Toro 31102 User manual

FormNo.3383-962RevD

AdapterKit

100inRearDischargeMowerfor2-WheelDriveor2013andBefore

4-WheelDriveGroundsmaster®360TractionUnit

ModelNo.31102

InstallationInstructions

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

Note:Thisadapterkitisusedtomountthe100-inchRearDischargeDeckontoallGroundsmaster®360Series2WD

TractionUnits,2013andbeforeGroundsmaster®360Series4WDTractionUnits,and2014Groundsmaster®360Series

Tractionunitsinthefollowingserialranges:

ModelSerialrange

31223314000101to314000104

30536314000101to314000105

30539314000101to314000116

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved*3383-962*D

Safety

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedormissing.

decal121-5463

121-5463

1.Height-of-cutselection

decal121-5498

121-5498

2

Installation

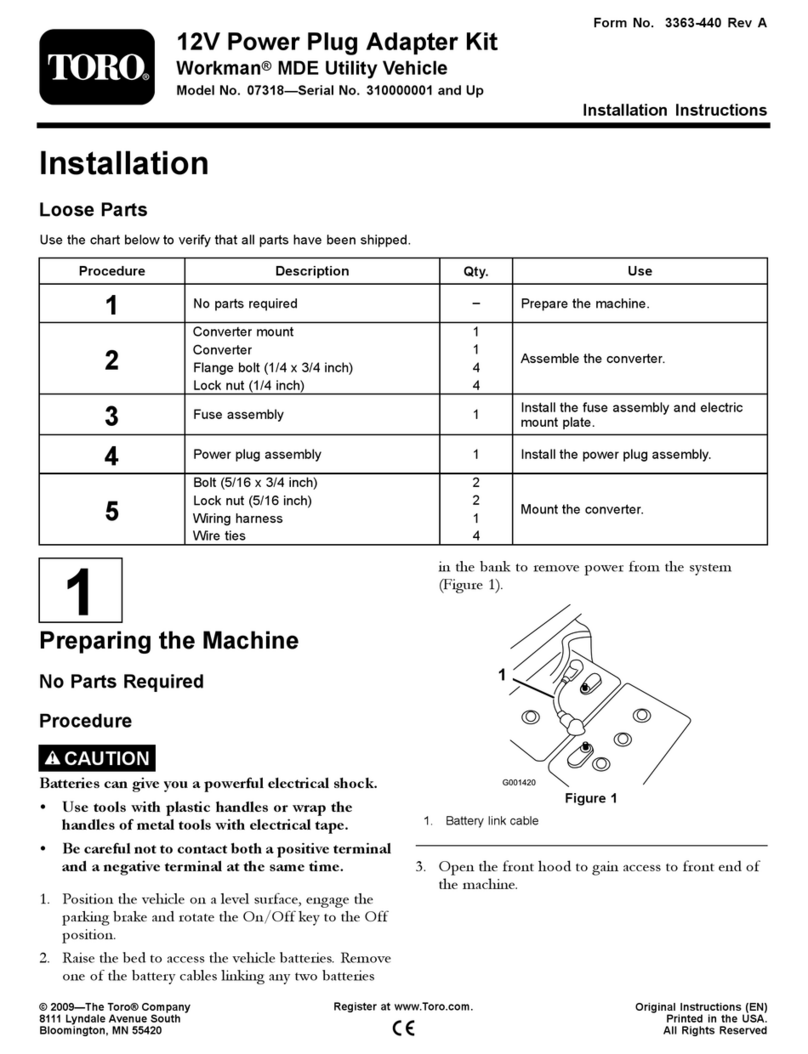

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

DescriptionQty.Use

Nopartsrequired–Removetheexistingdeck.

Height-of-cutdecal1

Bolt(1/2x2-3/4inches)1

Flatwasher1

Flangenut(1/2inch)1

Belt-routingdecal1

Orice1

Teetting1

Adaptertting1

Hydraulichose—28inches1

Hydraulichose—67inches1

Hydraulichose—13-1/2inches1

Teetting1

Cabletie4

R-clamp1

Bolt(3/8x1inch)1

Sheet-metalnut1

Wireharness1

Relay3

Washer-headscrew(#10x3/4inch)4

Nut(#10)4

Step1

Screw(5/16x7/8inch)2

Flangenut(5/16inch)2

Fuseblockandfuse1

Shuntwireharness1

Installtheadapterkit.

MediaandAdditionalParts

DescriptionQty.Use

Installationinstructions1Readtheinstructionsbeforeinstallingthekit.

Partscatalog1Referencethecatalogforpartnumbers.

3

RemovingtheExisting

Deck

Note:Ifthemachineisnotequippedwithadeck,skipthis

procedureandproceedtoInstallingtheAdapterKit(page5).

CAUTION

Thepulllinktorsionspringsmaycausesome

rotationofthepulllinksduringinstallation.

Becarefulwhenconnectingthepulllinkstothe

machine.

1.Parkthemachineonalevelsurfacewiththedeckinthe

fullyraisedposition.Shutofftheengine,engagethe

parkingbrake,andremovethekey.

Note:Whenthedeckisintheraisedposition,the

pulllinktorsionspringtension(Figure1)isreduced,

makingitmucheasiertodisconnectthepulllinksfrom

themachine.

g017279

1

2

3

4

5

6

7

g017279

Figure1

1.Pulllink(deckraised)5.Deckliftchain

2.Shoulderscrew6.Clevispin

3.Retainerpin7.Adjustmentclevis

4.Torsionspring

2.Disconnectthepulllinkfromeachsideofthemachine

(Figure1).

A.Removetheshoulderscrewthatsecuresthe

retainerpintothecarrierframe(Figure1).

B.Carefullyslidetheretainerpinfromthecarrier

frameandthepulllink(Figure1).

3.Notethelocationoftheheight-of-cut(HOC)pinin

theHOCbracketforassemblypurposes(Figure2),

andremovetheHOCpinfromtheHOCbracket.

1

2

G017278

g017278

Figure2

1.HOCpin2.HOCbracket

4.Starttheengineandfullylowerthedeck.Stopthe

engineandremovethekeyfromtheignitionswitch.

Note:Loweringthedeckontofurnituredollieseases

theremovalofthedeck.

Note:Elevatethefrontofthemachinetomovethe

deckawayfromthemachine.

5.Removetheboltsandnutsthatsecurethe4liftchains

totheliftarmsonthedeck(Figure1).

6.DisconnecttheendyokeofthePTOdriveshaftfrom

thedeckgearboxshaftasfollows:

A.Removetherollpinfromtheendyokeandthe

gearboxshaft(Figure3).

Note:Retaintherollpin.

g012230

Figure3

1.Driveshaft3.Rollpin

2.Capscrewsandlocknuts4.Gearbox

B.Loosenthe2capscrewsandlocknuts(Figure3).

4

C.Slidethedriveshaftendyokefromthegearbox

shaft.

D.Raisethedriveshaftandtieittotheframe.

7.Slidethedeckawayfromthemachine.

InstallingtheAdapterKit

ApplyingtheDecals

1.Removetheexistingheight-of-cutdecalfromthe

height-of-cutbracketonthemachine(Figure4).

g025286

Figure4

1.Height-of-cutdecal2.Height-of-cutbracket

2.Makesurethatthedecalmountingsurfaceofthe

height-of-cutbracketisfreeofallgreaseandgrime.

3.Afxthenewheight-of-cutdecaltothebracket

(Figure5).

g025287

Figure5

1.Locknut3.Bolt

2.Newheight-of-cutdecal4.Washer

4.Installthe1/2x2-3/4inchbolt,atwasher,and1/2

inchangenutintothelowerrearholeofthenew

decalasshowninFigure5.

Note:Thiskeepsthedeckfromloweringand

contactingthegroundiftheheight-of-cutpinis

removed.

5.Pivotopentheoorplate(Figure6).

g025288

Figure6

1.Belt-routingdecal2.Floorplate

6.Afxthenewbelt-routingdecalovertheexistingdecal

(Figure6).

Note:Makesurethatthemountingsurfaceisclean

beforeinstallingthenewdecal.

5

RemovingtheFender

Removethe3self-tappingscrewssecuringtheleftfront

fendertothemachineframe(Figure7),andremovethe

fender.

Note:Astepwillbeinstalledinplaceofthefenderafterthe

deckisinstalled.

g025289

Figure7

1.Self-tappingscrews2.Leftfrontfender

AssemblingtheDeckLiftManifold

Block

1.Raisetheseatplate.

2.Installtheoriceintothedeckliftvalvemanifoldas

follows:

CAUTION

Ifyouperformmaintenanceonthedecklift

manifoldwhilethedeckisraised,thepressure

ofthehydraulicsystemcouldcauseserious

injury.

Lowerthedecktorelievethepressureinthe

hydraulicsystem.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwith

thisformofinjuryorgangrenemayresult.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.

Note:Haveadrainpanoraragavailabletocatchthe

hydraulicuid.

A.Removethenutsecuringthespacer/coilassembly

tothesolenoidvalveinport“A”onthelift

valvemanifoldblock(Figure8),andremovethe

spacer/coilassembly.

B.Removethesolenoidvalvefromtheliftvalve

manifoldblock(Figure8)

g025290

Figure8

1.Liftvalvemanifoldblock4.Solenoidvalve

2.Orice5.Spacer

3.Coil6.Nut

6

C.Inserttheoriceintotheopeningofthemanifold

block,positioningitsothatthechamferedendis

inward(Figure8).

D.Threadthesolenoidvalveintotheliftvalve

manifoldblock,andtorquethevalveto27N-m

(20ft-lb).

Note:Donotovertightenthenut.

E.Insertthecoil/spacerassemblyontothesolenoid

valve(Figure8).

F.Securethecoil/spacerassemblytothevalvewith

thenut(Figure8),andtorquethenutto7N-m

(5ft-lb).

Note:Donotovertightenthenut.

3.Disconnectthehydraulichosefromthe90degree

ttingonthefrontoftheliftvalvemanifoldblock

(Figure9).

Note:Haveadrainpanoraragavailabletocatchthe

hydraulicuid.

g025291

Figure9

1.90degreetting3.Hydraulichose

2.Liftvalvemanifoldblock

4.Removethe90degreettingfromthefrontofthe

manifoldblock(Figure9)anddiscardthetting.

Note:Togainadditionalaccesstothettingsonthe

frontofthevalve,disconnectthehardhydraulicline

fromthevalveand/orremovethevalvemountingnuts

(Figure9).

5.Installtheteettingintothevacatedportonthefront

ofthemanifoldblock.

Note:PositiontheteettingasshowninFigure10.

g025598

Figure10

1.Teetting3.Hydraulichose

2.Frontofmanifoldblock4.Adaptertting

6.Installtheadapterttingtothenewlyinstalledtee

tting(Figure10).

7.Installtheendofthehydraulichose,disconnectedin

step3,totheadaptertting(Figure10).

7

MountingtheDecktotheMachine

1.RemovethenutssecuringtheliftchainU-boltstothe

undersideofthedeck(Figure11).

g025293

Figure11

1.U-bolt2.Nut(2)

2.Remove1ofthetopnutsfromtheU-bolts,insertthe

liftchainsontotheU-bolts,andtheninstallthetopnut.

3.InstalltheU-boltstothedeckwiththenutspreviously

removed(Figure11).

4.Slidethenewdeckunderthecarrierframeofthe

machine.

Note:Elevatethefrontofthemachinetoslidethe

newdeckunderthecarrierframeofthemachine.

5.ConnecttheendyokeofthePTOdriveshafttothe

deckgearboxasfollows:

A.Alignthesplineandrollpinholesofthedriveshaft

yokewiththegearboxshaft.

B.SlidethePTOdriveshaftendyokeontothe

gearboxshaft.

C.SecuretheendyokeofthePTOdriveshafttothe

gearboxshaftwiththerollpin(Figure3).

D.Tightenthelocknutstosecuretheendyoketothe

gearboxshaft(Figure3),andtorquethelocknuts

to20to25N-m(15to18ft-lb).

6.Removeandinstallthereardeckliftchainstothelift

bracketsasfollows:

Note:Wheninstallingtherearliftchainstothe

liftbrackets,usethesecondlinkfromthetop.This

providestherecommendedrakeforthedeck.

A.Securetherightrearliftchaintotheinboardside

oftheliftbracketwithaboltand2nuts(Figure

12).

B.Securetheleftrearliftchaintotheoutboardside

oftheliftbracketwithaboltand2nuts.

C.Usingthetopchainlinks,securethefrontlift

chainstotheoutboardsideoftheliftbrackets.

g025273

Figure12

1.Leftrearliftchain2.Rightrearliftchain

8

InstallingtheHoses

1.Looselyinstallthemid-lengthhydraulichosetothe

outboardportoftheright-handwingcylinder(Figure

13).

Note:Donottightenthetting.

g025303

Figure13

1.Longhose3.Right-handwingcylinder

2.Mid-lengthhose4.Deckliftcylinder

2.Routethehoseunderthehydraulictankbracketand

totheteettingonthefrontofthemanifoldblock

(Figure14).

g025294

Figure14

1.Longhose3.Shorthose

2.Deckliftvalveteetting4.Deckliftcylinder

Note:Makesurethatthehoseisnottwistedanddoes

notcontactanyhot,sharp,ormovingparts.

9

ConnectingtheLongHose

(4WDModels)

Forasimplermethodofconnectingthelonghoseon

2WDmodels,refertoConnectingtheLongHose(2WD

ModelsOnly)(page11).

1.Disconnectthehosefromthehydrauliclineontheleft

sideofthemachineandfromtheteettingonthetop

ofthepump(Figure15).Discardthehose.

Note:Haveadrainpanoraragavailabletocatchthe

hydraulicuid.

2

G025597

1

g025597

Figure15

Asviewedfromunderthemachine

1.Hydraulicline2.Newhose

2.Installateettingtothehydraulicline(Figure16).

3.Connectthe90degreettingendofthenewshort

hosetothehydrauliclineteettingandthestraight

ttingendtotheteettingonthepump(Figure16)

andtightenbothendsofthehose.

4

2

G025295

31

g025295

Figure16

Asviewedfromunderthemachine

1.Hydraulicline3.Shorthose

2.Teetting4.Longhose

4.Installtheendofthelonghydraulichosetotheinboard

portoftherightwingcylinderandtightenthetting.

5.Routethehosefromtherightwingcylinderalongthe

mid-lengthhose,underthehydraulictankbracketand

tothenewteetting(Figure16)andtightenthetting.

Note:Makesurethatthehoseisnottwistedanddoes

notcontactanyhot,sharp,ormovingparts.

10

ConnectingtheLongHose

(2WDModelsOnly)

Thisproceduredoesnotapplyto4WDmodels.

1.Installtheendofthelonghydraulichosetotheinboard

portoftherightwingcylinderandtightenthetting.

2.Routethehosefromtherightwingcylinderalongthe

mid-lengthhose,underthehydraulictankbracket,

abovetheliftshaft,andbelowtheoorboardsupport

tothecappedttingonthehydraulichardline(Figure

17andFigure18).

g027153

Figure17

1.Cappedtting

g027154

Figure18

Somepartsnotshown

1.Floorboardsupport3.Rightwingcylinderhose

2.Liftshaft4.Hydrauliclinetting

3.Removeanddiscardthecapfromthetting(Figure

17).

4.Connecttherightwingcylinderhosetothettingon

thehydraulicline(Figure18)andtightenthetting.

Note:Makesurethatthehoseisnottwistedandwill

notcontactanyhot,sharp,ormovingparts.

11

ConnectingthePullLinkstothe

Machine

1.Securethe2liftcylinderhosestotheundersideofthe

hydraulictankwithacabletieortheR-clamp,the3/8

x1inchbolt,andthesheet-metalnutsupplied.

Note:Makesurethehosesarenottwistedandwill

notcontactanyhot,sharp,ormovingparts.

g025296

Figure19

1.Sheet-metalnut3.Bolt(3/8x1inch)

2.R-clamp

2.Starttheengineandfullyraisethedeck.Stopthe

engineandremovethekeyfromtheignitionswitch.

Note:Placeawoodblockorsimilarshimundereach

linktoholditintheraisedposition(Figure20).

3.Alignthepulllinktothecarrierframeandattach

thelinkwiththeretainerpin(Figure20).Securethe

retainerpintotheframewiththeshoulderscrew

(Figure20).

g025301

Figure20

1.Pulllink(deckraised)4.Deckliftchain

2.Torsionspring5.Retainerpin

3.U-bolts6.Shoulderscrew

4.Slightlyraisethefrontofthemachinetoremovethe

woodblockorsimilarshimfromundereachpulllink.

InstallingtheWireHarness

1.Locatethefuseblockandthegroundblock(Figure21).

g025297

Figure21

1.Fuseblock2.Groundblock

2.Attachthenewwireharnessasfollows:

•Attachtheredwiretoanavailableconnectoron

thefuseblock.

Note:Ifthereisnotanavailableconnectoronthe

fuseblock,installanadditionalblock.Afuseblock,

fuseandmountingnutsandboltsareincludedin

thelooseparts.

•Attachtheblackwiretothenearbygroundblock.

3.Locatethe2holesatthebottomofthefuseblock

mountingplate(Figure22).

4.Mountthe3relaystothefuseblockmountingplate

with2washer-headscrews(#10x3/4inch)and2nuts

(#10);refertoFigure22.

g025298

Figure22

1.Relay(3)3.Nut—#10(2)

2.Washer-headscrew—#10

x3/4inch(2)

5.Plugthewireharnessconnectorsintotherelays.

6.Unplugtheconnectorsatthefrontofthetransmission

neartheoillter(Figure23).

12

g025299

Figure23

1.Transmissionconnectors2.Wireharnessconnectors

7.Routethewireharnesstothetransmissionandplugthe

2matingwireharnessconnectorsintotheunplugged

connectors(Figure23).

8.Routetheremaininglengthofwireharnesstotheleft

sideofthemachine,undertheoorandtowardthe

frontofthemachine.

9.Plugtheharnessconnectorintotheharnessonthe

frontcenterofthedeck.

10.Securetheharnesstotheexistingharnesswithtie

wraps,andsecureanyexcessharnessawayfromany

hot,sharp,ormovingparts.

11.Plugtheshuntwireharnessintothedeckwireharness

asshowningure.

Note:Usetheshuntwireharnessonlywhenthedecks

areremovedfromthemachine.

g206087

Figure24

1.Shuntwireharness

InstallingtheStep

1.Usingthe3existingfender-mountingholes,securethe

frontofthesteptothemachinewiththe3self-tapping

screwspreviouslyremoved(Figure25).

g025300

Figure25

1.Step

2.Usingtherearofthestepasatemplate,locate,mark,

anddrill2holes—8.3mm(0.328inch)diameter—in

theframeofthemachine.

3.Mounttherearofthesteptothemachinewith2

screws(5/16x7/8inch)and2angenuts(5/16);refer

toFigure25.

13

CompletingtheInstallation

1.InstalltheHOCpinintotheHOCbracketatthe

desiredheightofcut(Figure26).

g025302

Figure26

1.HOCpin2.HOCbracket

2.Checkthehydraulic-oillevelandreplenishtheoilas

required;refertothetractionunitOperator’sManual.

3.Levelthecuttingunit;refertotheCuttingUnit

OperatorsManual.

4.LubricatethecuttingunitandPTOdriveshaftgrease

ttings;refertothecuttingunitOperator’sManual.

14

Notes:

Table of contents

Other Toro Adapter manuals

Popular Adapter manuals by other brands

Philips

Philips Respironics 1116818 Battery Charging Guide

Discount Car Stereo

Discount Car Stereo A2D-3.5M Quick start installation guide

Warpia

Warpia SWP100A user guide

Westinghouse

Westinghouse JS-A002 instruction manual

CHIEF

CHIEF CMS-260 installation instructions

D-Link

D-Link D DPH-50U DPH-50U Quick user guide