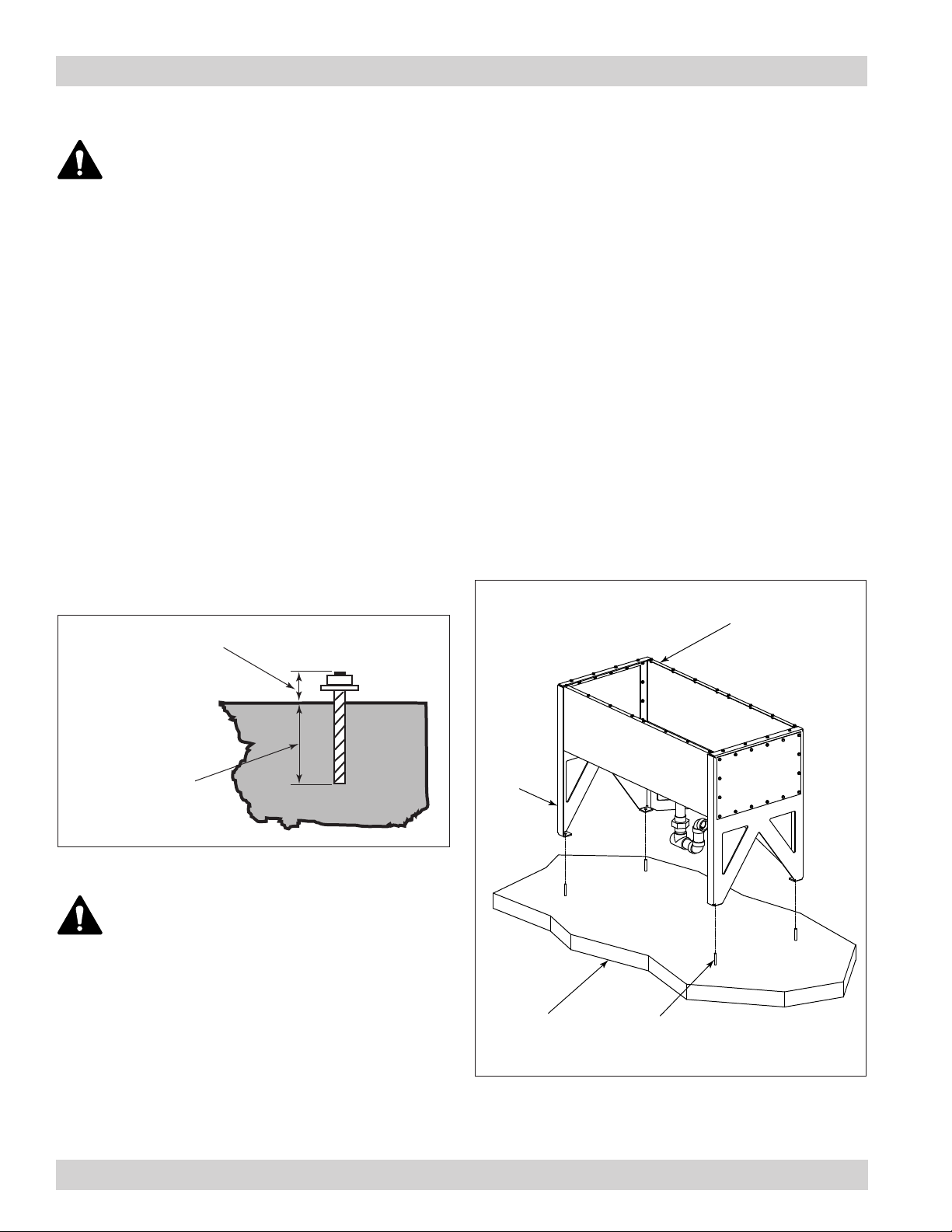

inlet plenum

foundation anchor bolt

leg

Inlet Plenum Installation, WSO 25-2 shown

Anchor should project

a minimum of 1 3/4-in

and account for nut,

washer, base plate

and shims/grout.

Embedment depth

Provisional Anchor Bolt Recommendations

1. Consider Hilti HIT-HY 200 Anchor System or

equivalent. Quantity of anchor bolts should match the

number of holes provided in the base plates.

2. Anchor diameter is typically 1/8-in less than

baseplate hole diameter.

3. Corrosive environment or outdoor installation may

require stainless steel anchors.

Anchors must comply with local code

requirements and must be capable of

supporting dead, live, wind, seismic, and other

applicable loads.

Anchor sizes shown are provisional, as final

anchor sizing will depend on jobsite load

conditions, collector location, foundation/

framing design variables and local codes.

Consult a qualified engineer for final selection

of suitable anchors.

Typical Floor Mount Installation

Leg sets for standard collector sizes are shown in the

Rating and Specification Information. Reference Typical

Foundation Anchor and leg assembly drawing shipped

with the collector prior to starting assembly.

1. Prepare the foundation or support framing in the

selected location. Locate and install anchors.

WSO Mist Collector, WSO 20, 25-1, 25-2, and 25-3

10

Completed Installation

Filter Cabinet Installation

Lifting Lug Angle

Incorrect Lifting Orientation

(correct lifting orientation

shown to the right)

filter

cabinet

sealant

inlet

plenum

lifting lug

Correct Lifting

Orientation

angle not to exceed

30° from vertical

(minimum 60°

from horizontal)

clevis

pin

lifting

lug

spreader bar

Completed Installation, Powered WSO 25-2 shown

7. Remove the first stage and primary filters from the

filter cabinet and set aside.

8. Using a crane or forklift, raise the filter cabinet

section to the required height. See below illustration

for correct lifting orientation.

9. Set cabinet on top of the inlet plenum flange and

attach with the supplied fasteners.

10. Remove crane or forklift.

11. Re-install the first stage and primary filters.

11

Donaldson Company, Inc.

Ceiling Mount (WSO 20 and 25-1)

Failure to lift the collector correctly can result

in severe personal injury or property damage.

Use appropriate lifting equipment and adopt

all safety precautions needed for moving and

handling the equipment.

A crane or forklift is recommended for

unloading, assembly, and installation of the

collector.

Location must be clear of all obstructions,

such as utility lines or roof overhang.

Ensure weight of oil-laden collector plus

weight of required materials and equipment

will be adequately supported. Failure to comply

may result in personal injury and/or property

damage.

Top View

45°

Front View

60°

Isometric View

customer-supplied

chain or cable

eye bolt

Ceiling Mount Installation, WSO 20 shown

1. Verify that the ceiling attachment points can bear the

live load.

2. Use properly sized cable or chain to attach to each

of the four WSO attachment lugs (WSO 25-1) or

eyebolts (WSO 20) to suspend the collector from the

ceiling.

3. To prevent sway, position the chain or cable to form

a 60 degree angle to the top of the collector and a 45

degree angle along the sides.

WSO Mist Collector, WSO 20, 25-1, 25-2, and 25-3

12

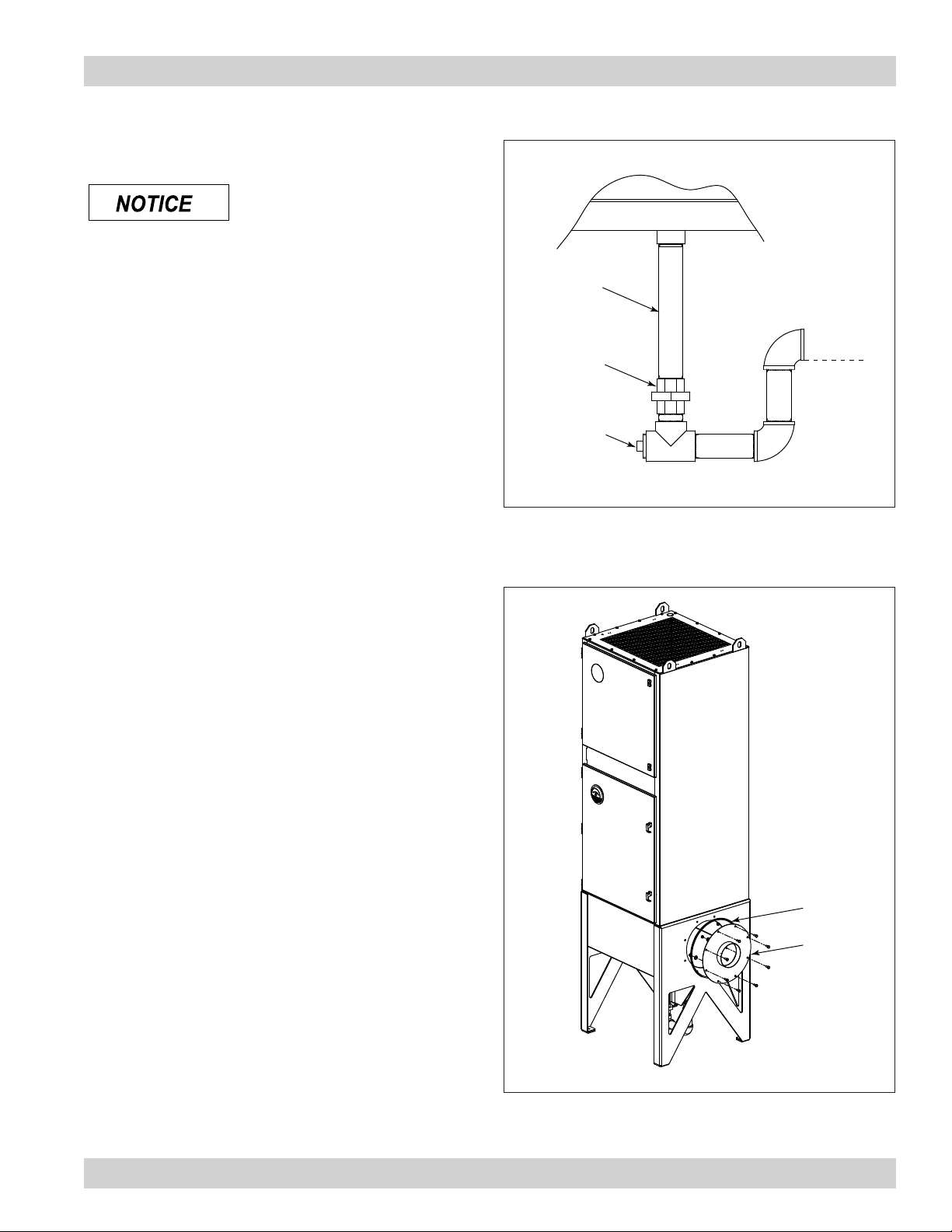

P-Trap Installation

Ensure collected material

properly flows through the

P-Trap. The P-Trap dimensions

should accommodate a column of coolant

greater than the static capacity of the fan

to avoid coolant pooling in the collector and

potentially causing property damage.

1. Install the P-Trap as shown in P-Trap Installation.

2. Position the P-Trap outlet to the proper location and

tighten the union.

3. Plumb the P-Trap to a receptacle or install a return

line back to the machine center.

4. Fill P-Trap before starting collector.

Note: The characteristics of some machining

fluids change with time, use, and exposure

to air. Check the condition of the collected

fluid before re-using.

Inlet Collar Installation

(WSO 20 and 25-1)

1. Install the inlet collar to the desired inlet location

using the supplied sealant and hardware.

2. For single-inlet configurations, install the inlet

blank to the inlet opposite the inlet collar using the

supplied sealant and hardware.

(WSO 25-2 and 25-3)

1. Refer to the Specification Control Drawing to get the

dimensions and bolt pattern of the inlet. Typically,

a rectangle-to-round transition, custom to your

particular installation, is obtained from the ducting

supplier. Install the rectangle-to-round transition to

the desired inlet location using the supplied sealant

and hardware.

2. For single-inlet configurations, install the inlet

blank to the inlet opposite the inlet collar using the

supplied sealant and hardware.

hopper

maximum

fill level

union

pipe plug

NPT pipe

P-Trap Installation

sealant

inlet collar

Inlet Collar Installation, WSO 25-1 shown

13

Donaldson Company, Inc.

Electrical Wiring

Electrical installation, service, or maintenance

work must be performed by a qualified

electrician and comply with all applicable

national and local codes.

This collector may start or stop unexpectedly

from a remote location. Turn power off and lock

out electrical power sources before performing

service or maintenance work.

Do not install in classified hazardous

atmospheres without an enclosure rated for

the application.

All electrical wiring and connections, including electrical

grounding, should be made in accordance with the

National Electric Code (NFPA No. 70-latest edition).

Check local ordinances for additional requirements that

apply.

The appropriate wiring schematic and electrical rating

must be used. See collector’s rating plate for required

voltage.

An electric disconnect switch having adequate amp

capacity shall be installed in accordance with Part IX,

Article 430 of the National Electrical Code (NFPA No.

70-latest edition). Check collector’s rating plate for

voltage and amperage ratings.

Refer to the wiring diagram for the number of wires

required for main power wiring and remote wiring.

WSO Mist Collector, WSO 20, 25-1, 25-2, and 25-3

14

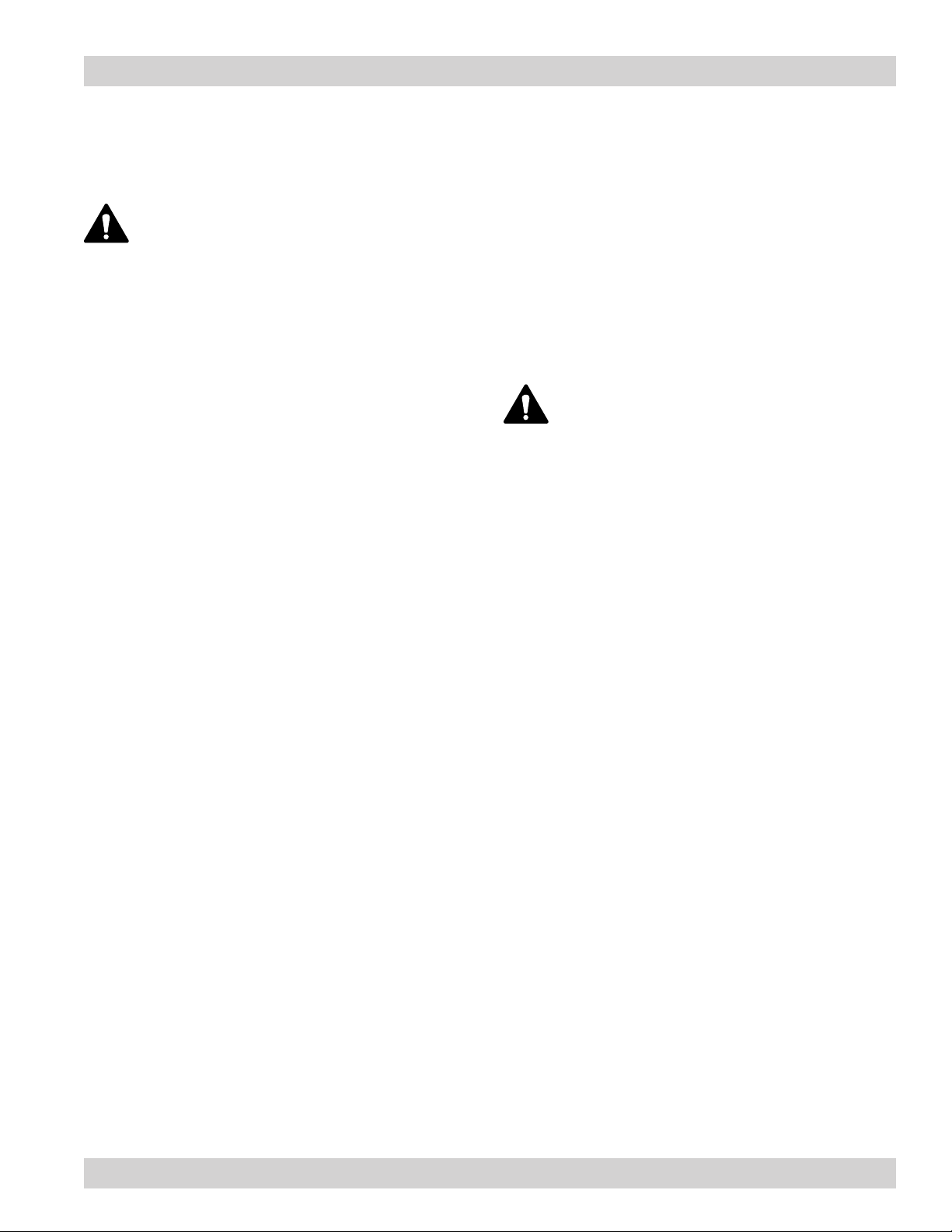

Motor Starter Control Box

Mount the motor starter control box in a convenient

location. For the WSO 20 and 25-1, an electrical

knockout, sized for 1/2-in fittings, is provided on the left-

hand side of the blower cabinet. Increase knockout size

using a drill as required.

1. Using the wiring diagram supplied inside the control

box and the instructions on the motor decal, make

the connections to the blower motor.

Note: If the collector is supplied with an optional

junction box, wire the motor starter to the

terminal strip located inside the junction box

according to the wiring diagram supplied

with the junction box.

Instruct all personnel on safe use and maintenance

procedures.

Electrical work during installation, service or

maintenance must be performed by a qualified

electrician and comply with all applicable

national and local codes.

Turn power off and lock out electrical

power sources before performing service or

maintenance work.

Check that the collector is clear and free of all

debris before starting.

Do not install in classified hazardous

atmospheres without an enclosure rated for

the application.

Optional fans over 600 lbs must be

independently supported.

Preliminary Start-Up Check

2. Check all electrical connections for tightness and

contact.

3. Check for proper rotation as noted on the fan and/

or hopper discharge device housing. Clockwise for

WSO 25-1, powered WSO 25-2 and 25-3 and see

rotation arrow on the motor’s mounting plate for

WSO 20.

To reverse rotation, single-phase power supply:

Follow manufacturer’s instructions on the motor’s

nameplate.

To reverse rotation, three-phase power supply:

Switch any two leads on the motor junction box.

Do not look into fan outlet to determine

rotation. View the fan rotation through the

back of the motor.

Check that the exhaust plenum is free of tools

or debris before checking blower/fan rotation.

Stand clear of exhaust to avoid personal injury.

Do not interchange a power lead with the

ground wire. Severe personal injury and/or

property damage may result.

4. Check that all filters are properly installed.

5. All access panels should be sealed and secure.

6. Check and remove all loose items in or near the inlet

and outlet of the collector.

7. Check that all remote controls are properly wired

and all service switches are in the OFF position.

8. Check that all optional accessories are installed

properly and secured.

9. Fill P-Trap if equipped, or close faucet valve on drain

collection container if used.

10. Turn blower fan motor ON.

15

Donaldson Company, Inc.

6. If equipped with a HEPA or 95% DOP, monitor

pressure drop across after filter. Initial final filter

pressure drop is approximately 1-2”wg. Replace the

final filter when the gauge reads 3.5 to 4.0”wg. Do

not attempt to clean or wash the final filter. Replace

only.

Do not operate the collector

without the first- or primary-

stage filter in place. Significant reduction in

final filter life can result.

Instruct all personnel on safe use and maintenance

procedures.

Use proper equipment and adopt all safety

precautions needed for servicing equipment.

Use appropriate access equipment and

procedures. Note the standard collector is not

equipped with access platforms unless noted

on the specification drawings.

Electrical service or maintenance work must

be performed by a qualified electrician and

comply with all applicable national and local

codes.

Turn power off and lock out electrical

power sources before performing service or

maintenance work.

Do not install in classified hazardous

atmospheres without an enclosure rated for

the application.

Maintenance Information

Operational Checklist

1. Monitor the physical condition of the collector and

repair or replace any damaged components.

Routine inspections will minimize downtime and

maintain optimum system performance. This

is particularly important on continuous-duty

applications.

2. Monitor pressure drop across filters.

Abnormal changes in pressure drop may indicate a

change in operating conditions and possibly a fault

to be corrected.

3. Monitor exhaust.

4. Monitor hopper drainage. If slow or stopped, check

hopper for obstructions and clean as necessary.

5. Check that the P-Trap is full. Refill if low or dry.

First Stage Filter Cleaning and Installation

Remove the first stage filter through the lower access

door. Clean the first-stage screen by tapping it gently

over an appropriate waste container. If further cleaning

is required, wash in an appropriate wash tank. To clean

the first-stage filter, soak in an appropriate wash tank,

rinse, dry, and re-install.

High temperature, steam-

cleaning methods should not be

used with the polypropylene filters due to the

temperature limitations.

Do not operate the WSO mist collector without

the first-stage filter in place. Significant

reduction in primary filter life can result.

Use proper safety and protective equipment

when removing contaminants and filters.

Dirty filters may be heavier than they appear.

Use care when removing filters to avoid

personal injury and/or property damage.

Turn power off and lock out electrical

power sources before performing service or

maintenance work.

Do not operate with missing or damaged filters.

Filter Removal and Installation

WSO Mist Collector, WSO 20, 25-1, 25-2, and 25-3

16

Primary Filter Installation

Note: With the collector’s airflow off, allow mist-

laden, wet filter to drain into the inlet plenum

for at least 15 minutes prior to removal.

1. Remove the filter cartridge by pulling the filter

retention lever down to a horizontal position. Remove

cartridge from collector and dispose of properly for

the materials collected.

Note: A large plastic garbage bag placed over the

top of the used filter allows cleaner filter

change out. The filter can be tipped forward

and out of the collector while the bag is

pulled up over the bottom of the cartridge.

2. Place new filter on the filter retention platform,

gasket side up. Slide filter back as far as it will go.

Note: The primary filter must be replaced. Do not

wash.

3. Lift the filter retention lever up and close access

door.

primary

filter cartridge

filter retention lever

pull down

Primary Filter Replacement, WSO 25-1 shown

17

Donaldson Company, Inc.

Final Filter Installation (WSO 20 and 25-1)

Note: The final filter must be replaced. Do not

wash.

1. Unlatch the final filter on top of the collector.

2. Remove the filter and dispose of properly for the

materials collected.

Dirty filters may be heavier than

they appear. Provide a support

platform or have two people, one on each side

of the filter and pull the filter out.

3. Install the replacement filter gasket-side down.

4. Latch the new filter in place.

Final Filter Installation (WSO 25-2 and 25-3)

Note: The final filter must be replaced. Do not

wash.

1. Open the final filter access door and lower the

retention handles to release the filter.

2. Remove the filter and dispose of properly for the

materials collected.

Dirty filters may be heavier than

they appear. Provide a support

platform or have two people, one on each side

of the filter and pull the filter out.

3. Install the replacement filter gasket-side up.

4. Seal the filter in place by lifting the retention handles

to the upright position.

final filter

(gasket-side

down)

latch

Final Filter Installation, WSO 25-1 shown

final filter

(gasket-side up)

retention

handle

Final Filter Installation, Powered WSO 25-2 shown

This manual suits for next models

3

Table of contents

Popular Fan manuals by other brands

Craftmade

Craftmade PU52OB5 installation guide

Monte Carlo Fan Company

Monte Carlo Fan Company 5HLR54 Series Owner's guide and installation manual

NScessity

NScessity NSMTF-18 instruction manual

Vents

Vents CF user manual

minkaAire

minkaAire aluma wet instruction manual

Vent-Axia

Vent-Axia Centrif Duo Installation and wiring instructions