5

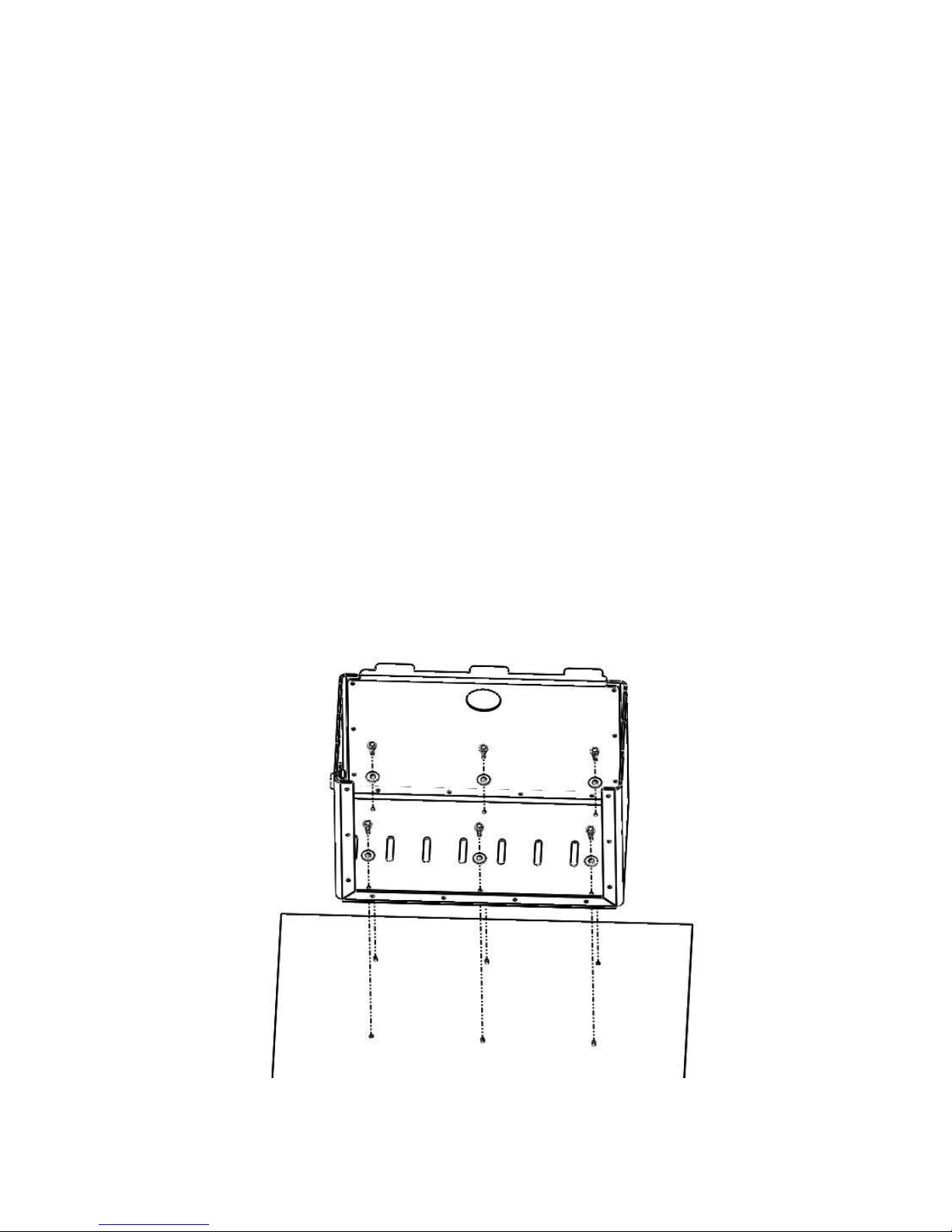

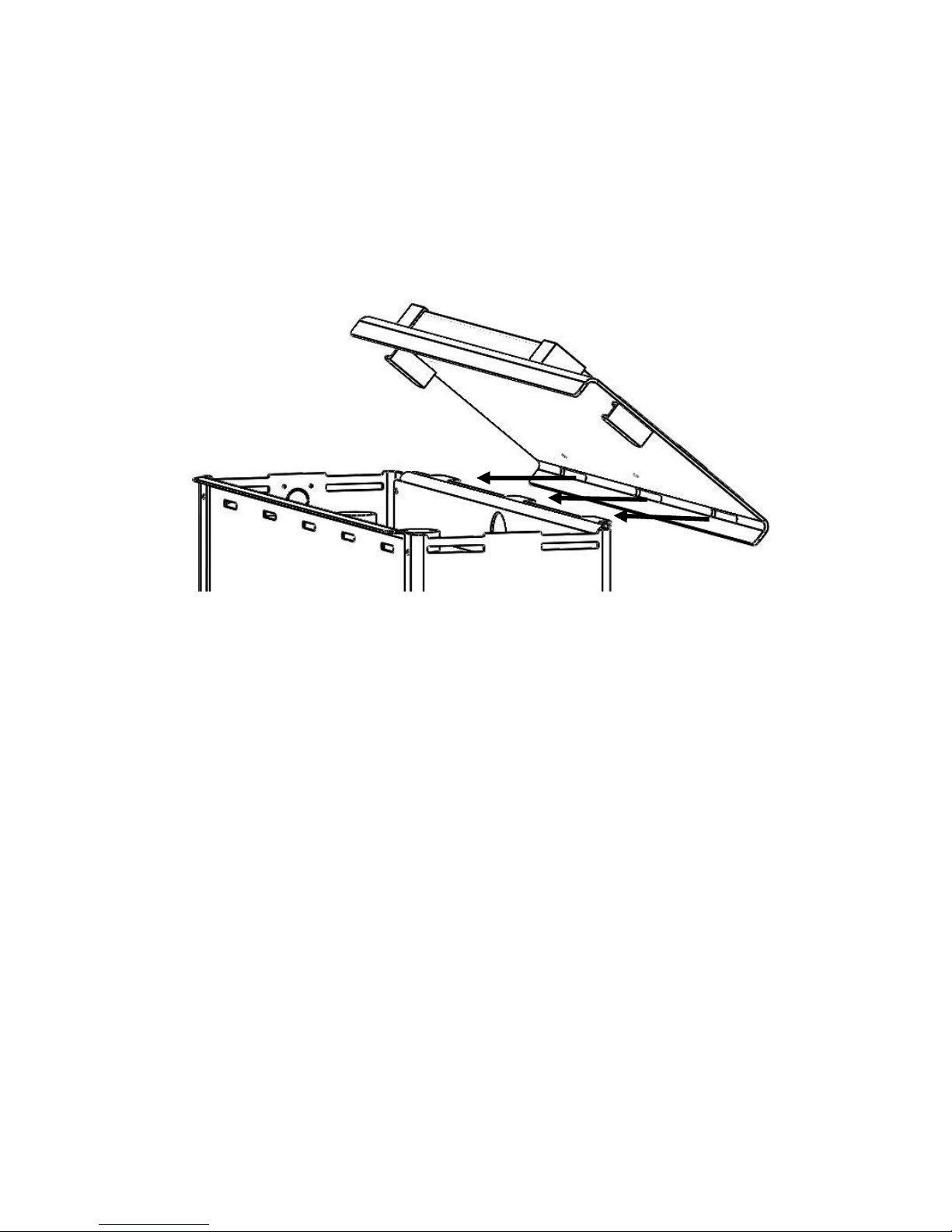

Step 3 –Option 2

In some cases the Power Armor battery box will fit between the two steel of

angles used to secure the stock battery box. If this is the case on your

trailer, refer back to Step 3 - Option 1.

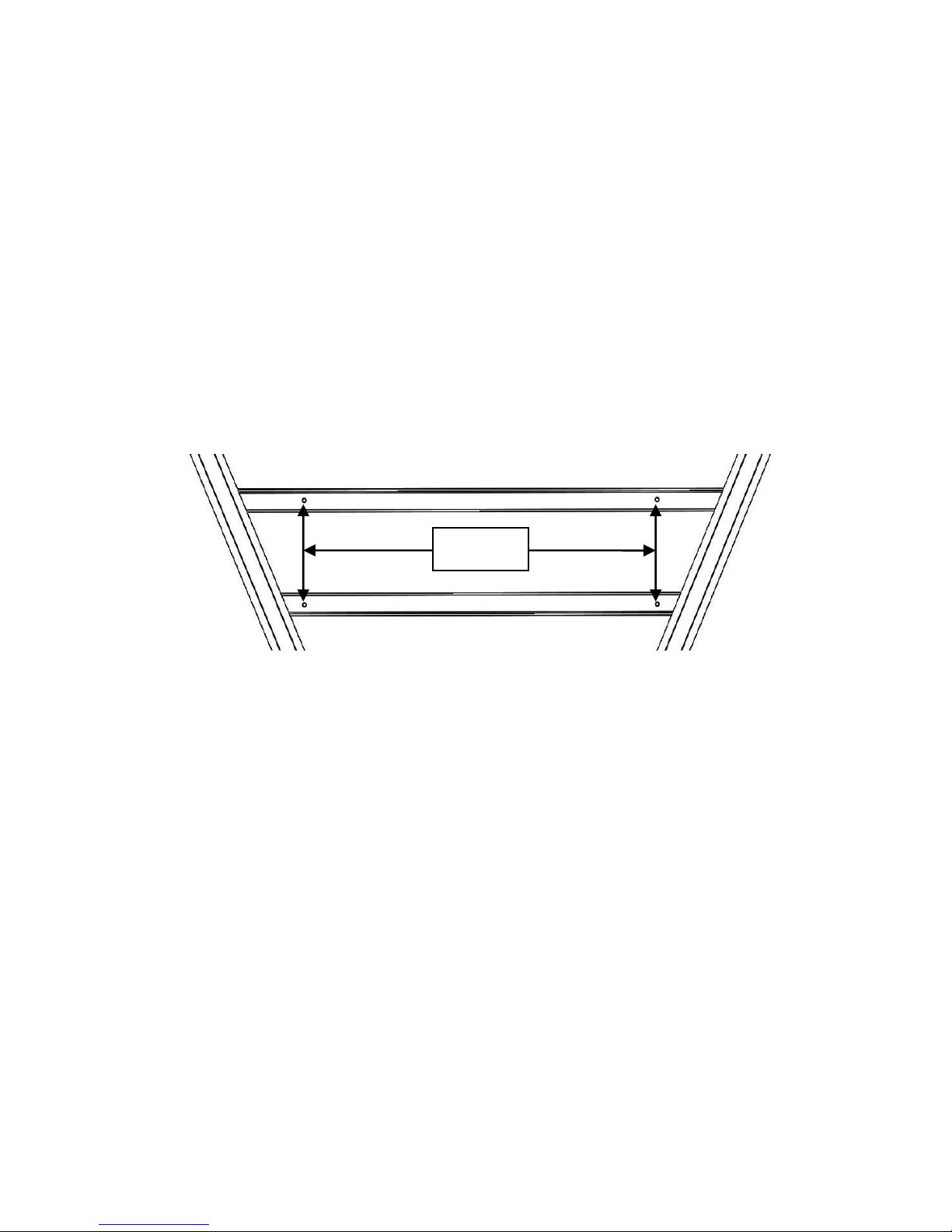

If the Power Armor battery box is too wide to fit between the steel angles,

begin by drilling two 1/4” holes in each of the battery support straps. The

holes should be 15-1/2” apart. (see dimension “X” in figure 3.2)

Figure 3.2

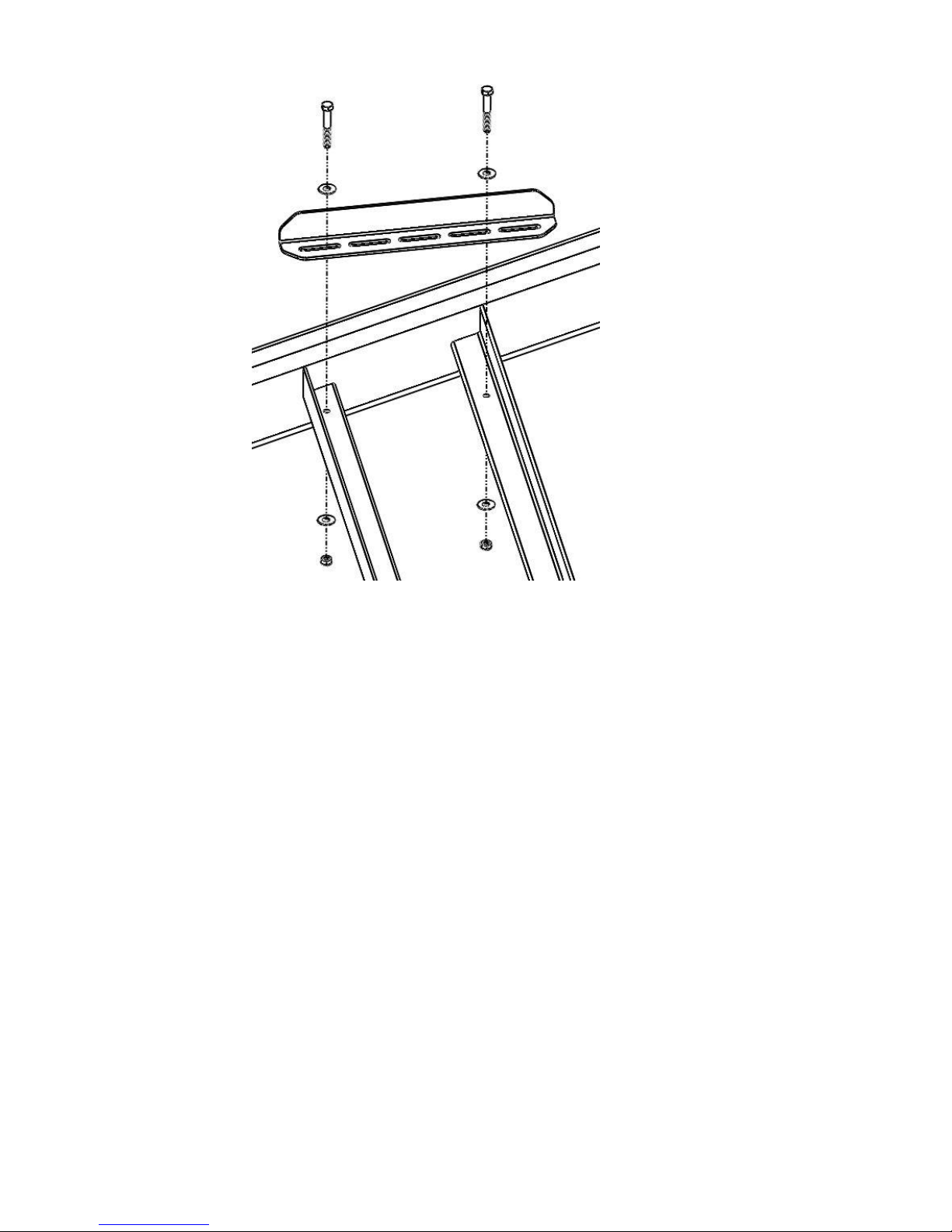

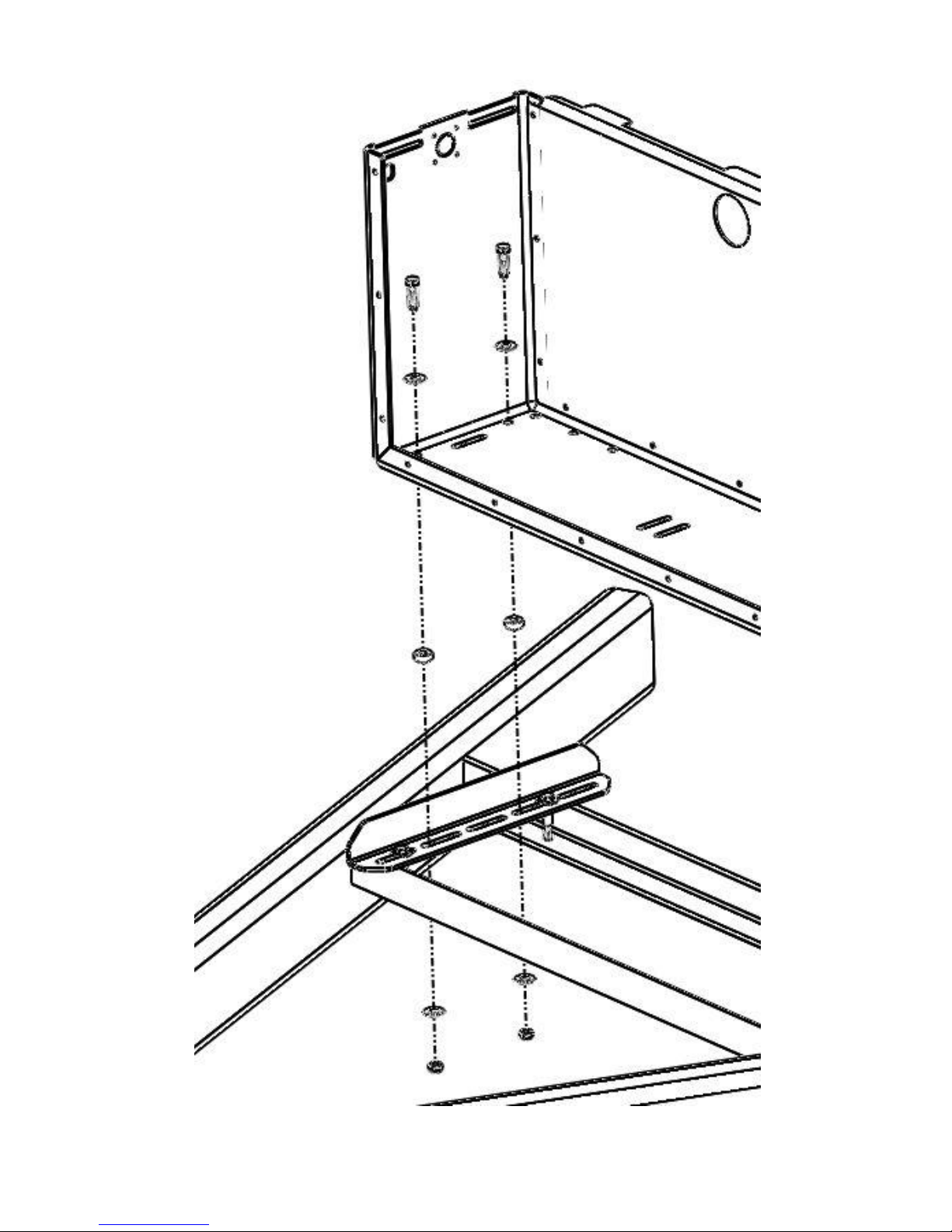

Insert one 1/4"-20 x 2” Hex Bolt with one 1/4" SS USS Flat Washer down

through the slots of the Angle Extension Bracket and through each of the

holes previously drilled. The vertical flange on each Angle Extension

Bracket should be facing towards the outside of the trailer. Lightly secure

each bolt with one 1/4" SS USS Flat Washer and one 1/4"-20 SS Thin

Nylock Nut. Test fit to make sure the “Angle Extension Mounting Holes”in

the Power Armor Battery Box will align with the slots in the Angle

Extension Brackets. Adjust as necessary and tighten the 1/4"-20 x 2” Hex

Bolts. See figure 3.3